Low-energy-consumption high-pressure powder conveying device

A high-pressure conveying and low-energy-consumption technology, applied in the field of coal chemical industry, can solve problems such as poor coal-water slurry feeding effect, narrow selection range, and short service life of gasifier burners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

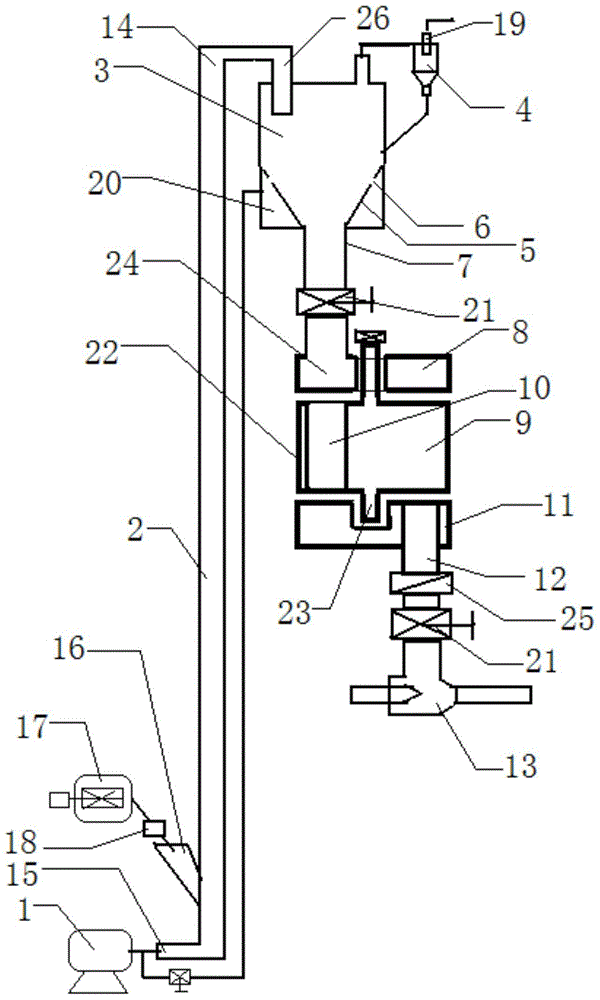

[0026]Example 1, during specific operation, after the pulverized coal is crushed into fine coal powders smaller than 150 μm by the pulverizer (17), a large amount of gas from the fan (1) enters the riser (2) through the low-pressure delivery air inlet (15), and the The fine coal powder added from the powder inlet (16) at the lower part of the riser (2) is conveyed to the top of the riser (14), and then the fine coal powder is conveyed to the upper hopper (3) through the quick separation (26). The gas passes through the gas-solid separator (4) to recover the fine coal powder and then discharges. A small amount of gas from the fan (1) is connected to the fluidization gas chamber (20) through a bypass, and then injected into the air inlet (6) on the upper side wall of the conical hopper (5) to make the fine coal in the upper hopper (3) The powder forms a fluidized state, and the fine coal powder flows into the conical hopper (5) material leg (7), and flows through the valve (21) ...

Embodiment 2

[0030] Example 2: Coal powder is replaced by coke powder, the pressure of the fan (1) is 0.03MPa, the conveying height is 50m, and the rest remain unchanged.

[0031] The powder low-energy and high-pressure conveying equipment provided by the present invention adopts low-pressure lifting, fluidized state material distribution and output, horizontal rotation and staggered discharge, and high-pressure working gas is used to pump and transport through high-pressure jet pumps, and the powder flow performance is hardly affected by gas. Influenced by pressure changes, and the requirements for the water content of pulverized coal are greatly reduced, which solves the problem of fine powder transported by dense-phase pipes from the source. Due to excessive pressure, the flow characteristics of the powder will change, resulting in difficulty in transportation and affecting the stability of the device. Difficulties in operation, avoiding the use of external high-pressure nitrogen or CO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com