X120 high grade pipeline steel and preparation method thereof

A technology of X120 and pipeline steel, applied in the field of iron and steel metallurgy, can solve the problems of low control rolling temperature, easy to produce mixed crystals, etc., and achieve the effect of large increase in strength, increase in conveying pressure, and save process cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of X120 high steel grade pipeline steel specifically comprises the following steps:

[0028] Step 1: Smelting and casting;

[0029] Put the prepared low-phosphorus (≤0.015%), low-sulfur (≤0.005%), low-oxygen (≤0.0030%), low-nitrogen (≤0.0050%) high-quality steel scrap and other alloys prepared into the laboratory into 100kg vacuum smelting The furnace is vacuumized and started for melting and smelting. After being melted, it is cast into a rectangular steel mold and cast into a rectangular steel billet with a size of 150×200×250mm.

[0030] Step 2: heating and rolling;

[0031] The steel billet is loaded into the high temperature resistance furnace with a manipulator. The heating temperature is 1180~1220℃, and the total time in the furnace is ≥240min to ensure uniform temperature of the billet. When the billet meets the heating requirements, the billet is sent to the φ750×550mm experimental rolling mill by a manipulator. The manufacturing proce...

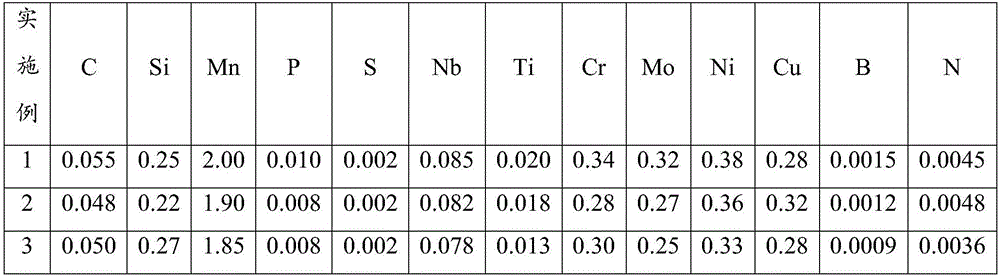

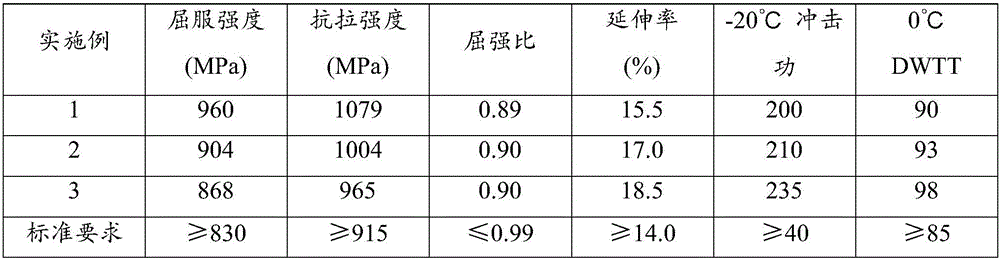

Embodiment 1

[0038] It is smelted according to the chemical composition shown in Table 1, and cast into steel ingots, and the steel ingots are heated to 1202 ° C, and the total time in the furnace is 245 minutes. The first-stage rolling is carried out on the experimental rolling mill, that is, the rolling in the austenite recrystallization zone. When the thickness of the piece is 45mm, it is heated to 945°C on the roller table, and then the second stage of rolling is carried out, that is, rolling in the austenite non-recrystallized zone. The final rolling temperature is 800°C. After rolling, the steel plate enters the laminar flow cooling device and is cooled to 285°C at a rate of 40°C / s, and then loaded into a simulated coiling furnace. Finally, a steel plate can be obtained.

[0039] like figure 1 Shown is the metallographic structure diagram of the steel plate in Example 1 of the present invention. The steel plate is bainite and lath martensite.

Embodiment 2

[0041] Embodiment is the same as Example 1, wherein the heating temperature is 1205° C., and the total time in the furnace is 246 minutes. The starting temperature of the first stage of rolling is 1182°C, the thickness of the intermediate billet is 45mm, the starting temperature of the second stage of rolling is 948°C, and the final rolling temperature is 805°C. After rolling, the steel plate enters the laminar flow cooling device , cooled to 330°C at a rate of 35°C / s, and then loaded into a simulated coiling furnace. Finally, the steel plate can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com