Pulping equipment based on air blasting energy and with secondary repulping function

An air blasting and pulping technology, which is applied in the field of pulping equipment and pulping equipment, can solve the problems of high energy consumption, low efficiency, and low slurry quality, and achieve the effect of increasing the amount of air bubbles and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

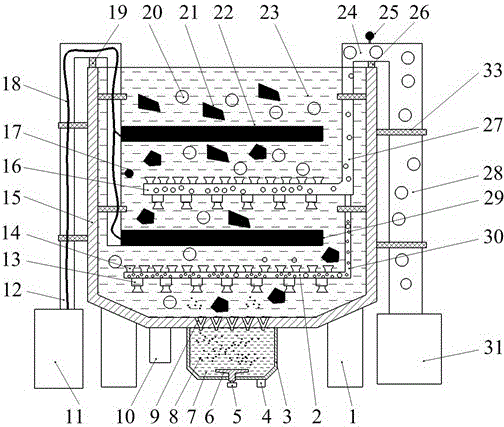

[0036] Such as figure 1 As shown, a pulping equipment based on the air blasting energy and secondary pulping of the present invention mainly includes a coarse pulp generating device, a bubble generating device, a bubble heating device and a fine pulp generating device, and a bubble generating device and a bubble heating device. The main components are installed in the coarse slurry generator, and the fine slurry generator is installed directly below the coarse slurry generator.

[0037] The coarse pulp generating device mainly includes a coarse pulping drum 15. The lower end of the coarse pulping drum 15 is provided with 4 circumferentially evenly distributed pillars 1, and the inner side of the lower end of the coarse pulping drum 15 is provided with a coarse pulp outlet 10, and the coarse pulping drum 15 is provided with There are coarse crushed materials 21 and coarse pulping drum water 23.

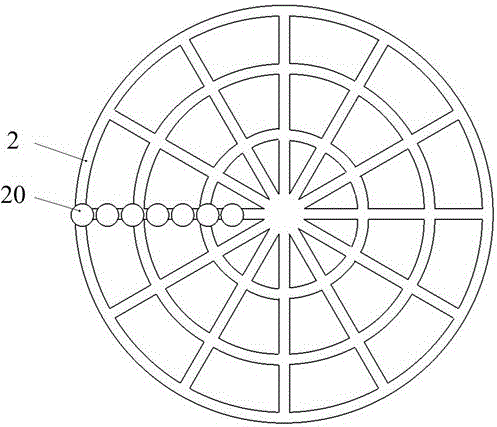

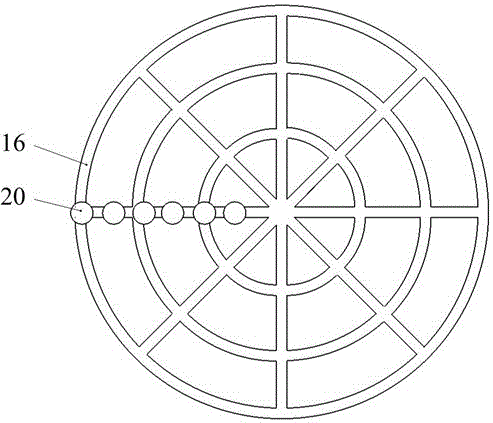

[0038] Combine figure 2 , image 3 , Figure 4 with Figure 5 As shown, the bubble gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com