Compound recycling low-nitrogen combustion method for chain boiler

A chain boiler, low-nitrogen combustion technology, applied in the combustion method, control combustion, combustion equipment and other directions, can solve the problems of increased fuel mechanical and chemical incomplete combustion loss, increased smoke exhaust heat loss, etc., to reduce the supply , The effect of promoting full combustion and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

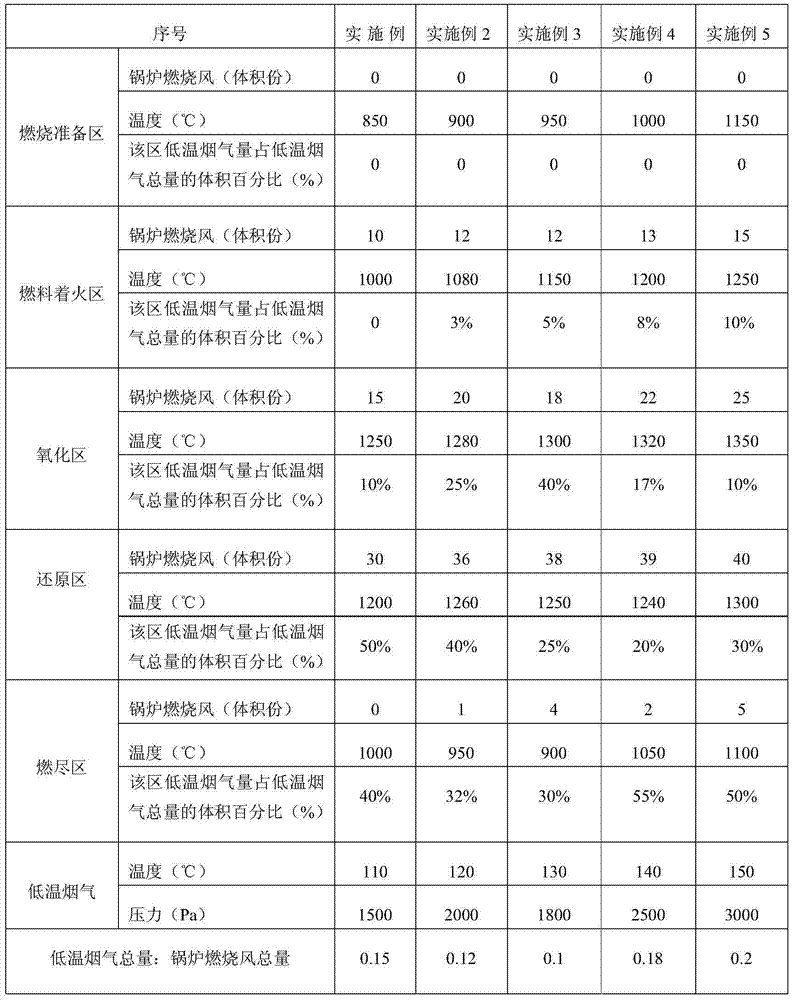

[0043] The compound recirculation low-nitrogen combustion method of chain boilers according to the present invention will be further described according to specific embodiments and accompanying drawings, but this description does not constitute an improper limitation of the present invention.

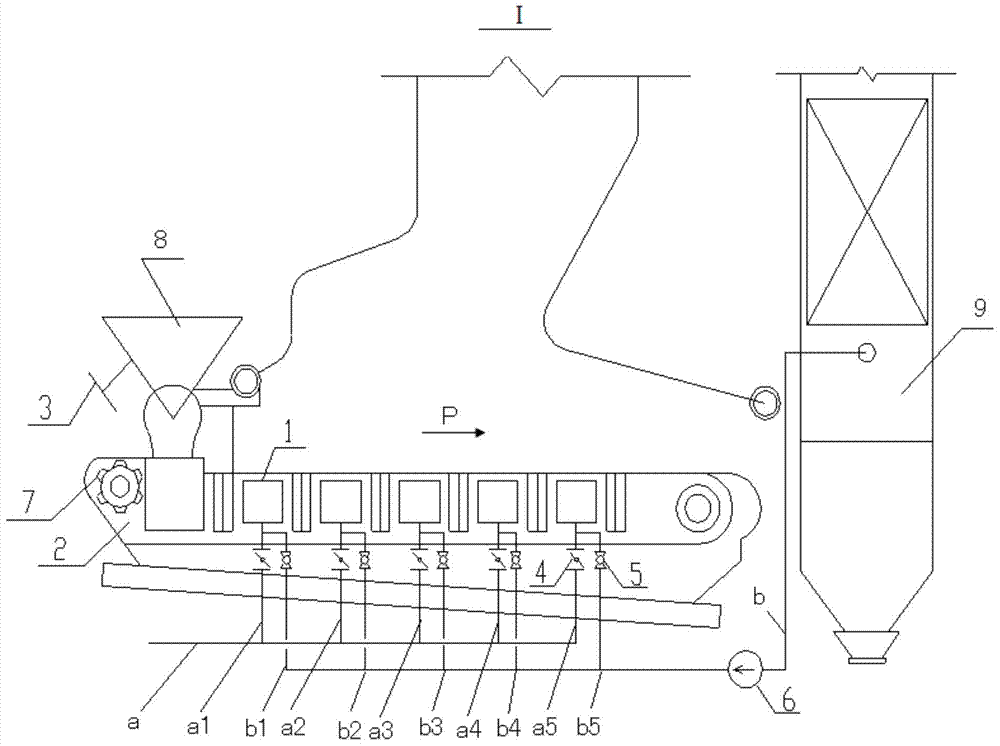

[0044] figure 1 The structure of the chain boiler adopted in one embodiment of the chain boiler double recirculation low-nitrogen combustion method according to the present invention is illustrated.

[0045] Such as figure 1 As shown, the chain boiler 1 includes: an air chamber 1, a chain grate 2, a flashboard 3, a baffle plate 4, a flow valve 5, a recirculation fan 6, a gear 7, a feeding device 8 and an air preheater 9 for supplying The material device 8 provides fuel to the boiler furnace, the shutter 3 is used to control the thickness of the fuel layer, the chain grate 2 is arranged in the furnace, the air chamber 1 is arranged under the chain grate 2, and the gear 7 is used to cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com