Integrated pump and injector for exhaust after treatment

A technology of injector and integrated pump, which is applied in the direction of exhaust treatment, exhaust device, machine/engine, etc., can solve the problems of high cost, complexity, and additional, and achieve the effect of reduced power consumption and low pressurized volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

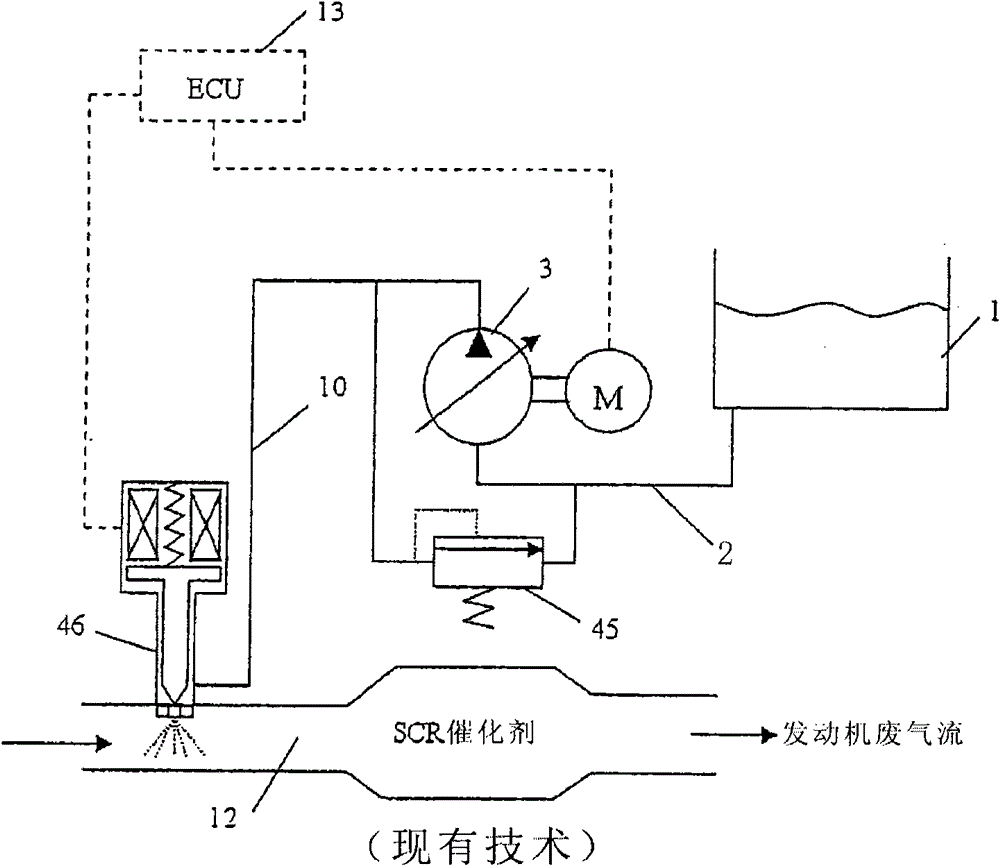

[0034] figure 1 is a schematic representation of a prior art airless system outlined in the Background section.

[0035] Urea solution is stored in storage tank 1 and passes through line 2 from where it enters pump 3 . The pump 3 is driven by an electric motor. The motor is driven and controlled by an electronic control unit (ECU) 13 to deliver sufficient volume through line 10 and into injector 46 . A substantially constant pressure is maintained in the line 10 and in the injector 46 by means of a regulator 45 which is either a separate component or integrated in the pump 3 . Injector 46 is electromagnetically operated and is controlled and powered by ECU 13 . The injector delivers an atomized urea solution into the engine exhaust 12 where the atomized urea solution can react with the SCR catalyst. The control of the injection quantity is determined by the operating frequency and duration of the injector opening. Storage tank 1 and lines 2 and 10 are heated to avoid free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com