Phosphorous pig iron desulfurizer used for casting pre-roasting anode

A pre-baked anode and desulfurizer technology, applied in the direction of reducing gas emissions, can solve problems such as stomata shrinkage defects, affecting pouring quality, thermal cracking, etc., achieve good furnace conditions and operating conditions, reduce labor intensity of workers, and improve working environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

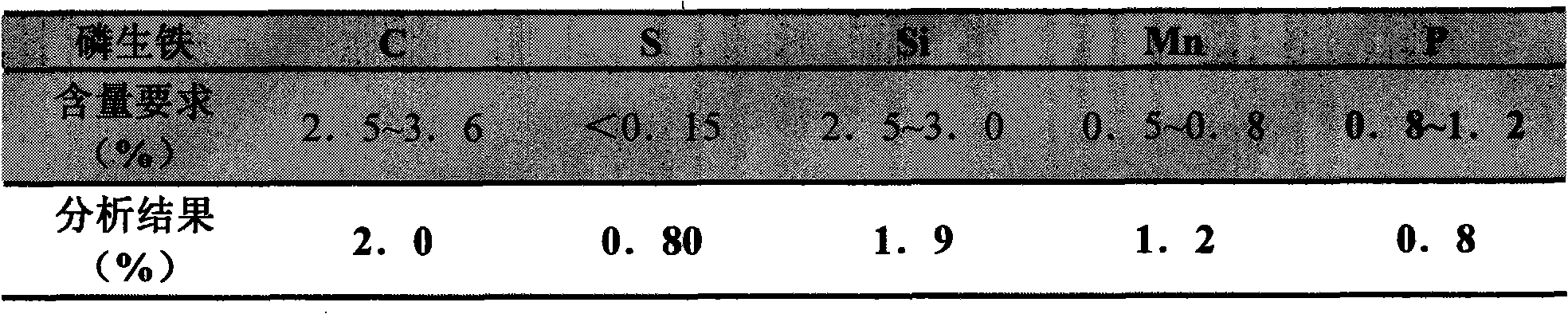

Method used

Image

Examples

preparation Embodiment 1

[0021] Graphite was selected as the carbon-increasing substance in the test, and CaO, CaF 2 As a desulfurization substance, accompanied by Na 2 CO 3 、Na 2 SiO 3 Prepare phosphorus pig iron desulfurizer for prebaked anode pouring with FeO, its formula is: graphite: 2%, CaO: 42.3%, CaF 2 : 3%, Na 2 CO 3 : 3.5%, Na 2 SiO 3 : 47.7%, FeO: 1.5%.

preparation Embodiment 2

[0023] The difference between this embodiment and Example 1 is that the formula has changed, and its formula is: graphite: 3%, CaO: 40%, CaF 2 : 3%, Na 2 CO 3 : 2%, Na 2 SiO 3 : 50%, FeO: 2%.

preparation Embodiment 3

[0025] The difference between this embodiment and Example 1 is that the formula has changed, and its formula is: graphite: 4%, CaO: 45%, CaF 2 : 3%, Na 2 CO 3 : 3%, Na 2 SiO 3 : 44%, FeO: 1%.

[0026] The above-mentioned embodiments can also be exemplified. The inventor's experiments have proved that as long as it is within the scope of the present invention, a phosphorus pig iron desulfurizer for prebaked anode casting that meets the requirements can be obtained.

[0027] According to experiments, it is shown that when using the phosphorus pig iron desulfurizer for prebaked anode pouring of the present invention, the amount added in every ton of phosphorus pig iron is 2.5%. It should be added as required in the first two batches of furnace charge, otherwise it will cause poor furnace start.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com