Patents

Literature

57results about How to "Guaranteed later strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Special masonry mortar for self-insulating wall

InactiveCN101182178AImprove water retentionReduce the impactSolid waste managementCrack resistanceEmulsion

The invention relates to masonry mortar special for self-insulation walls, which is a powdery mixture and consists of the components with the following weight portions of 52-68 portions of cementing materials, 20-36 portions of gradation aggregates, 12-25 portions of vitrified hollow micro-pearl, 0.2-0.26 portions of redispersibility emulsion, 3-12 portions of thickener rheology agent, 0.05-0.3 portions of water retaining agent, 0.05-0.3 portions of anti-fissure strengthening agent and 0.012-0.035 portions of anti-entraining agent. The invention has the advantages of good water retention, lowheat conductivity, high mechanical strength, good flexible crack resistance, good waterproof performance, good dry shrinkage resistance, good fireproof performance, easy construction, high performance-price ratio, energy saving performance, etc.

Owner:WUHAN LAIKELIAN SCI & TECH

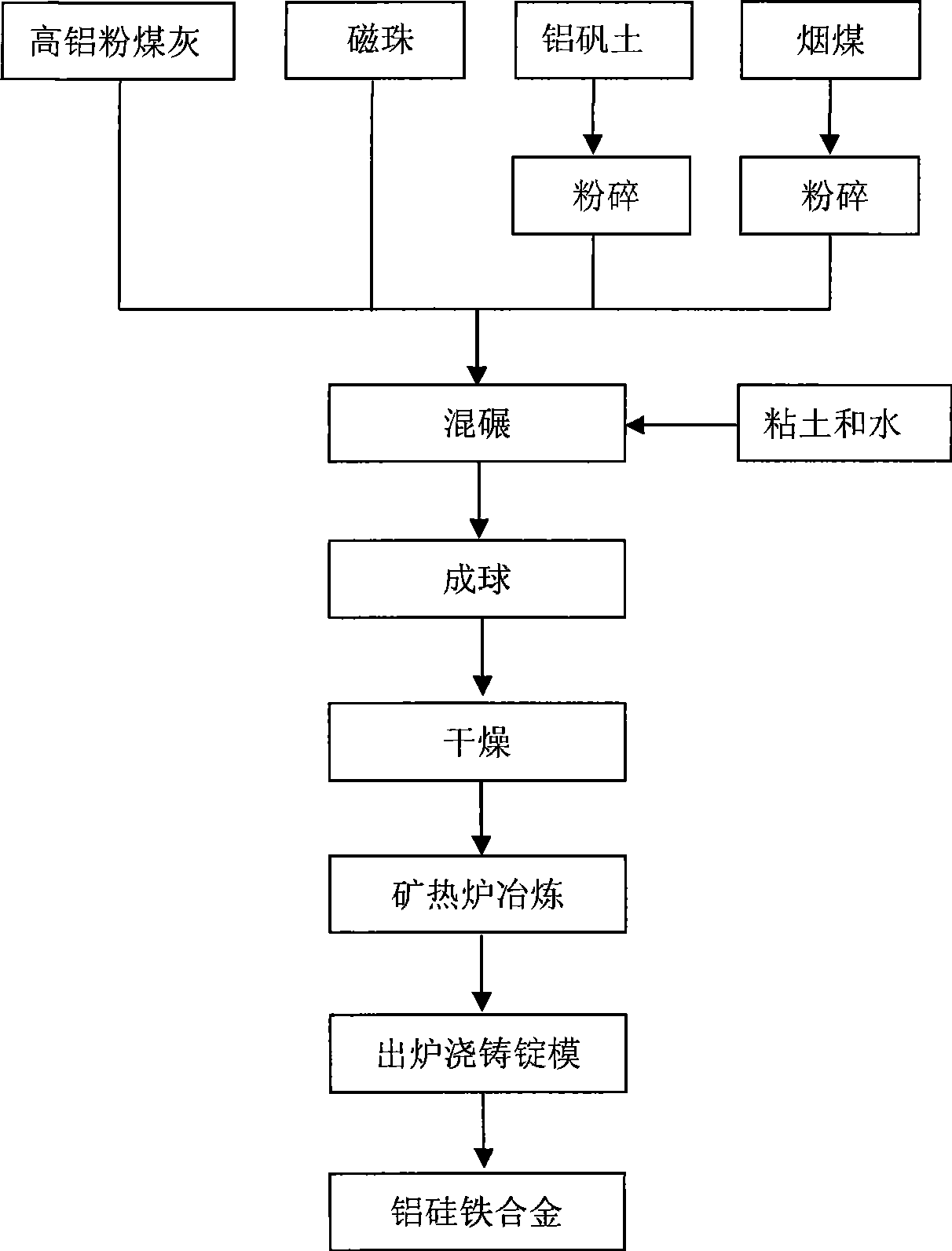

Method for preparing alsifer from high-alumina fly ash and magnetic beads

ActiveCN101469378AEvenly distributedHigh activityMagnetic separationResource utilizationMagnetic bead

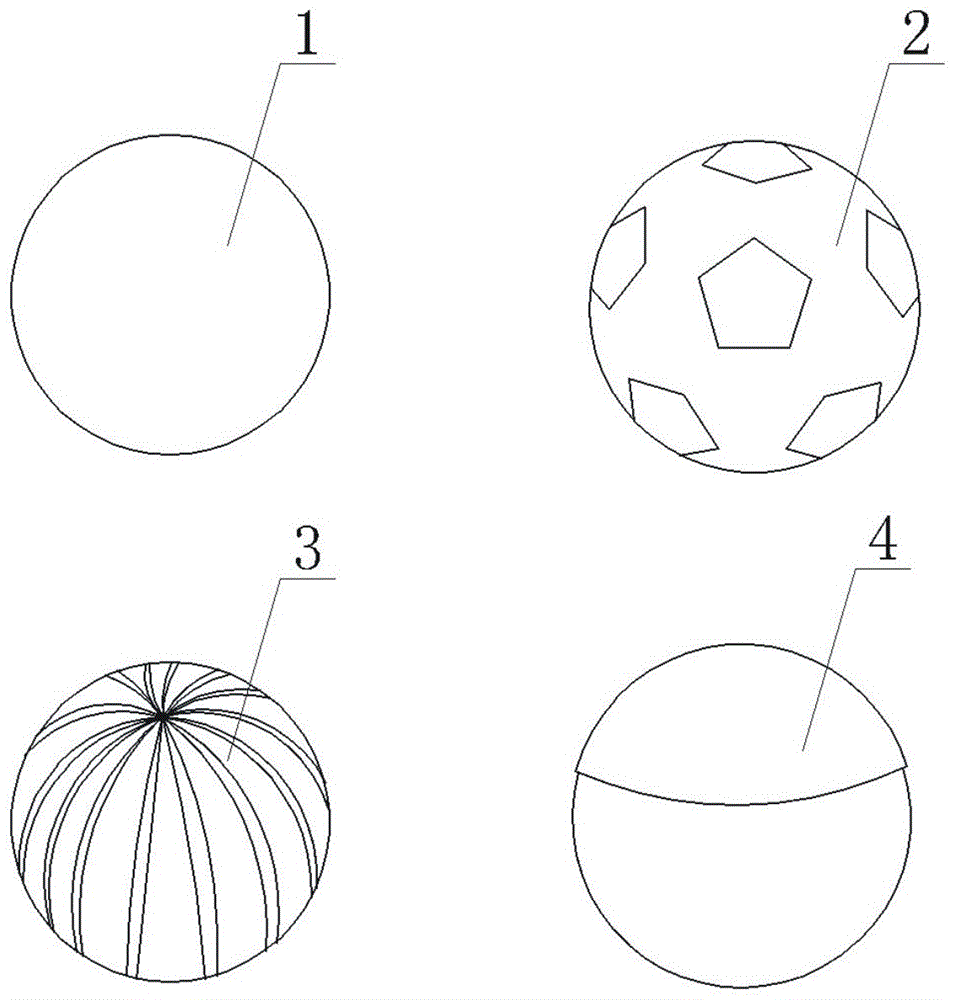

The invention discloses a method for preparing AL-Si-Fe alloy by utilizing high-aluminum fly ash and magnetic beads, which relates to the technical field of nonferrous metallurgy. The method comprises the following steps: 1) a bauxite raw material and a reducing agent-bituminous coal are crushed, and the crushed materials and raw materials (the high-aluminum fly ash and the magnetic beads) are sent into a mixing pan; 2) an adhesive-clay and a certain amount of water are added into the mixing pan to mixedly roll the materials; 3) the materials which are mixedly rolled evenly enter a twinroller machine for granulation; 4) pellets which come from the twinroller machine enter a drying kiln for drying; 5) the dried pellets are added into a submerged arc furnace for high-temperature smelting; and 6) molten iron is taken out of the furnace, and an ingot mold is cast to obtain the AL-Si-Fe alloy. The method has the advantages of broad raw material source, low production cost, good performance of the pellets containing fly ash, even furnace-entering smelting constituents, and complete reaction, makes the submerged arc furnace keep good furnace condition, ensures that the produced AL-Si-Fe alloy has steady performance, and realizes the resource utilization of waste.

Owner:TONGFANG ENVIRONMENT

Jet concrete fast hardening agent

InactiveCN1478750AReduce pollutionGuaranteed later strengthSolid waste managementClinker productionShotcreteSlag

Owner:徐州华泰混凝土外加剂厂

Cement-based rapid repair material with high early strength, and preparation method thereof

The invention discloses a cement-based rapid repair material with high early strength, wherein the cement-based rapid repair material is prepared from the following raw materials by mass: 500-650 parts sulphoaluminate cement, 200-400 parts of ordinary Portland cement, 800-900 parts of quartz sand, 4.5-9.0 parts of nanometer silicon dioxide, 0.25-0.6 part of a dispersing agent, 1.1-10.8 part of a water reducing agent, 0.045-0.160 part of a retarder, 0.10-0.25 part of a defoaming agent and 315-360 parts of water. The invention further provides a preparation method of the cement-based rapid repair material with improved early strength. According to the invention, the field preparation is convenient and easy, sulphoaluminate cement and Portland cement are compounded so as to ensure the early strength and the later strength, the microstructure of the composite repair system is obviously improved through the nanometer material, the early mechanical property of the cement-based material is remarkably improved, the driving quality and the driving safety of the repaired pavement are ensured, the repair cost is low, and the practicability is high.

Owner:GANSU ELECTRIC POWER DESIGN INST

Early-strength shield wall post-grouting formula

The invention belongs to the field of underground construction, and particularly discloses an early-strength shield wall post-grouting formula. The early-strength shield wall post-grouting formula comprises the following substances in parts by weight: 800 to 1000 parts of fine sand, 35 to 50 parts of bentonite, 110 to 220 parts of coal ash, 400 to 600 parts of Portland cement, 70 to 100 parts of gypsum, 5 to 8 parts of an early strength agent and 400 to 600 parts of water. The early-strength shield wall post-grouting formula has relatively high condensation rate, and also has the characteristic of high early strength; and moreover, the long-term strength and shear resistance of the grouting are further effectively guaranteed, ground deformation and duct piece floating are controlled, and the damage of duct pieces is reduced.

Owner:HOHAI UNIV

Ceramic grinding ball for cement ball mill, and preparation method thereof

The invention discloses a ceramic grinding ball for a cement ball mill, and a preparation method thereof. The ceramic grinding ball for the cement ball mill comprises the following raw materials in weight percentage: 92-95% of alumina, 0.5%-2% of ferric oxide, 0.8-3% of kaolin, 0.2-2% of silicon carbide, 1.5-2% of titanium dioxide, 0.8-1% of titanium carbide, and 0.3-2% of molybdenum disulfide. According to the technical scheme of the invention, the grinding ball is prepared through the compression moulding and high-temperature sintering process. The preparation method comprises the steps of burdening, ball-milling, spray granulation, ageing in a stock bin, compression processing, high-temperature sintering, powder removing, polishing, finished product drying, and the like. The ceramic grinding ball for the cement ball mill has the advantages of high hardness, high temperature resistance, corrosion resistance, low operation energy consumption, low material consumption, good bonding force, strong impact resistance, shock resistance and detonation resistance. The produced cement is uniform in fineness, reasonable in particle morphology and high in later strength.

Owner:SHANDONG TIANHUI GRINDING WEAR TECH DEV CO LTD

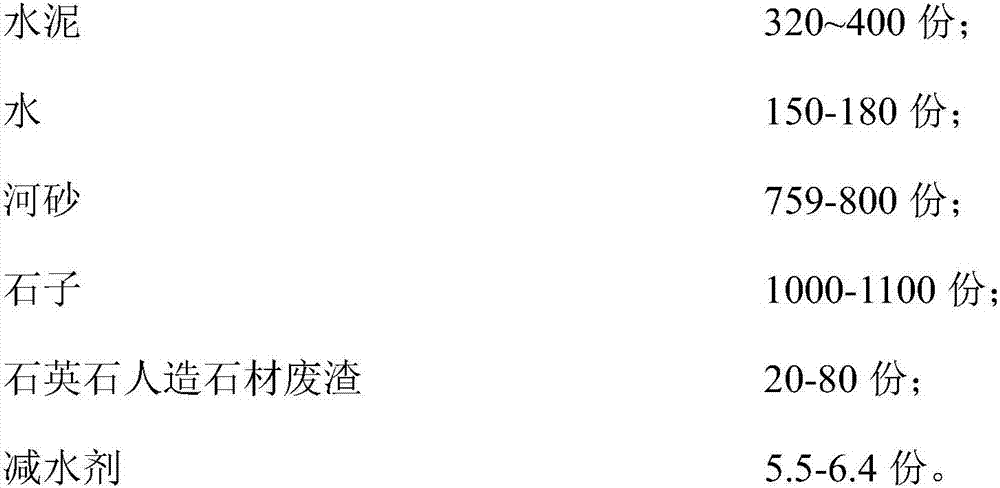

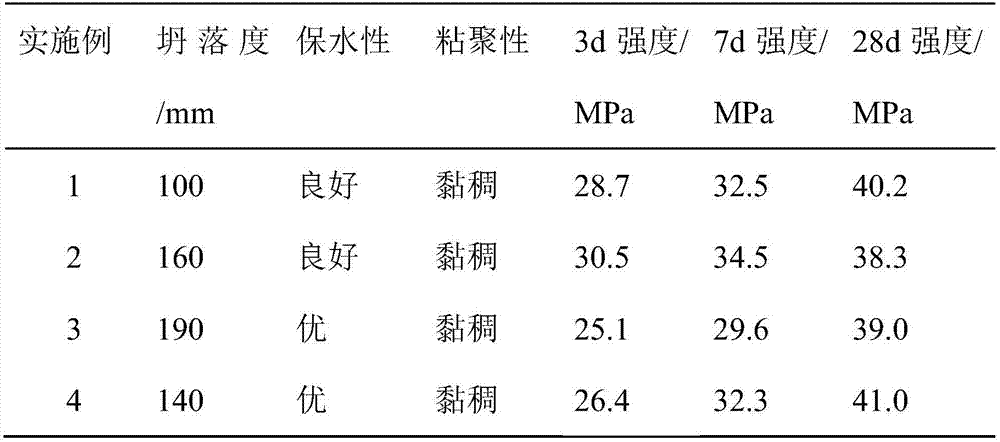

Concrete doped with quartz stone artificial stone waste residues

The invention discloses a concrete doped with quartz stone artificial stone waste residues. The concrete comprises, by weight, 320-400 parts of cement, 150-180 parts of water, 759-800 parts of river sands, 1000-1100 parts of stones, 20-80 parts of quartz stone artificial stone waste residues and 5.5-6.4 parts of a water reducer. The quartz stone artificial stone waste residues are used as an admixture to substitute parts of cement in order to reduce the use amount of cement in per square of the concrete, and a low water-binder ratio is adopted to guarantee the late strength of the concrete, so the cohesiveness and the water retention of the concrete are improved, the reduction of separation, water segregation and other adverse phenomena of the concrete is facilitated, the recycling of the quartz stone artificial stone waste residues is promoted, the reduction of the cost of the concrete is facilitated, the ecologic benefit is created, and the economic benefit is obtained.

Owner:SOUTH CHINA UNIV OF TECH

Well cementation material suitable for low-temperature environment and production method of well cementation material

ActiveCN110105030AImprove liquidity impactReduce the rate of hydrationDrilling compositionPortland cementUltimate tensile strength

The invention provides a well cementation material suitable for a low-temperature environment and a production method of the well cementation material. The well cementation material is prepared by mainly mixing 75-89% of portland cement clinker, 1-8% of sulphoaluminate cement clinker, 1-8% of high-alumina cement clinker, 2-4% of dihydrate gypsum, 0.5-1.2% of a dispersing agent and 1-4% of a retarder by weight. The well cementation material has the advantages that selected raw materials of raw meal cooperate with one another, on the basis of meeting the early strength, the later strength is ensured, the hydration rate is also slowed down to a certain extent, the setting time is prolonged, time guarantee is provided for radial grouting, and the risk ratio of blockage caused by the generationof cement plugs during grouting is reduced.

Owner:葛洲坝石门特种水泥有限公司

Glass fiber coral/sea sand concrete and production method thereof

The invention provides glass fiber coral / sea sand concrete and a production method thereof and relates to the technical field of marine building engineering materials. The glass fiber coral / sea sand concrete is mainly made with, by volume, 98% of sea sand concrete and 2% of glass fiber, wherein the sea sand concrete is made with a cementing material, coral, sea sand, a water reducer, an anti-freezing agent and sea water. The glass fiber coral / sea sand concrete has the advantages that coral is used as concrete coarse aggregate, sea sand is used as concrete fine aggregate, the materials are taken in situ, and therefore, production cost is lowered and economic benefit is increased; the water reducer is added, and therefore, mixing property and mobility of concrete mix are improved, gaps in the coral are filled with the fine aggregate and the cementing material, hollowness is decreased, and mechanical properties are improved; the glass fiber is added, and therefore, the problems of marineengineering concrete, such as poor durability, proneness to cracking and low corrosion resistance, are solved; the anti-freezing agent helps improve the fiber brittleness problem, and extend the lifeof the concrete.

Owner:GUANGXI UNIV

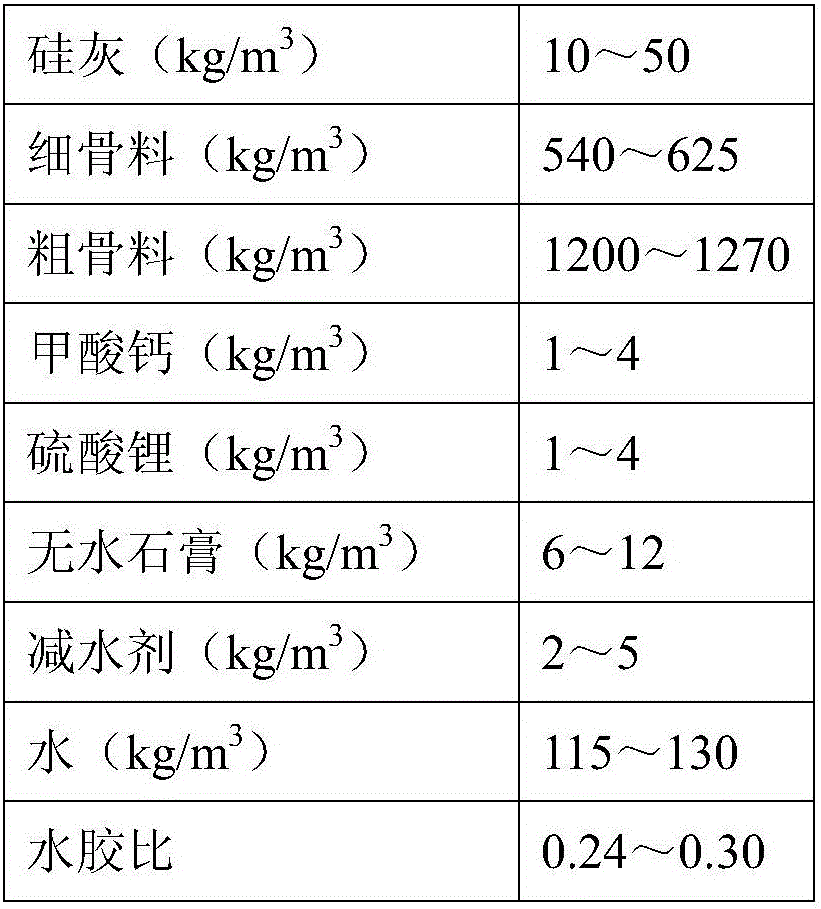

Concrete for large tubular pile of autoclaving-free process

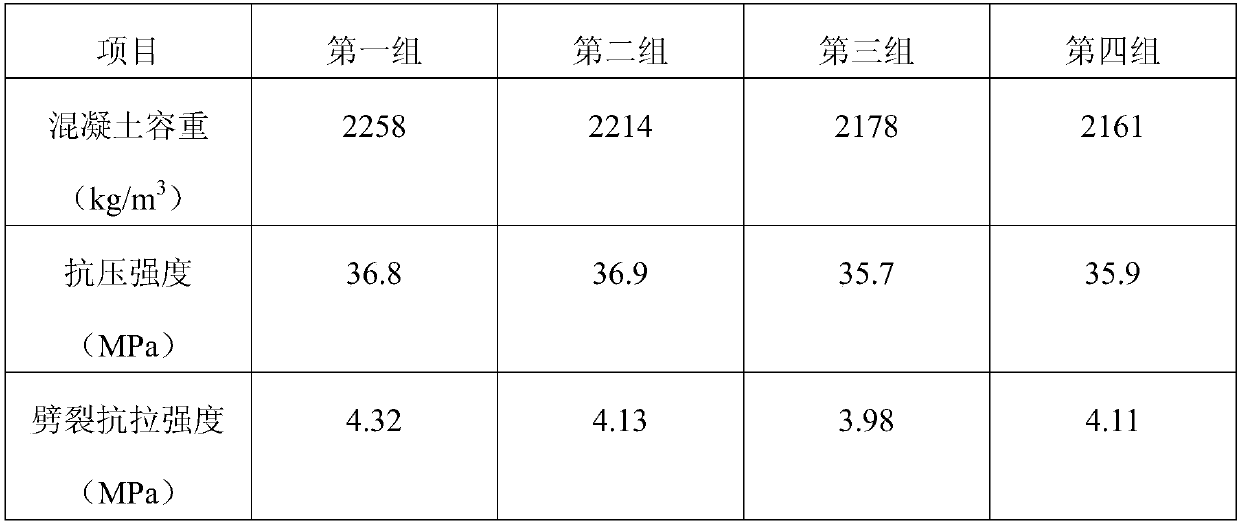

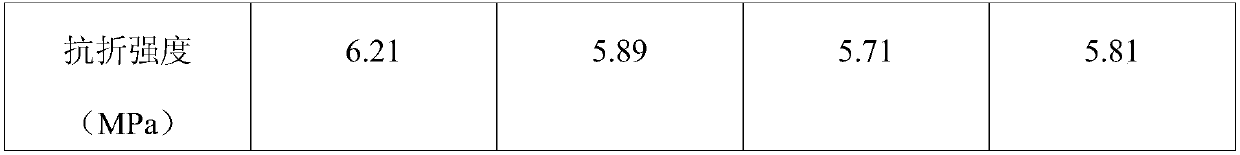

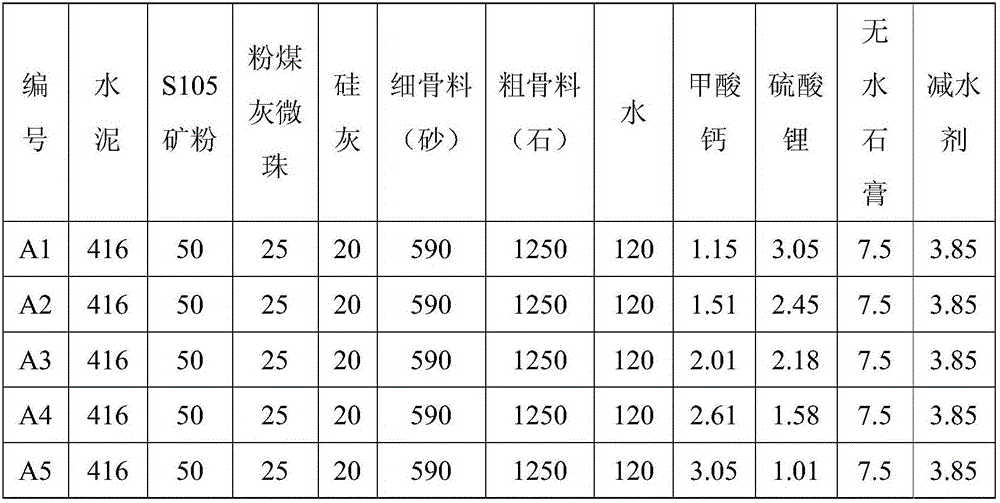

The invention belongs to the technical field of concrete materials, and in particular relates to concrete for a large tubular pile of an autoclaving-free process. Each cubic meter of preparation materials of the concrete comprise the following components: 360-450kg of cement, 30-80kg of slag powder, 10-70kg of coal ash microbeads, 10-50kg of silicon ash, 540-625kg of fine aggregate, 1200-1270kg of coarse aggregate, 1-4kg of calcium formate, 1-4kg of lithium sulfate, 6-12kg of anhydrite, 2-5kg of a water reducing agent and 115-130kg of water. A series of tests and studies on the proportioning ratio of the concrete provided by the invention are implemented, and an optimal concrete proportioning ratio which can meet the requirement of large tubular pile demolding strength and strength of C60 concrete within a relatively short time at a normal temperature can be obtained.

Owner:CCCC THIRD HARBOR ENG +2

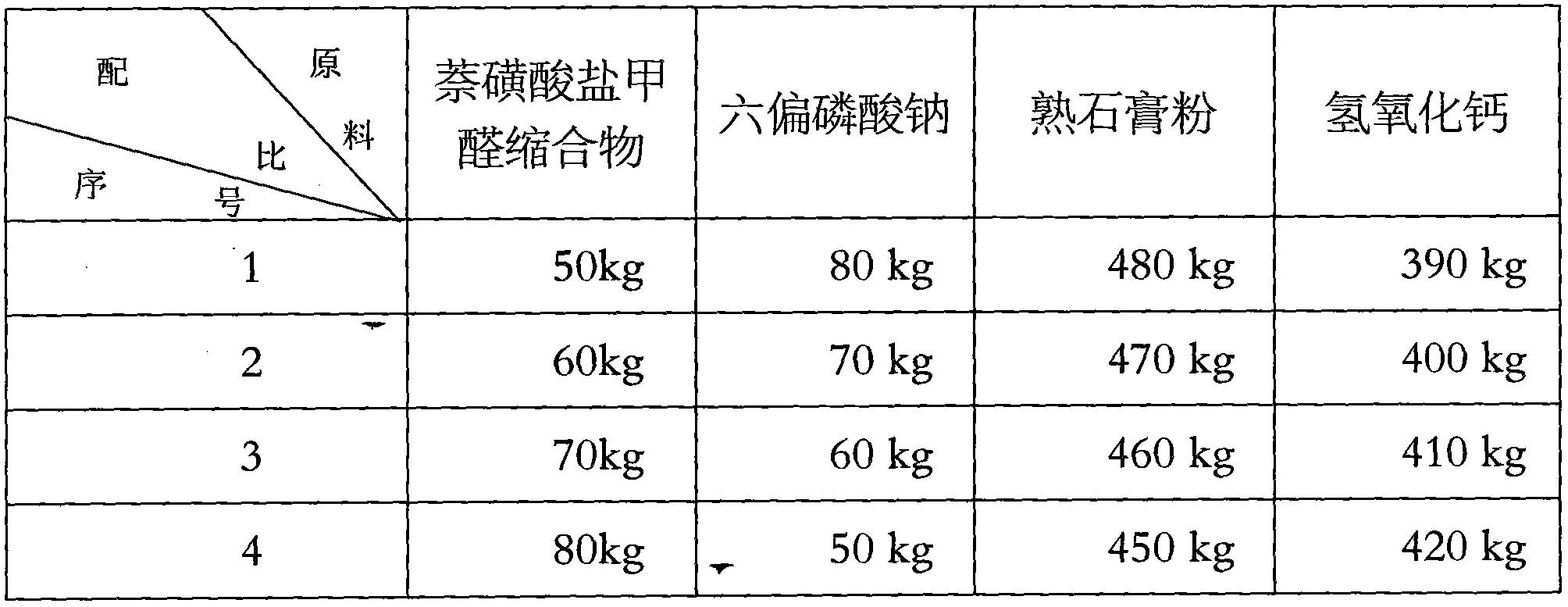

Additive for activating flyash

The invention discloses an additive for activating flyash, relating to a building material. The additive comprises the following components in parts by weight: 5-10 parts of naphthyl sulfonate formaldehyde condensate, 4-8 parts of sodium hexametaphosphate, 45-48 parts of gypsum powder and 38-42 parts of calcium hydroxide. The additive of the invention has the advantages that: 1, the additive has simple and feasible production process and is convenient to operation; 2, the alkalinity is extremely low, and no chlorides exist; 3, the additive accounts for 1.5-2% of gelled material, and has low doped amount and favorable price; and 4, due to the doped additive, the problem that the doped flyash reduces the initial strength of concrete is solved, and the later strength of the concrete can be ensured even and improved to some extent.

Owner:重庆达华砼外加剂科技发展有限公司

Light-weight anti-corrosion concrete for light steel structure wall body and preparation method thereof

The invention discloses light-weight anti-corrosion concrete for a light steel structure wall body and a preparation method thereof, and relates to the technical field of a building material. The light-weight anti-corrosion concrete for the light steel structure wall body is prepared from the following ingredients in parts by weight: 170 to 190 parts of ordinary Portland cement, 114 to 139 parts of fly ash, 35 to 50 parts of expanding agents, 0.5 to 1.0 part of hydroxypropyl methyl cellulose, 0.8 to 1.2 parts of redispersible powder, 8.5 to 9.5 parts of EPS particles, 3.7 to 4 parts of water reducing agents and 135 to 140 parts of water. The concrete provided by the invention has the advantages that the concrete cracking is reduced; the moisture seepage is prevented; the sulphate corrosionresistance is realized.

Owner:HEFEI GUORUI INTEGRATED CONSTR TECH CO LTD

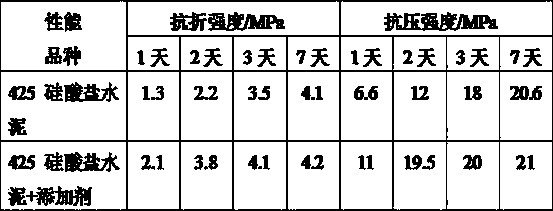

Novel additive for cement mortar and application method of novel additive

The invention relates to a novel additive for cement mortar and an application method of the novel additive. The additive is composed of the following components by weight percent: 1-5wt% of acrylamide (AM), 0.2-1wt% of N,N'-methylene bisacrylamide (MBAM), 0.02-0.2wt% of ammonium persulfate (APS) and 0.02wt% of N, N, N',N'-tetramethylethylenediamine (TEMED). The problems that repeated watering and water replenishing are required in the process of cement hydration and the hydration speed is slow in the middle and later periods of cement under the condition of low water-cement ratio, and the like are solved. The setting time is effectively adjusted, the intensity in the early and middle periods is improved, and the ultimate strength of components is not reduced is ensured, and therefore, the additive has a wide application prospect.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Alkali-free liquid accelerator and preparation method thereof

The invention discloses an alkali-free liquid accelerator and a preparation method thereof. The liquid accelerator is prepared from the following components in parts by weight: 30 to 50 parts of polyaluminum sulfate; 5 to 10 parts of ferrous sulfate; 0.1 to 2 parts of oxalic acid; 1 to 5 parts of triisopropanolamine; 1 to 4 parts of sodium fluoride; 0.1 to 2 parts of polyacrylamide; and a reagentcarrier. The invention is expected to solve the problems that a common liquid accelerator is relatively strong in alkalinity, relatively high in cost and not easy to store.

Owner:湖南武源建材有限责任公司

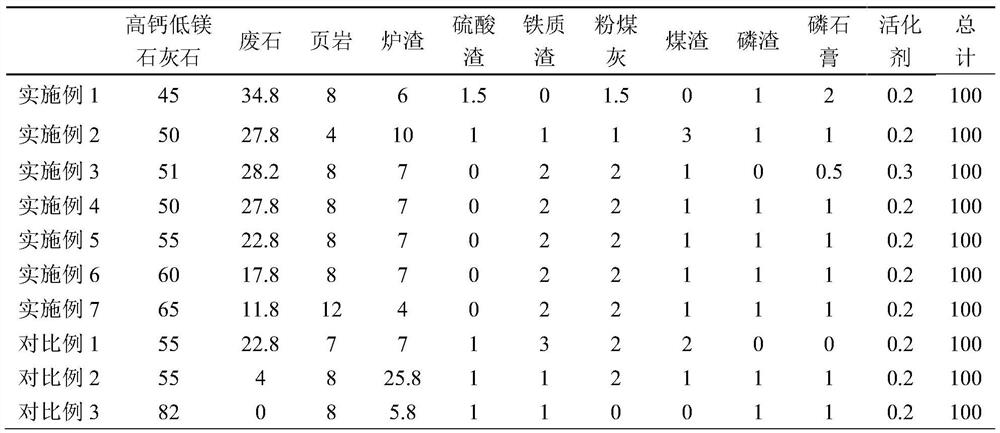

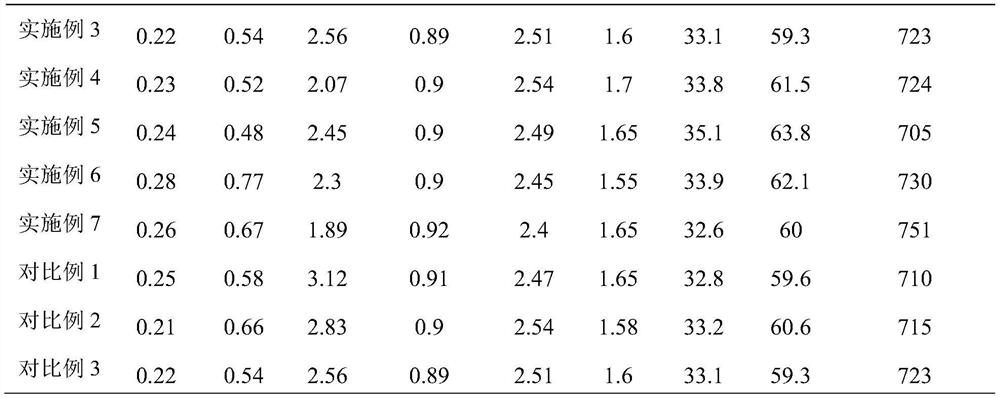

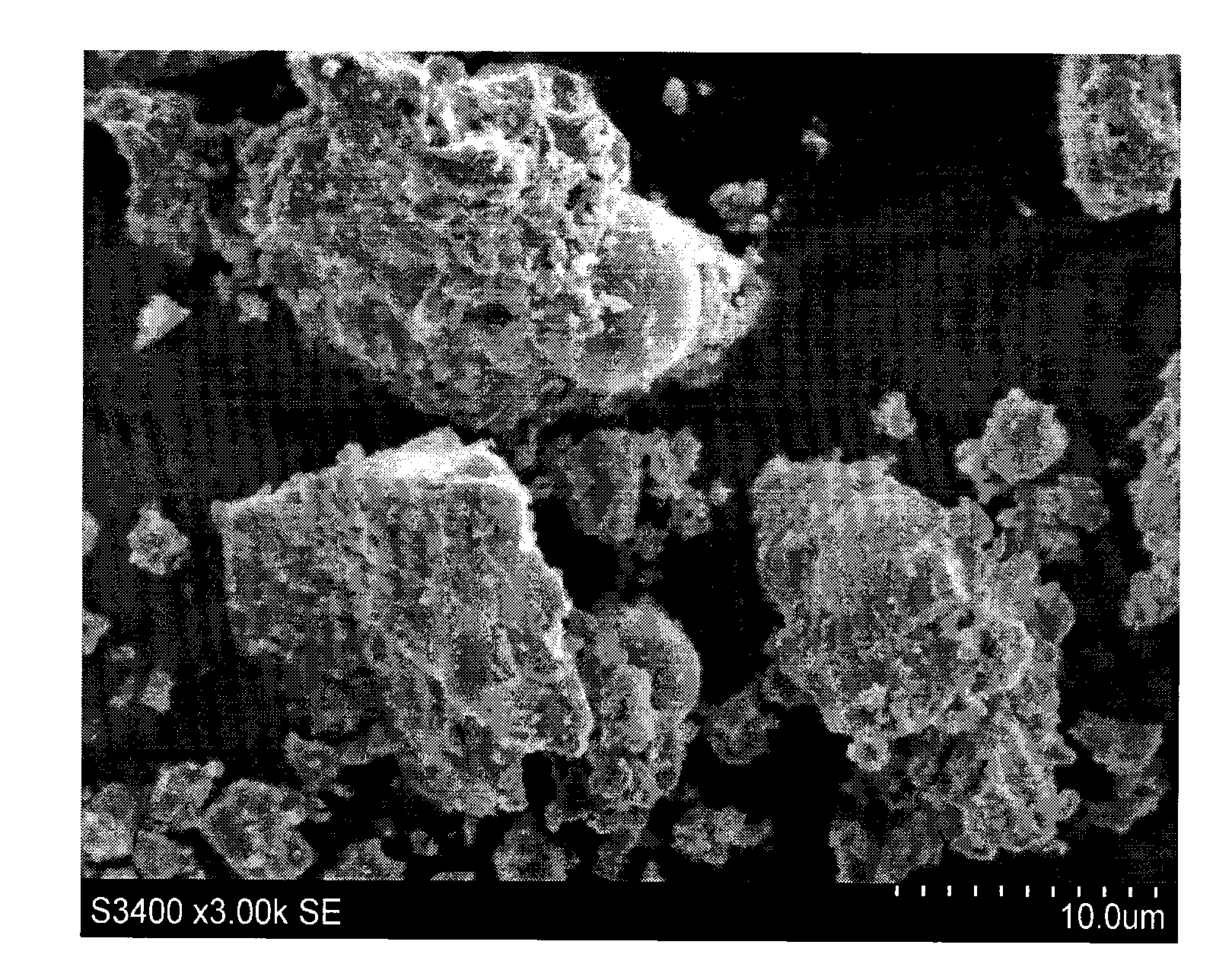

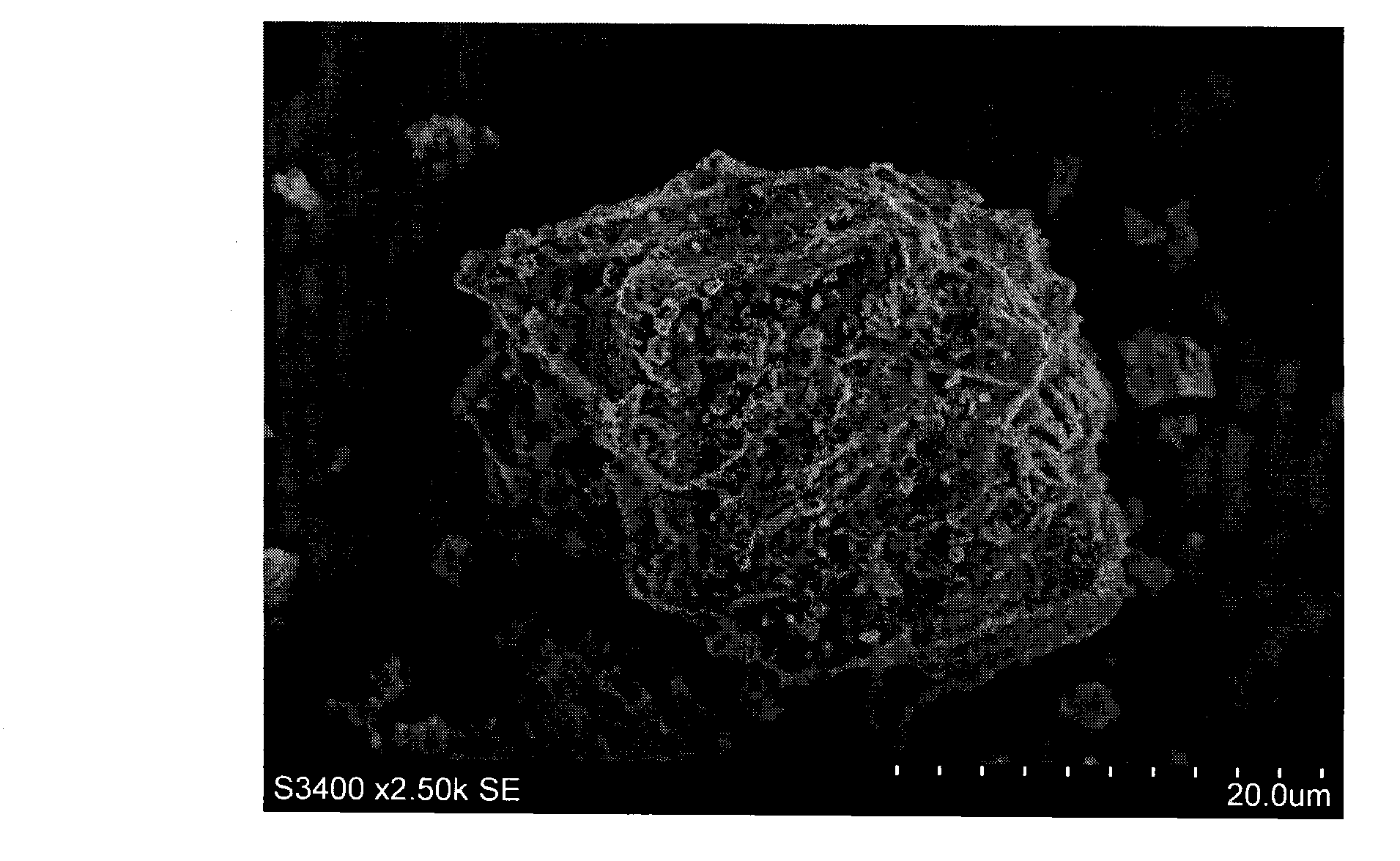

Resource-saving low-carbon cement clinker and preparation method thereof

The invention discloses a resource-saving low-carbon cement clinker and a preparation method thereof, and belongs to the technical field of Portland cement clinker production. The cement clinker comprises the following raw materials in percentage by mass: 45-70% of high-calcium low-magnesium limestone, 10-40% of barren rock, 4-12% of shale or sandstone, 4-12% of slag, 1-3% of sulfate slag or iron slag, 1-3% of fly ash, 0-3% of coal cinder or coal gangue, 0.5-3% of phosphorus slag and phosphogypsum and 0.1-0.3% of an added activating agent. According to the resource-saving low-carbon cement clinker and the preparation method thereof of the invention, a large amount of solid waste is utilized, the adopted industrial waste residue is formed by high-temperature calcination, carbonate hardly exists, and CO2 hardly occurs after high-temperature calcination is performed again; the mixing amount of the industrial waste residues is high, the use amount of limestone is greatly reduced; the mineralization of trace elements in the industrial waste residues is utilized, and the activating agent is added, so that the burnability of the raw materials is improved, the sintering stability of the clinker is reduced, and the performance of the clinker is improved; the firing temperature of the low-carbon cement clinker is reduced by 100-150 DEG C compared with the firing temperature 1450 DEG C of traditional Portland cement clinker, and therefore, the coal consumption is obviously reduced, and the emission of CO2 is reduced.

Owner:阳新娲石水泥有限公司

Accelerator and preparation technology thereof

The invention relates to an accelerator and a preparation technology thereof. The technology comprises the following steps: preparing a raw material from 35wt% of bauxite, 24wt% of soda ash, 30wt% of limestone and 11% of coal, milling the raw material to form powder, adding the powder to a 1250DEG C high temperature furnace segment, burning the powder to form aluminum oxygen chamotte, milling the aluminum oxygen chamotte to form powder with the fineness being smaller than 15%, and uniformly stirring 40-60wt% of the aluminum oxygen chamotte powder and 40-60wt% of fly ash to prepare the accelerator. The fly ash is generated after calcining gangue in a fluidized bed boiler, the vulcanic ash active component content of the fly ash is large, and the Al2O3 content reaches 27.39% (the alum stone content is about 20%), so the condensation time is further shortened, and the later strength of concrete is guaranteed under the action of activity of vulcanic ash. The accelerator and the preparation technology thereof have the following advantages: the fly ash from a power plant is used, and is changed into valuables from wastes, so pollution of the fly ash to environment is reduced; and high temperature calcined alum stone is omitted, so electric energy is saved, the production cost is reduced, and the later strength of the concrete is guaranteed.

Owner:QINGDAO WEIYE FORGING & STAMPING MACHINERY CO LTD

Seawater mixed culture coral reef sand C120UHPC and preparation method thereof

The invention discloses seawater mixed culture coral reef sand C120UHPC and a preparation method thereof. The UHPC comprises the following components in proportion: 690.2 kg / m<3> of aluminoferrite cement; 138.6 kg / m<3> of fine coral reef powder; 194.1 kg / m<3> of coarse coral reef powder; 776.3 kg / m<3> of quartz sand; 138.6 kg / m<3> of silica fume; 34.7 kg / m<3> of fly ash; 182.3 kg / m<3> of seawater;41.6 kg / m<3> of a superplasticizer; and 140.4 kg / m<3> of steel fibers. The invention also discloses a preparation method of the UHPC, and a curing method comprises the following steps: placing a concrete test block in a standard curing chamber, covering the test block with wet linen, or placing the test block in water, maintaining multiple watering curing in the curing process, and preventing evaporation of water in the concrete, so that the curing method avoids steam curing of the UHPC. The seawater mixed culture coral reef sand C120UHPC and the method have the technical advantages that themethod is beneficial to application and popularization of UHPC, has important significance in meeting large-scale engineering construction of island reefs in the South China Sea, achieving local material utilization, reducing cost, shortening the construction period and the like, the construction cost of offshore engineering is reduced, and the requirements for greenization, energy conservation and environmental protection of civil engineering are met.

Owner:XIANGTAN UNIV

Slag-coal ash compound solid exciter and preparation method thereof

The invention relates to a slag-coal ash compound solid exciter and a preparation method thereof, and belongs to the field of cement and concrete building materials. The preparation method for the slag-coal ash compound solid exciter comprises the steps as follows: carrying out compound modification on sodium hydroxide, sodium carbonate and low-modulus liquid water glass as well as a modifying agent-polyacrylamide or polyphosphate, ageing and digesting in vacuum condition, drying and grinding. The slag-coal ash compound solid exciter overcomes the defects of poor stability of the traditional solid base exciter and difficult field construction of the traditional liquid exciter, has the advantages of good stability, unsuitability for moisture absorption or air slaking and a wide range of material sources, and can be directly mixed and ground with the slag and the coal ash to prepare high-strength hydraulic cementing materials. The cement can be fully replaced with the cementing material obtained by the excitation of the exciter in the concrete, so that the concrete strength can be enhanced by about 20-30%, and the concrete durability can be improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Jet concrete fast hardening agent

InactiveCN1194926CReduce pollutionGuaranteed later strengthSolid waste managementClinker productionShotcreteSlag

Owner:徐州华泰混凝土外加剂厂

Compound admixture for anti-crack limestone powder and preparation method of compound admixture

The invention provides a compound admixture for anti-crack limestone powder and a preparation method of the compound admixture. The compound admixture comprises, by mass, 60-70 parts of limestone powder, 28-40 parts of coal ash, 1-2 parts of polypropylene fibers and 0.1-0.2 part of triethanolamine. By the compound admixture for the anti-crack limestone powder, concrete contraction can be reduced and concrete anti-crack performance can be improved while working performance and mechanical performance of concrete are guaranteed, so that durability of limestone powder concrete is improved, and application of the limestone powder to the concrete is widened.

Owner:CENT SOUTH UNIV

Technology for preparing baking-free brick from iron tailings

InactiveCN106242408AHigh strengthGuaranteed later strengthDischarging arrangementSolid waste managementBrickMixing effect

The invention discloses a technology for preparing a baking-free brick from iron tailings. The packing density of raw materials after rolling treatment is increased,the compactness of a brick body is improved, the intensity of the baking-free brick is improved, the mixing effects of the raw materials can be the best by controlling rolling time, and besides, changes in particle size are inapparent; the raw materials have better uniformity under synergistic effects of stirring and mixing as well as rolling and mixing; and the development of the early strength of the baking-free brick can be accelerated through an appropriate quantity of additives, and the later strength of the baking-free brick can be guaranteed. The baking-free brick prepared by adopting the preparation technology has the advantages of being high in compression resistance and large in freezing resistance, and is large in market potential and broad in prospects.

Owner:明光市凯旋新型建材厂

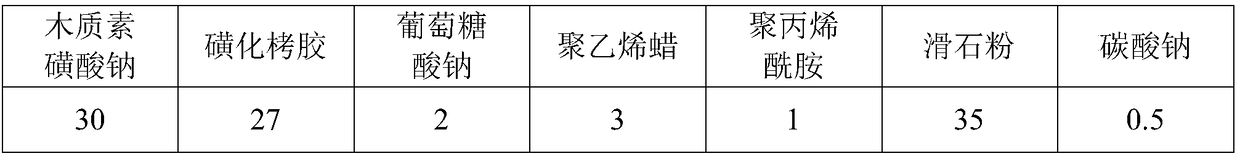

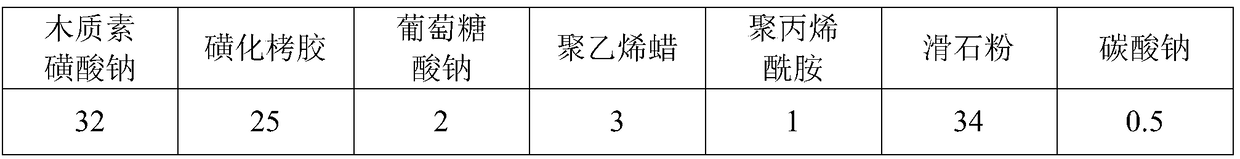

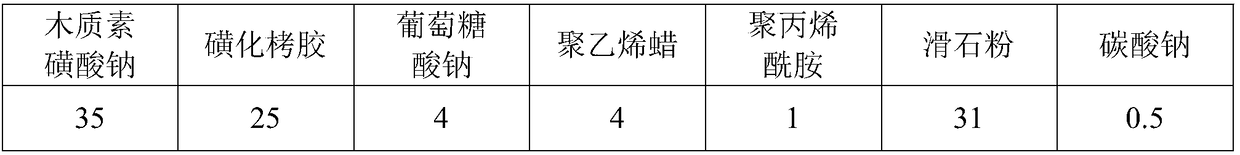

Pumping agent for hydraulic reclamation of silt solidified soil and preparation method thereof

InactiveCN109502936AIncrease moisture contentIt can have good fluidity under the condition of moisture contentFixation/solidifcation sludge treatmentSulfonateLignosulfonates

The invention discloses a pumping agentfor blowing silt solidified soil and a preparation method thereof. The provided pumping agent is compounded by lignin sulfonate, sulfonated tannin extract, sodium gluconate, polyethylene wax, polyacrylamide, talc and sodium carbonate. The weight part of each component is: 30 to 35 parts of the lignin sulfonate, 25 to 35 parts of the sulfonated tannin extract,2 to 4 parts of the sodium gluconate, 3 to 4 parts of the polyethylene wax, 1 to 2 parts of the polyacrylamide, 30 to 35 parts of the talc and 0.5 to 1 parts of the sodium carbonate. The pumping agent for hydraulic reclamation of silt solidified soil provided by the invention has the advantages of low addition amount, simple adding process and good environmental protection, and the addition of the pumping agent can significantly improve the fluidity, lubricity and stability of the fresh silt solidified soil, makes the low-water content fresh silt solidified soil (water content of 100 percentto 150 percent) to maintain good fluidity within 2h, ensures the late strength of the solidified soil and prolongs the pumpable time of the silt solidified soil, which helps to improve the efficiencyand quality of silt solidified soil hydraulic reclamation construction, and has obvious technical, economic and environmental advantages.

Owner:JIANGSU NATURE WAY TECH

Repairing agent for subway shield segments and preparation method of repairing agent

InactiveCN111995349AGuaranteed crack resistanceImprove compactnessSolid waste managementAluminateCellulose

The invention discloses a repairing agent for subway shield segments and a preparation method of the repairing agent. The repairing agent is prepared from the following raw materials in parts by mass:200 to 300 parts of ordinary Portland cement; 150-200 parts of white cement; 100 to 250 parts of sulphoaluminate cement; 20-50 parts of microbeads; 50 to 100 parts of silica fume (silica powder); 150to 250 parts of active glass powder; 1 to 10 parts of excitant; 50 to 100 parts of concrete expanding agent; 0.1 to 0.4 part of plastic expanding agent; 1 to 5 parts of water reducing agent; 0.1 to 0.4 part of defoaming agent; 0 to 0.5 part of cellulose; 15 to 35 parts of redispersible latex powder; and A parts of water. The sum of the dosages of the components excepting water, namely the sum ofthe parts of the components excepting water is B, and the water-material ratio, namely the ratio of A to B, is 0.15-0.20: 1. The invention further provides a preparation method of the repairing agent.Through the synergistic effect of all the components, the repairing agent is high in early and later compressive strength, good in wear resistance and small in color difference with old concrete repairing, has the characteristics of good bonding performance and crack resistance, and is convenient to apply and popularize.

Owner:刘翠芬

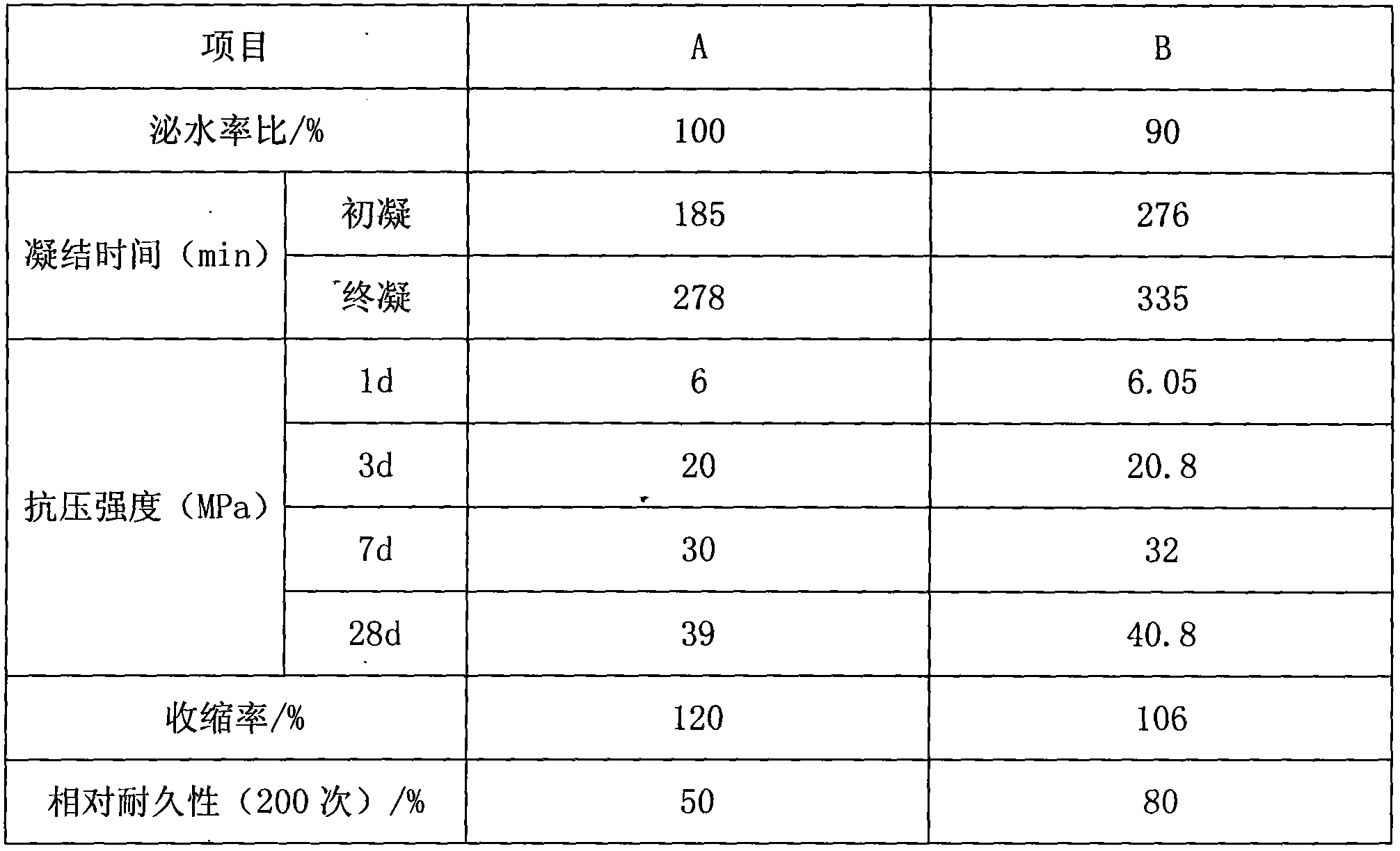

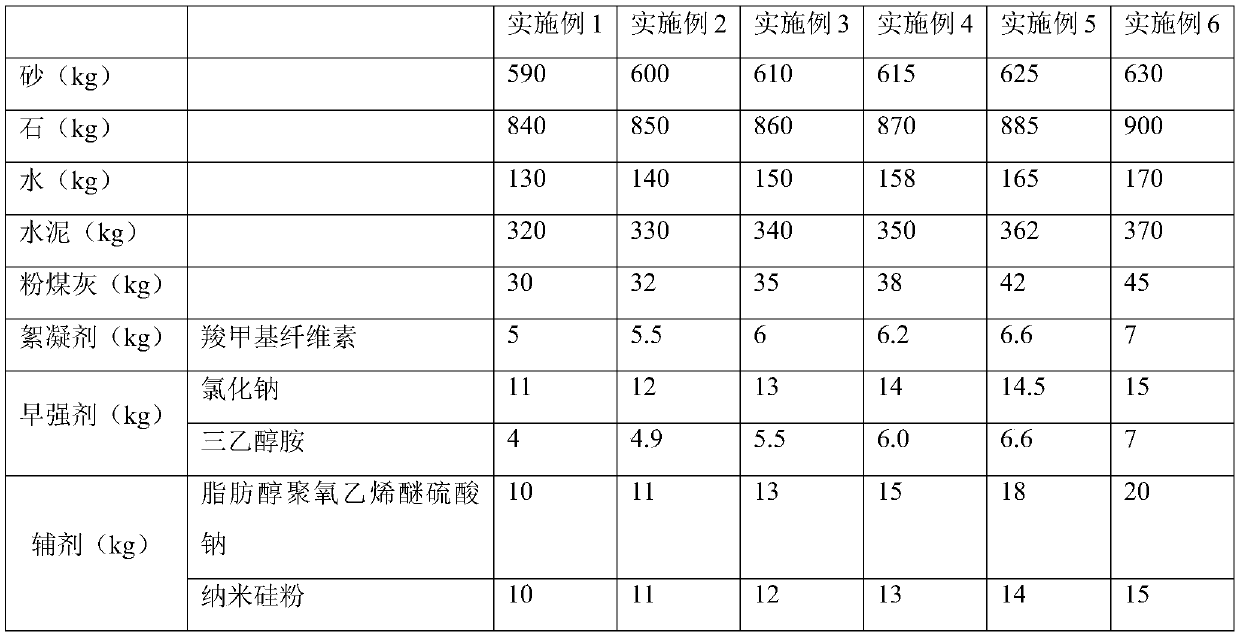

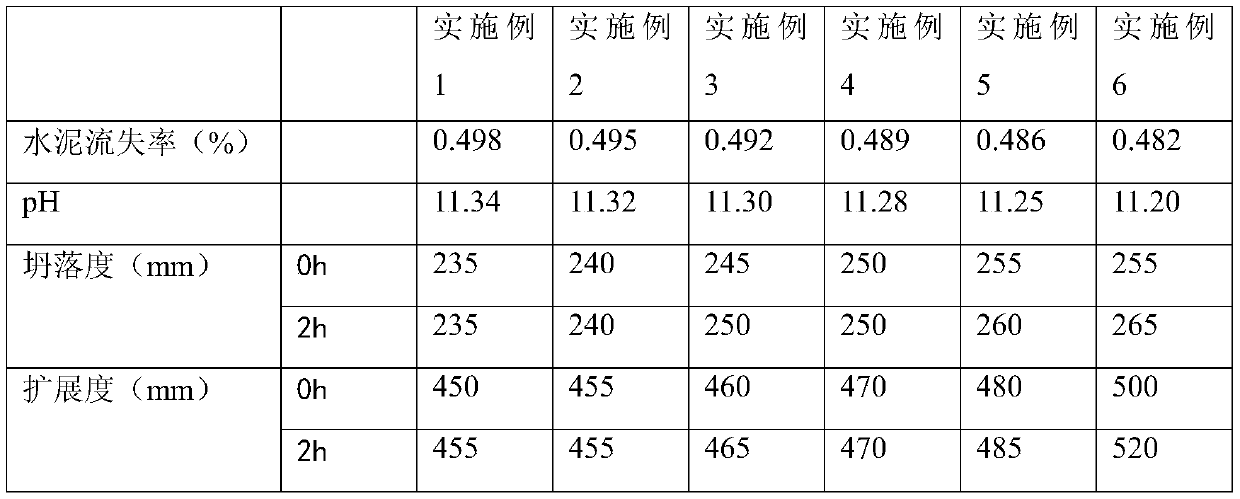

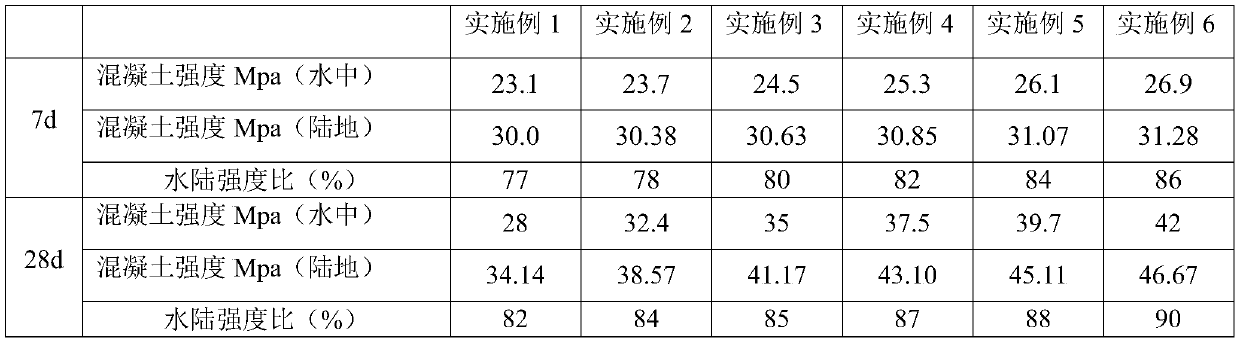

Underwater non-dispersible concrete and its preparation method

Owner:天津市滨涛混凝土有限公司

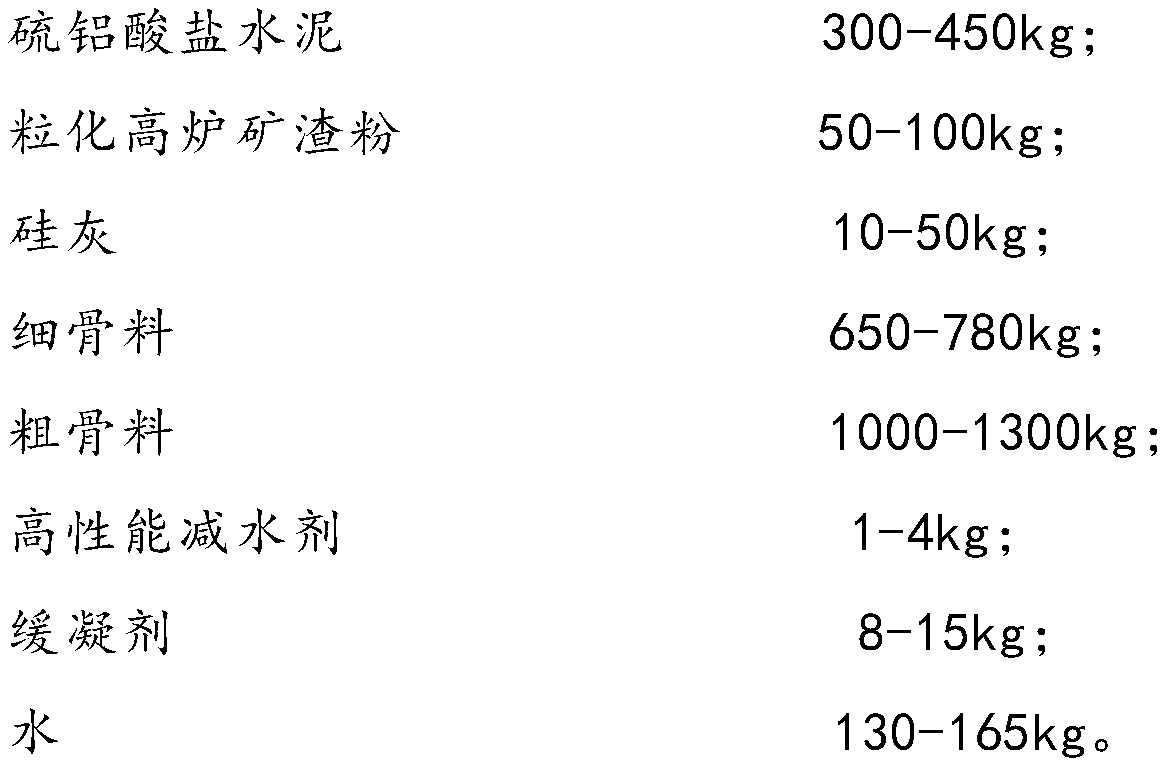

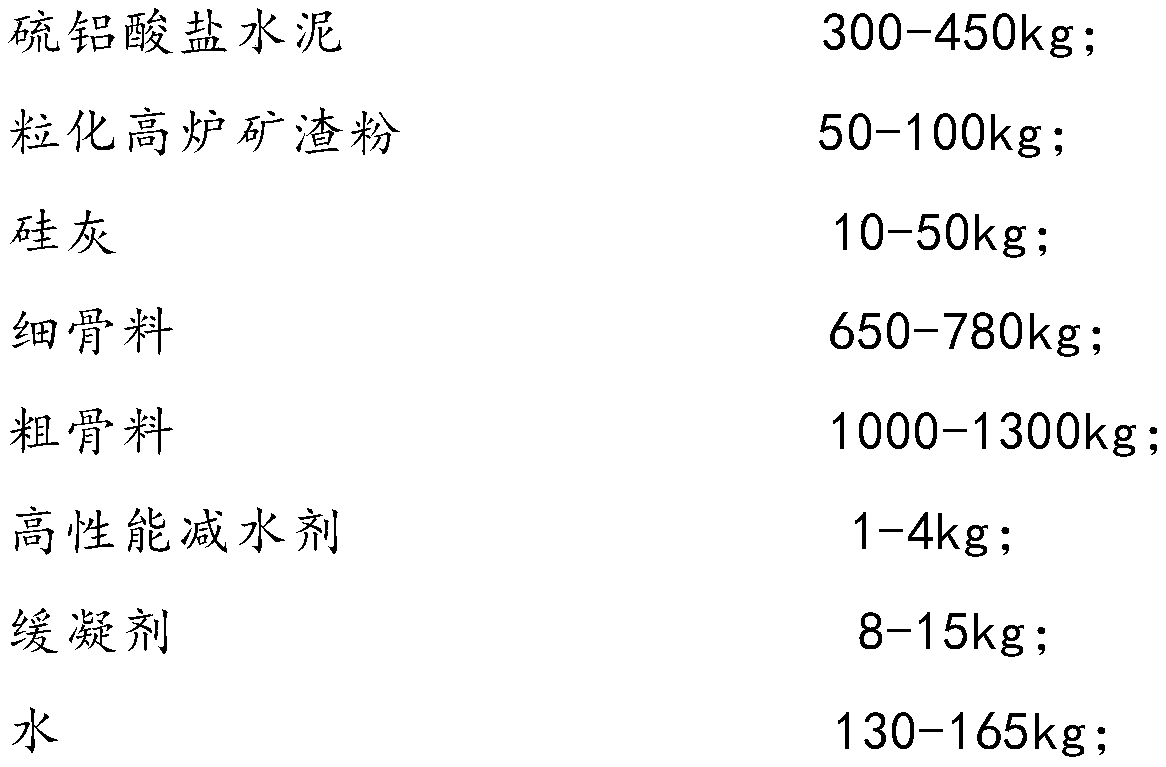

Concrete for rapid construction under marine environment and preparation method thereof

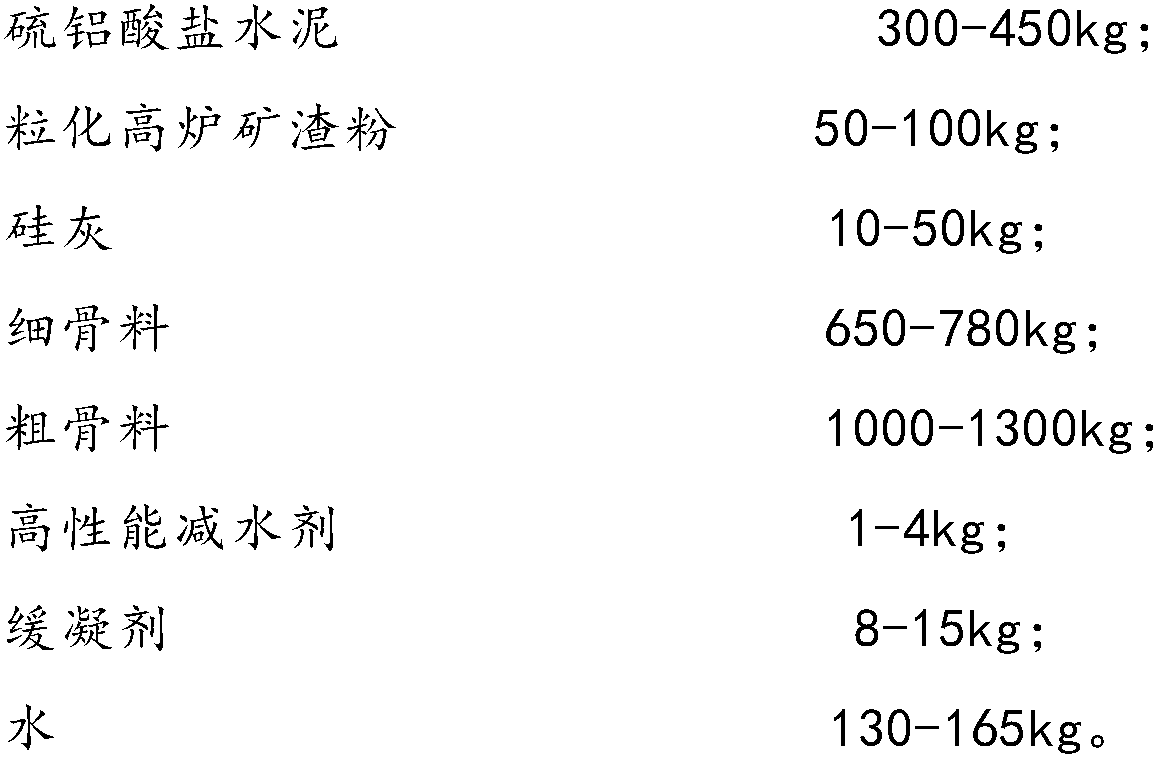

The invention discloses concrete for rapid construction under the marine environment. The concrete is prepared from, per cubic meter, 300-450 kg of sulphate aluminum cement, 50-100 kg of granulated blast-furnace slag powder, 10-50 kg of silica fume, 650-780 kg of fine aggregates, 1,000-1,300 kg of coarse aggregates, 1-4 kg of high-performance water reducer, 8-15 kg of retarder and 130-165 kg of water. The concrete for rapid construction under the marine environment achieves the demolding strength earlier under the normal temperature and low temperature conditions, and can be widely applied tothe environment under the low-temperature condition such as anti-chloride corrosion and freezing resistance in the North under the marine environment.

Owner:CCCC THIRD HARBOR ENG +2

Reinforced concrete admixture and preparation method thereof

The invention relates to the technical field of building materials, in particular to a reinforced concrete admixture and a preparation method thereof.The reinforced concrete admixture comprises modified marble-slag powder, silica fume and an early strength agent; wherein the modified marble-slag powder is prepared by grinding a marble raw material, slag powder and a grinding aid; the grinding aid is prepared by the following steps: dropwise adding alcohol amine, molasses, urea and glycerol into water for reaction, and obtaining the grinding aid after the reaction is finished, the specific surface area of the modified marble-slag powder is 1000-1200 m<2> / kg, the water demand ratio is less than 85%, and the 28d strength activity index is greater than 90%. According to the reinforced concrete admixture provided by the invention, waste marble stones can be recycled in concrete, the stability and the later strength of the concrete can be ensured, the problem of treatment of stone powder wastes is solved, cheap raw materials can be provided for the concrete, and the reinforced concrete admixture has huge economic benefits and wide market application values.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Road as well as water-stable layer and preparation process thereof

PendingCN113716928AGuaranteed early strengthGuaranteed later strengthIn situ pavingsSolid waste managementEnvironmental engineeringPhosphogypsum

The invention discloses a road as well as a water-stable layer and a preparation process thereof, and belongs to the technical field of phosphogypsum solid waste recycling. The road water-stable layer is a solidified soil structure layer formed by solidifying and forming a water-stable mixture, the water-stable mixture comprises modified phosphogypsum, an active component, loosened soil and water, the modified phosphogypsum is formed by calcining phosphogypsum and a modifier at high temperature, and the modifier comprises the following components in percentage by weight: 88-94% of CaO, 4-9% of SiO2 and 1.5-3% of Al2O3. The phosphogypsum-based cementing material is used for a temporary road and a water stable layer of the road, so that the phosphogypsum-based cementing material can replace a large amount of lime, cement, fly ash and other traditional road building materials, the strength, especially the early strength, of the lime-ash soil base layer is effectively improved, the structural integrity is enhanced, the shrinkage of the base layer material is reduced, and the crack resistance is improved.

Owner:深圳市颐泰中和科技有限公司

Low-temperature cement and preparation method thereof

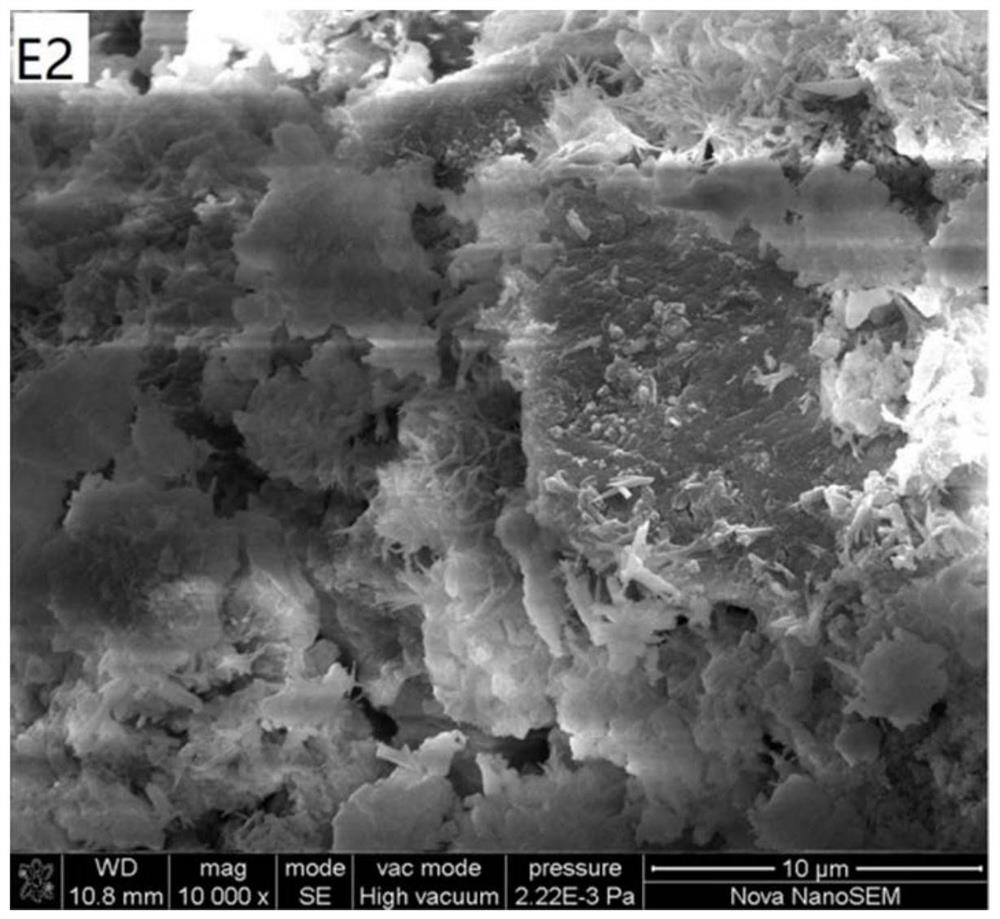

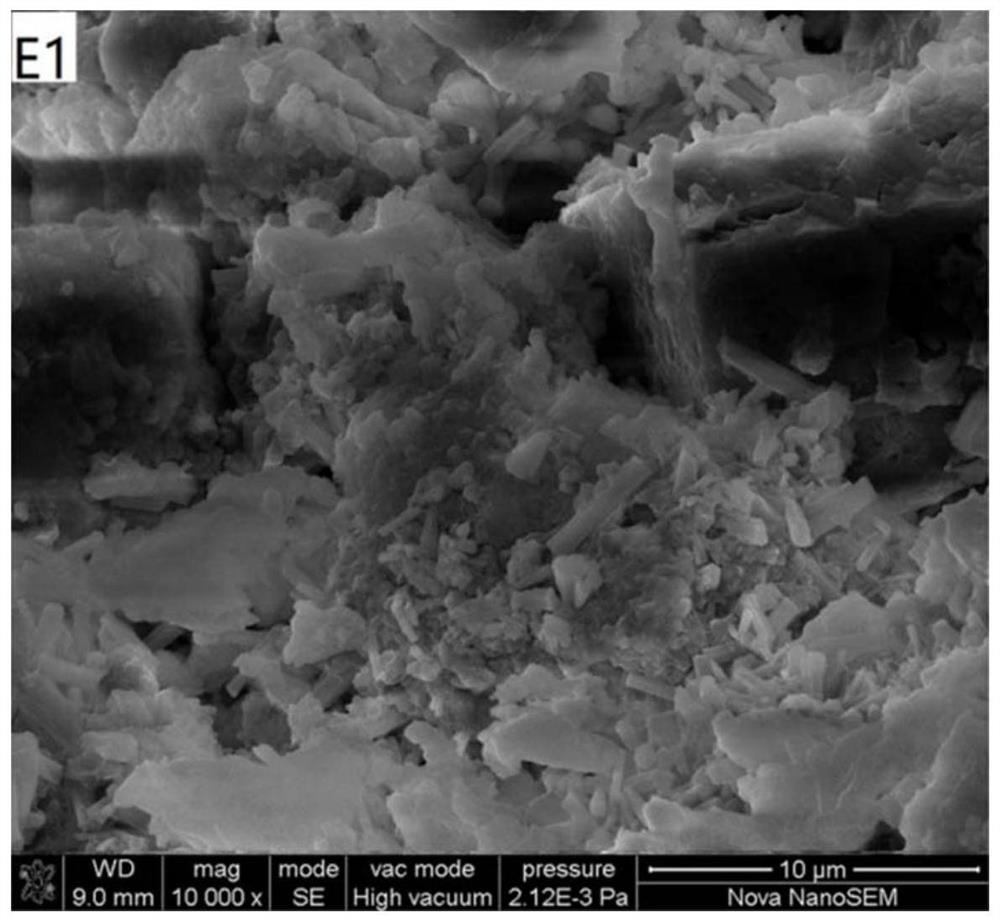

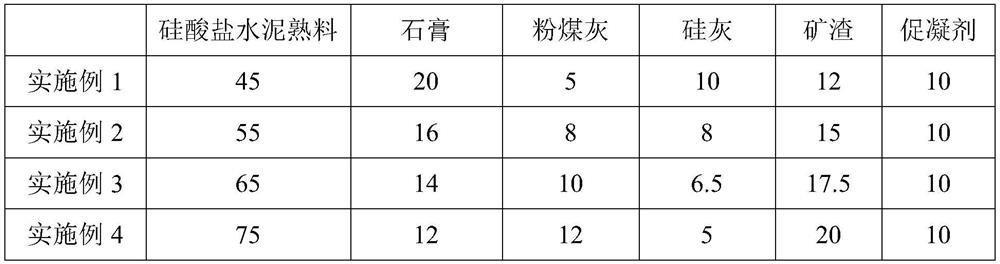

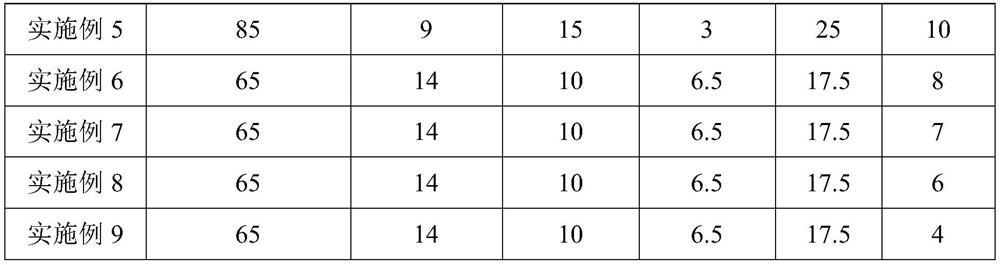

The invention relates to the field of building materials, and particularly discloses low-temperature cement and a preparation method thereof. The low-temperature cement is prepared from the following raw materials in parts by weight: 45-85 parts of Portland cement clinker, 9-20 parts of gypsum, 5-15 parts of fly ash, 3-10 parts of silica fume, 12-25 parts of slag and 2-6 parts of a coagulant. The coagulant is prepared from the following raw materials in parts by weight: 20-31 parts of aluminum sulfate, 16-25 parts of a fluorine-aluminum complex, 1-5 parts of a complexing agent, 0.3-1 part of organic salt, 0.8-2 parts of inorganic salt and 38-53 parts of water. The preparation method comprises the following steps: uniformly mixing the raw materials except the coagulant, adding the coagulant, and uniformly mixing to obtain the low-temperature cement. The low-temperature cement has the advantages that the setting time is shortened, and the early strength and the later strength of the cement are guaranteed.

Owner:厦门美益建材有限公司

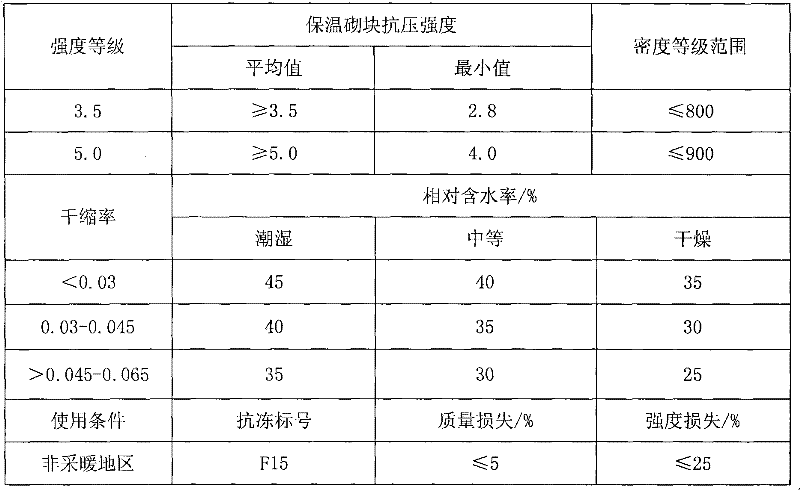

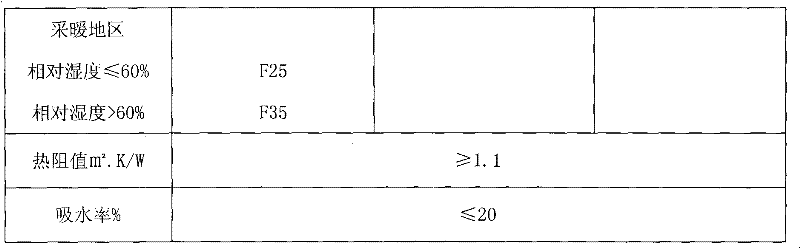

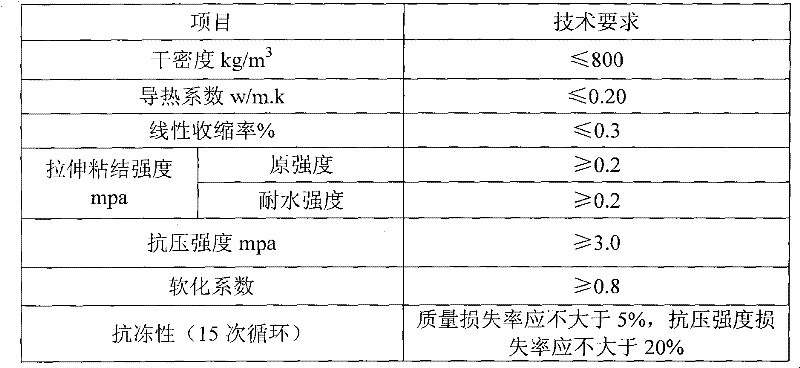

Expanded and vitrified small ball wall self-insulation system

ActiveCN101787744BImprove thermal insulationHigh fire ratingSolid waste managementWallsThermal bridgeThermal coefficient

The invention discloses an expanded and vitrified small ball wall self-insulation system, which comprises expanded and vitrified small ball insulation blocks, expanded and vitrified small ball masonry mortar and an expanded and vitrified small ball insulation template. The expanded and vitrified small ball insulation blocks and the matched expanded and vitrified small ball masonry mortar achieve the wall self-insulation effect, and the expanded and vitrified small ball insulation template solves the problems of thermal bridge of a shear wall, a shockproof column, a ring beam and the like. An expanded and vitrified small ball inorganic thermal insulation material is added into the expanded and vitrified small ball insulation blocks to play a role in preserving heat and insulating heat; theexpanded and vitrified small ball masonry mortar solves the problem of thermal bridge of a cross joint and a longitudinal joint; and the expanded and vitrified small ball insulation template is mainly prepared from expanded and vitrified small balls which are paved on a support to form the template, a structural layer and an insulating layer. The expanded and vitrified small ball wall self-insulation system has the advantages of good integrity, low thermal coefficient, environmental protection and comfortableness, good water-retaining property, good flexibility and anti-cracking ability, no detachment and permanence, and low construction cost.

Owner:江苏华伟佳建材科技有限公司 +1

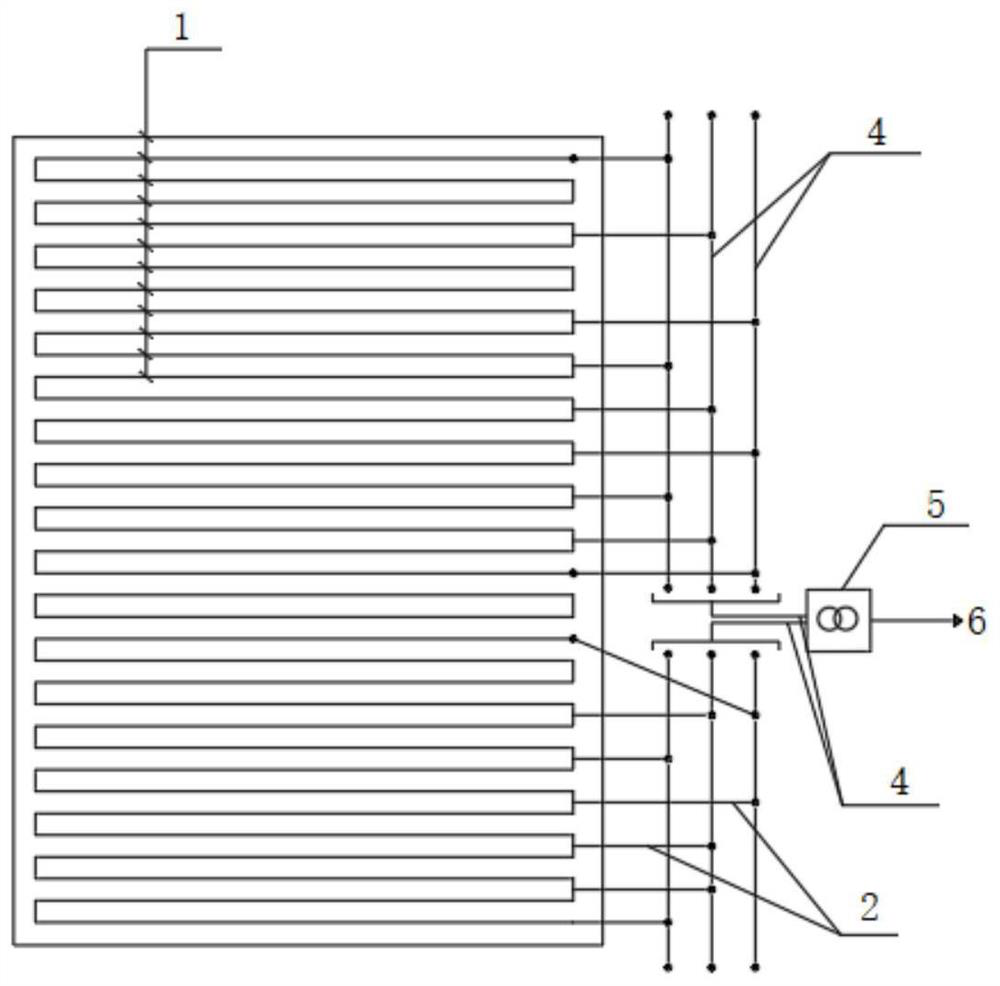

Concrete in-mold temperature control system applied to cold conditions

PendingCN112684825AAvoid freezingGuaranteed early strengthTemperatue controlBuilding material handlingRebarTemperature control

The invention discloses a concrete in-mold temperature control system applied to cold conditions, the control system comprises a heating device; the heating device is arranged on a steel bar to be poured and is connected with the steel bar, the heating device is connected with a power supply bus through a cable, and the heating device is poured in a concrete structure. The temperature required by initial setting and final setting of the concrete can be effectively controlled, early freezing of the concrete is avoided, the early strength of the concrete is guaranteed, mass concrete cracks are reduced, and the later strength and durability of the concrete meet the requirements.

Owner:CCCC SHANGHAI HARBOR ENG DESIGN & RES INST +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com