Glass fiber coral/sea sand concrete and production method thereof

A glass fiber and concrete technology, applied in the field of glass fiber coral sea sand concrete and its preparation, can solve the problems of inability to guarantee the normal function of the fiber, high cost of carbon fiber, low economy, etc., so as to improve the mixing performance and fluidity, improve the Mechanical properties and the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

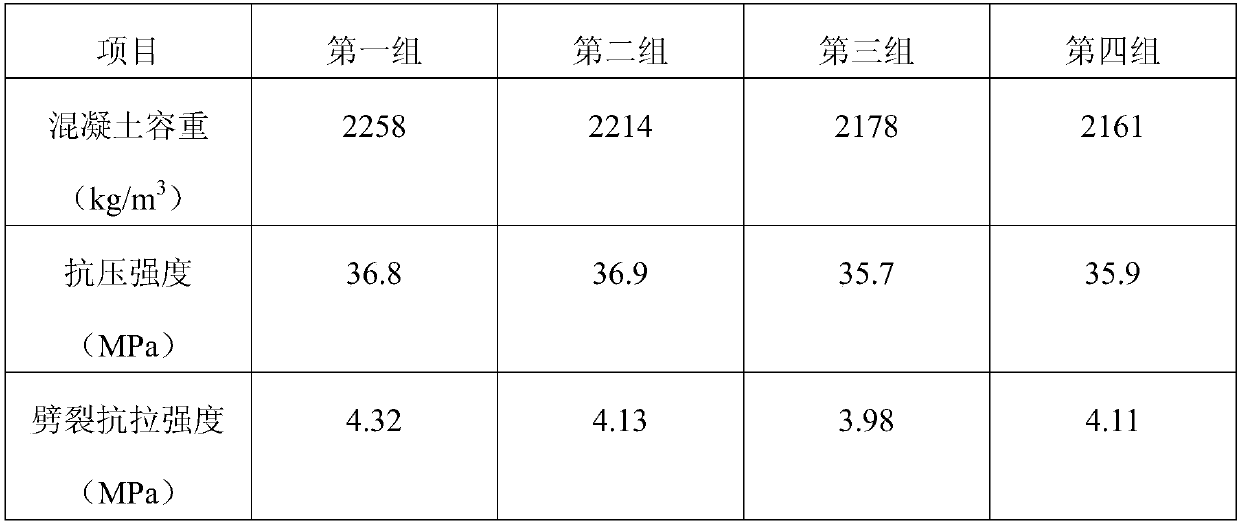

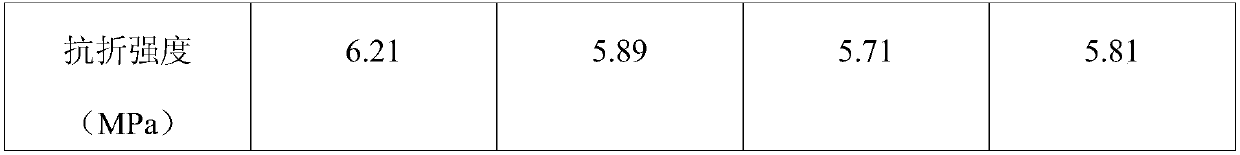

Examples

Embodiment 1

[0026] A kind of glass fiber coral sea-sand concrete provided by this embodiment is made up of sea-sand concrete and glass fiber, and the volume percentage content of two components is 98% sea-sand concrete and 2% glass fiber; Wherein, sea-sand concrete It consists of the following raw materials in parts by weight: 450 parts of cementitious material, 700 parts of coral, 800 parts of sea sand, 3 parts of water reducer, 4 parts of antifreeze and 160 parts of seawater; After processing, it is made into a monofilament bundle, and its tensile strength is greater than 1700MPa; the water reducing agent is a polycarboxylate high-performance water reducing agent.

[0027] This embodiment also provides a method for preparing the above-mentioned glass fiber coral sea sand concrete, which specifically includes the following steps:

[0028] (1) Preparation of gelling materials

[0029] Mix slag micropowder, silica micropowder, expansion agent, chopped glass fiber and sodium dioctyl sulfos...

Embodiment 2

[0038] A kind of glass fiber coral sea-sand concrete provided by this embodiment is made up of sea-sand concrete and glass fiber, and the volume percentage content of two components is 98% sea-sand concrete and 2% glass fiber; Wherein, sea-sand concrete It consists of the following raw materials in parts by weight: 470 parts of cementitious material, 750 parts of coral, 820 parts of sea sand, 4 parts of water reducer, 6 parts of antifreeze and 170 parts of seawater; the length of glass fiber is 13mm, and it is made of waste glass fiber After processing, it is made into a monofilament bundle, and its tensile strength is greater than 1700MPa; the water reducing agent is a polycarboxylate high-performance water reducing agent.

[0039] This embodiment also provides a method for preparing the above-mentioned glass fiber coral sea sand concrete, which specifically includes the following steps:

[0040] (1) Preparation of gelling materials

[0041] Mix slag micropowder, silica micr...

Embodiment 3

[0050] A kind of glass fiber coral sea-sand concrete provided by this embodiment is made up of sea-sand concrete and glass fiber, and the volume percentage content of two components is 98% sea-sand concrete and 2% glass fiber; Wherein, sea-sand concrete It consists of the following raw materials in parts by weight: 500 parts of cementitious material, 800 parts of coral, 850 parts of sea sand, 5 parts of water reducer, 8 parts of antifreeze and 190 parts of seawater; the length of glass fiber is 14mm, and the waste glass fiber is recycled After processing, it is made into a monofilament bundle, and its tensile strength is greater than 1700MPa; the water reducing agent is a polycarboxylate high-performance water reducing agent.

[0051] This embodiment also provides a method for preparing the above-mentioned glass fiber coral sea sand concrete, which specifically includes the following steps:

[0052] (1) Preparation of gelling materials

[0053] Mix slag micropowder, silica mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com