Novel additive for cement mortar and application method of novel additive

A cement mortar and additive technology, which is applied in the field of new cement mortar additives, can solve the problems of fast hardening cement strength decline quickly, and the hydration speed cannot be increased, so as to achieve the goal that the final strength will not decrease, the workload can be reduced, and the setting time can be adjusted Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: the preparation of Portland cement concrete when the water-cement ratio is 1:1

[0015] The first step: add acrylamide (AM) and N,N'-methylenebisacrylamide (MBAM) to water at a weight ratio of 5:1 to prepare a 50% premix;

[0016] Step 2: Commercially available No. 425 Portland cement powder, configure cement mortar according to the water-cement ratio of 1:1, then weigh 5% of the mortar weight and mix it with the cement mortar and mix it evenly;

[0017] The third step: according to the weight ratio, add 0.08wt% concentration of 10wt% ammonium persulfate (APS) solution and 0.02wt% concentration of 10wt% N,N,N',N'- Tetramethylethylenediammonium (TEMED) solution, stir quickly and evenly.

[0018] Step 4: The mortar obtained in Step 3 is poured into the model within 1 hour to complete the molding operation.

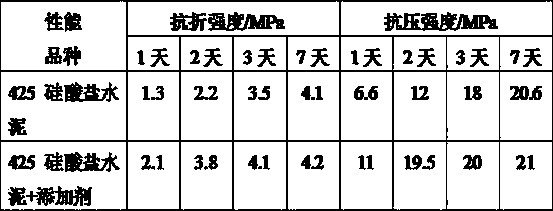

[0019] The cement slurry in the model will be initially set within 30 minutes. When no additives are added, the above cement is mixed according to th...

Embodiment 2

[0021] Embodiment 2: the preparation of Portland cement concrete when the water-cement ratio is 1: 1.2

[0022] Step 1: Add acrylamide (AM) and N,N'-methylenebisacrylamide (MBAM) to water at a weight ratio of 12:1 to prepare a 50% premix;

[0023] The second step: commercially available No. 425 Portland cement powder, according to the water-cement ratio of 1 ︰ 1.2 Configure cement mortar, then weigh 8% of the weight of the mortar and mix it with the cement mortar and stir evenly;

[0024] The third step: according to the weight ratio, add 0.15wt% concentration of 10wt% ammonium persulfate (APS) solution and 0.02wt% concentration of 10wt% N,N,N',N'- Tetramethylethylenediammonium (TEMED) solution, stir quickly and evenly.

[0025] Step 4: The mortar obtained in Step 3 is poured into the model within 1 hour to complete the molding operation.

[0026] The cement slurry in the model will be initially set within 40 minutes. When no additives are added, the above cement will hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com