Patents

Literature

76results about How to "Guaranteed early strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Concrete super instant coagulant

The invention discloses a concrete early-strength agent, which is characterized in comprising the following components according to weight percentage: inorganic salt early-strength component 35-55 percent, organic early-strength component 5-10 percent, water reducing component 15-25 percent, wherein the inorganic salt early-strength component is prepared by at least two among sulfate, carbonate, nitrate, and nitrite; the organic early-strength component selects any one among calcium formate, sodium acetate, calcium oxalate, triethanolamine, tri-iso-propanolamine and carbamide; the water reducing component selects one among naphthalenesulfuric acid type, melamine type and polycarboxylate type. The invention makes the concrete be coagulated and hardened rapidly under the condition of low temperature, so that the early strength of the concrete is greatly improved as well as later strength is ensured.

Owner:ZHONGYIFENG CONSTR GRP +1

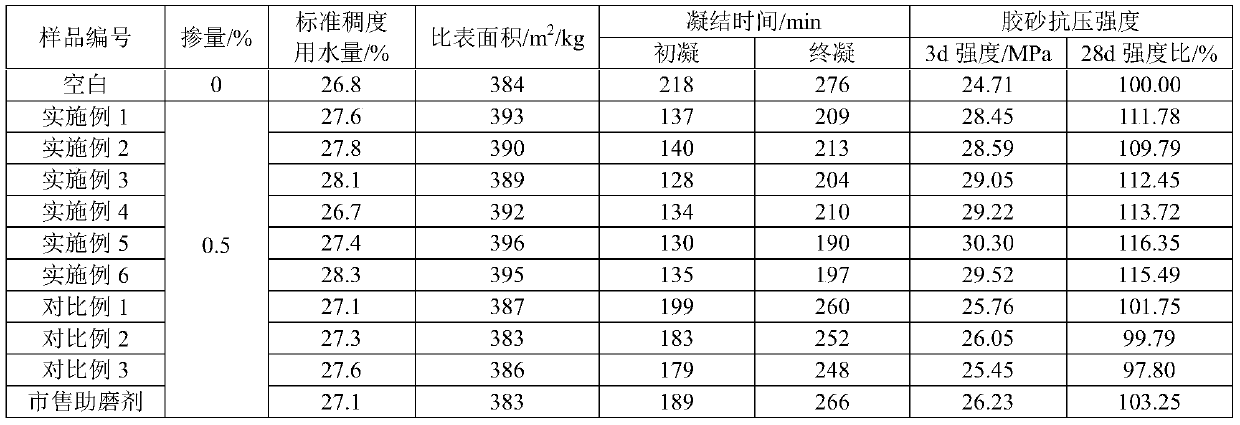

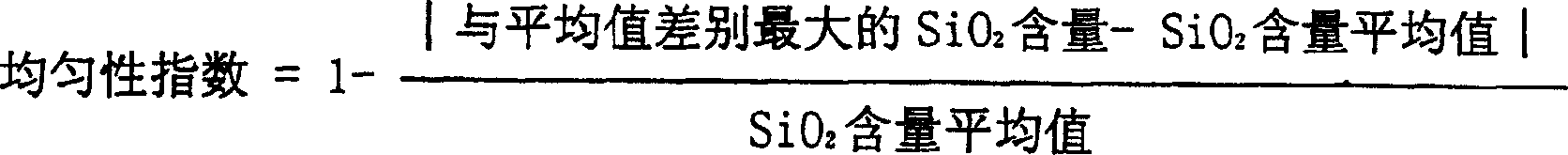

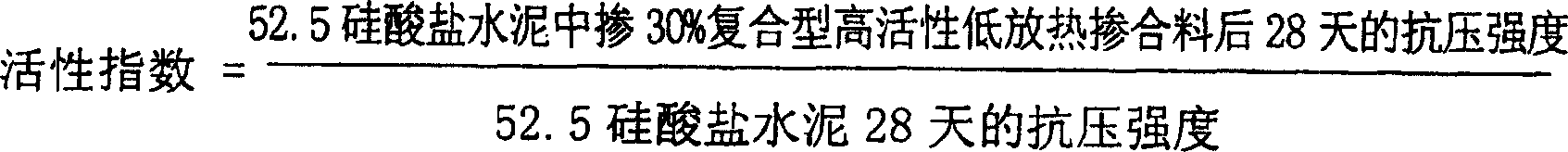

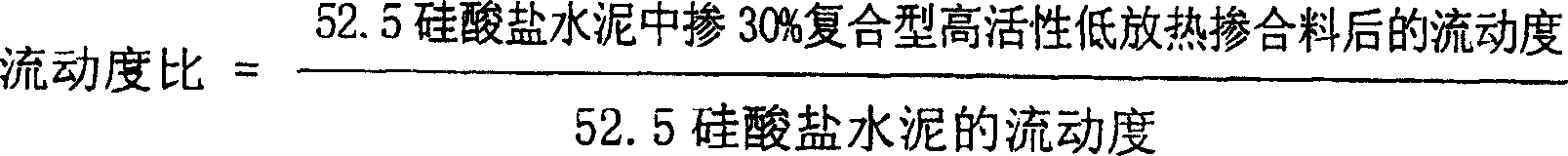

Composite low-heat-release high-active superfine powder concrete admixture and making method thereof

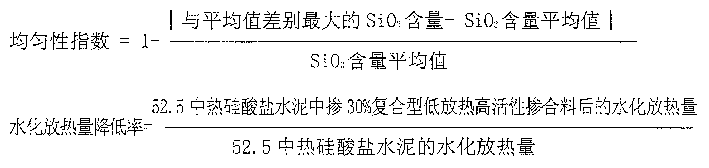

InactiveCN1401607ALow exotherm High hydration reactivityIncreased hydration reactivitySolid waste managementSlagHomogeneity index

A high-activity superfine additive for concrete is prepared from at least two of steel slag, flyash, granular slag of blast furnace and phosphur slag, and gypsum through grinding, proportional mixing and further pulverizing. Its advantages are high specific surface area (more than 400 sq.m / kg), high activity, and low heat release.

Owner:CHINA BUILDING MATERIALS ACAD +2

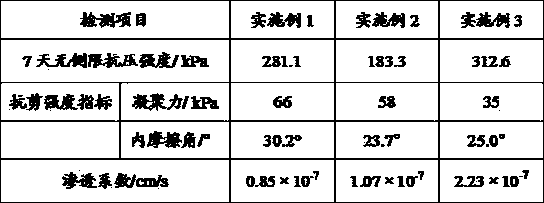

Method for using phosphogypsum in mine goaf consolidated filling

The invention discloses a method for cemented filling of phosphogypsum in a mine goaf. The method mainly comprises the following steps: mixing the following materials in weight ratio: 0.8 to 1.2 percent of cement, 1.2 to 0.8 percent of water quenched iron (steel) slag, 10 to 14 percent of the phosphogypsum, and 0.4 to 0.8 percent of lime; adding water to the mixture and stirring the mixture to form filling slurry with the weight concentration of between 55 and 65 percent; conveying the filling slurry to the mine goaf; and curing the filling slurry to form a high-strength filling material. The method can significantly reduce the curing time of the filling slurry taking the phosphogypsum as the main raw material, is suitable for various mining techniques and the cement filling for various types of mine goafs, and has strong economic and social benefits.

Owner:TONGLING CHEM IND GRP

Method for preparing non-sintered ceramsite by adding dredged sludge

The invention relates to a method for preparing non-sintered ceramsite by adding dredged sludge. The method comprises the following steps: (1) pre-treatment of the dredged sludge; (2) material preparation: mixing and stirring smashed dredged sludge, cement, quick lime, gypsum and coal ash to prepare a dry mixture; the mass portions of the smashed dredged sludge, cement, quick lime, gypsum and coal ash are as follows: 60 to 80 parts of the dredged sludge, 1 to 6 parts of the cement, 1 to 6 parts of the quick lime, 1 to 6 parts of the gypsum and 3 to 15 parts of the coal ash; then uniformly mixing water glass with water to obtain a mixed solution of the water glass and the water, wherein the mass ratio of the adding amount of the water glass to the dredged sludge is 3 to 15: 60 to 80, and the adding amount of the water accounts for 40 to 60 percent of the total mass of the dry mixture and the water glass; (3) disc granulation; (4) primary curing of a product; (5) waterproofing work; (6) ultimate curing of the product, namely obtaining a finish product of the non-sintered ceramsite. According to the method provided by the invention, a large amount of dredged sludge can be added, the purpose of utilizing waste materials is realized, the requirements of a dredging Industry are met, the production energy consumption is low, and the produced non-sintered ceramsite can meet the demands of construction market.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Casing method of dredging sediment non-sintered ceramsites

The invention relates to a casing method of dredging sediment non-sintered ceramsites, comprising following steps: (1) crushing cement, quicklime, glass fibre powder, and fly ash by using a crusher; (2) mixing the pretreated cement, quicklime, glass fibre powder, and fly ash to make dry mixed casing material, weighing dredging sediment non-sintered ceramsites, wherein the mass ratio is : 10-20 parts of cement, 1-10 parts of quicklime, 1-10 parts of glass fiber powder, 1-10 parts of fly ash, and 50-70 parts of dredging sediment non-sintered ceramsites; (3) adopting a disc shot blasting machine for polishing casing; (4) maintaining for prepared non-sintered casing ceramsites. The casing method can consume a large amount of dredging sediment and meets the requirement for resource utilization of dredging industry, and largely promotes intensity of the dredging sediment non-sintered ceramsites, furthermore the production energy consumption is low, the non-sintered casing ceramsites have a wide application range and meet the requirements of construction markets.

Owner:TIANJIN UNIV OF SCI & TECH

Cement-based rapid repair material with high early strength, and preparation method thereof

The invention discloses a cement-based rapid repair material with high early strength, wherein the cement-based rapid repair material is prepared from the following raw materials by mass: 500-650 parts sulphoaluminate cement, 200-400 parts of ordinary Portland cement, 800-900 parts of quartz sand, 4.5-9.0 parts of nanometer silicon dioxide, 0.25-0.6 part of a dispersing agent, 1.1-10.8 part of a water reducing agent, 0.045-0.160 part of a retarder, 0.10-0.25 part of a defoaming agent and 315-360 parts of water. The invention further provides a preparation method of the cement-based rapid repair material with improved early strength. According to the invention, the field preparation is convenient and easy, sulphoaluminate cement and Portland cement are compounded so as to ensure the early strength and the later strength, the microstructure of the composite repair system is obviously improved through the nanometer material, the early mechanical property of the cement-based material is remarkably improved, the driving quality and the driving safety of the repaired pavement are ensured, the repair cost is low, and the practicability is high.

Owner:GANSU ELECTRIC POWER DESIGN INST

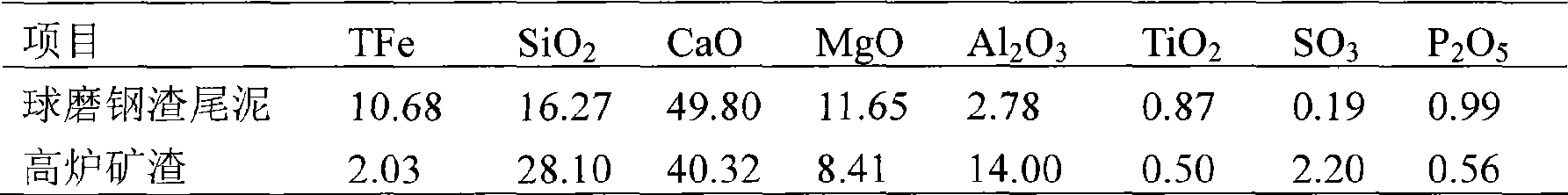

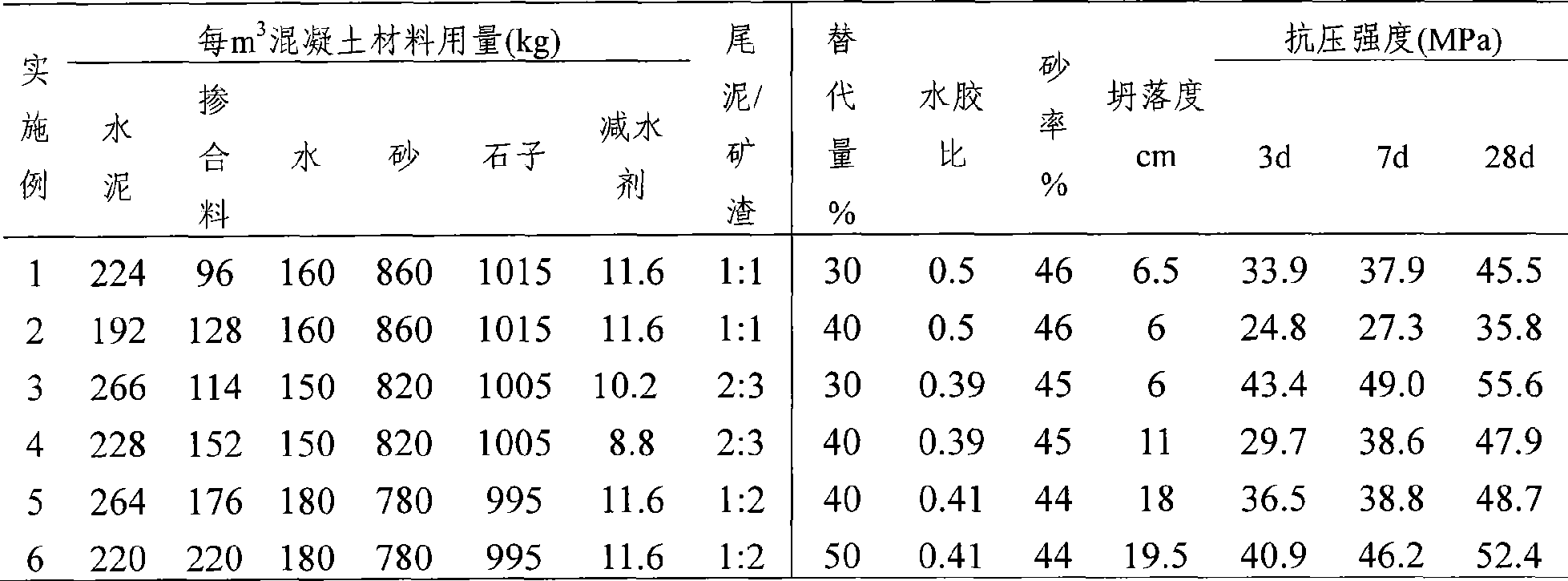

Compound active powder of ball milling steel slag tailing slurry and blast-furnace slag and application of compound active powder in preparing concrete

InactiveCN101544479AReduced volume stabilityReduced Volume Stability EffectsCement productionSlagSlurry

The invention relates to compound active powder of ball milling steel slag tailing slurry and blast-furnace slag and the application of the compound active powder in preparing concrete. The admixture is prepared by mixing ball milling steel slag tailing slurry powder and blast-furnace slag powder with equal Brinell specific surface area of 500-600 m <2> / kg according to the weight ratio of 1:1-2. When the compound active powder is used as concrete admixture, proper concrete mixing portion is adopted; and the admixture can be used for partially replacing equivalent cement gel according to the proportion of 30-50 percent so as to prepare the concrete with C30-C50 strength degree. The invention utilizes solid wastes of steel enterprises, changes the solid wastes into valuable and has simple production process, ensures that the concrete has good performance and markedly lowered manufacturing cost.

Owner:LAIWU IRON & STEEL GRP

Method of preparing baking-free brick with dredge sediment aggregate

The invention relates to a method of preparing baking-free brick with a dredge sediment aggregate, which includes the steps of (1) sieving the dredge sediment aggregate; (2) smashing cement, quick lime, gypsum and fly ash in a pulverizer; (3) material blending: mixing and stirring the cement, the quick lime, the gypsum and the fly ash to obtain a dry-mixed material, weighing the dredge sediment aggregate, wherein the dry-mixed material comprises, by mass, 5-20 parts of the cement, 3-13 parts of the quick lime, 1-10 parts of the gypsum and 15-30 parts of the fly ash, and the dredge sediment aggregate accounts for 45-70 parts by weight; (4) adding water and stirring the mixture; (5) aging the mixture material; (6) press-moulding the mixture in a brick pressing machine; (7) performing product maintenance to obtain the baking-free brick. The method can consume the dredge sediment in a large quantity, thereby achieving resource recycling. The method can satisfy requirement in dredge industry and is low in production cost due to the baking-free process. The prepared baking-free brick is low in cost, is excellent in performances, can develop a utilization approach of recycling the dredge sediment resource, and satisfies the requirement of building material market.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

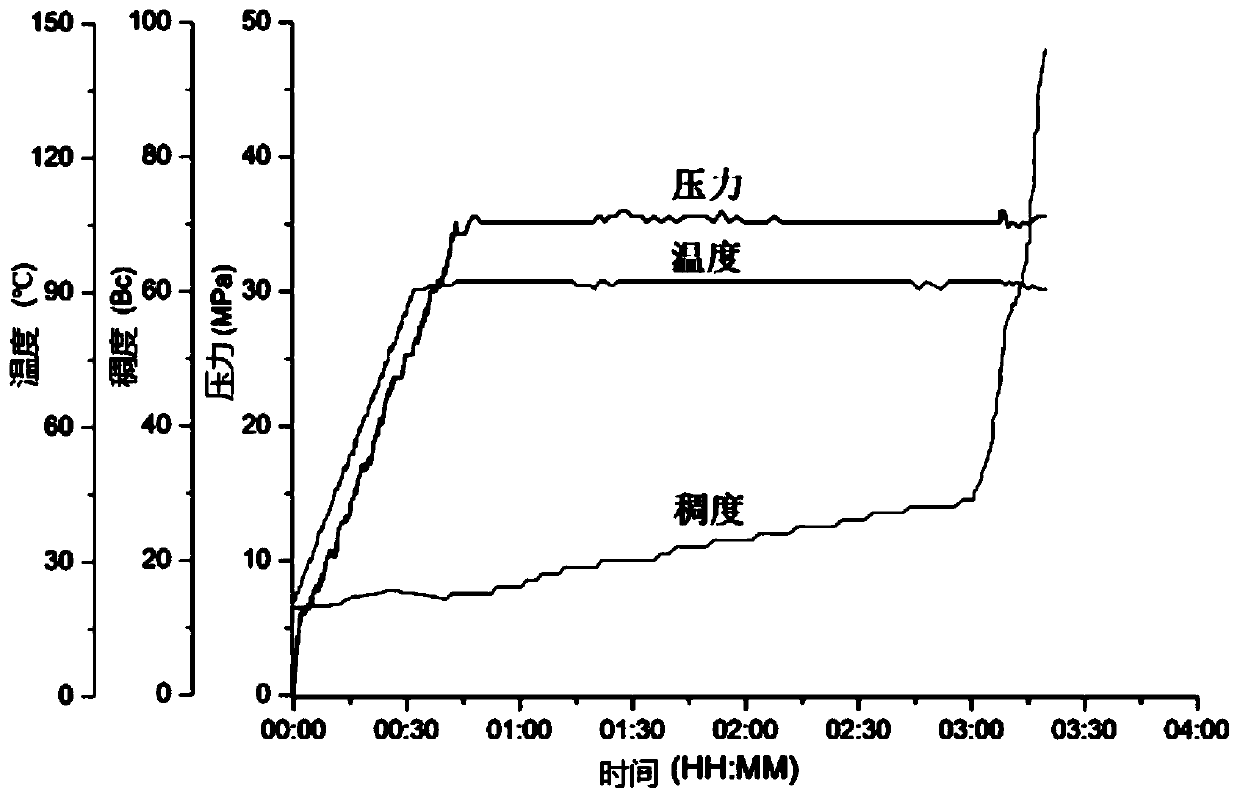

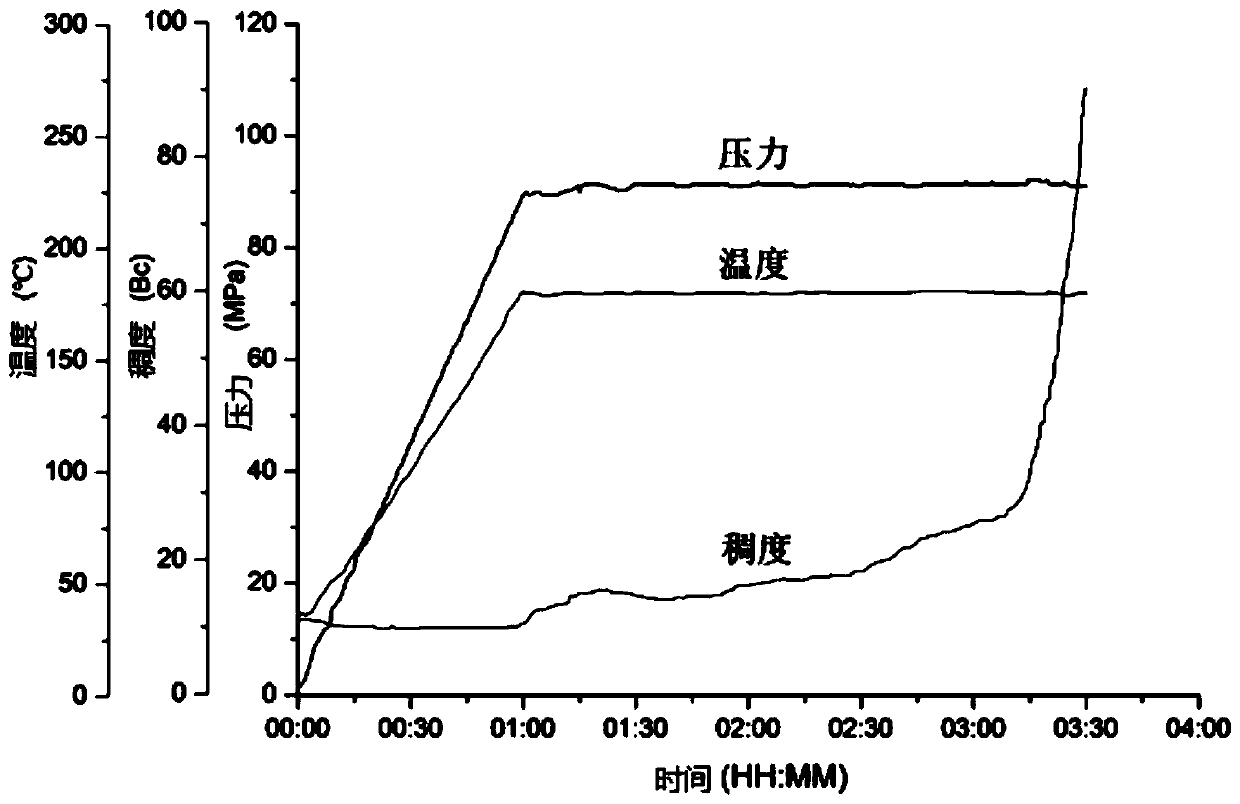

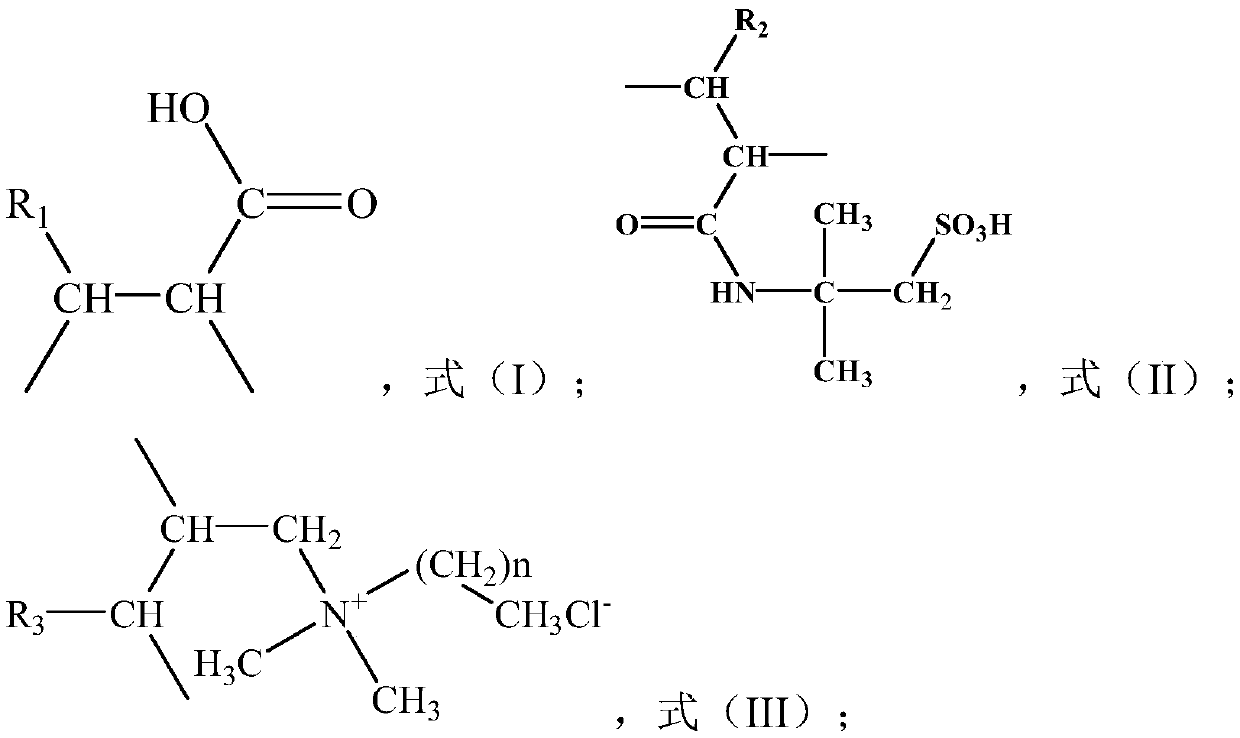

Temperature-responsive high temperature retarder suitable for oil-gas well cementation, preparation method thereof and well cementing slurry

ActiveCN109824822AExtend thickening timeDoes not affect settlement stabilityDrilling compositionPolymer scienceWell cementing

The invention belongs to the technical field of oil-gas well development and discloses a temperature-responsive high temperature retarder suitable for oil-gas well cementation, a preparation method thereof and a well cementing slurry. The temperature-responsive high temperature retarder comprises a structural unit A shown as the formula (I), a structural unit B shown as the formula (II) and a structural unit C shown as the formula (III), wherein structural percentages of the structural units A, B and C include x=37.2-57.23%, y=40.52-61.4% and z=1.38-4.35%; the addition of the temperature-responsive high temperature retarder can be adjusted according to cementation design so that thickening time of oil well cement meets the requirements of well cementing construction, and the temperature-responsive high temperature retarder helps effectively improve thickening performance of cement slurry and improve early strength of top set cement during well cementation.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Construction organization method of complete set of tunnel mechanical equipment

ActiveCN108915696AImprove management abilityImprove the construction work environmentUnderground chambersTunnel liningArchitectural engineeringMechanical equipment

The invention discloses a complete set of tunnel mechanical equipment, which specifically refers to an excavation trolley (or an excavation gantry), a drainage and steel bar binding trolley, a liningtrolley, a spray maintenance trolley, a ditch cable trough trolley, an inverted arch self-propelled hydraulic trestle and a wet spray manipulator, referred to as five trolleys, one trestle and one wetspray machine. A construction organization method matched with the complete set of mechanical equipment comprises the following construction organization steps: S1, hole excavation; S2, initial support; S3, inverted arch lining; S4, arched wall lining; S5, ditch cable troughs and the complete set of mechanical equipment. The construction organization method is reasonable, effectively improves tunnel management effect, improves construction operation environment, ensures construction safety and quality, improves construction progress and is worthy of promotion.

Owner:CHINA RAILWAY SEVENTH GRP CO LTD +1

High-performance foam concrete

The invention discloses a high-performance foam concrete which comprises the following raw materials: cement, river sand, lime, a composite foaming agent, fly ash, metakaolin, expanded perlite, lignin fiber, polypropylene glycol, hydroxymethyl propyl cellulose, styrene-acrylic emulsion, 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate, a water-reducing agent, an early strength agent and water; the composite foaming agent comprises the following raw materials: tea saponin, lauryl sodium sulfate, sodium fatty alcohol polyoxyethylene ether sulfonate, 1,4-butanediol, triethanolamine, soybean oil, sodium hydroxide, zeolite powder, polyacrylate resin and water. The high-performance foam concrete disclosed by the invention is good in pumpability in the construction process, high in compressive strength and good in durability.

Owner:无为县严桥双龙建材厂

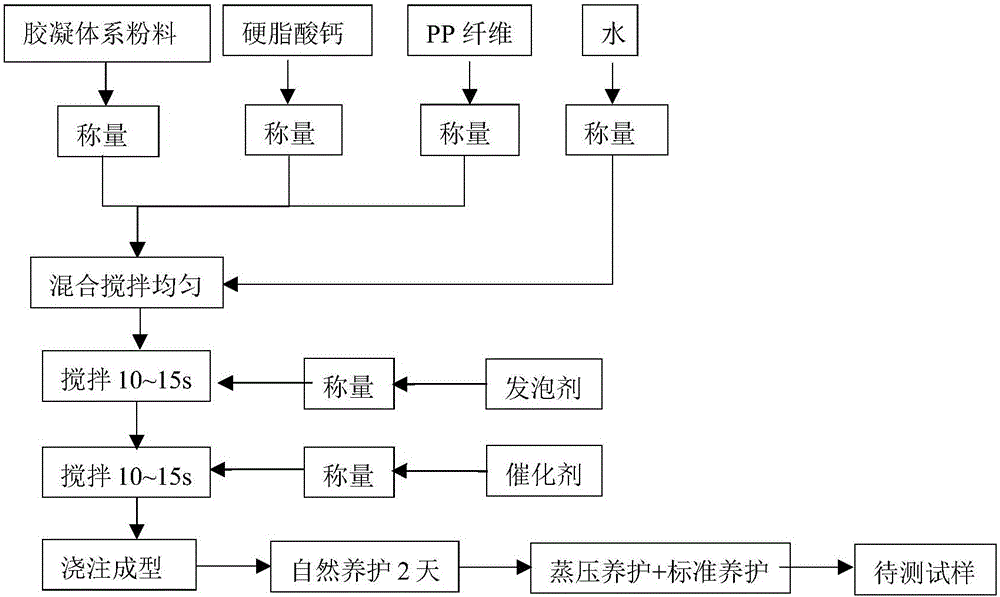

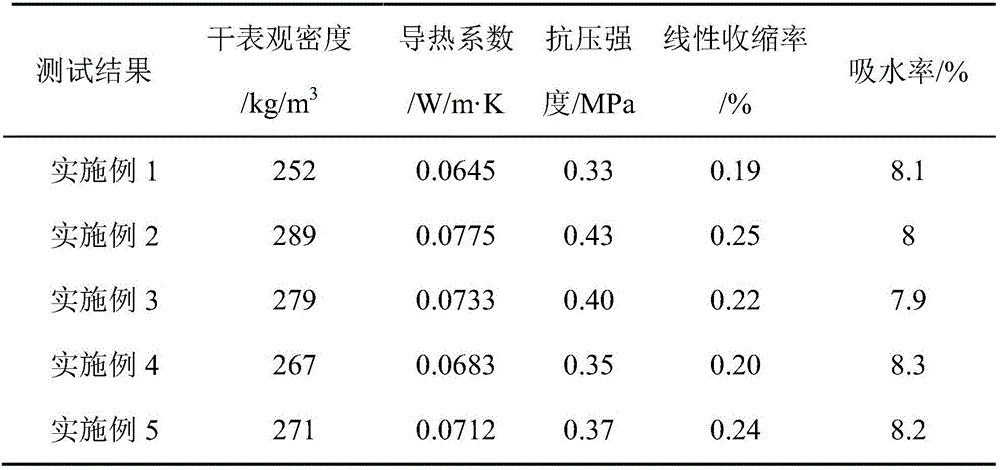

Foam concrete prepared from undisturbed desulfurization gypsum and preparation method thereof

ActiveCN105859233AGuaranteed early strengthImprove the coagulation effectCeramic shaping apparatusCeramicwareFoam concreteSlag

The invention provides foam concrete prepared from undisturbed desulfurization gypsum and a preparation method thereof. The foam concrete is prepared from the following raw materials in parts by weight: 30-50 parts of wet desulfurization gypsum, 13-32 parts of dry desulfurization gypsum, 19-28 parts of superfine slag powder, 6-11 parts of cement, 6-9 parts of ash calcium powder, 0.63-0.70 part of a water reducer, 1.0-1.9 parts of an alkaline activator, 2.3-2.7 parts of a foaming agent, 2.8-3.4 parts of a foam stabilizer, 0.03-0.05 part of a catalyst, 0.13-0.17 part of polypropylene fiber, and 35-42 parts of water. The foam concrete prepared by the method provided by the invention is environment-friendly, energy saving, high in strength, low in thermal conductivity, low in linear shrinkage, etc. The undisturbed desulfurization gypsum is successfully used for preparing the foam concrete, natural resources are effectively saved, a new way for the comprehensive utilization of solid waste is opened up, and the scope of application of industrial waste gypsum is greatly expanded.

Owner:SOUTHEAST UNIV

Method for producing baking-free brick by doping phosphogypsum and fly ash

The invention discloses a method for producing a baking-free brick by doping massive industrial residues phosphogypsum and fly ash, which has the advantages of low production energy consumption and high product strength. The method comprises the following steps: a. pretreating phosphogypsum; b. mixing the pretreated phosphogypsum, fly ash, cement and quicklime to prepare a dry mixture, wherein the dry mixture comprises 35-65 wt% of phosphogypsum, 15-40 wt% of fly ash, 7-18 wt% of quicklime and 8-12 wt% of cement; adding water, and sufficiently mixing to prepare a wet mixture, wherein the water accounts for 27-33 wt% of the dry mixture; c. pouring, and carrying out vibratory compaction; d. curing in a curing chamber; e. curing in a steam curing chamber; and f. naturally curing to prepare the baking-free brick. The method disclosed by the invention can dope massive industrial residues phosphogypsum and fly ash, and has the advantages of low production energy consumption and high product strength.

Owner:SICHUAN CHINA STRUCTURE RESIDENTIAL IND

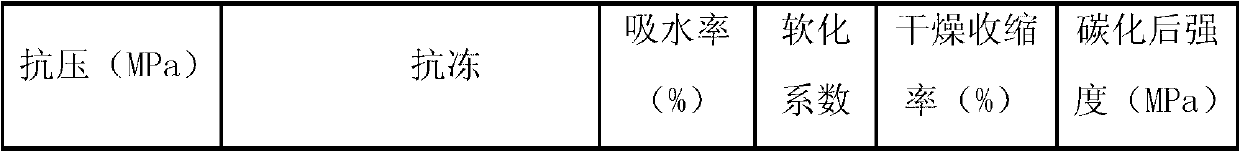

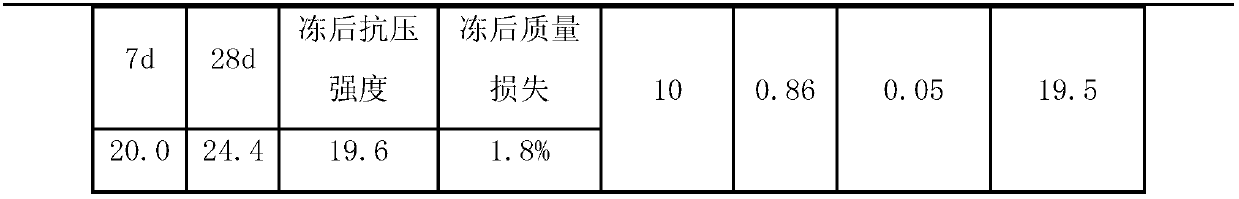

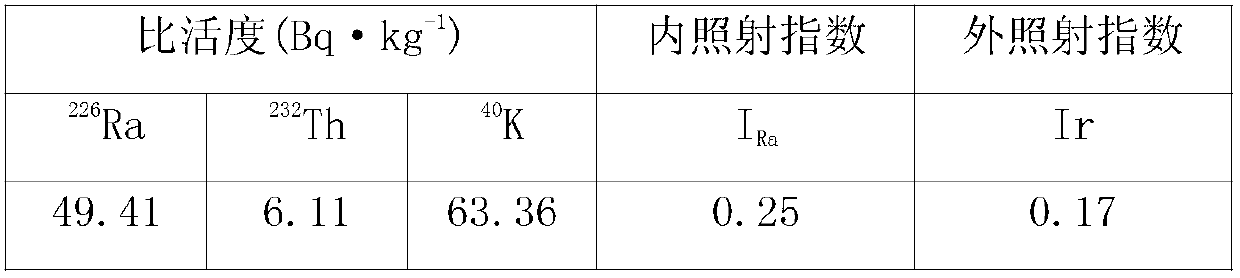

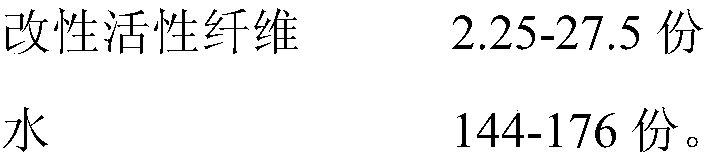

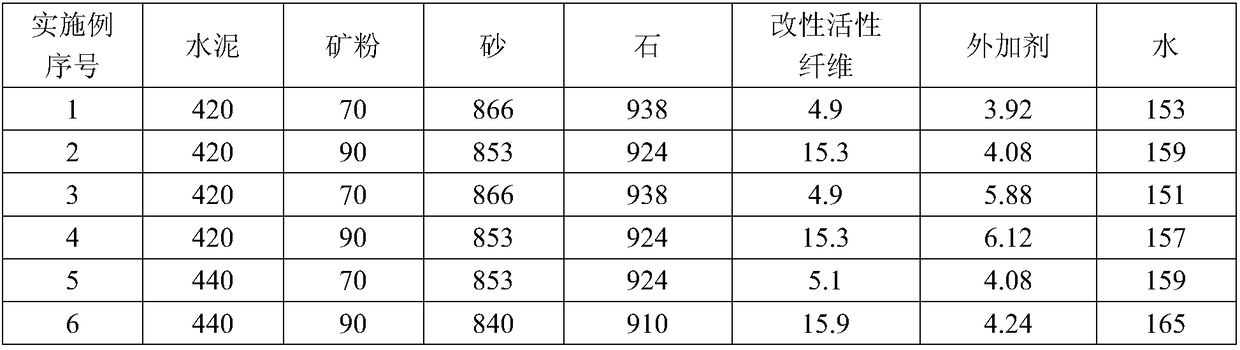

Early-strength setting-retarding high pier stud machine-made sand concrete and preparation method thereof

ActiveCN108069663AImprove early strengthGuaranteed early strengthSolid waste managementControl setFiber

The invention discloses early-strength setting-retarding high pier stud machine-made sand concrete and a preparation method thereof. The concrete is composed of, by mass, 450-550 parts of cement, 50-100 parts of mineral admixture, 827-891 parts of machine-made sand, 896-965 parts of gravel, 2.25-8.25 parts of admixture, 2.25-27.5 parts of modified active fiber and 144-176 parts of water. An early-strength setting-retarding function of the composite admixture and early-strength anticracking performance of the modified active fiber are utilized fully, so that the concrete has the advantages of long setting time, high early strength, good anticracking performance and excellent durability, the problem that artificial sand is increasingly in shortage is solved by utilizing the machine-made sand, and the problem of contradiction between ensuring early strength and controlling setting time in the prior art is solved.

Owner:中建西部建设贵州有限公司

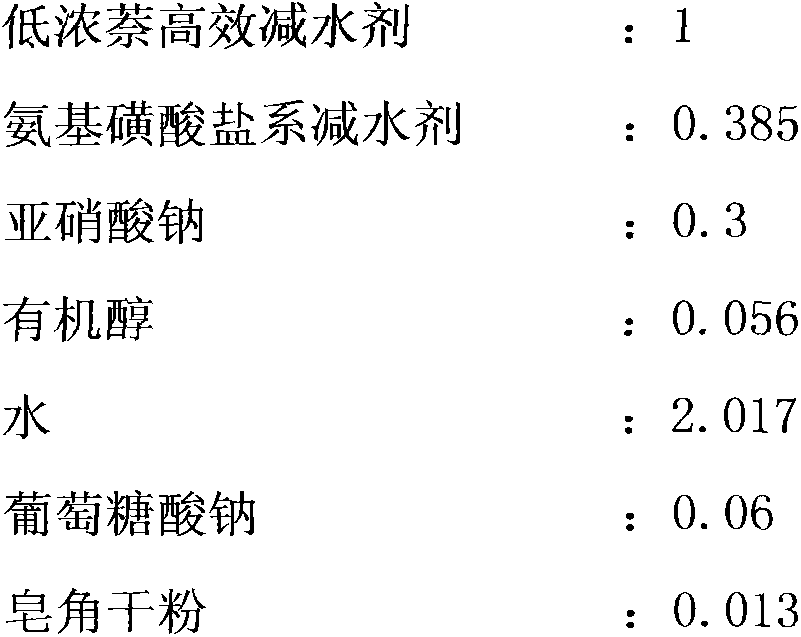

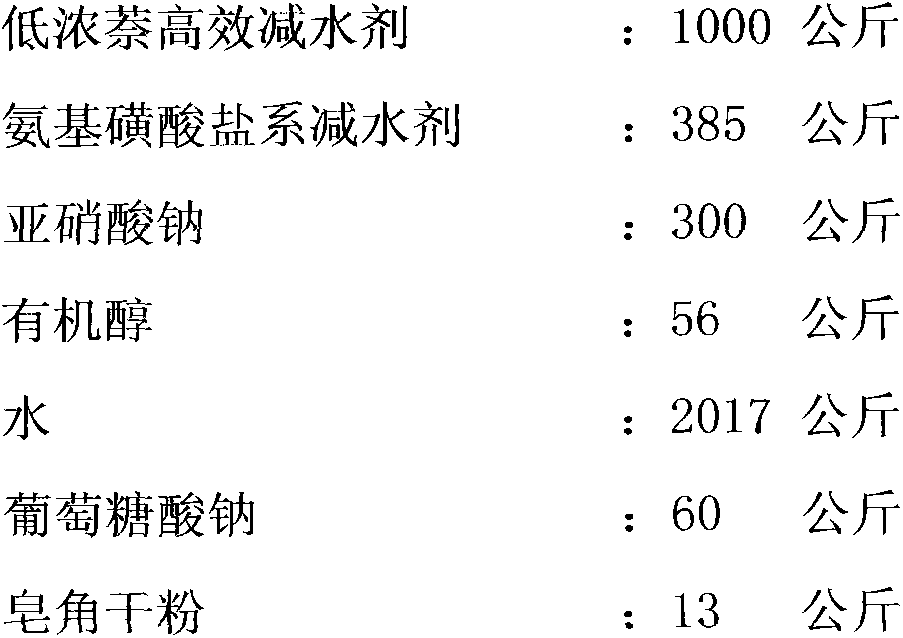

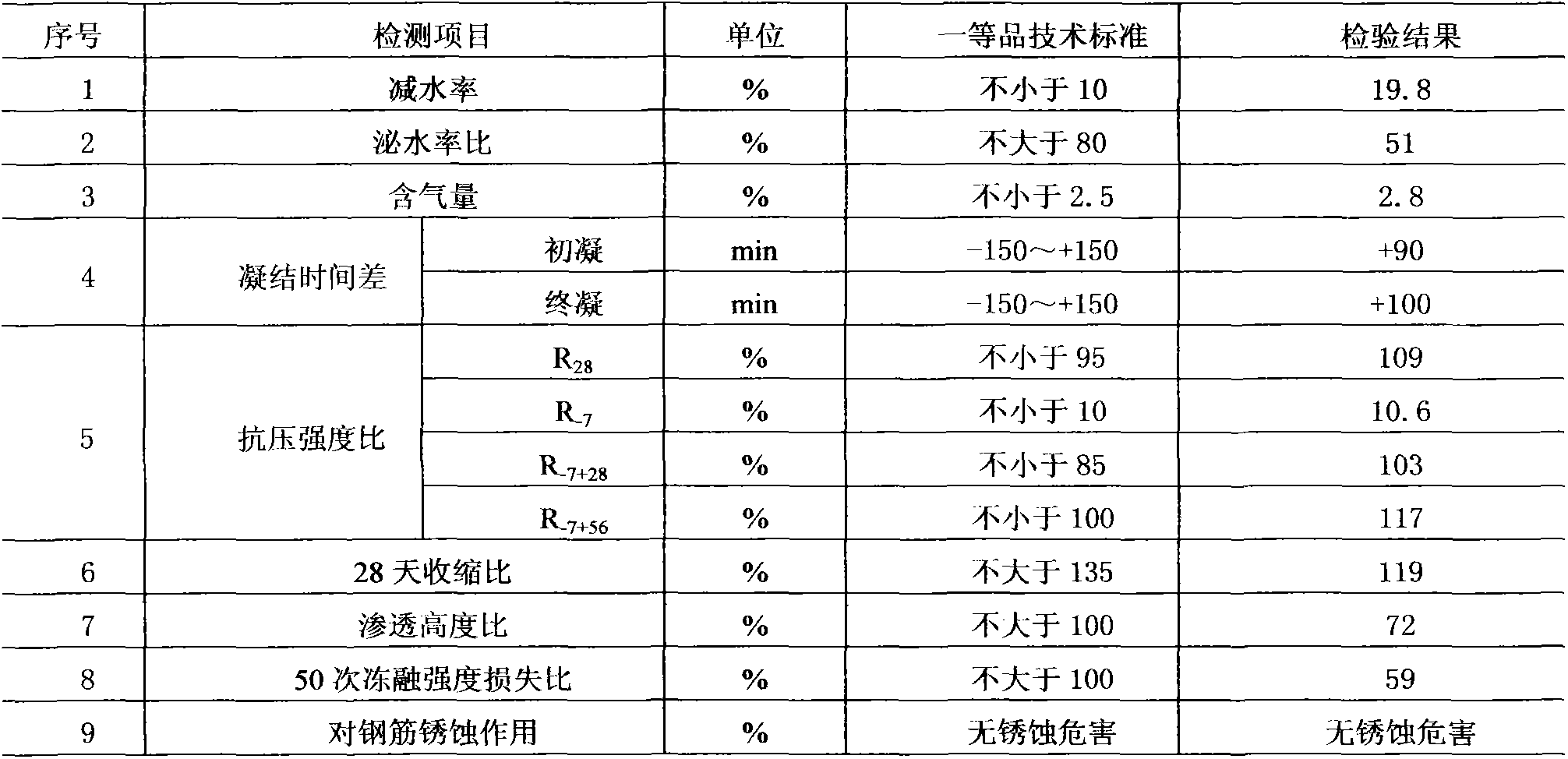

Concrete composite liquid anti-freezing pumping agent

The invention provides a concrete composite liquid anti-freezing pumping agent and belongs to the technical field of the concrete pumping agent. The pumping agent is composed of the following components: a low-concentration naphthalene efficient water reducer, a sulfamate water reducer, sodium nitrite, an organic alcohol, water, sodium gluconate and dry Chinese honeylocust fruit powder, in a weight ratio of 1: 0.385: 0.3: 0.056: 2.017: 0.06: 0.013. The concrete composite liquid anti-freezing pumping agent provided by the invention has the advantages that all the components have synergistic effect to inhibit crystallization of an early strength component at a minus temperature, well control the slump of the concrete and keep development of the early strength of the concrete, and simultaneously, bubbles are introduced into the concrete and neat paste to improve the workability (peaceability) of the concrete and the cement neat paste, and therefore, the adaptability of the liquid anti-freezing pumping agent can be improved and the anti-freezing durability of the concrete can be greatly improved; besides, the anti-freezing pumping agent is free of chlorine, low in alkali, and in the form of a liquid, and thereby more convenient for storage, transportation and use.

Owner:韩越

Natural anhydrite self-leveling anti-crack mortar

The invention discloses a natural anhydrite self-leveling anti-cracking mortar, which is prepared by mixing the following components: natural anhydrite, composite activator, fly ash, quartz sand, water reducer, fiber, defoamer, Dispersed latex powder, water retaining agent, shrinkage reducing agent. The natural gypsum self-leveling anti-cracking mortar of the present invention uses natural gypsum as a main material, and an additional composite activator effectively stimulates the hydration rate of the anhydrite. It ensures the setting and hardening of the mortar and its early strength. Adding water-retaining agent, defoamer, dispersible latex powder, etc. greatly improves the construction and compactness of the mortar. Fiber and shrinkage reducing agent are also added in the formula to reduce the internal stress generated by the hardening of the mortar and prevent the mortar from cracking and deforming.

Owner:张学健

Liquid grinding aid capable of promoting coagulating, and preparation method thereof

The invention discloses a liquid grinding aid capable of promoting coagulating, and a preparation method thereof, and belongs to the technical field of cement additive. The liquid grinding aid capableof promoting coagulating is prepared from, by mass, aluminum sulfate of 5% to 15%, magnesium sulfate of 5% to 10%, modified alcohol amine small organic molecules of 40% to 50%, sodium lignosulfonateof 3% to 10%, calcium formate of 1.5% to 3%, and balance deionized water. According to the preparation method, aluminum sulfate and magnesium sulfate are mixed as a coagulating promoting main component, so that cement hydration process is accelerated; chemical imbalance caused by high content aluminium ions is capable of realizing dissolving of gypsum and C3A easily, promoting early stage generation of a large amount of ettringite, and realizing rapid coagulation; the modified alcohol amine small organic molecules are taken as a grinding aid enhancing component, and is high in stability; the preparation technology is simple; reaction is relatively mild; the liquid grinding aid is capable of promoting cement early stage rapid coagulation, and at the same time, early stage strength is ensured, later stage strength increasing is not influenced, and the adaptability on cement is excellent.

Owner:安徽海螺材料科技股份有限公司 +1

Early strength filling cementing material for copper-nickel ore full tailings and rod-mill tailings mixed filler

The invention, for a copper-nickel ore full tailings and rod-mill tailings mixed filler, discloses an early strength filling cementing material. The early strength filling cementing material consists of the following components in percentage by mass: 5-6% of high-calcium lime, 17-19% of desulfurization residue, 1-3% of mirabilite, 72-77% of superfine slag powder, as well as no more than 1.5% of sodium sulfite. Furthermore, the invention discloses filler slurry prepared from the filling cementing material, mixed filler of copper-nickel sulfide ore deposit full tailings and rod-mill tailings as well as running water, wherein mass ratio of the copper-nickel sulfide ore full tailings to the rod-mill tailings is at (2: 8)-(3: 7), mass ratio of the filling cementing material to the mixed filler is at 1: 4, and the running water accounts for 22% in percentage by mass. The filler prepared by the method disclosed by the invention is high in strength, especially in early strength, and is low in cost.

Owner:JINCHUAN GROUP LIMITED +1

Curing agent for hydraulic filling of marine mud and curing method thereof

InactiveCN103964809AImprove cracking performanceResolve shrinkageSludge treatment by de-watering/drying/thickeningSolid waste managementSulfateFly ash

The invention discloses a curing agent for hydraulic filling of marine mud and a curing method thereof. The curing agent comprises the following raw materials in parts by weight: 8 to 23 parts of lime, 37 to 45 parts of fly ash, 0.2 to 0.5 part of triethanolamine, 18 to 23 parts of calcium sulfate, 2 to 5 parts of strong base, and 10-16 parts of water glass. The curing method comprises the following steps: the water content of an undisturbed mud sample is controlled by a cutter-suction pump in the range of 80% to 90%, and according to the mechanical stress borne by a soil mass in practical engineering, the curing agent is admixed; the admixture is then maintained for 6 to 8 days under a natural curing condition after admixing. According to the curing agent disclosed by the invention, lime and fly ash are mainly adopted as the main curing agents, auxiliary curing agents are added to improve the cracking property of the lime-fly ash stabilized soil, clay soil with higher plastic index are the main targets for curing, and the problem of greater shrinkage of the lime-fly ash stabilized soil used on the clay soil with higher plastic index is solved.

Owner:ZHEJIANG INST OF HYDRAULICS & ESTUARY +2

Composite low-heat-release high-active superfine powder concrete admixture and making method thereof

InactiveCN1185178CLow exotherm High hydration reactivityIncreased hydration reactivitySolid waste managementSlagHomogeneity index

A high-activity superfine additive for concrete is prepared from at least two of steel slag, flyash, granular slag of blast furnace and phosphur slag, and gypsum through grinding, proportional mixing and further pulverizing. Its advantages are high specific surface area (more than 400 sq.m / kg), high activity, and low heat release.

Owner:CHINA BUILDING MATERIALS ACAD +2

Water reducing agent composition for steam-curing-free concrete and preparation method thereof

The invention provides a water reducing agent composition for steam-curing-free concrete and a preparation method thereof. The water reducing agent composition comprises an early-strength polycarboxylate water reducing agent, a C-S-H crystal nucleus, a lithium salt, nanoparticles and a general early strength agent. The acid-ether ratio of the water reducing agent is 4:1-5:1, and the water reducing agent is formed by copolymerization of HPEG, acrylic acid, acrylamide, 2-acrylamide-2-methyl propanesulfonic acid, DMC or DAP. The nanoparticles are nano metal oxides, and the early strength agent comprises at least one inorganic early strength agent and an organic early strength agent. The preparation method comprises the following steps: 1, mixing tricalcium silicate with the inorganic early strength agent, the organic early strength agent and water to obtain a gel system containing C-S-H crystal nucleus; 2, adding a water reducing agent to obtain a dispersion liquid containing C-S-H crystal nucleus; 3, adding the nanoparticles and a lithium salt into a water reducing agent, and stirring to obtain a dispersion liquid containing the nanoparticles and the lithium salt; and 4, slowly adding the product obtained in the step 2 into the product obtained in the step 3 to obtain the water reducing agent composition for steam-curing-free concrete. The composition disclosed by the invention is good in early strength effect, good in concrete construction performance, free of steam curing, simple in process and beneficial to shortening the construction period.

Owner:武汉新绿博恩科技有限公司

Quick repairing material and preparation method

InactiveCN107540321AHigh compressive strengthSatisfied with fast hardening and high strengthFiberChemical admixture

The invention discloses a quick repairing material and a preparation method. The quick repairing material is prepared from sulphoaluminate cement, fly ash, intermediate sand, polyvinyl alcohol fiber,water and a chemical admixture, and comprises the following specific components: 100 parts of sulphoaluminate cement, 0-30 parts of fly ash, 80-100 parts of intermediate sand, 0.8-1.2 parts of a naphthalene water reducing agent, 0-0.5 part of borax, 0-0.12 part of sodium gluconate, 0-0.15 part of citric acid, 0-1.5 parts of lithium carbonate, 0-2.0 parts of aluminum sulfate, 0-1.5 parts of aluminum chloride, 0-1.5 parts of calcium nitrate, 0-2.0 parts of sodium chloride and 0-2.0 parts of polyvinyl alcohol fiber. Firstly, the repairing material can be constructed under the temperature condition of 10 DEG C below zero to 40 DEG C, the initial setting time is 15-25 minutes, and the final setting time is 25-35 minutes; secondly, the repairing material achieves excellent compressive strength,the 2h compressive strength is 15-45MPa, and the 7d compressive strength is 45-80MPa; finally, the polyvinyl alcohol fiber is selected for reinforcing the sulphoaluminate cement, so that the quick repairing material has the 1d folding strength of 10-12MPa, the 7d folding strength of 12-14MPa and the 7d bending strength of 5-7MPa, and is free of dry shrinkage, therefore, requirements on quick hardening, high strength and toughness of a repairing project can be met.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

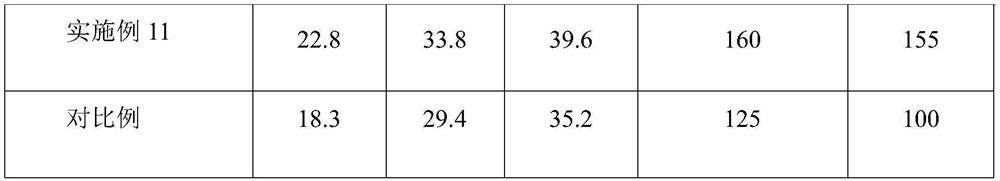

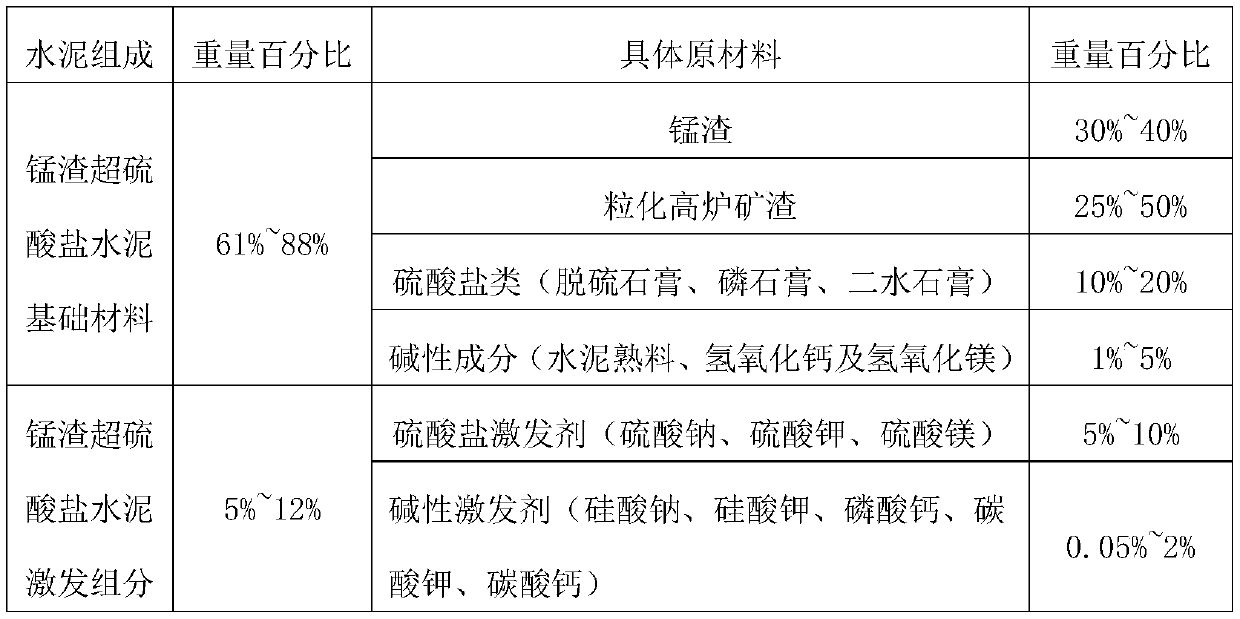

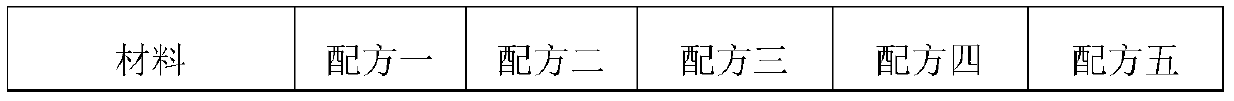

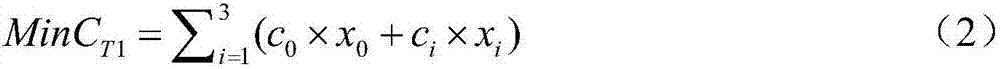

Manganese slag supersulfate cement and preparation method thereof

The invention belongs to the technical field of special cement, and particularly relates to a manganese slag supersulfate cement and a preparation method thereof. The manganese slag supersulfate cement is prepared from the components in percentage by weight: 30-40% of manganese slag, 25%-50% of granulated blast furnace slag powder, 10-20% of sulfates, 5%-10% of a sulfate activator, 1-5% of an alkaline component and 0.05-2% of an alkaline activator. The manganese slag which is a high-temperature slag waste discharged during the blast furnace smelting process of manganese iron or silicomaganeseis used as a main raw material, a material science principle is combined, the mineral characteristics of manganese slag and slag are taken as a basis, the potential hydration activity of the manganeseslag is activated by using sulfates and alkaline environment to form the initial strength, and novel manganese slag supersulfate cement with excellent properties is further designed.

Owner:中建西部建设新疆有限公司 +1

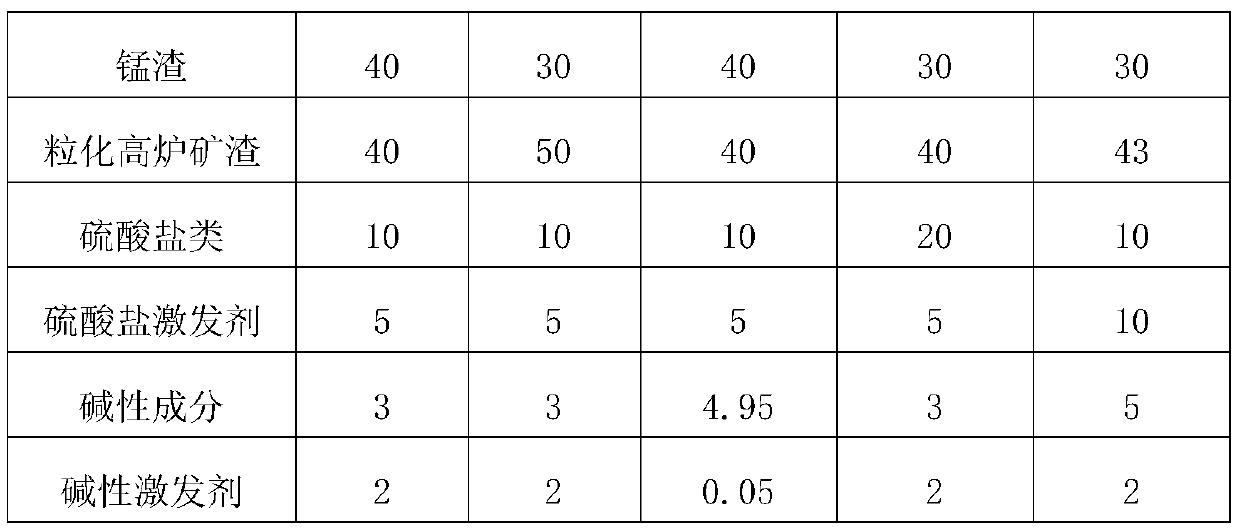

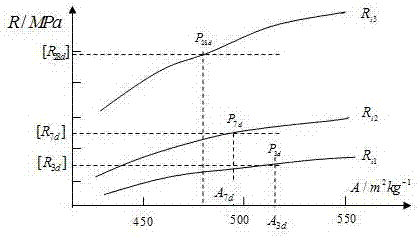

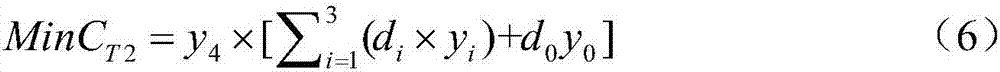

Low-cost early strength cementing material ratio decision-making method

ActiveCN107311582AGuaranteed early strengthImprove resource utilizationEconomic benefitsUltimate tensile strength

The invention discloses a low-cost early strength cementing material ratio decision-making method. The method includes: establishing a composite activator ratio decision-making model, and solving the composite activator ratio decision-making model to obtain a composite activator ratio; then, establishing an early strength grinding aid ratio and adding amount decision-making model to obtain a ratio and adding amount of an early strength grinding aid; according to the composite activator ratio and the ratio and adding amount of the early strength grinding aid, carrying out strength test of cement backfill of early strength cementing materials different in specific surface area and corresponding fineness, establishing a relation curve between cement backfill strength and specific surface areas of the cementing materials, and determining the specific surface areas of the cementing materials and corresponding fineness. The ratio decision-making method has advantages that by adoption of smelting waste for development of the cementing materials, early strength of cement backfill can be guaranteed, recyclability of solid wastes in filling mining is improved, mining cost is reduced, and mining economic benefits are increased.

Owner:JINCHUAN GROUP LIMITED +1

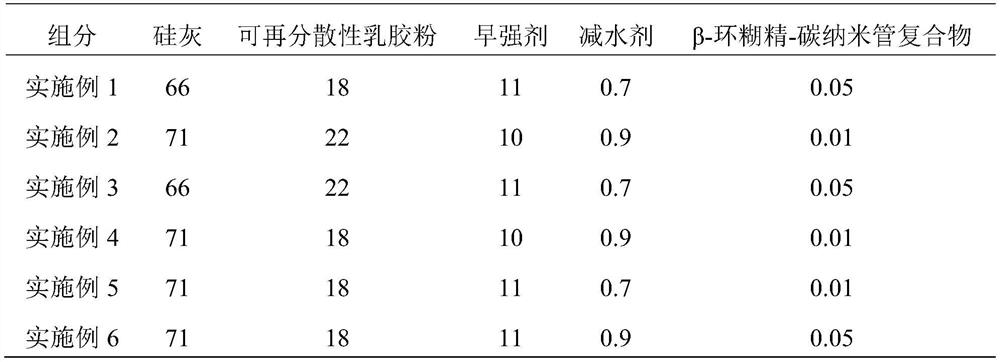

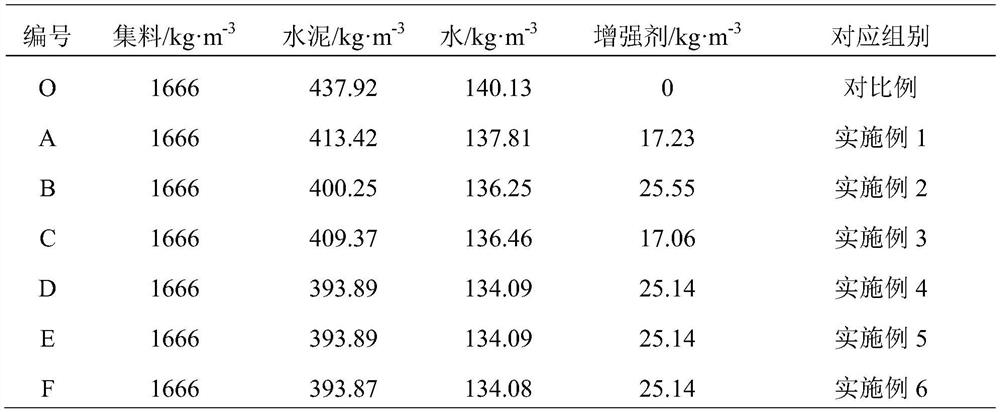

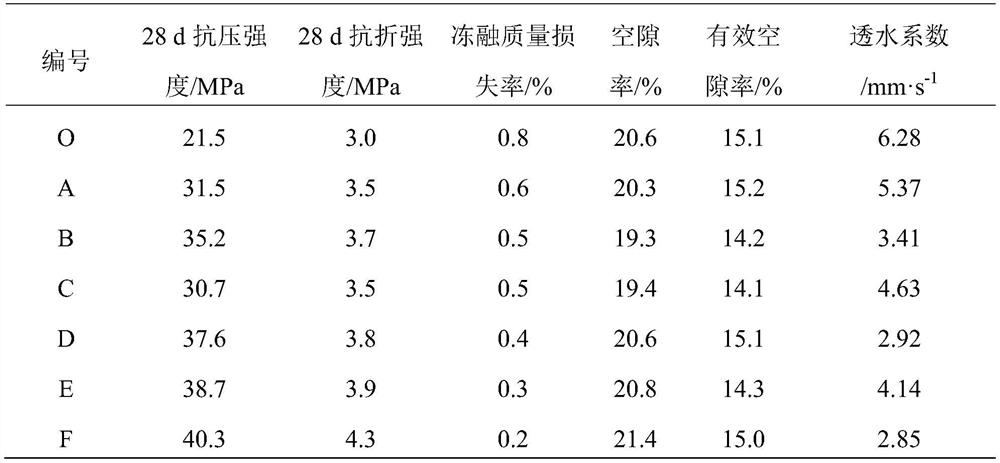

Inorganic-organic composite powder reinforcing agent for pervious concrete and application of inorganic-organic composite powder reinforcing agent

PendingCN112794673AIncrease contentImprove flexibilitySolid waste managementCyclodextrinCement mortar

The invention relates to an inorganic-organic composite powder reinforcing agent for pervious concrete and application of the inorganic-organic composite powder reinforcing agent. The reinforcing agent comprises the following components in parts by weight: 66-71 parts of silica fume, 18-22 parts of redispersible latex powder, 10-11 parts of an early strength agent, 0.7-0.9 part of a water reducing agent and 0.01-0.05 part of a [beta]-cyclodextrin-carbon nanotube compound, and during application, the reinforcing agent is added in the mixing process of pervious concrete, and the mixing amount of the reinforcing agent is 4-6% of the mass of cement. Compared with the prior art, the preparation method has the advantages that inorganic reinforcing and organic toughening composite modification methods are combined, and specific components are mixed according to a certain proportion, so that the cohesion performance and the adhesion performance of cement mortar can be effectively improved, and the compressive strength and the breaking strength of the pervious concrete are improved on the premise of keeping the same porosity; and the freeze-thaw durability is also well improved.

Owner:TONGJI UNIV

Early-strength-type polycarboxylate water reducer and preparation method thereof

InactiveCN110128601AImprove early compressive strengthImprove workabilityEthylenediamineMonoisopropanolamine

The invention provides an early strength type polycarboxylate superplasticizer and a preparation method thereof. The polycarboxylate superplasticizer is mainly prepared from the following raw materials, by weight, 420 to 440 parts of unsaturated polyoxyalkylene ether monomer with weight-average molecular weight of more than 5000, 2.7 to 3 parts of oxidant, 0.3 to 0.7 part of a reducing agent, 3 to5 parts of unsaturated anhydride monomer, 1.5 to 2 parts of a chain transfer agent, 500 to 540 parts of water, 70 to 100 parts of alcohol amine organic material, and unsaturated monocarboxylic acid and derivative monomer thereof. The alcohol amine organic material is at least one of triethanolamine, triisopropanolamine, diethanol monoisopropanolamine and ethylenediamine. Based on the oxidant-reductant initiation system in the formula, strong alkali does not need to be added into the whole system for neutralization instead of the alcohol amine organic material; after specific combination of polymer monomers with large molecular weight, unsaturated acid anhydride monomers and other substances is adopted, the early strength of the concrete is remarkably improved.

Owner:上饶市天佳新型材料有限公司

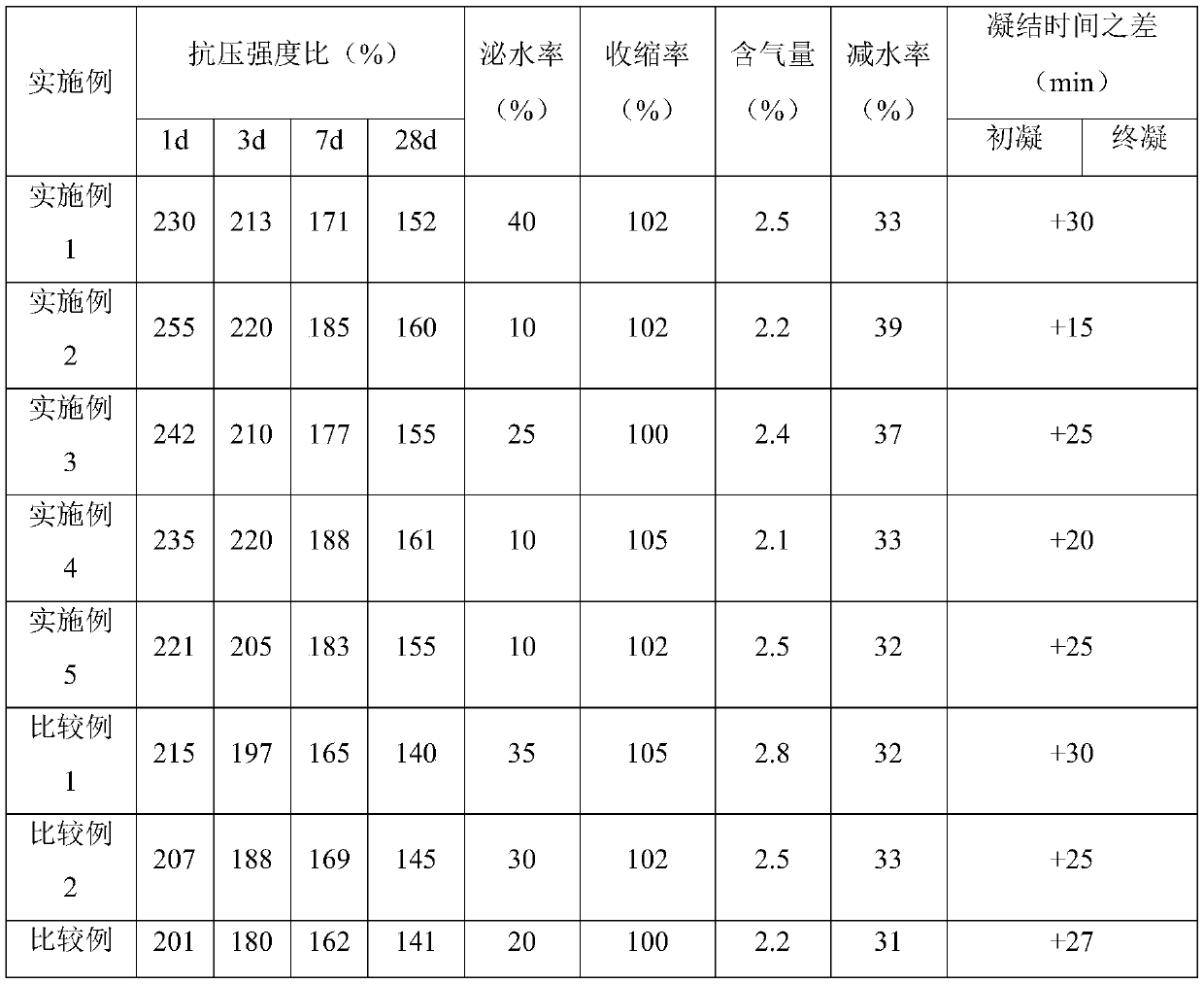

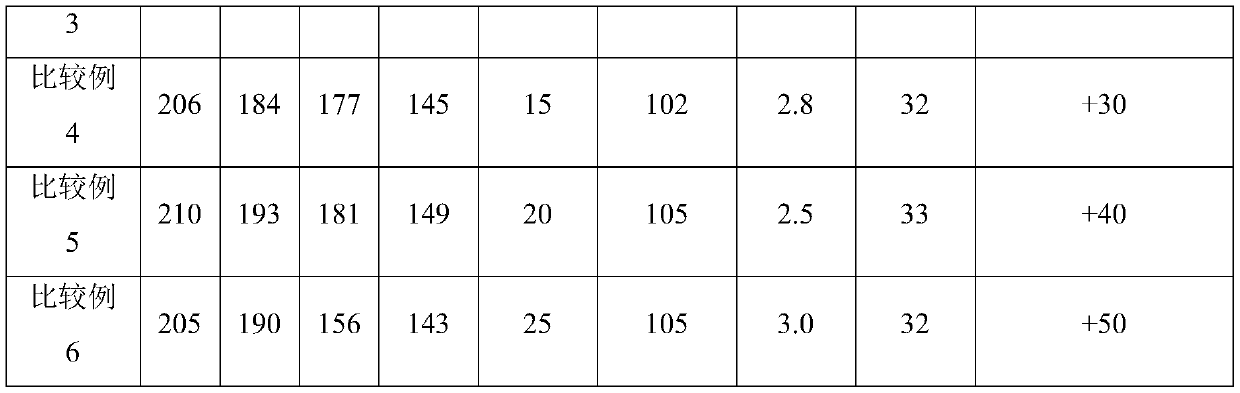

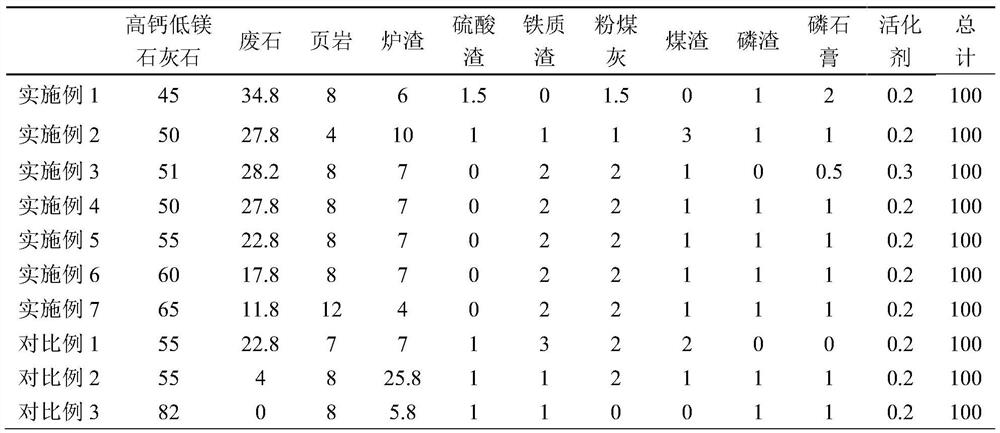

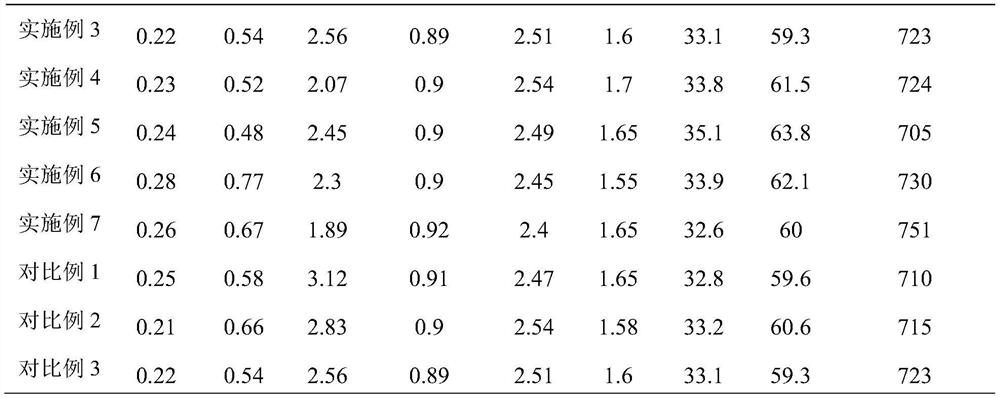

Resource-saving low-carbon cement clinker and preparation method thereof

The invention discloses a resource-saving low-carbon cement clinker and a preparation method thereof, and belongs to the technical field of Portland cement clinker production. The cement clinker comprises the following raw materials in percentage by mass: 45-70% of high-calcium low-magnesium limestone, 10-40% of barren rock, 4-12% of shale or sandstone, 4-12% of slag, 1-3% of sulfate slag or iron slag, 1-3% of fly ash, 0-3% of coal cinder or coal gangue, 0.5-3% of phosphorus slag and phosphogypsum and 0.1-0.3% of an added activating agent. According to the resource-saving low-carbon cement clinker and the preparation method thereof of the invention, a large amount of solid waste is utilized, the adopted industrial waste residue is formed by high-temperature calcination, carbonate hardly exists, and CO2 hardly occurs after high-temperature calcination is performed again; the mixing amount of the industrial waste residues is high, the use amount of limestone is greatly reduced; the mineralization of trace elements in the industrial waste residues is utilized, and the activating agent is added, so that the burnability of the raw materials is improved, the sintering stability of the clinker is reduced, and the performance of the clinker is improved; the firing temperature of the low-carbon cement clinker is reduced by 100-150 DEG C compared with the firing temperature 1450 DEG C of traditional Portland cement clinker, and therefore, the coal consumption is obviously reduced, and the emission of CO2 is reduced.

Owner:阳新娲石水泥有限公司

Low temperature rapid hardening grouting material for offshore oil well and preparation method thereof

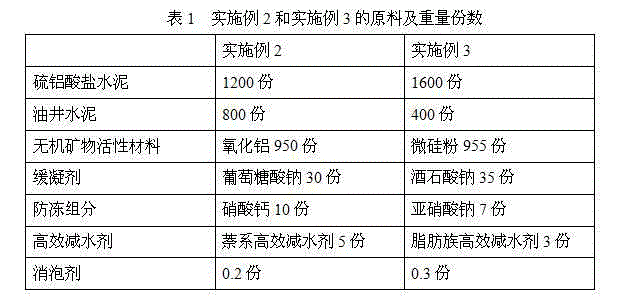

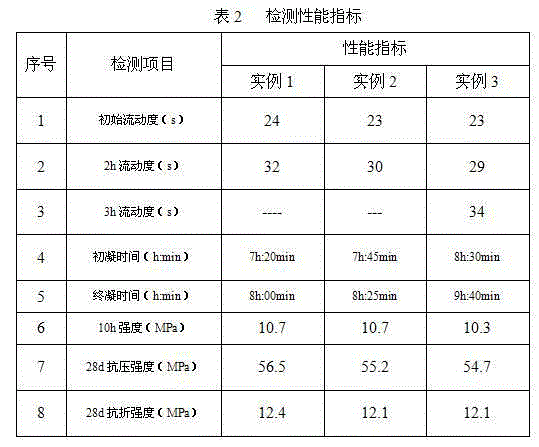

The invention relates to a low temperature rapid hardening grouting material for an offshore oil well. The low temperature rapid hardening grouting material for the offshore oil well comprises the following raw materials in parts by weight: 2,000 parts of gel materials, 950-965 parts of inorganic mineral active materials, 25-35 parts of retarders, 5-10 parts of anti-freezing ingredients, 3-5 parts of high efficiency slushing agents, and 0.1-0.3 part of defoaming agents, wherein the gel materials are quick-hardening sulphate aluminium cement and oil well cement; the mass ratio of the quick-hardening sulphate aluminium cement and oil well cement is 5:5-8:2. The invention also provides a preparation method thereof. The grouting material is suitable for construction under a well cementation low-temperature environment, slurry can maintain better mobility and is high in early strength, the slurry is full without shrinkage, the long-term strength is high, and the well cementation construction time and the underground grouting environment parameter requirement are effectively ensured.

Owner:河北铁园科技发展有限公司

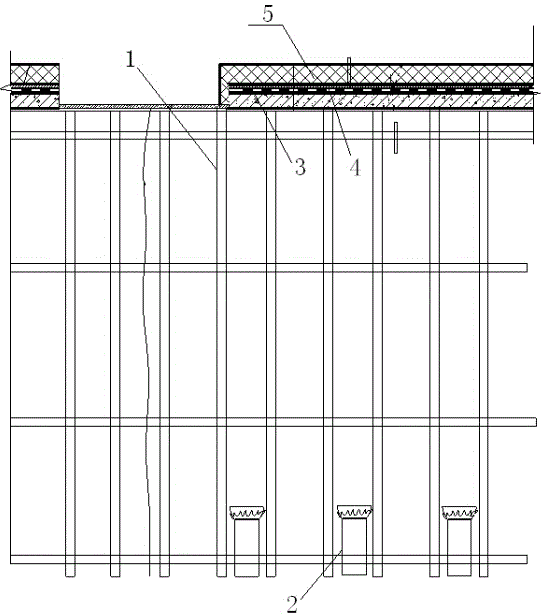

Frost damage prevention method for cast-in-place concrete beams and slabs

InactiveCN104790666AGuaranteed early strengthImprove work efficiencyBuilding material handlingFalseworkFrost

The invention discloses a frost damage prevention method for cast-in-place concrete beams and slabs. Before the concrete beams and slabs are cast, a scaffold is arranged on the ground, and formworks are arranged on the scaffold to cast the concrete beams and slabs. The frost damage prevention method includes the following steps that 1, the periphery of the scaffold is closed; 2, multiple heating devices are erected below the scaffold and used for heating the formwork located on the scaffold; 3, the concrete beams and slabs are cast on the formworks above the heating devices; 4, a sealing film, a straw mattress and an extruded sheet are sequentially laid on the upper surfaces of the concrete beams and slabs to seal cast concrete and preserve the heat of the cast concrete. According to the frost damage prevention method for the cast-in-place concrete beams and slabs, the concrete can be in a positive temperature environment in the casting and curing processes to effectively ensure the early-stage strength of the concrete.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

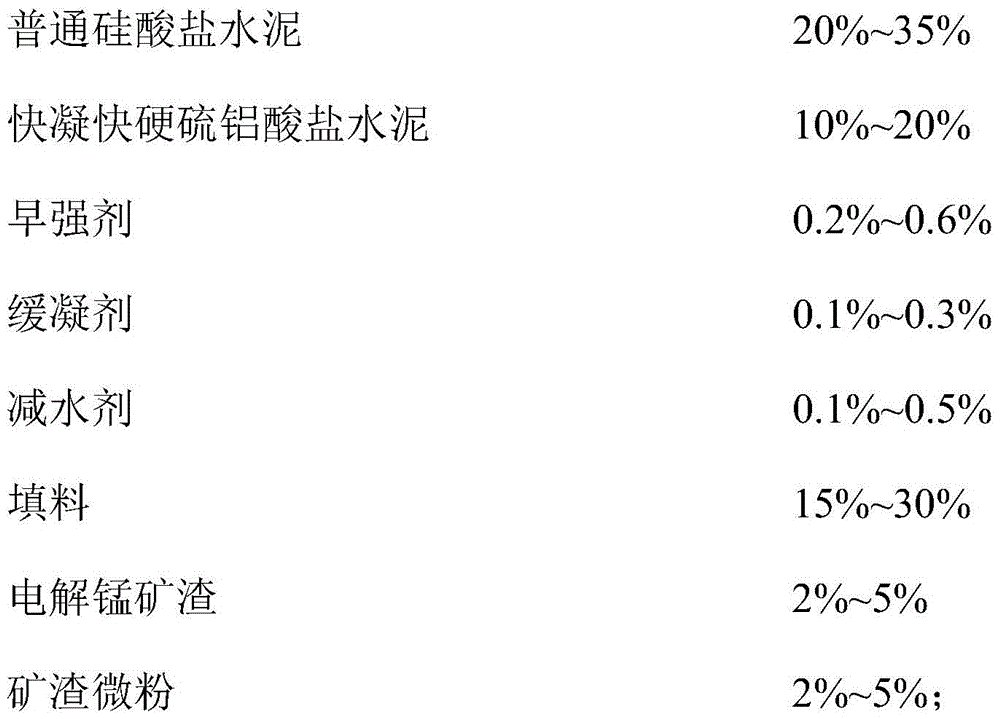

Fast setting type (I type) polymer cement waterproof slurry and preparation method thereof

ActiveCN104402364BFast setting and fast hardening guaranteeGuaranteed early strengthSolid waste managementAlkalinityPolymer science

The invention discloses a rapid setting type (I type) polymer cement waterproof slurry and a preparation method thereof. The rapid setting type (I type) polymer cement waterproof slurry is prepared by employing ordinary portland cement, quick setting and rapid hardening sulphoaluminate cement, low-alkalinity sulphoaluminate cement and the like as inorganic binders, taking a high-molecular emulsion as an organic binder, adding an early strength agent, a retarding agent, a water reducer and other auxiliary agents, and using electrolytic manganese ore slag and slag micro powder as functional filling materials, and performing dispersing. The rapid setting type (I type) polymer cement waterproof slurry is simple and rapid in construction, rapid in strength development and good in flexibility, and is applicable to construction of dry, wet and leaked interfaces.

Owner:苏州市姑苏新型建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com