Low-cost early strength cementing material ratio decision-making method

A cementitious material and decision-making model technology, applied in the field of filling mining, can solve problems such as high cost of filling mining, poor economic benefits, and waste of secondary resources, and achieve the goal of improving mining economic benefits, reducing mining costs, and improving resource utilization Effect

Active Publication Date: 2017-11-03

JINCHUAN GROUP LIMITED +1

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, filling mining mainly uses cement as the cementitious material, and rod sand or tailings as the filling aggregate, so the cost of filling mining is high and the economic benefit is poor.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

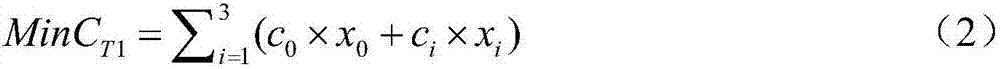

[0019] (1) Proportion decision of low activity metallurgical slag compound activator. Cement clinker, desulfurized gypsum and sodium sulfate were selected as the compound activator, and the 28-day strength orthogonal test and proportion decision of the cemented filling body were carried out. The specific implementation steps are as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Login to View More

Abstract

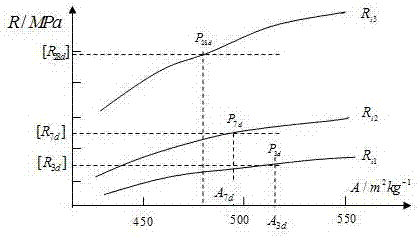

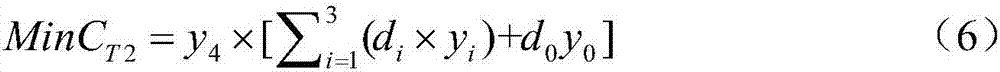

The invention discloses a low-cost early strength cementing material ratio decision-making method. The method includes: establishing a composite activator ratio decision-making model, and solving the composite activator ratio decision-making model to obtain a composite activator ratio; then, establishing an early strength grinding aid ratio and adding amount decision-making model to obtain a ratio and adding amount of an early strength grinding aid; according to the composite activator ratio and the ratio and adding amount of the early strength grinding aid, carrying out strength test of cement backfill of early strength cementing materials different in specific surface area and corresponding fineness, establishing a relation curve between cement backfill strength and specific surface areas of the cementing materials, and determining the specific surface areas of the cementing materials and corresponding fineness. The ratio decision-making method has advantages that by adoption of smelting waste for development of the cementing materials, early strength of cement backfill can be guaranteed, recyclability of solid wastes in filling mining is improved, mining cost is reduced, and mining economic benefits are increased.

Description

Technical field: [0001] The invention belongs to the technical field of filling and mining, and in particular relates to a low-cost early-strength cementitious material ratio decision-making method. Background technique [0002] Filling mining can backfill waste residues, waste rocks, tailings, waste water and other wastes into the underground stope, effectively control the pressure of the stope and avoid surface subsidence; at the same time, it also reduces waste discharge, and realizes green development and resources without waste or less waste Comprehensive utilization, so as to protect the environment and prevent geological disasters. Compared with other mining methods, the backfill mining method has complex mining technology, low mining production capacity, and poor economic benefits. Usually used for non-ferrous or precious metal ore mining. As our country faces more and more complex and difficult-to-mining ore bodies and environmental protection is becoming increasi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/08

CPCC04B28/08C04B2111/00724C04B2201/50C04B22/143C04B22/147C04B24/02C04B24/122C04B22/002C04B22/08

Inventor 杨志强高谦肖柏林董越杨晓炳王安福李立涛刘世和

Owner JINCHUAN GROUP LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com