Composite low-heat-release high-active superfine powder concrete admixture and making method thereof

A technology of low heat release and admixtures, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problem that the fluidity of concrete mixed with slag powder is not significantly improved, and the fluidity of concrete is not significantly improved. The effect of use is not ideal, etc., to achieve the effect of increasing corrosion resistance, high hydration reaction activity, and saving cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

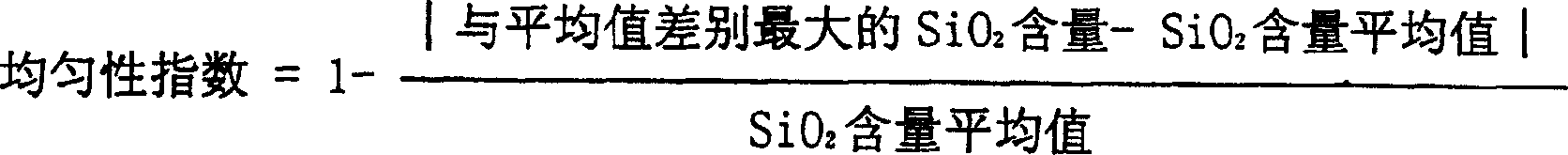

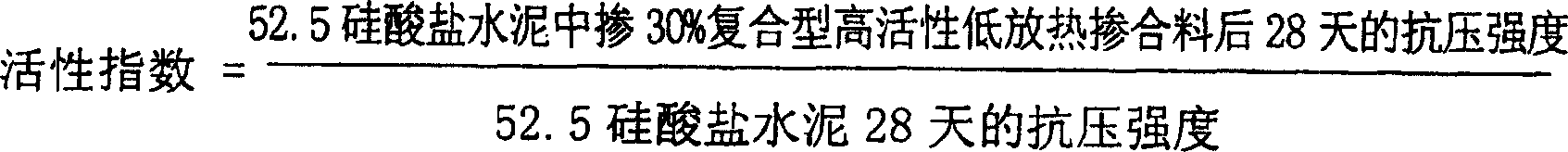

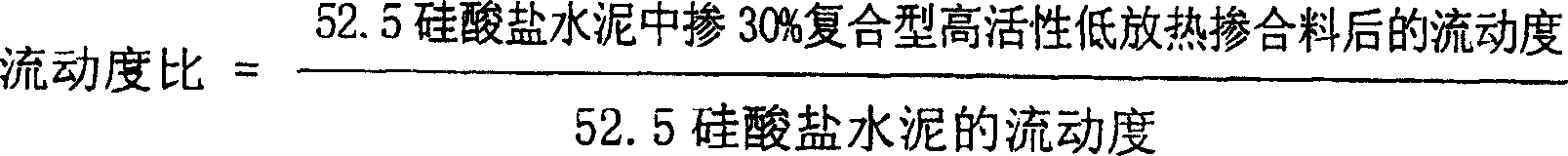

[0029] (1) Crush the steel slag to less than 6mm, according to the weight ratio: 70% of steel slag, 30% of primary fly ash, and grind together to a specific surface area of 510m 2 / kg, made into a composite admixture. The basicity coefficient of steel slag is 3.05. The homogeneity index of the product is 0.94 (weight), the activity index is 0.82 (strength ratio), the fluidity ratio is 1.07, the reduction rate of the heat of hydration in 3 days is 29%, and the reduction rate of heat of hydration in 7 days is 21%.

[0030] Concrete mix ratio

(kg / m 3 )

(cm)

(h:min)

(MPa)

Compound Admixture

water

the sand

stone

initial

1 hour

initial setting

final set

7 days

28 days

90 days

410

0

188

850

1017

21.5

8.6

8:25

12:10

26.6

41.3

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com