A preparation method of biocorrosion-resistant concrete with surface adjustment function

A bio-resistant concrete technology, applied in the field of concrete production, can solve the problems of inability to accurately deal with the complex environment of microbial corrosion, and achieve the effect of improving hydration reaction activity, strengthening the skeleton of the cornerstone, and increasing the self-shrinkage strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

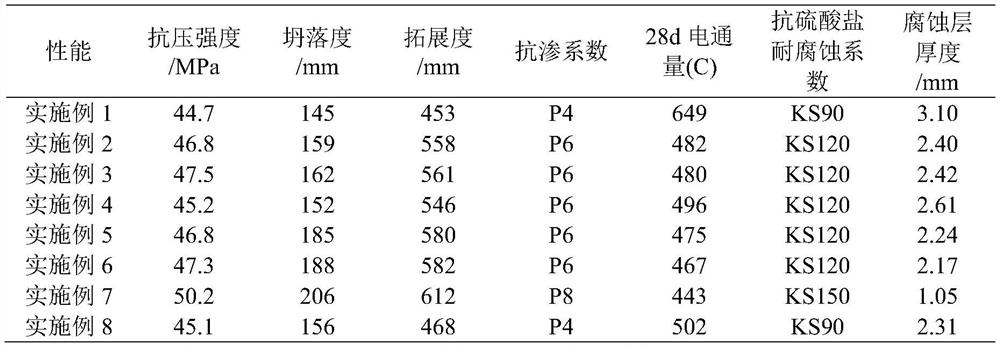

Embodiment 1

[0030] Take 10 parts by weight of silica fume, 15 parts by weight of nano-silica, 450 parts by weight of cement, 15 parts by weight of organic silicon, 800 parts by weight of sand, and 400 parts by weight of gravel. After stirring for 1 min, add 225 parts by weight of water evenly and slowly, and reduce 2 parts by weight of the water agent were stirred, and the concrete of Example 1 was obtained after stirring for 3-4 minutes.

Embodiment 2~8

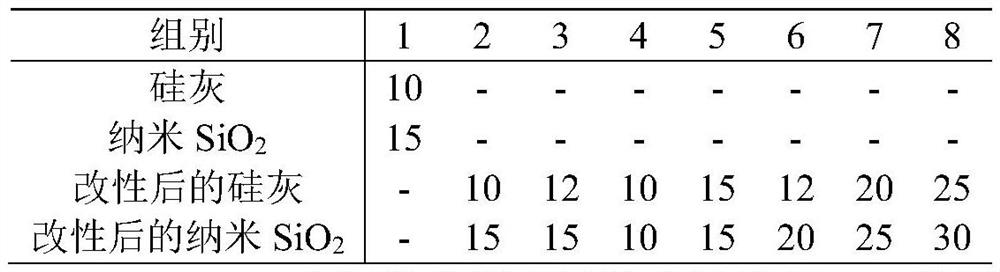

[0032] 1) Take 10 parts by weight of silica fume, then add 20 parts by weight of trimethoxysilane quaternary ammonium salt, keep stirring mechanically at 40-50°C, react for 4-8 hours, add 6 parts by weight of copper sulfate, add 6 parts by weight of lemon Sodium acid, and finally get the quaternary ammonium salt modified silica fume covering the copper nanoparticles.

[0033] 2) Take 15 parts by weight of nano-silica, add 20 parts by weight of carboxysilane, continuously stir mechanically at 30-40° C., react for 2-4 hours, and centrifuge to obtain carboxyamination-modified nano-silica.

[0034] 3) Take 10-25 parts by weight of modified silica fume obtained in step 1, 10-30 parts by weight of modified nano-silica obtained in step 2, 450 parts by weight of cement, 15 parts by weight of organic silicon, 800 parts by weight of sand, and 400 parts by weight of gravel. After stirring for 1 minute in parts by weight, 225 parts by weight of water and 2 parts by weight of water reducer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com