Curing agent for hydraulic filling of marine mud and curing method thereof

A curing method and curing agent technology are applied in the field of material science to achieve the effects of shortening drainage consolidation time, improving soil construction performance, and reducing raw material costs and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

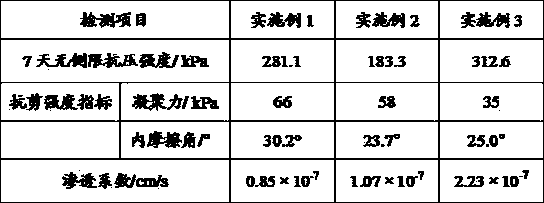

Embodiment 1

[0023] A dredging reclamation mud solidifying agent, which is composed of the following raw materials in proportion by weight: 20.6 parts of quicklime, 41.3 parts of secondary fly ash, 0.3 part of triethanolamine, 20.6 parts of raw gypsum, 3.4 parts of sodium hydroxide, water 13.8 parts of glass; the preparation of the dredging and reclamation marine sludge curing agent is carried out as follows: first add quicklime and secondary fly ash to the mixer according to the above ratio and stir for 5 minutes, then add triethanolamine, quick gypsum, sodium hydroxide Add the water glass and water glass into the blender according to the above ratio and stir evenly.

[0024] The solidification method of the dredged marine sediment solidification agent comprises the following steps: using a cutter suction pump to control the water content at 85% on the original mud sample, and blending the above-mentioned The dredging reclamation mud curing agent is cured under natural curing conditions f...

Embodiment 2

[0026] A dredging reclamation mud solidifying agent, which is composed of the following raw materials in proportion by weight: 18.5 parts of quicklime, 37 parts of secondary fly ash, 0.5 part of triethanolamine, 23 parts of raw gypsum, 5 parts of sodium hydroxide, water 16 parts of glass; the preparation of the dredging and reclamation mud solidifying agent is carried out as follows: first add quicklime and secondary fly ash to the mixer according to the above ratio and stir for 5 minutes, then add triethanolamine, quick gypsum, sodium hydroxide Add the water glass and water glass into the blender according to the above ratio and stir evenly.

[0027] The solidification method of the dredged marine sediment solidification agent comprises the following steps: using a cutter suction pump to control the water content at 80% on the original mud sample, and blending the above-mentioned The dredged reclamation mud curing agent is cured under natural curing conditions for 7 days afte...

Embodiment 3

[0029] A dredging reclamation mud solidifying agent, which is composed of the following raw materials in proportion by weight: 23 parts of quicklime, 45 parts of secondary fly ash, 0.2 part of triethanolamine, 18 parts of raw gypsum, 2 parts of sodium hydroxide, water 11.8 parts of glass; the preparation of the blown reclamation marine sludge solidifying agent is carried out as follows: first add quicklime and secondary fly ash to the mixer according to the above ratio and stir for 5 minutes, then add triethanolamine, quick gypsum, sodium hydroxide Add the water glass and water glass into the blender according to the above ratio and stir evenly.

[0030] The solidification method of the dredged marine sediment solidification agent comprises the following steps: using a cutter suction pump to control the water content at 90% on the original mud sample, and blending the above-mentioned The dredged reclamation sludge curing agent is cured under natural curing conditions for 7 day...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com