Alloying molten zinc-plated steel sheet and manufacturing method therefor

A hot-dip galvanized steel sheet, hot-dip galvanized technology, applied in hot-dip galvanizing process, chemical instruments and methods, manufacturing tools, etc. The effect of excellent slab cracking resistance and excellent resistance to secondary processing embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

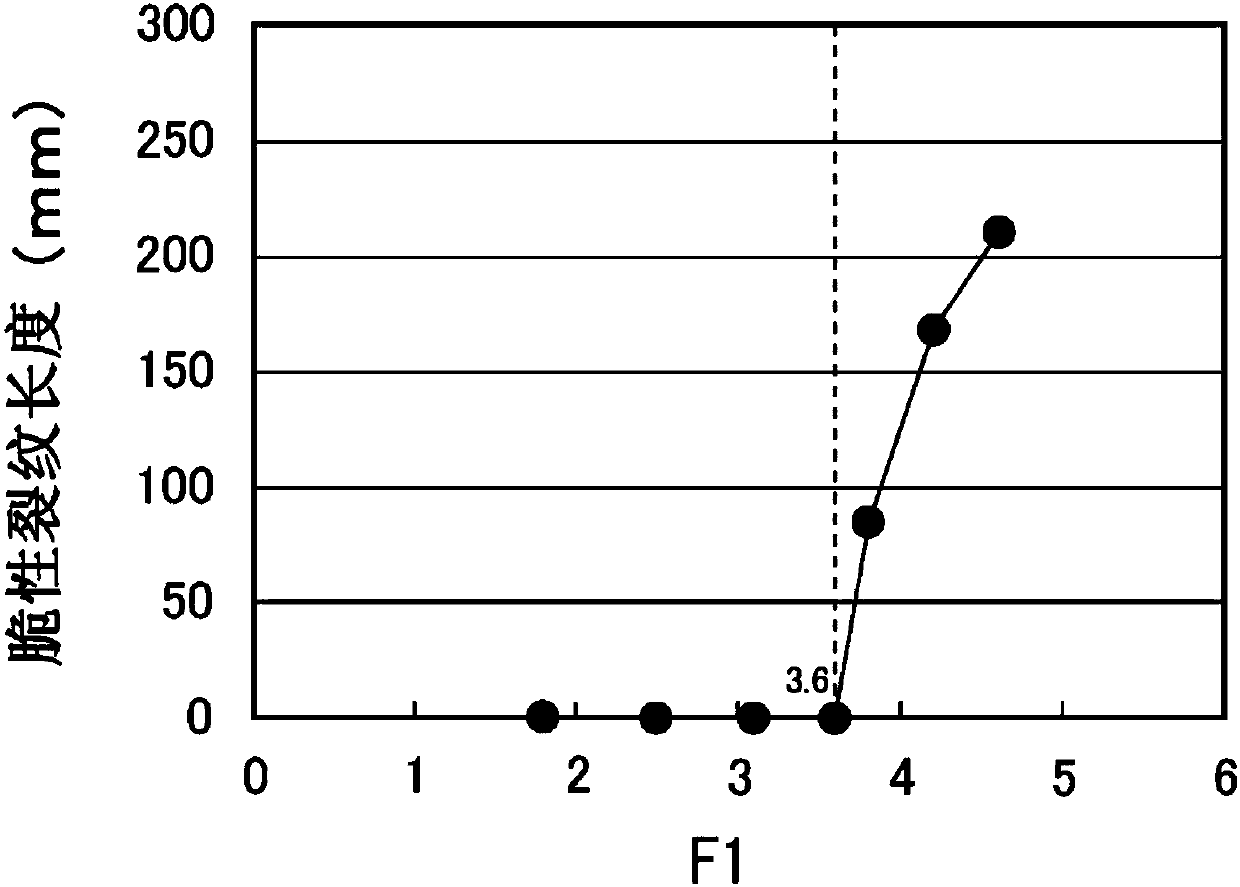

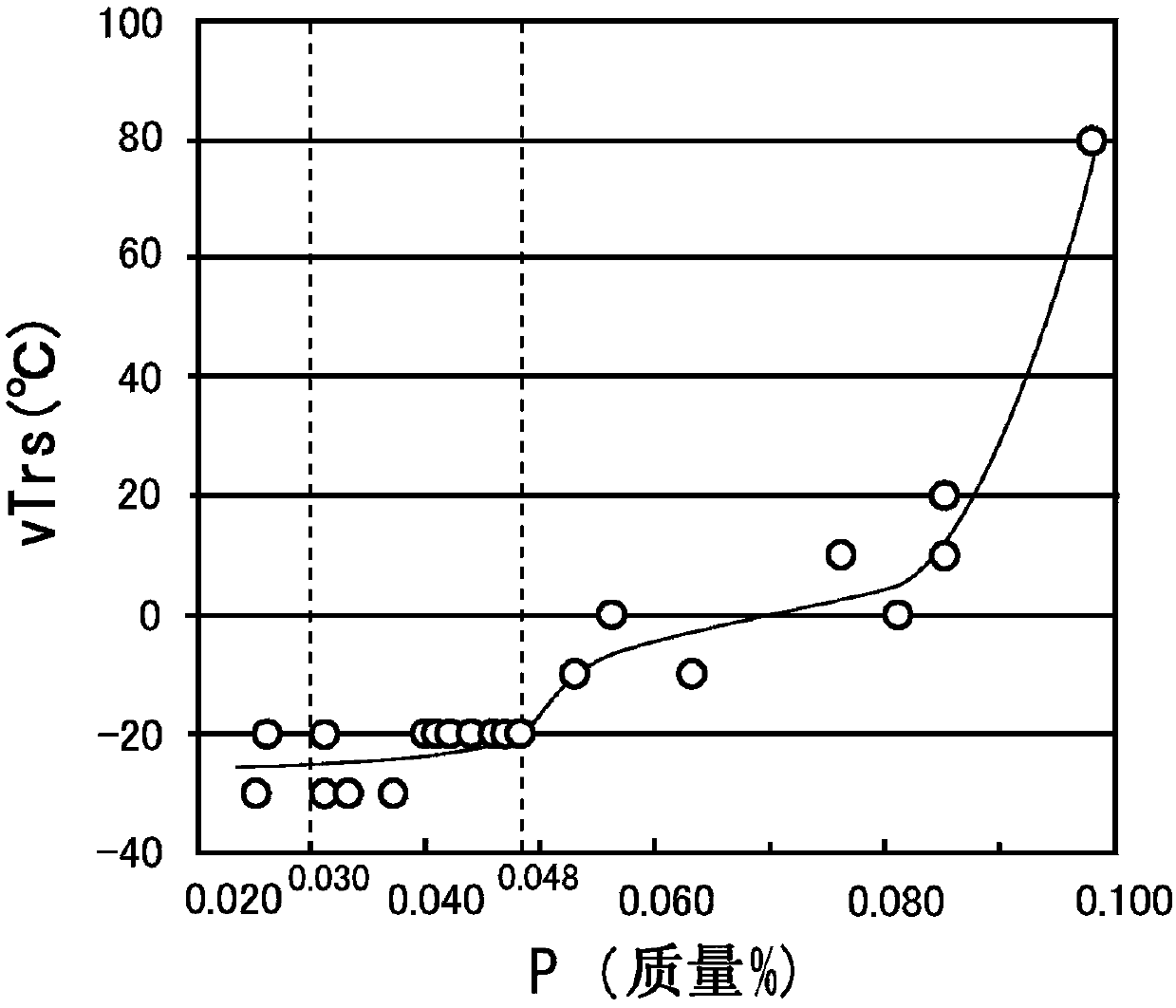

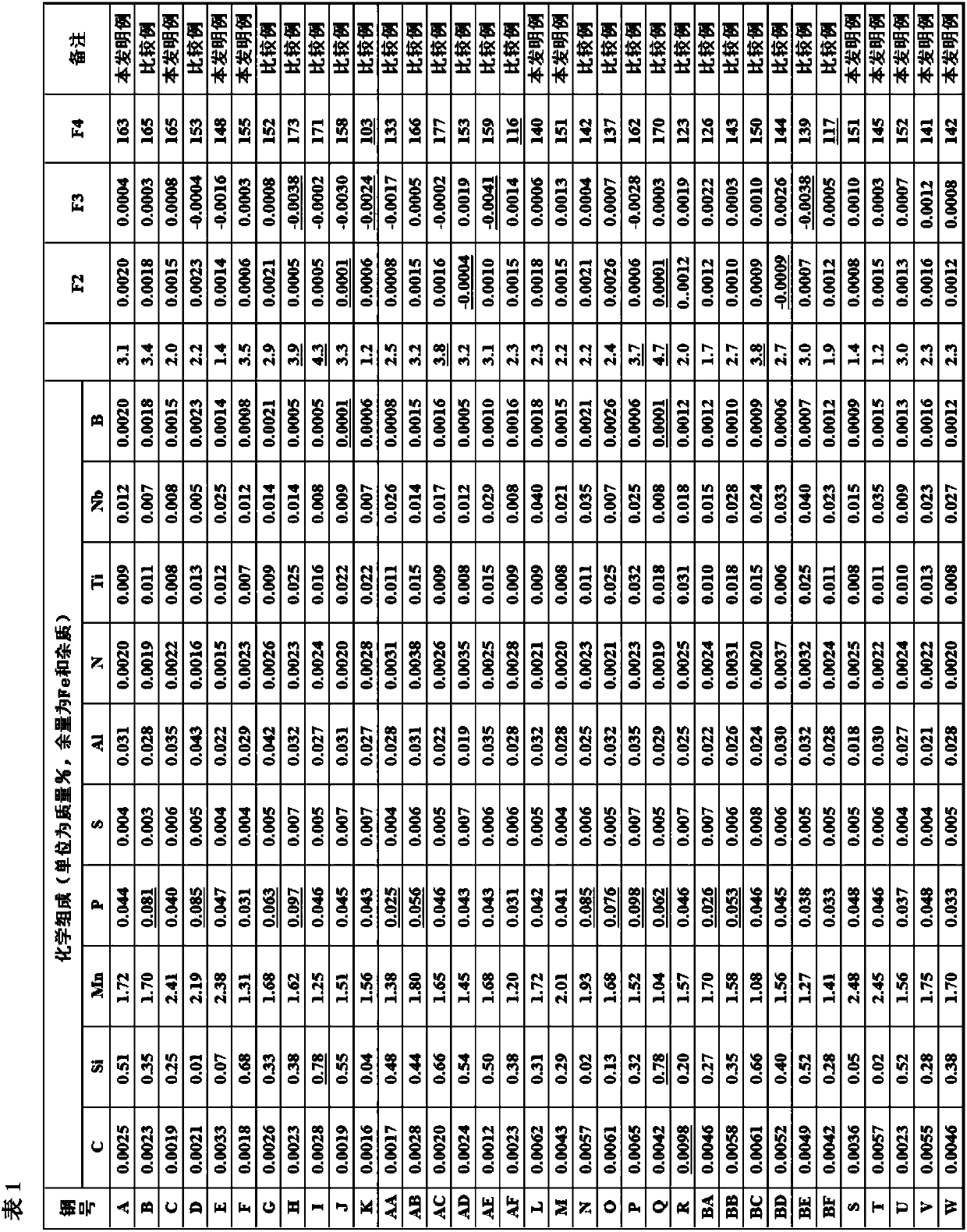

[0210] Molten steel having the chemical composition shown in Table 1 was produced, and the molten steel was cast to produce a slab.

[0211] [Table 1]

[0212]

[0213] With respect to the slabs of the respective steel numbers, hot-rolled steel sheets were produced at the finishing temperature FT (° C.) and the coiling temperature CT (° C.) shown in Table 2. The hot-rolled steel sheet was cold-rolled at a rolling ratio of 80% to manufacture a cold-rolled steel sheet. The cold-rolled steel sheets were annealed at the annealing temperatures (° C.) shown in Table 2 to manufacture base steel sheets. For base steel sheets of test numbers other than test numbers 49 and 50, after annealing and pickling treatment, Ni pre-plating treatment is performed to form a coating with a coating weight of 0.5g / m on the surface of the base steel sheet 2 Ni coating. Hot-dip galvanizing treatment is carried out on the base steel plate after Ni pre-plating treatment (set the Zn deposition amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com