Concrete composite liquid anti-freezing pumping agent

A pumping agent and composite technology, applied in the field of concrete pumping agent, can solve the problems of unfavorable pumping construction concrete commercialization, impact on concrete durability, high alkali content, etc., to achieve improved workability, improved adaptability, and convenient storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: The concrete composite liquid antifreeze pumping agent of the present invention:

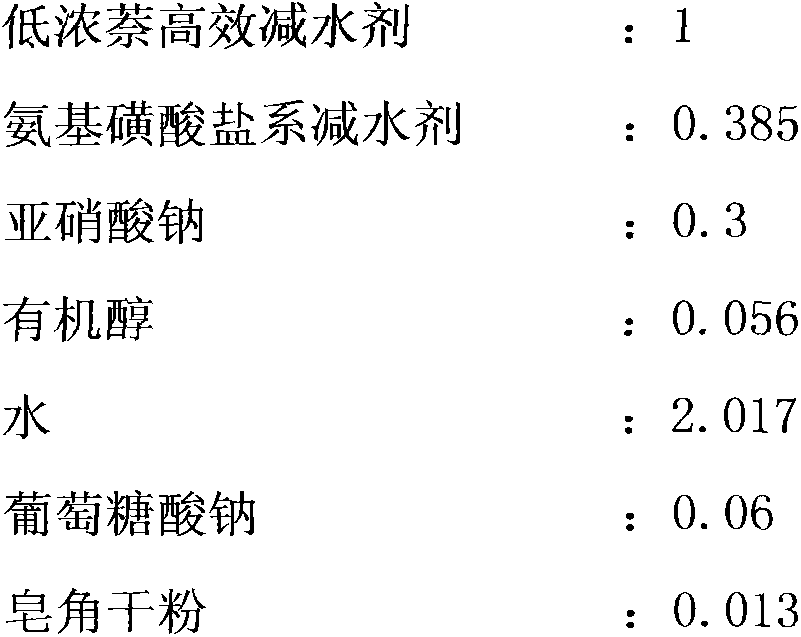

[0028] Weigh the following substances by weight:

[0029]

[0030] The organic alcohol is selected from ethylene glycol, methanol or a mixture of ethylene glycol and methanol in any ratio; the ratio between the organic alcohol and the low-concentration naphthalene superplasticizer is 1:0.056.

[0031] After mixing the above substances, a concrete composite liquid antifreeze pumping agent is obtained.

Embodiment 2

[0032] Example 2: The concrete composite liquid antifreeze pumping agent of the present invention:

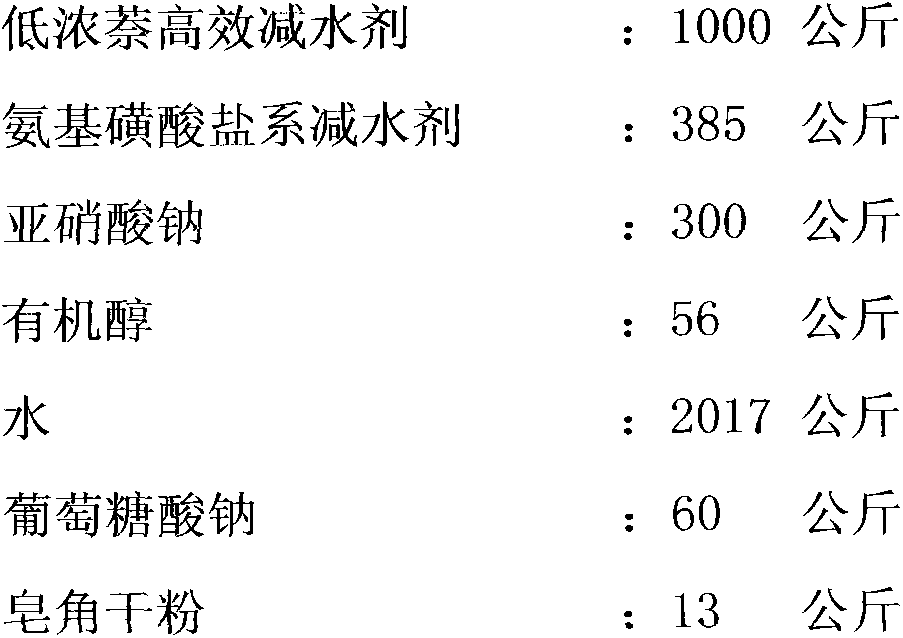

[0033] Weigh the following substances:

[0034]

[0035] After mixing the above substances, a concrete composite liquid antifreeze pumping agent is obtained.

[0036] The organic alcohol in this embodiment is selected from ethylene glycol, methanol, or a mixture of ethylene glycol and methanol in any ratio; the ratio of organic alcohol to low-concentration naphthalene superplasticizer is 1:0.056.

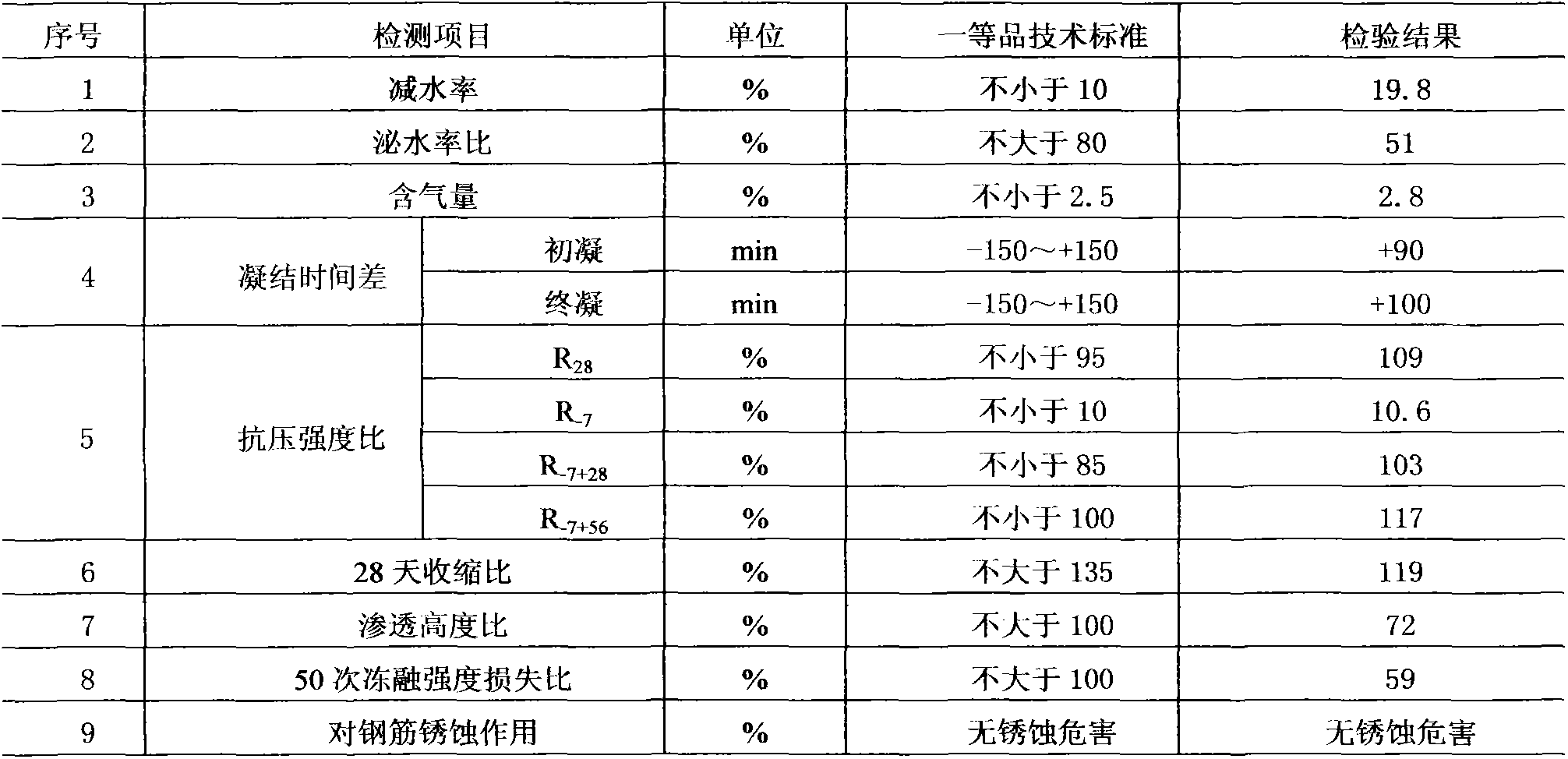

[0037] In order to better understand the beneficial effects of the present invention, the following test examples illustrate the effects of the concrete composite liquid antifreeze pumping agent of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com