Method for producing baking-free brick by doping phosphogypsum and fly ash

A technology of phosphogypsum and fly ash, which is applied in the field of non-fired bricks produced by phosphorus-doped gypsum and fly ash, can solve the problems of non-compliance with low-carbon environmental protection, unfavorable cost control, and large energy consumption, so as to promote dissolution and diffusion, The effect of reducing the average pore size and reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

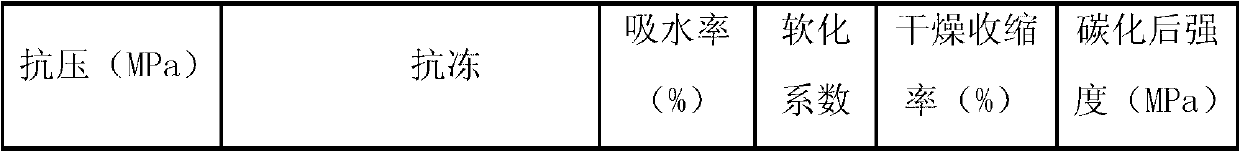

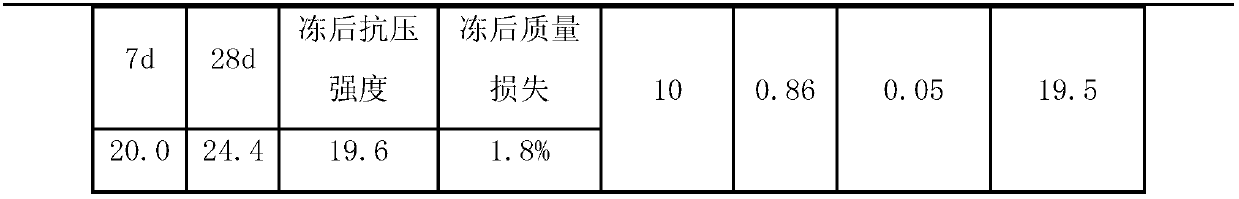

Embodiment 1

[0044] 1. Pretreatment of phosphogypsum: Neutralize and age for 24 hours with quicklime according to 2.5% of the mass of phosphogypsum;

[0045]2. Ingredients: The ingredients are composed of phosphogypsum, fly ash, quicklime and cement; the content of each component is: calculated according to the mass percentage of each raw material, 45% of phosphogypsum, 30% of fly ash, 15% of quicklime, and 10% of cement %, water consumption is 30% of all solid materials;

[0046] 3. Mixing and stirring: put phosphogypsum, fly ash, cement and quicklime into the mixer and mix and stir, then add water to fully stir to obtain the mixture;

[0047] 4. Pouring and forming: pour the mixture into the brick mold and form it, and then vibrate and form it on the vibrating table;

[0048] 5. Product curing: put the vibration-formed mold into the curing room for 24 hours. The temperature of the curing room should be kept at about 20°C, and the humidity should be above 60%. After the brick has initial...

Embodiment 2

[0051] 1. Pretreatment of phosphogypsum: Neutralize and age for 24 hours with quicklime according to 2.5% of the mass of phosphogypsum;

[0052] 2. Ingredients: The ingredients are composed of phosphogypsum, fly ash, quicklime and cement; the content of each component is: calculated according to the mass percentage of each raw material, 40% of phosphogypsum, 35% of fly ash, 15% of quicklime, and 10% of cement %, water consumption is 30% of all solid materials;

[0053] 3. Mixing and stirring: put phosphogypsum, fly ash, cement and quicklime into the mixer and mix and stir, then add water to fully stir to obtain the mixture;

[0054] 4. Pouring and forming: pour the mixture into the brick mold and form it, and then vibrate and form it on the vibrating table;

[0055] 5. Product curing: put the vibration-formed mold into the curing room for 24 hours. The temperature of the curing room should be kept at about 20°C, and the humidity should be above 60%. After the brick has initia...

Embodiment 3

[0058] 1. Pretreatment of phosphogypsum: Neutralize and age for 24 hours with quicklime according to 2.5% of the mass of phosphogypsum;

[0059] 2. Ingredients: The ingredients are composed of phosphogypsum, fly ash, quicklime and cement; the content of each component is: calculated according to the mass percentage of each raw material, 40% of phosphogypsum, 35% of fly ash, 15% of quicklime, and 10% of cement %, water consumption is 30% of all solid materials;

[0060] 3. Mixing and stirring: put phosphogypsum, fly ash, cement and quicklime into the mixer and mix and stir, then add water to fully stir to obtain the mixture;

[0061] 4. Pouring and forming: pour the mixture into the brick mold and form it, and then vibrate and form it on the vibrating table;

[0062] 5. Product curing: put the vibration-formed mold into the curing room for 24 hours. The temperature of the curing room should be kept at about 20°C, and the humidity should be above 60%. After the brick has initia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com