Inorganic-organic composite powder reinforcing agent for pervious concrete and application of inorganic-organic composite powder reinforcing agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

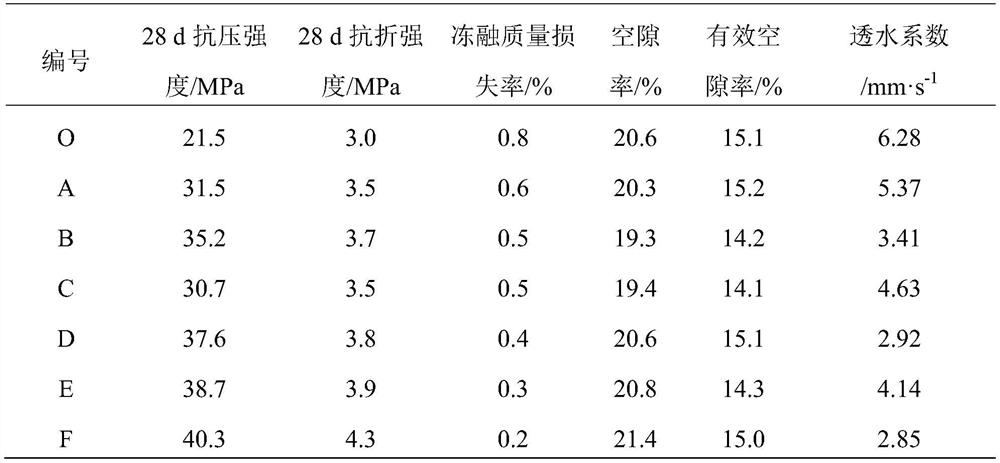

Examples

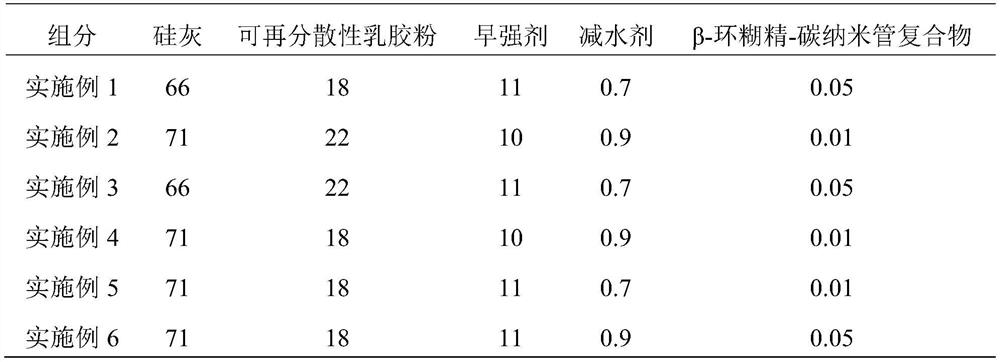

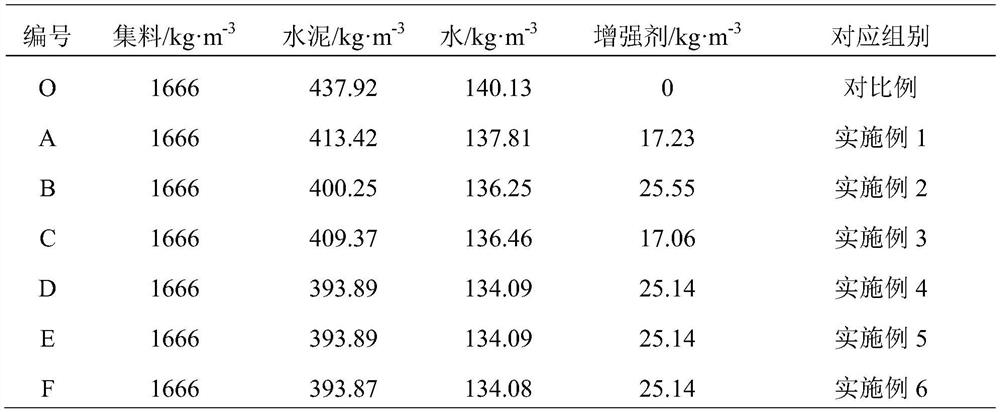

Embodiment 1

[0033] As shown in Table 1, an inorganic-organic composite powder reinforcing agent for permeable concrete includes the following components and parts by weight: 66 parts of silica fume, 18 parts of redispersible latex powder, 11 parts of early strength agent, and 0.7 parts of water, 0.05 parts of β-cyclodextrin-carbon nanotube complex. Its use method is as follows: the strengthening agent is added in the concrete mixing process, and its dosage is 4% of the cement mass.

Embodiment 2

[0035] As shown in Table 1, an inorganic-organic composite powder reinforcing agent for permeable concrete includes the following components and content in parts by weight: 71 parts of silica fume, 22 parts of redispersible latex powder, 10 parts of early strength agent, minus 0.9 part of water agent, 0.01 part of β-cyclodextrin-carbon nanotube compound. Its use method is as follows: the strengthening agent is added in the concrete mixing process, and its dosage is 6% of the cement mass.

Embodiment 3

[0037] As shown in Table 1, an inorganic-organic composite powder reinforcing agent for permeable concrete includes the following components and parts by weight: 66 parts of silica fume, 22 parts of redispersible latex powder, 11 parts of early strength agent, minus 0.7 parts of water, 0.05 parts of β-cyclodextrin-carbon nanotube complex. Its use method is as follows: the strengthening agent is added in the concrete mixing process, and its dosage is 4% of the cement mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com