Water reducing agent composition for steam-curing-free concrete and preparation method thereof

A technology of water reducer and concrete, which is applied in the field of water reducer composition for steam-free concrete and its preparation, which can solve the problems of longer construction period and complicated operation process, and achieve the effect of accelerating nucleation and growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

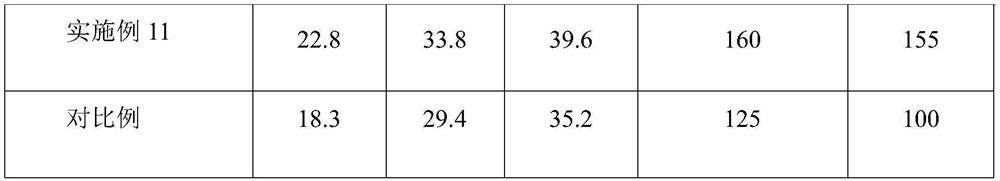

Examples

Embodiment 1

[0054] This example provides the preparation method of the early-strength polycarboxylate water reducer in the present invention. In this example, a high-molecular-weight polyether and unsaturated early-strength functional monomers are used to prepare an early-strength polycarboxylate water reducer with a suitable acid-ether ratio. On the one hand, it can achieve the effect of early strength, and on the other hand, it can also avoid collapse. decrease in fall.

[0055] Specifically, the early-strength polycarboxylate water reducer is formed by copolymerization of methallyl polyoxyethylene ether (HPEG), unsaturated acid and early-strength functional monomers.

[0056] The molecular weight of HPEG is 4000-8000, the unsaturated acid is acrylic acid or methacrylic acid, and the early-strength functional monomer is acrylamide, 2-acrylamide-2-methylpropanesulfonic acid, methacryloyloxyethyltrimethyl Ammonium chloride (DMC) or N-(3-dimethylaminopropyl) methacrylamide (DAP) or a mixtur...

Embodiment 2

[0067] A water-reducing agent composition for steam-free concrete, which is prepared by the following method:

[0068] Step 1, preparing a gel system containing C-S-H crystal nuclei;

[0069] Mix 4 parts by mass of tricalcium silicate with 1 part by mass of inorganic early-strength agent calcium formate, 1 mass part of organic early-strength agent triethanolamine and 40 parts by mass of water, and stir for 3-6 hours to obtain C-S-H crystal nuclei gel system;

[0070] Step 2. Add 8 parts by mass of early-strength polycarboxylate superplasticizer to the gel system containing C-S-H crystal nuclei to prepare a dispersion containing C-S-H crystal nuclei;

[0071] Step 3, preparing a dispersion liquid containing nanoparticles and lithium salt;

[0072] 5 parts by mass of nanoparticles Al 2 o 3 Add 8 parts by mass of early-strength polycarboxylate water reducer to 0.1 mass part of lithium salt lithium carbonate, and stir to obtain a dispersion containing nanoparticles and lithium...

Embodiment 3

[0075] A water-reducing agent composition for steam-free concrete, which is prepared by the following method:

[0076] Step 1, preparing a gel system containing C-S-H crystal nuclei;

[0077] Mix 7 parts by mass of tricalcium silicate with 1 part by mass of inorganic early-strength agent calcium formate, 1 mass part of organic early-strength agent triethanolamine and 50 parts by mass of water, and stir for 3-6 hours to obtain C-S-H crystal nuclei gel system;

[0078] Step 2. Add 12 parts by mass of early-strength polycarboxylate superplasticizer to the gel system containing C-S-H crystal nuclei to prepare a dispersion containing C-S-H crystal nuclei;

[0079] Step 3, preparing a dispersion liquid containing nanoparticles and lithium salt;

[0080] 7 parts by mass of nanoparticles Al 2 o 3 Add 11 parts by mass of early-strength polycarboxylate water reducer to 0.1 mass part of lithium salt lithium carbonate, and stir to obtain a dispersion containing nanoparticles and lithi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com