A kind of preparation method of waste glass refractory high-strength concrete

A high-strength concrete and waste glass technology, applied in the field of building materials, can solve the problems of not being widely used, low strength, and high porosity of refractory materials, and achieve excellent fire resistance, performance improvement, and early strength improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

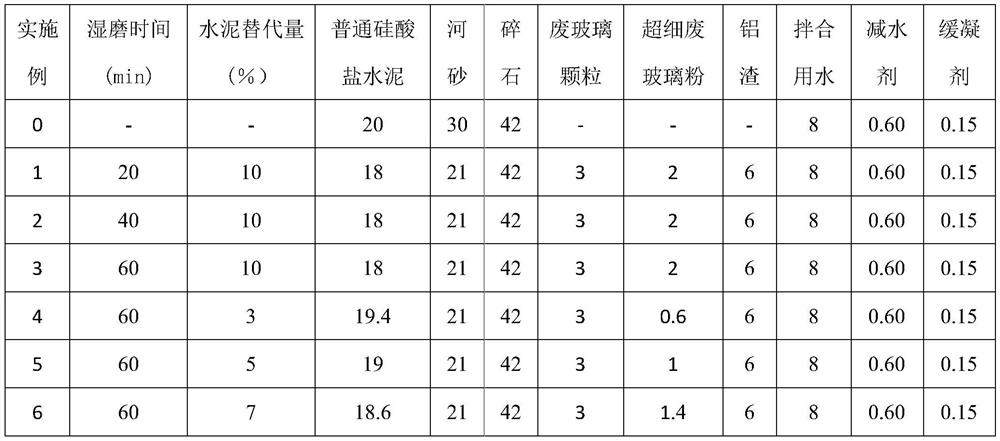

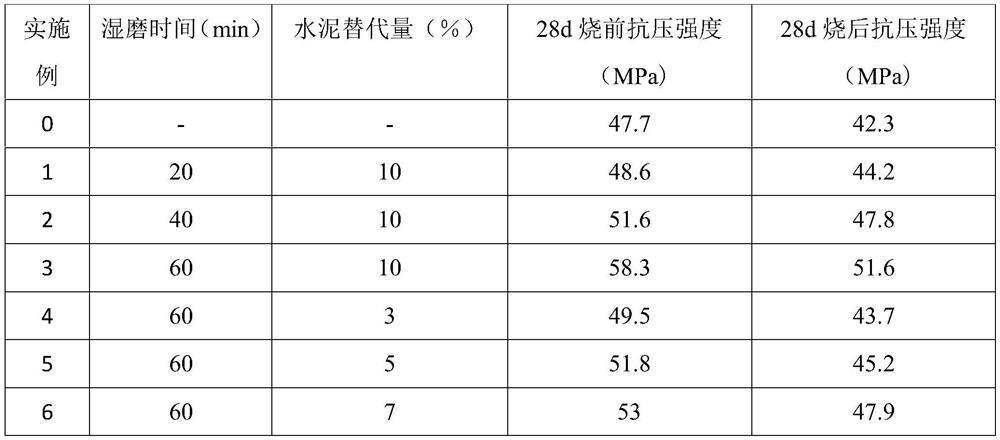

Embodiment 1

[0033] The preparation method of waste glass refractory high-strength concrete comprises the following steps:

[0034] Step 1: sending waste glass and aluminum slag into a ball mill for dry grinding and crushing, grinding for 3-15 minutes, and sieving to obtain waste glass particles of 2.3-3.0 mm, aluminum slag and waste glass powder of 20-25 μm.

[0035] Step 2: Mix the 20-25 μm glass powder and absolute ethanol obtained by the above-mentioned dry grinding in a ratio of 1:2, add grinding balls of zirconia media, put them into a reaction kettle, and pass through a planetary wet mill Carry out wet grinding at a rotational speed of 400r / min for 20min to obtain a glass powder slurry.

[0036] Step 3: suction filtration operation, the glass powder slurry obtained in step 2 is suction filtered with clear water for 2-3 times on a suction filter machine to obtain ultrafine waste glass powder without absolute ethanol, which can replace 10% cement.

[0037] Step 4: In terms of parts b...

Embodiment 2

[0039] The preparation method of waste glass refractory high-strength concrete comprises the following steps:

[0040] Step 1: sending waste glass and aluminum slag into a ball mill for dry grinding and crushing, grinding for 3-15 minutes, and sieving to obtain waste glass particles of 2.3-3.0 mm, aluminum slag and waste glass powder of 20-25 μm.

[0041] Step 2: Mix the waste glass powder of 20-25 μm obtained by the above-mentioned dry grinding with absolute ethanol in a ratio of 1:2, add grinding balls of zirconia media, put them into a reaction kettle, and pass planetary wet grinding machine for wet grinding at a speed of 400r / min for 40min to obtain glass powder slurry.

[0042] Step 3: suction filtration operation, the glass powder slurry obtained in step 2 is suction filtered with clear water for 2-3 times on a suction filter machine to obtain ultrafine waste glass powder without absolute ethanol, which can replace 10% cement.

[0043]Step 4: In terms of parts by mass, ...

Embodiment 3

[0045] The preparation method of waste glass refractory high-strength concrete comprises the following steps:

[0046] Step 1: sending waste glass and aluminum slag into a ball mill for dry grinding and crushing, grinding for 3-15 minutes, and sieving to obtain waste glass particles of 2.3-3.0 mm, aluminum slag and waste glass powder of 20-25 μm.

[0047] Step 2: Mix the waste glass powder of 20-25 μm obtained by the above-mentioned dry grinding with absolute ethanol in a ratio of 1:2, add grinding balls of zirconia media, put them into a reaction kettle, and pass planetary wet grinding machine for wet grinding at a speed of 400r / min for 60min to obtain glass powder slurry.

[0048] Step 3: suction filtration operation, the glass powder slurry obtained in step 2 is suction filtered with clear water for 2-3 times on a suction filter machine to obtain ultrafine waste glass powder without absolute ethanol, which can replace 10% cement.

[0049] Step 4: In terms of parts by mass,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com