A kind of antistatic release emulsion with good stability and preparation method thereof

A stable performance, antistatic technology, applied in the direction of conductive coatings, coatings, etc., can solve the problems of increasing the amount of catalyst, antistatic performance failure, long production cycle, etc., to achieve good storage stability, enhanced conductivity, peeling force stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] An antistatic release emulsion with good stability, which is composed of 20 parts of alkenyl polysiloxane, 8.5 parts of hydrogen-containing polysiloxane, 0.05 parts of phenyl hydroxy network silicone resin, 0.05 parts of conductive polymer polythiophene, 2 parts of single-armed carbon nanotube aqueous solution, 3.5 parts of epoxy-containing linear silane coupling agent, 5.9 parts of surfactant, and 60 parts of water.

[0047] The alkenyl polysiloxane consists of 5 parts of linear vinyl-terminated polyorganosiloxane with a viscosity of 100 mPa·s and 15 parts of vinyl-terminated MQ resin with a viscosity of 700 mPa·s.

[0048] The hydrogen-containing polysiloxane is a methylhydrogensiloxane-dimethylsiloxane cyclic copolymer (the hydrogen content is 0.8mmol / g).

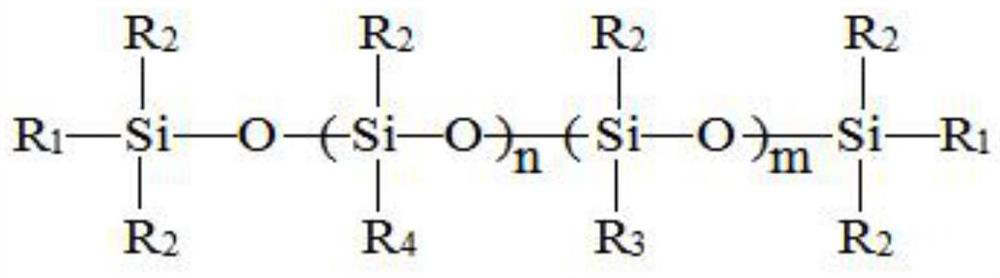

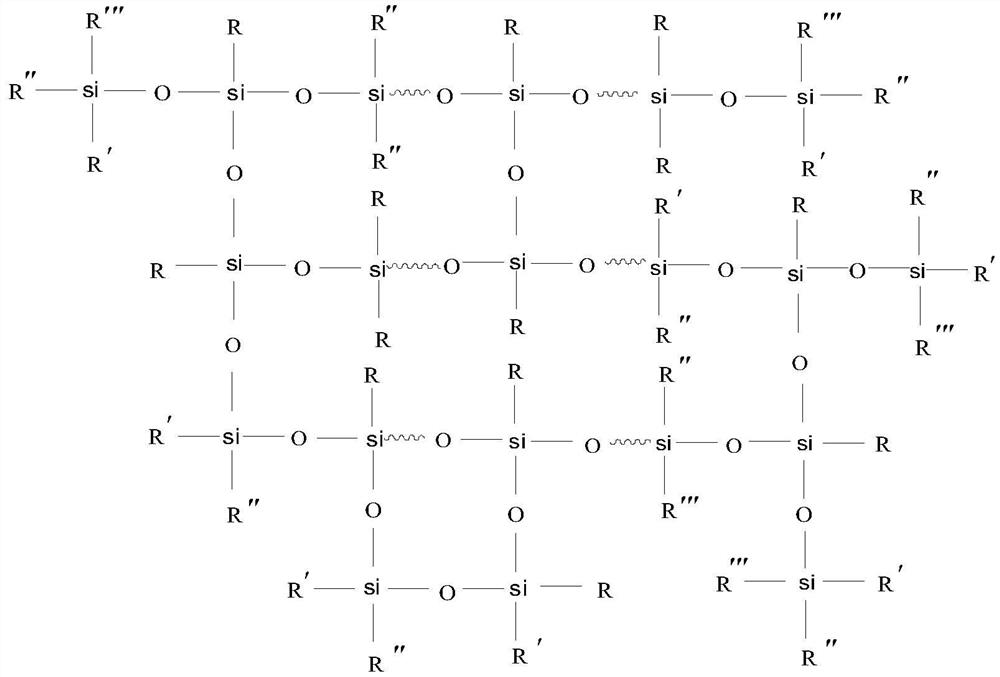

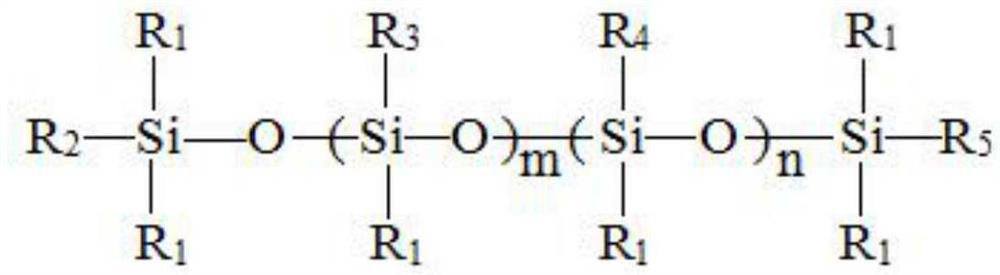

[0049] The structural formula of the phenyl hydroxy reticular silicone resin is as follows:

[0050]

[0051] Wherein, R, R", R"' are the same or different linear or branched aryl groups of 6-20 carbon atoms o...

Embodiment 2

[0063] A kind of antistatic release type emulsion with good stability, by weight, it is composed of: 5 parts of alkenyl polysiloxane, 4 parts of hydrogen-containing polysiloxane, 1 part of phenyl hydroxy network silicone resin, 5 parts of conductive polymer polythiophene, 0.05 parts of single-armed carbon nanotube aqueous solution, 5 parts of epoxy-containing linear silane coupling agent, 10 parts of surfactant, and 69.95 parts of water.

[0064] The alkenyl polysiloxane is a vinyl-terminated MT resin with a viscosity of 100 mPa·s.

[0065] The hydrogen-containing polysiloxane is a methylhydrogensiloxane-dimethylsiloxane cyclic copolymer (hydrogen content is 0.45mmol / g).

[0066] The structural formula of the phenyl hydroxy reticular silicone resin is as follows:

[0067]

[0068] Among them, R, R", R"' are the same or different linear or branched aryl groups with 6 to 20 carbon atoms or aralkyl groups with 7 to 20 carbon atoms, and R' is a hydroxyl group;

[0069] The pr...

Embodiment 3

[0080] A kind of antistatic release emulsion with good stability performance, by weight, it is composed of: 9 parts of alkenyl polysiloxane, 0.5 part of hydrogen-containing polysiloxane, 0.8 part of phenyl hydroxy network silicone resin, 2.5 parts of conductive polymer polythiophene, 1.2 parts of single-armed carbon nanotube aqueous solution, 1 part of linear silane coupling agent containing epoxy group, 1 part of surfactant, and 85 parts of water.

[0081] The alkenyl polysiloxane is a linear vinyl-terminated polyorganosiloxane with a viscosity of 500 mPa·s.

[0082] The hydrogen-containing polysiloxane is dimethyl polysiloxane (hydrogen content: 1.7 mmol / g) whose two ends are capped with dimethylhydrogensiloxy groups.

[0083] The structural formula of the phenyl hydroxy reticular silicone resin is as follows:

[0084]

[0085] Among them, R, R", R"' are the same or different linear or branched aryl groups with 6 to 20 carbon atoms or aralkyl groups with 7 to 20 carbon a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com