Patents

Literature

154 results about "Ion accelerators" patented technology

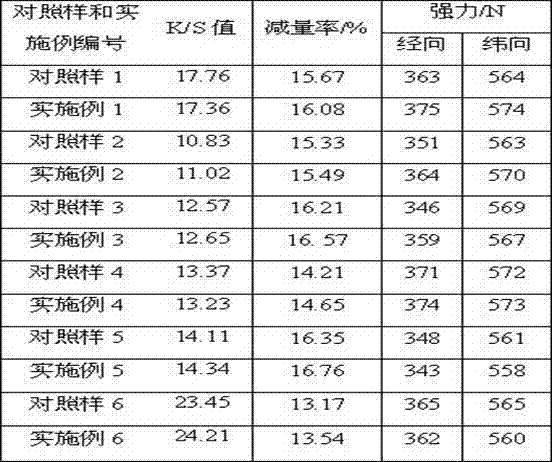

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

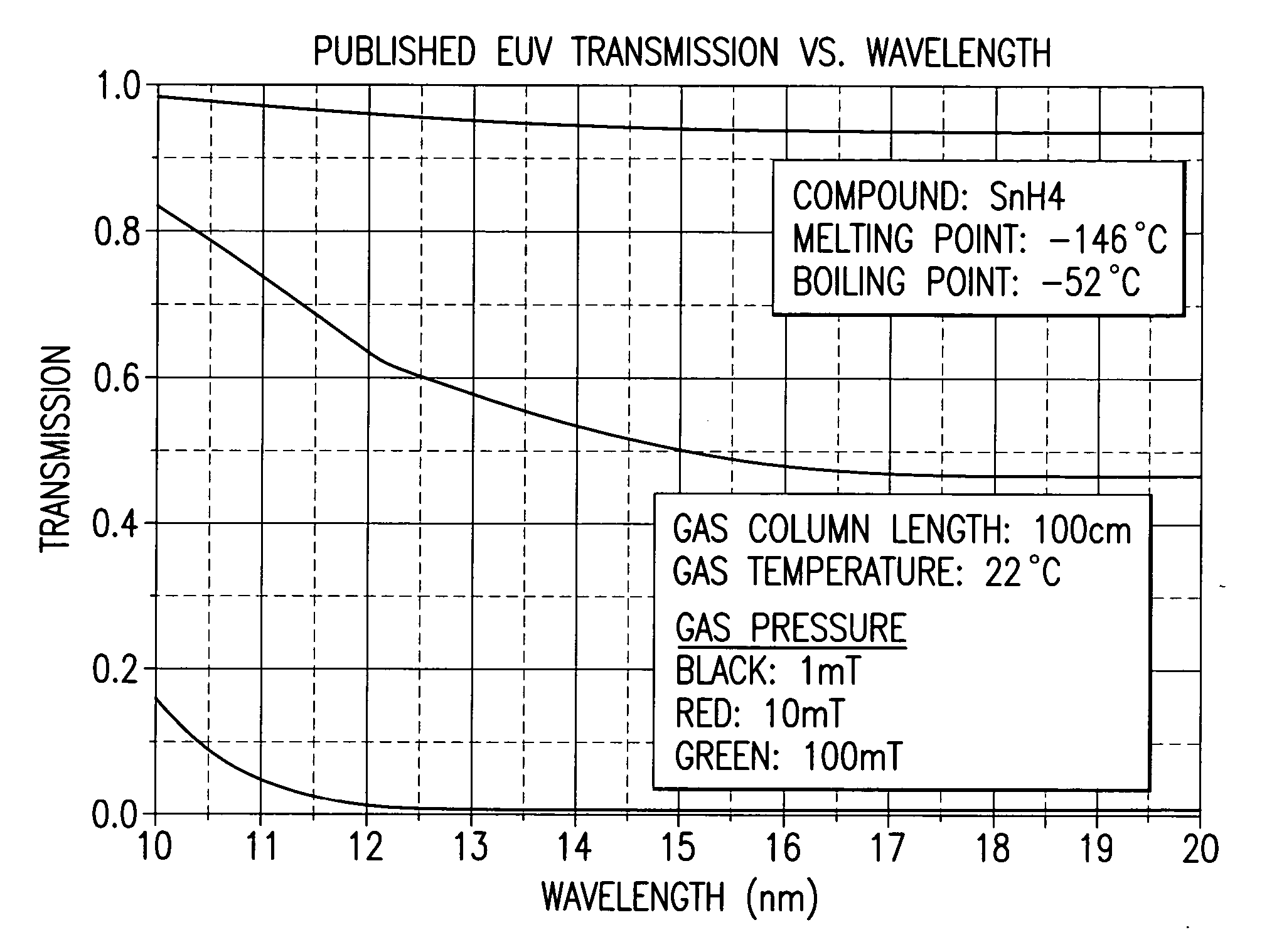

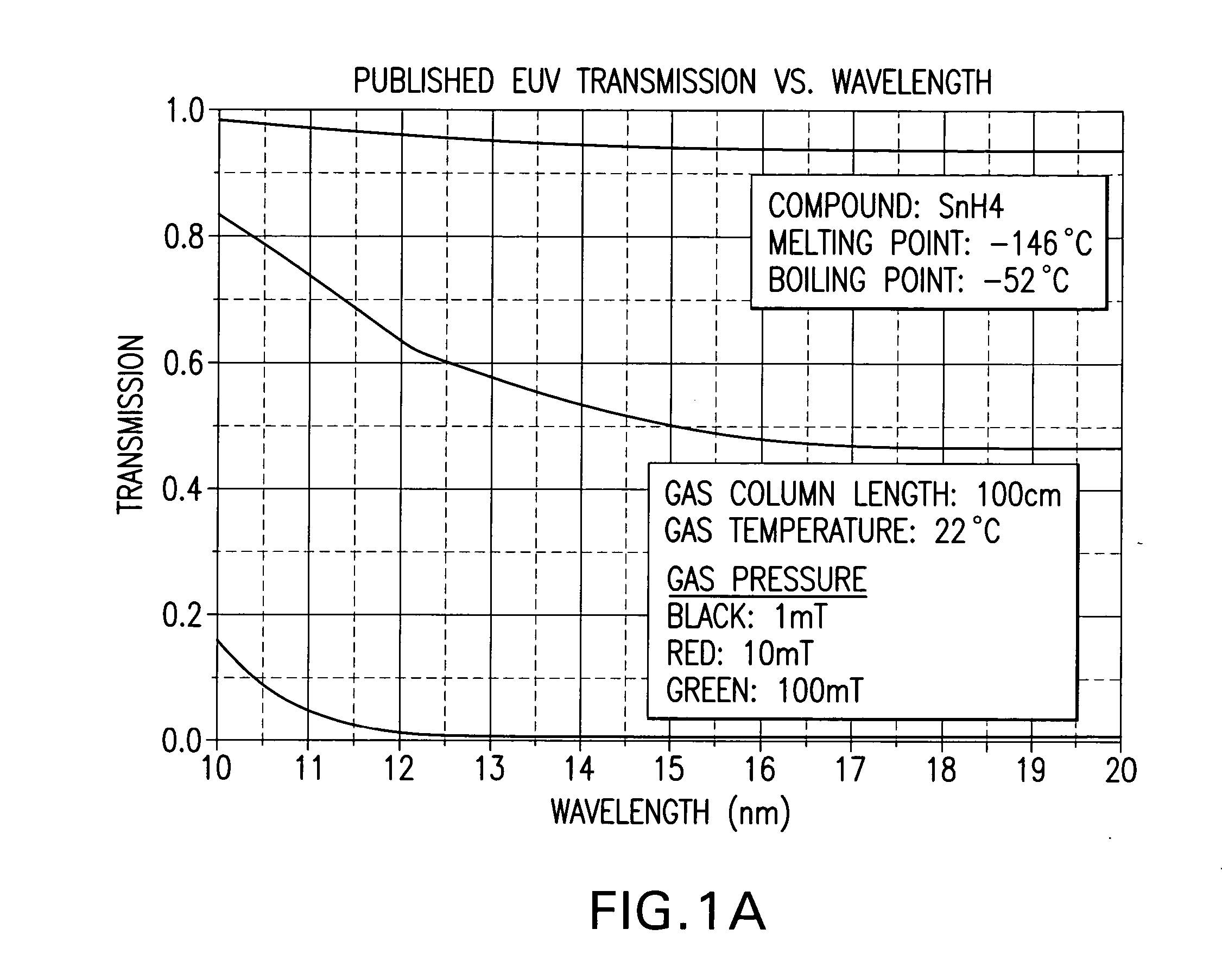

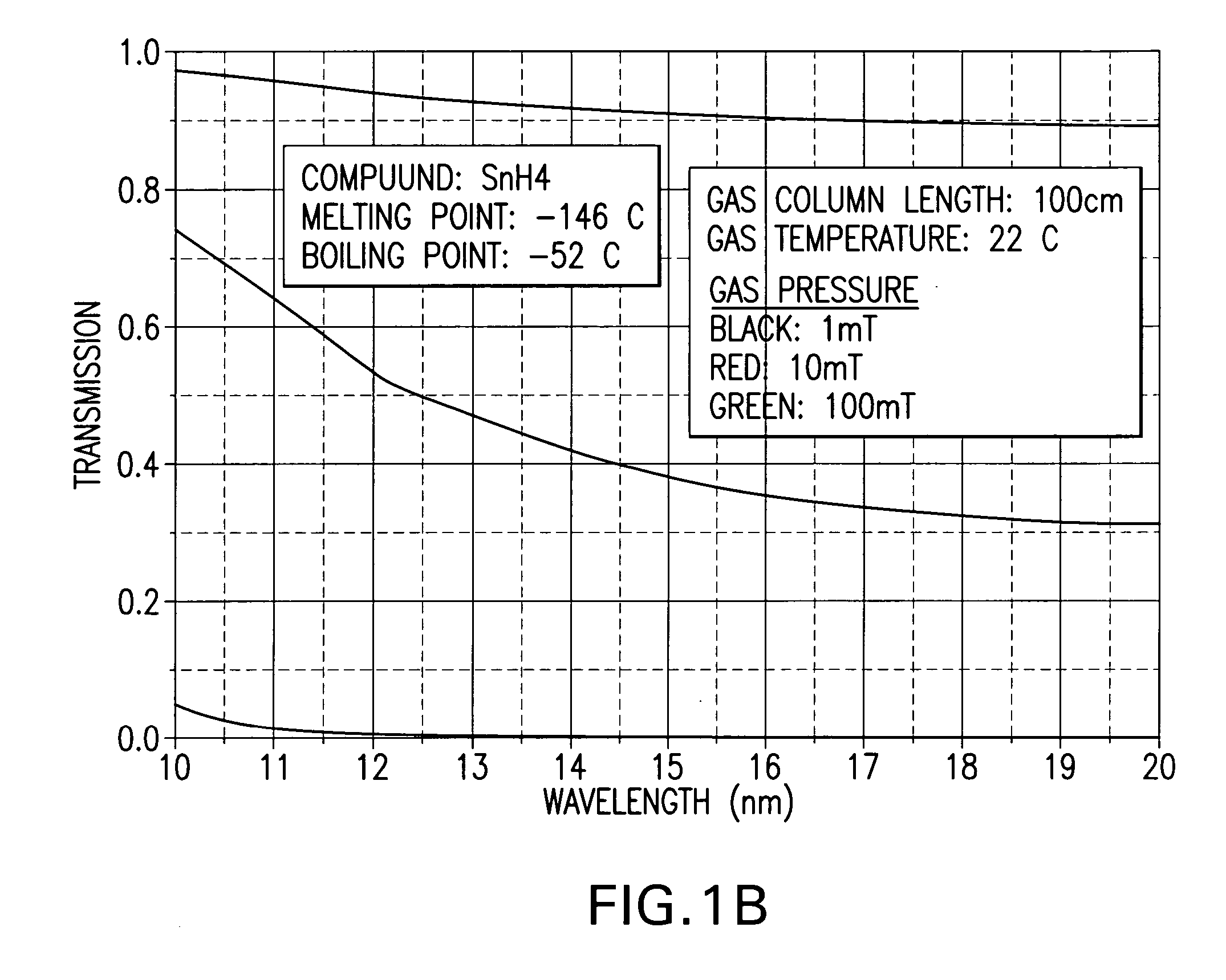

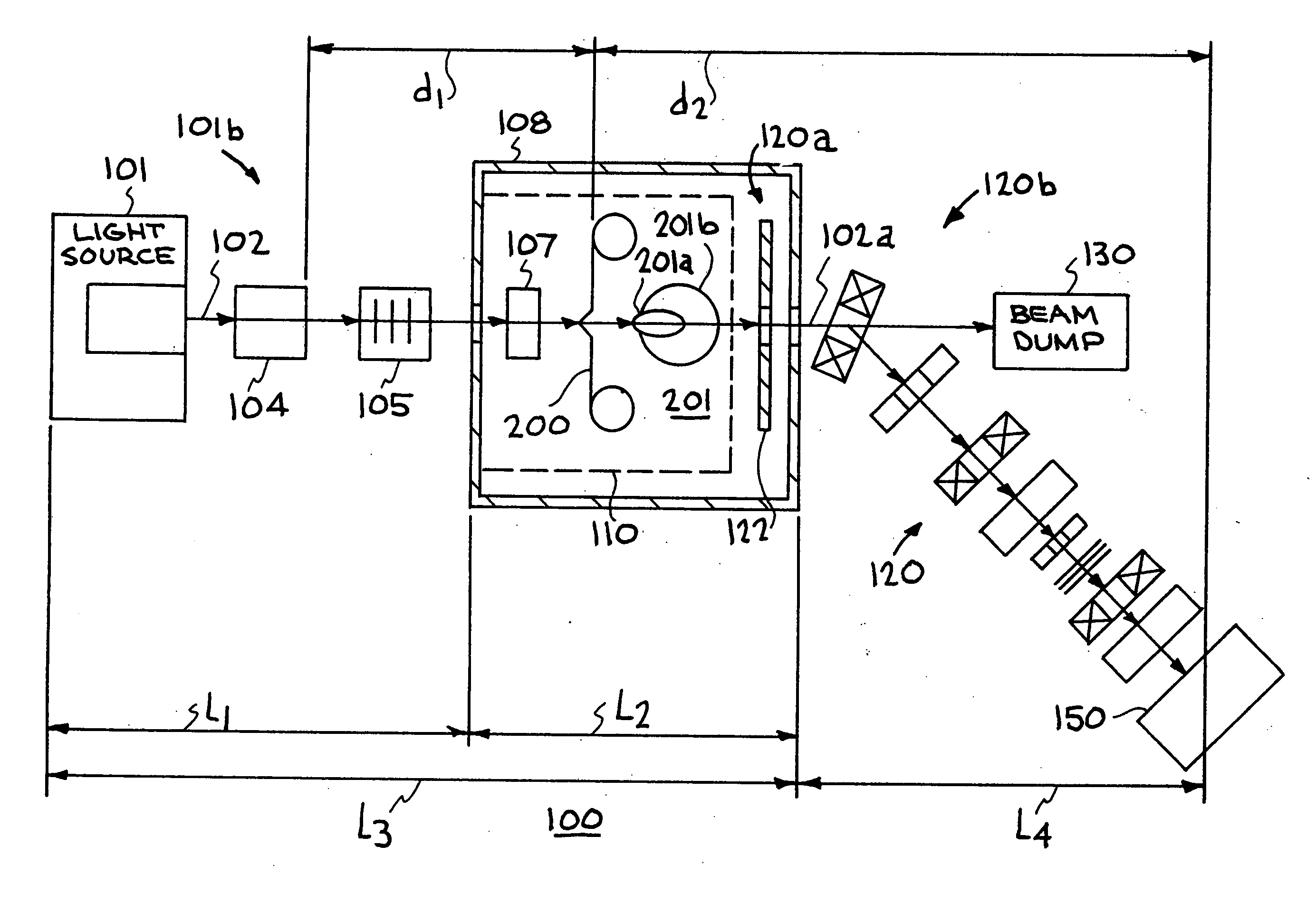

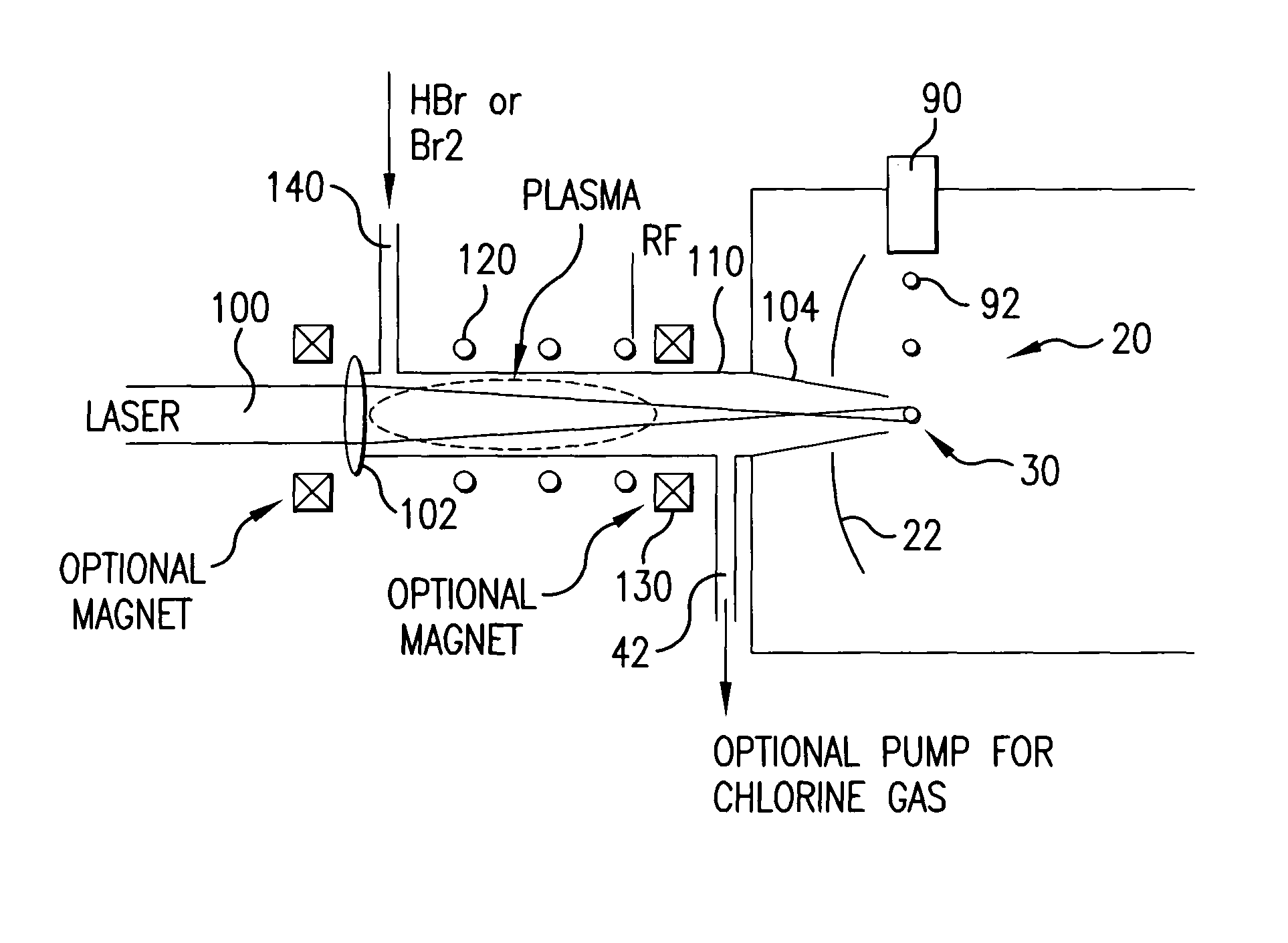

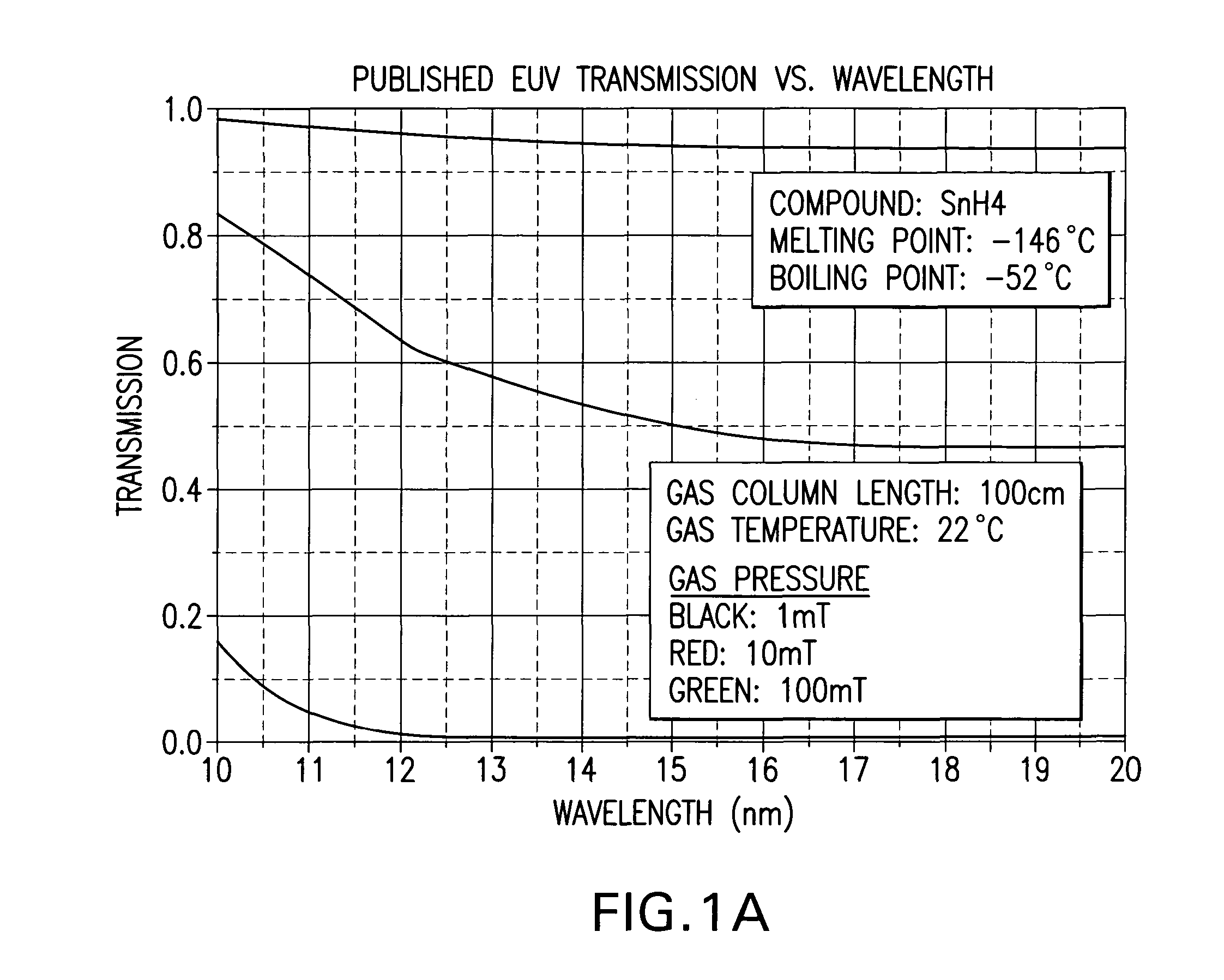

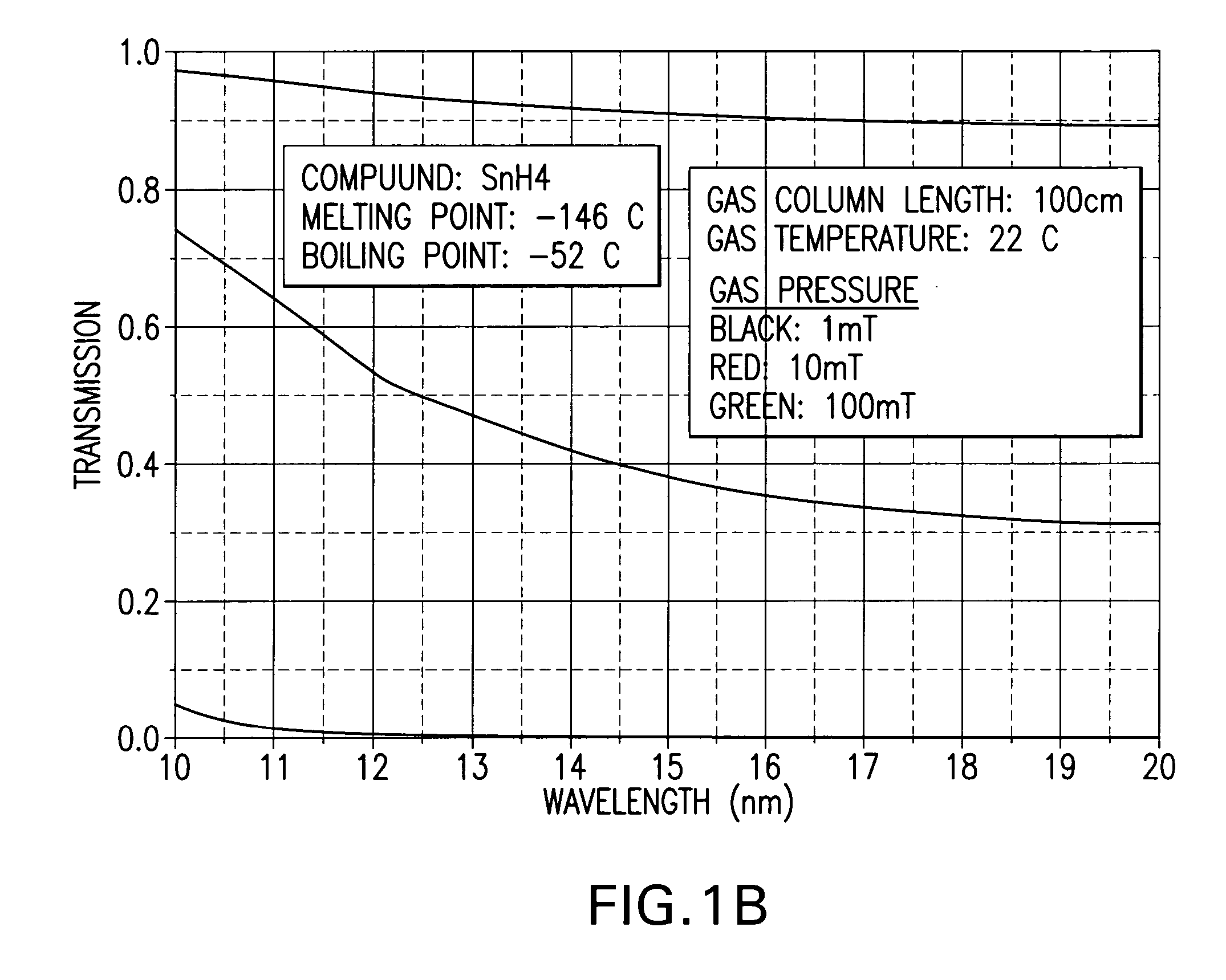

EUV collector debris management

InactiveUS20060091109A1Reduce reflectivityLow material performance requirementsDecorative surface effectsSemiconductor/solid-state device manufacturingEtchingSource material

A method and apparatus that may comprise an EUV light producing mechanism utilizing an EUV plasma source material comprising a material that will form an etching compound, which plasma source material produces EUV light in a band around a selected center wavelength comprising: an EUV plasma generation chamber; an EUV light collector contained within the chamber having a reflective surface containing at least one layer comprising a material that does not form an etching compound and / or forms a compound layer that does not significantly reduce the reflectivity of the reflective surface in the band; an etchant source gas contained within the chamber comprising an etchant source material with which the plasma source material forms an etching compound, which etching compound has a vapor pressure that will allow etching of the etching compound from the reflective surface. The etchant source material may comprises a halogen or halogen compound. The etchant source material may be selected based upon the etching being stimulated in the presence of photons of EUV light and / or DUV light and / or any excited energetic photons with sufficient energy to stimulate the etching of the plasma source material. The apparatus may further comprise an etching stimulation plasma generator providing an etching stimulation plasma in the working vicinity of the reflective surface; and the etchant source material may be selected based upon the etching being stimulated by an etching stimulation plasma. There may also be an ion accelerator accelerating ions toward the reflective surface. The ions may comprise etchant source material. The apparatus and method may comprise a part of an EUV production subsystem with an optical element to be etched of plasma source material.

Owner:ASML NETHERLANDS BV

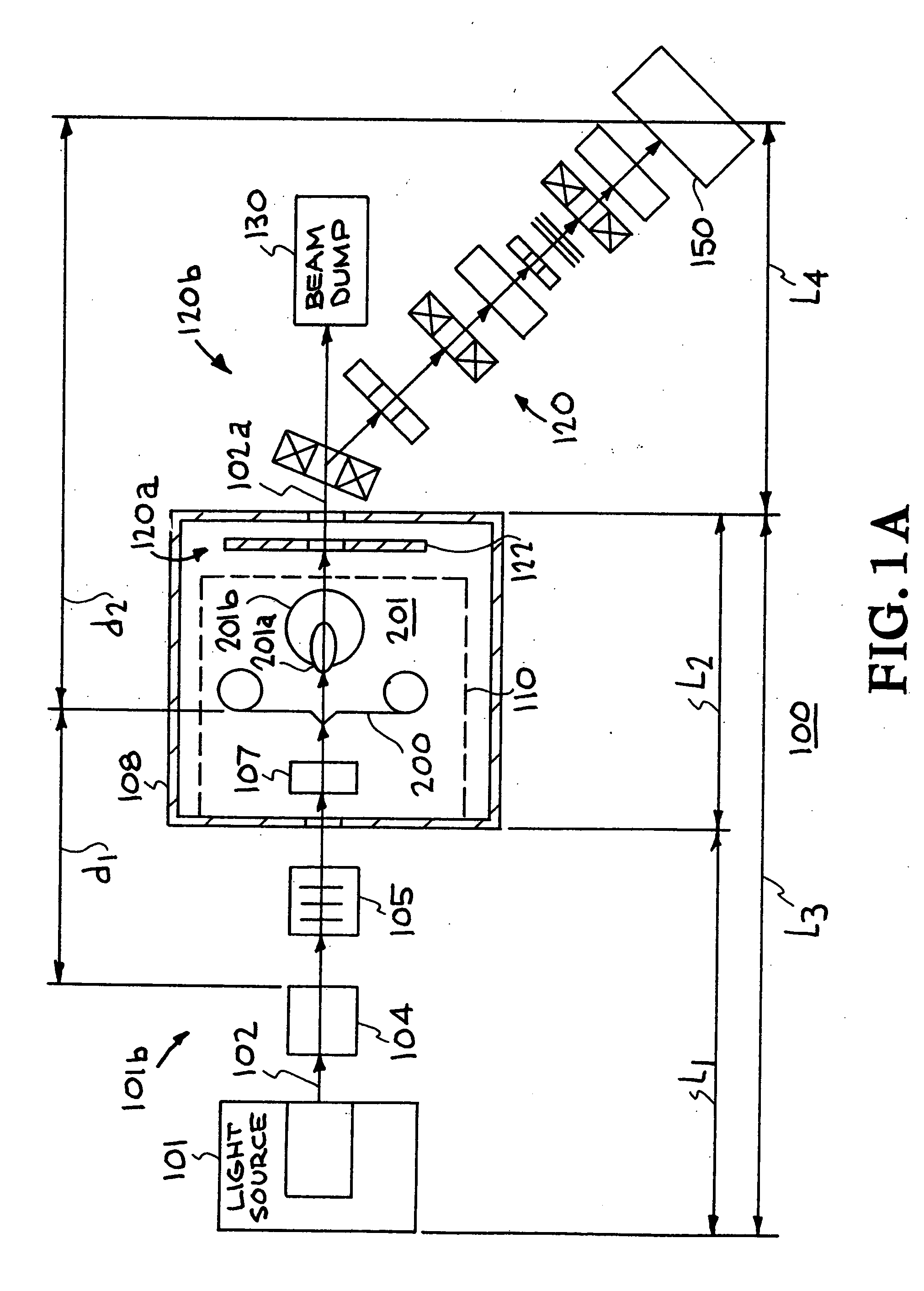

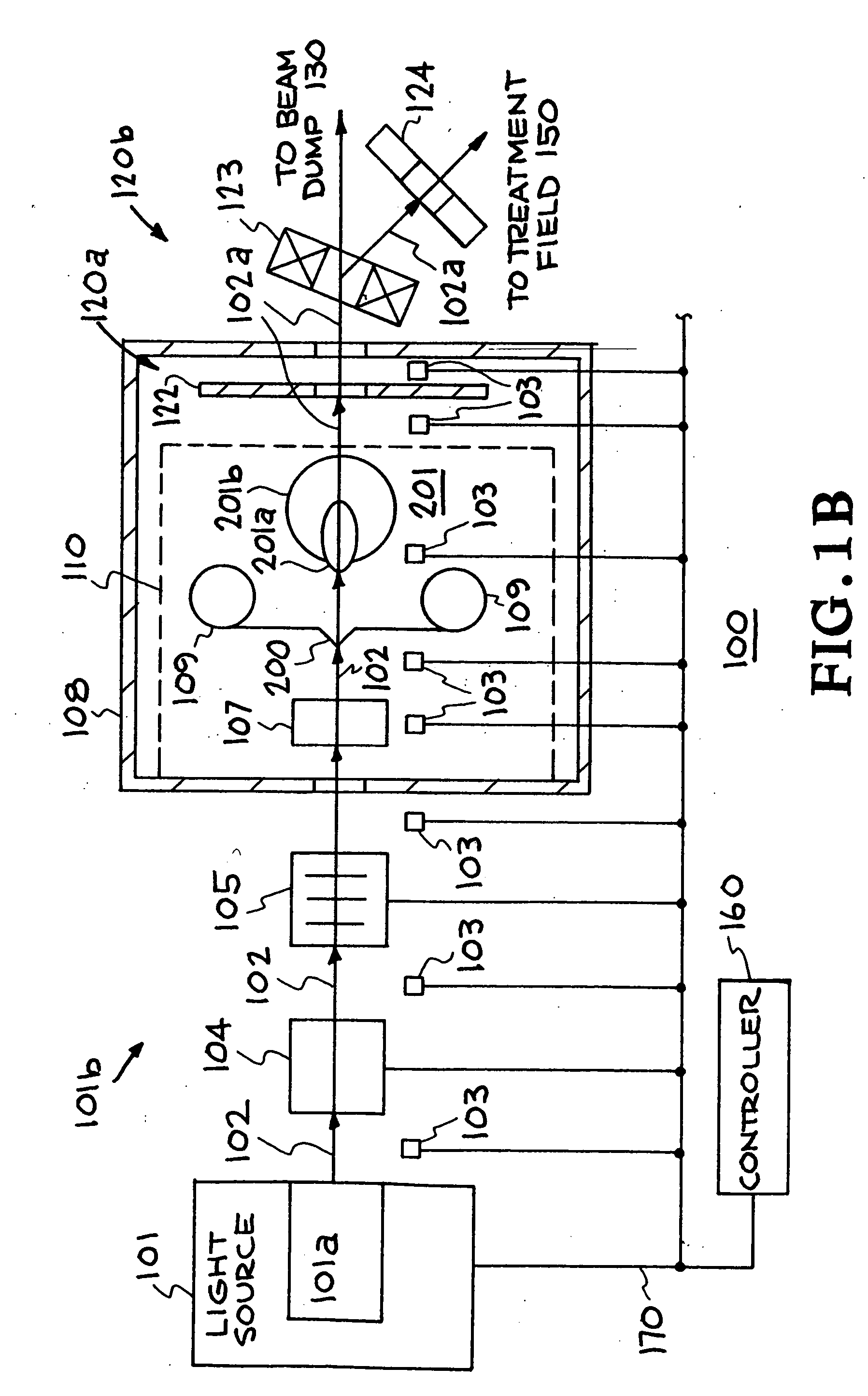

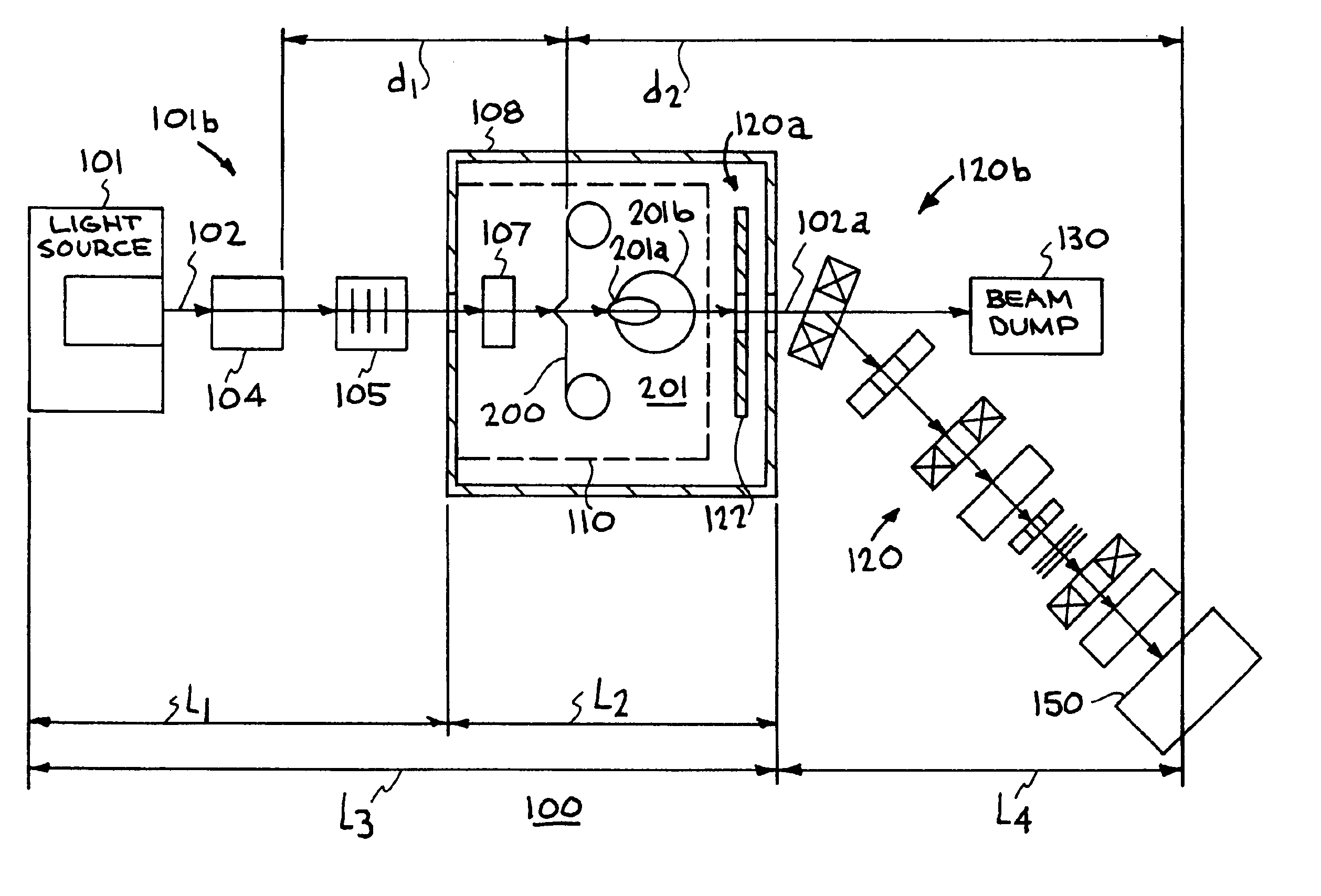

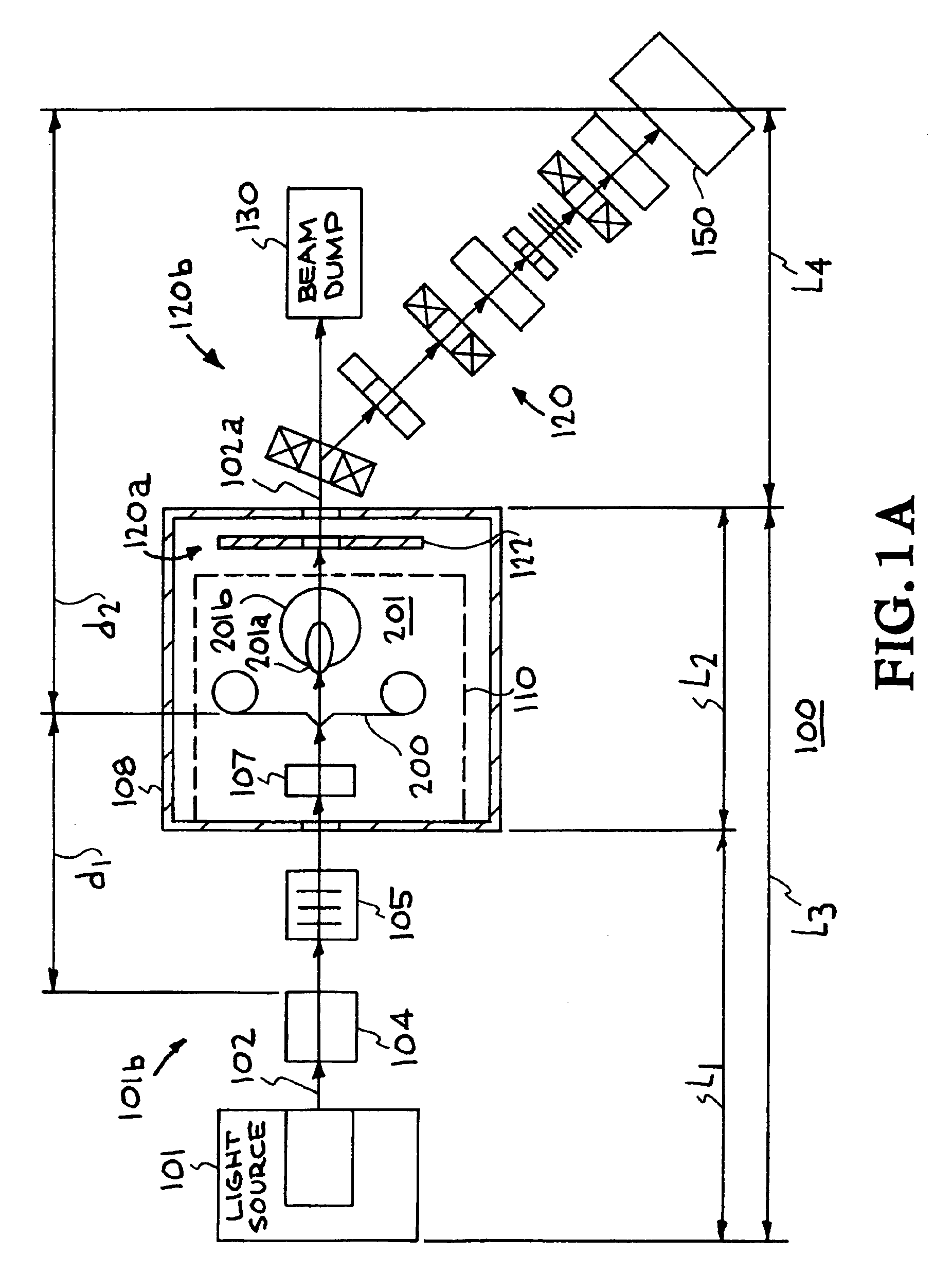

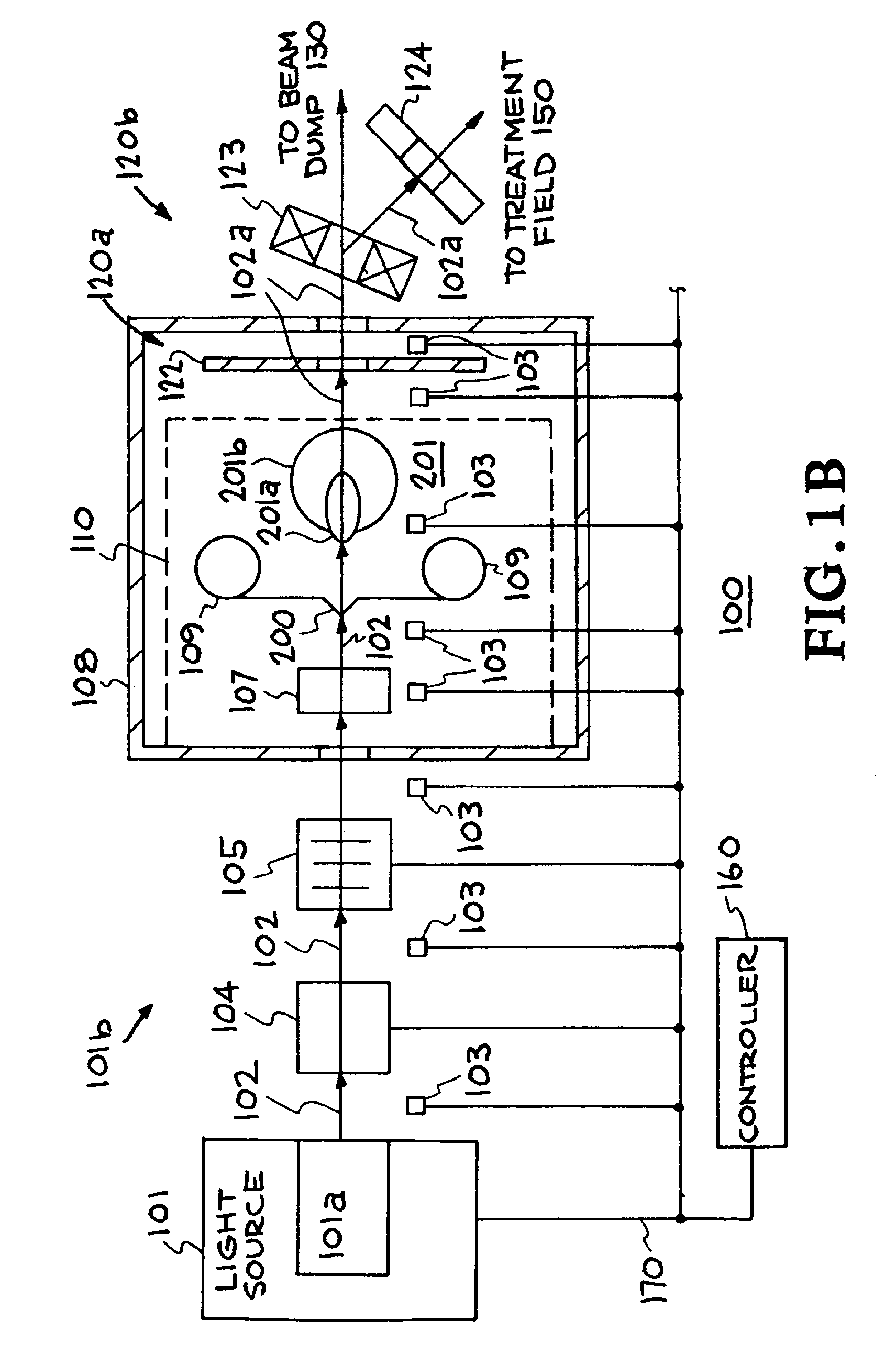

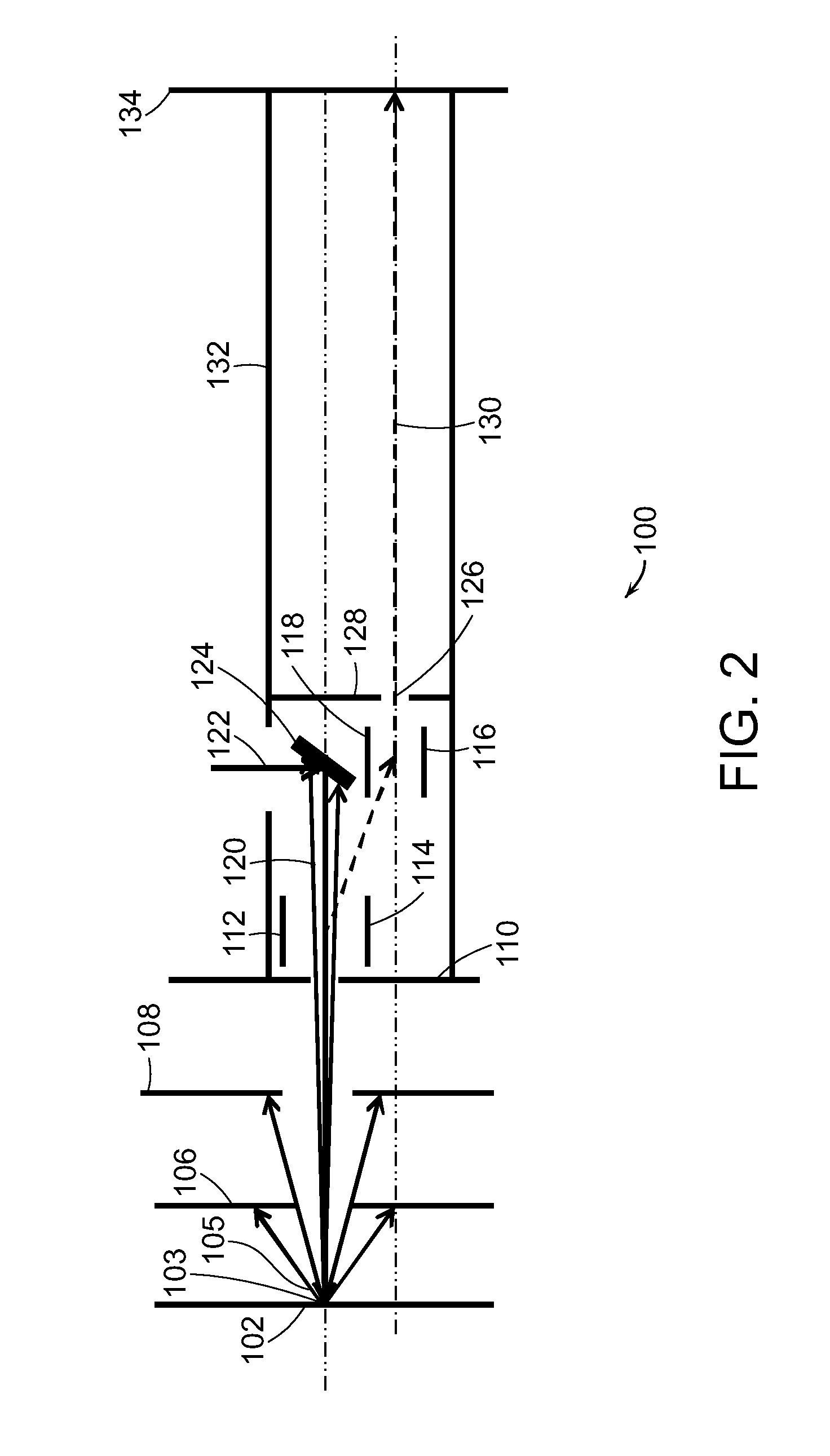

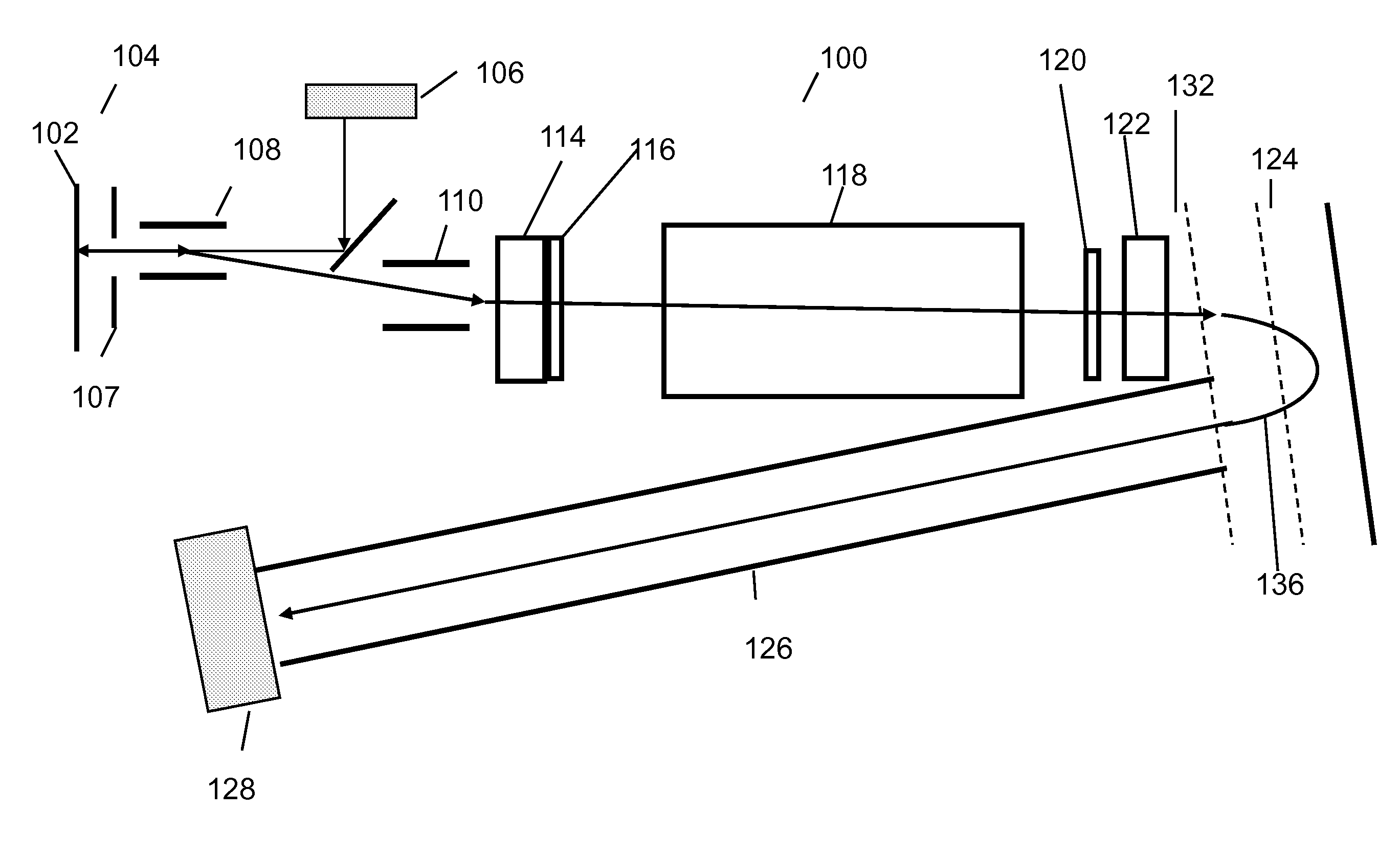

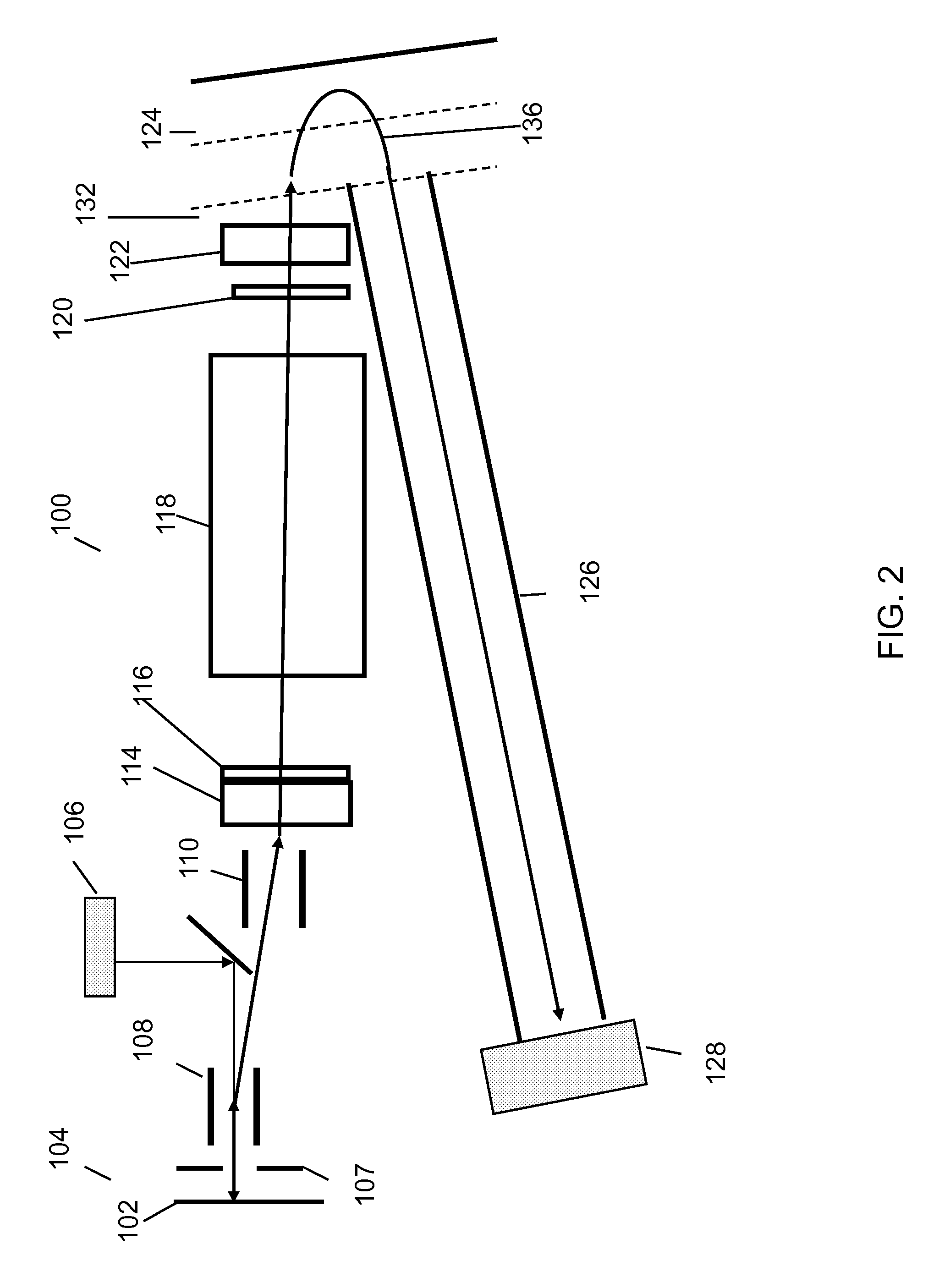

Laser driven ion accelerator

InactiveUS20050167610A1Thermometer detailsStability-of-path spectrometersIon accelerationIon accelerators

A system and method of accelerating ions in an accelerator to optimize the energy produced by a light source. Several parameters may be controlled in constructing a target used in the accelerator system to adjust performance of the accelerator system. These parameters include the material, thickness, geometry and surface of the target.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

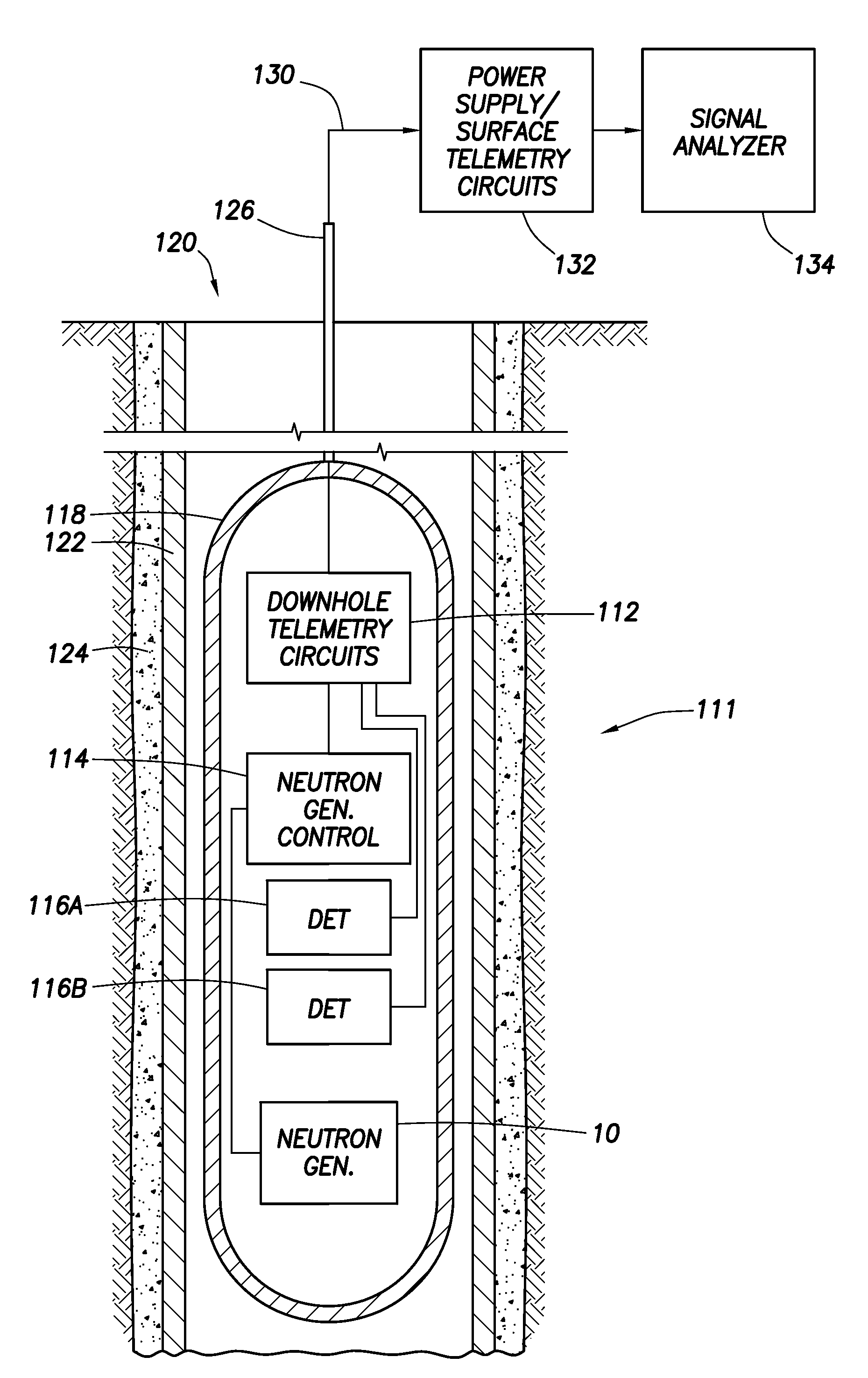

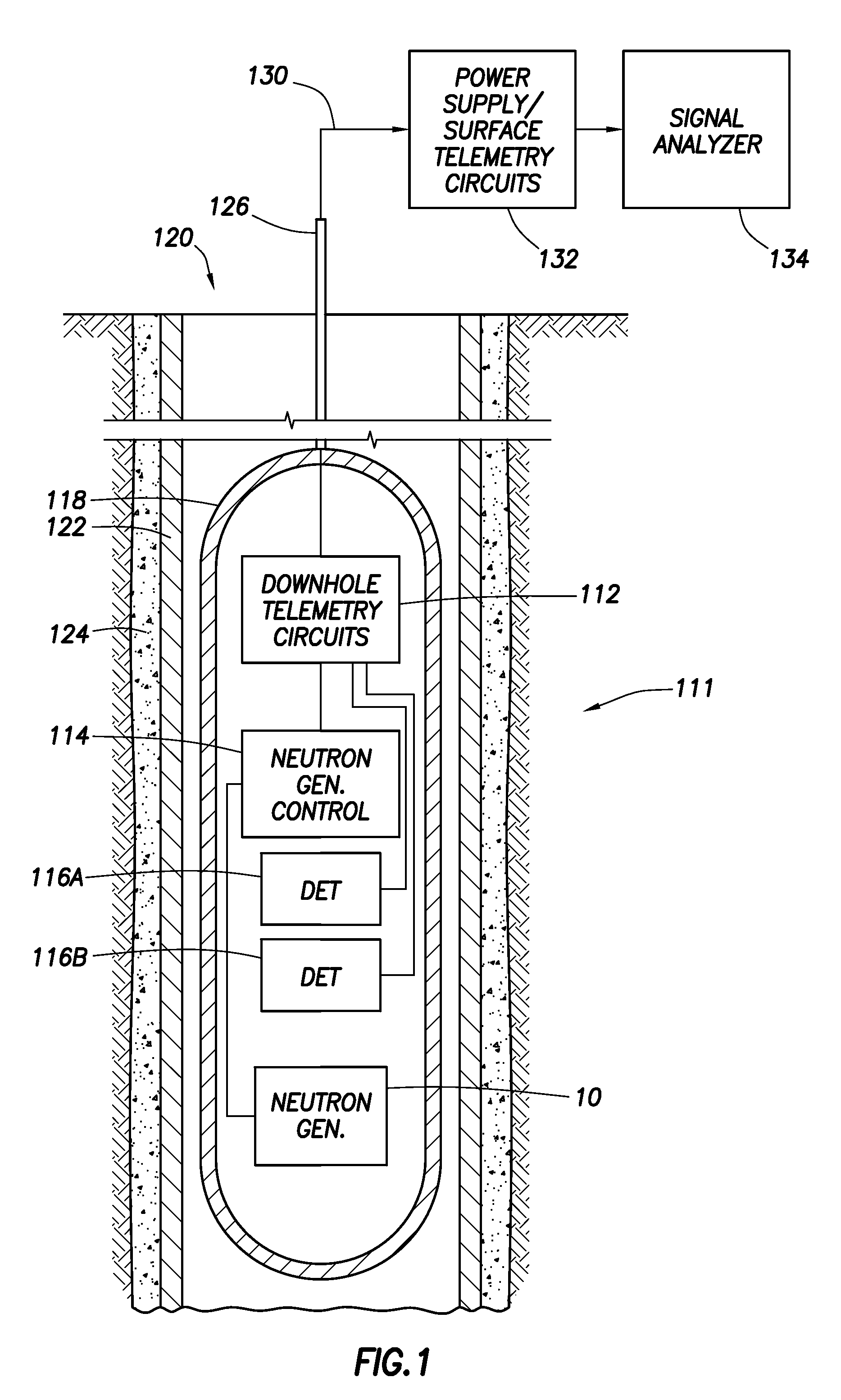

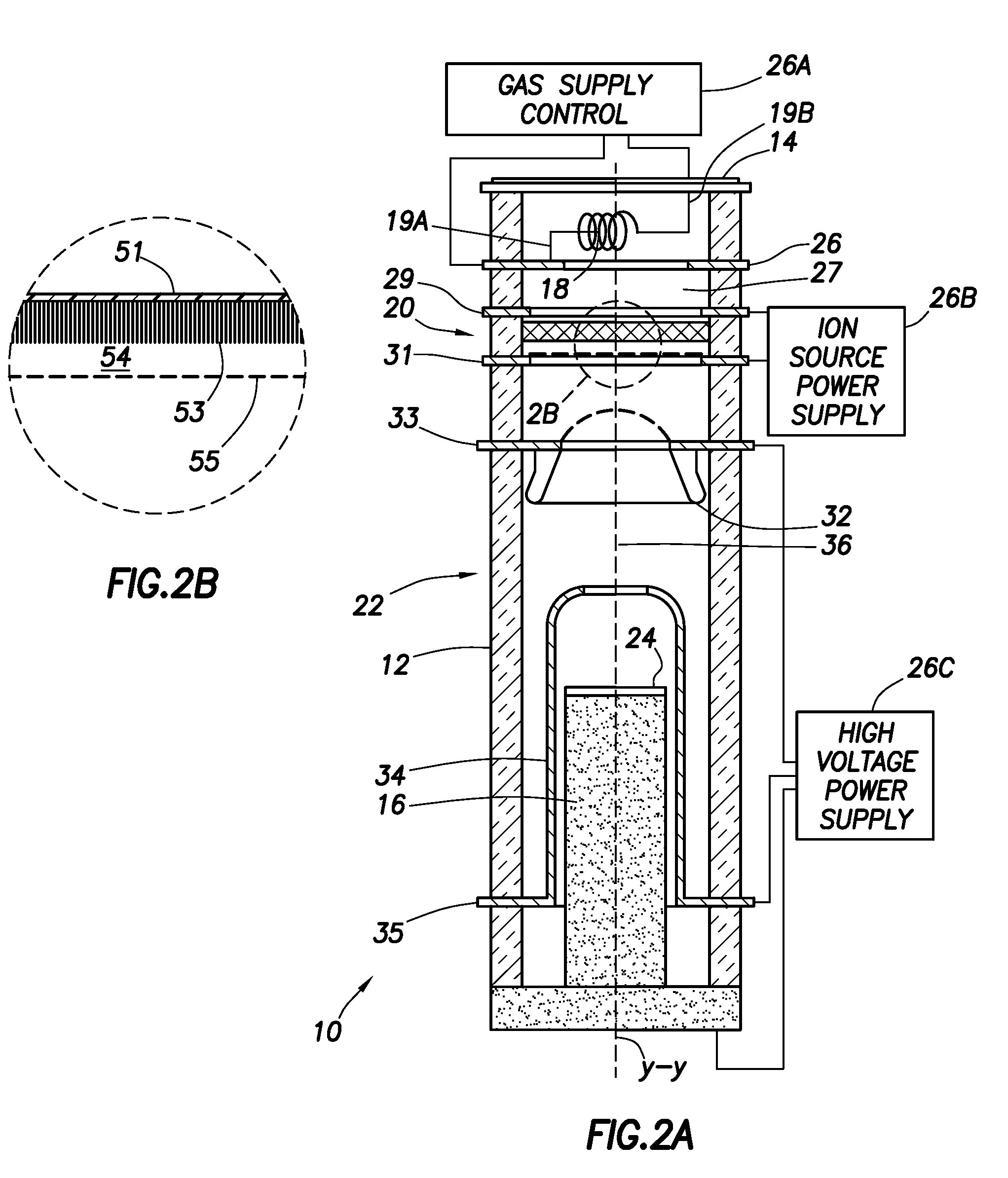

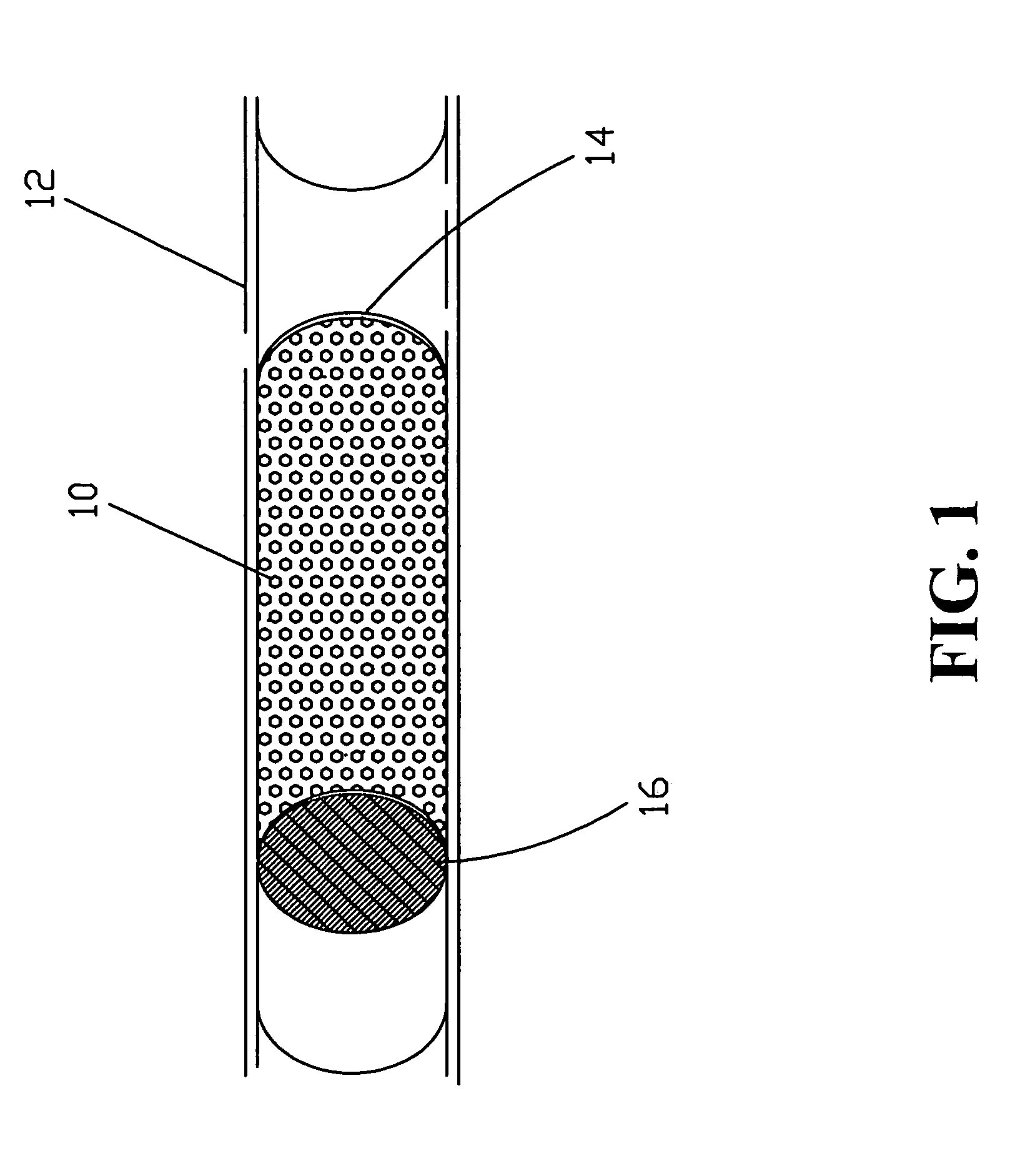

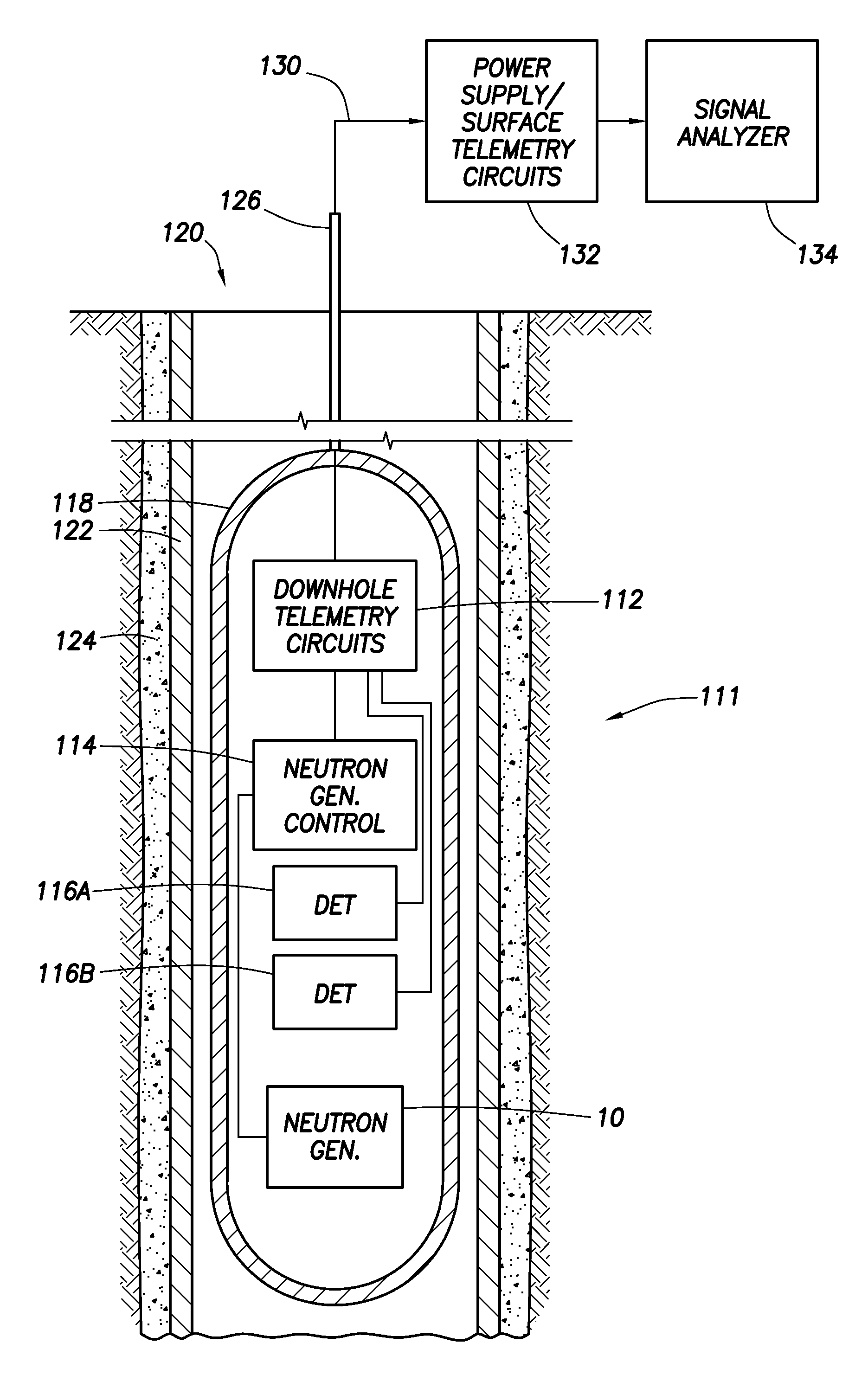

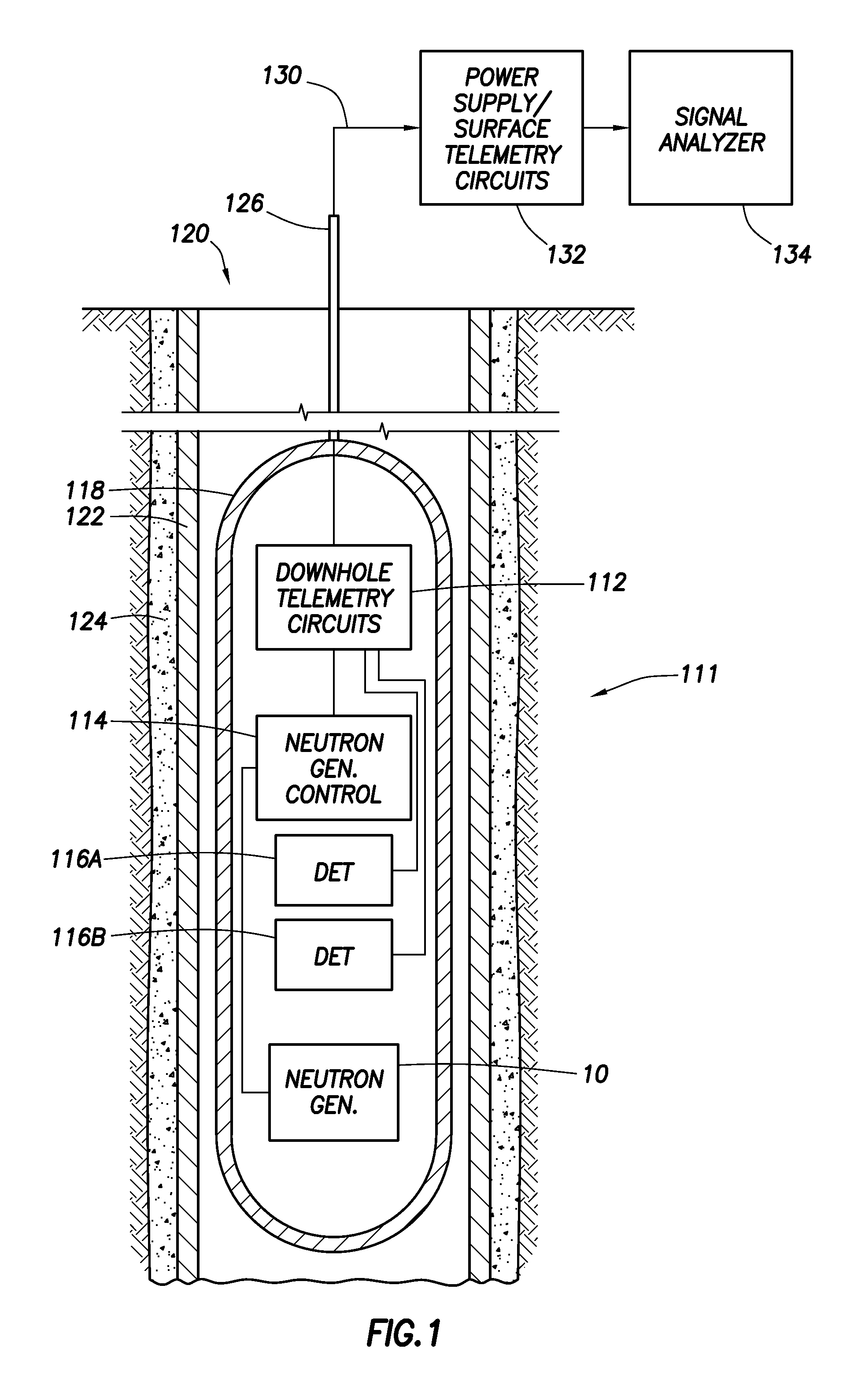

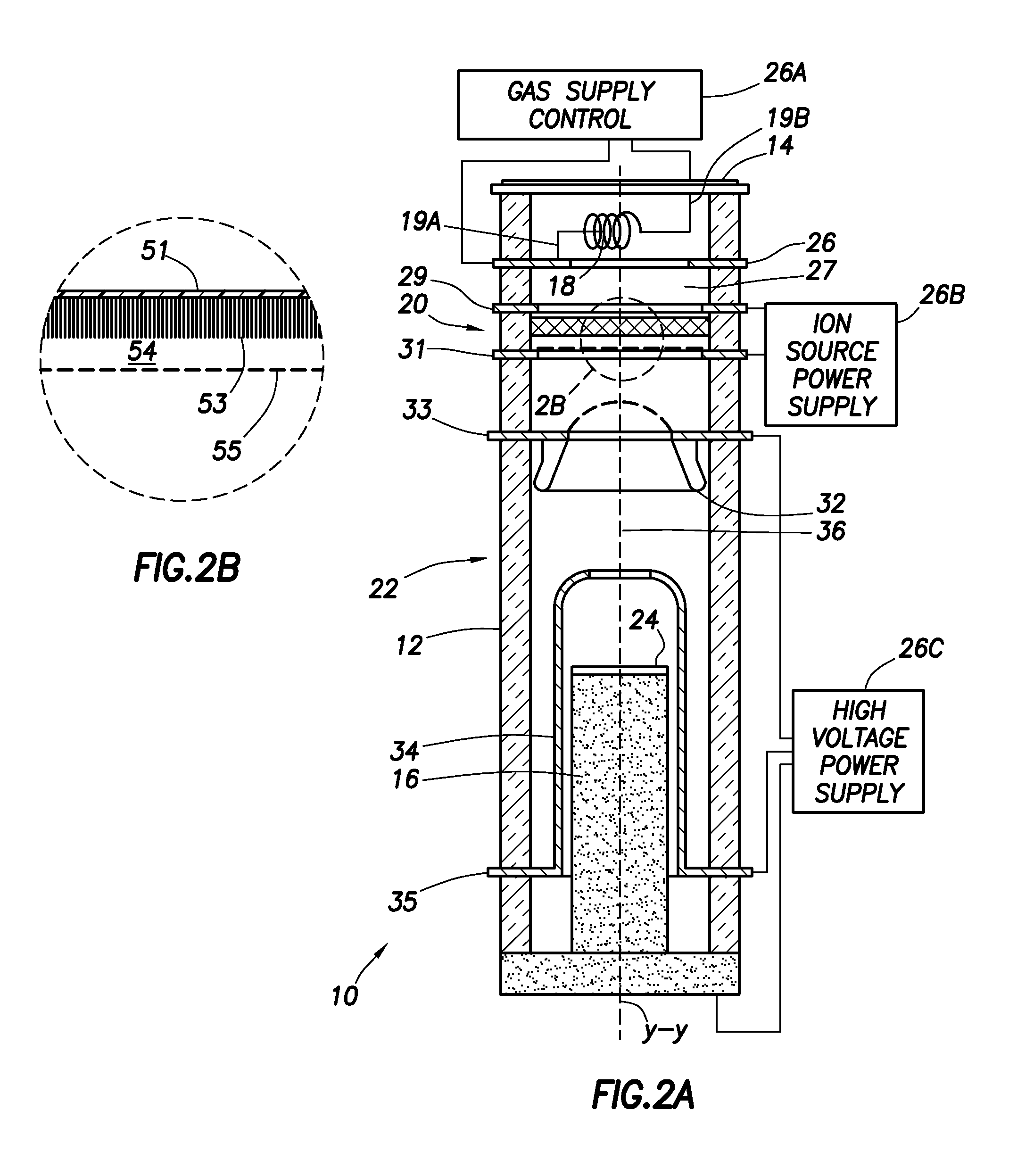

Neutron Generator

A neutron generator includes an ion source disposed in a pressurized environment containing an ionizable gas. The ion source includes a substrate with a bundle of carbon nanotubes extending therefrom. The ends of the nanotubes are spaced from a grid. Ion source voltage supply circuitry supplies a positive voltage potential between the substrate and the grid of the ion source to cause ionization of the ionizable gas and emission of ions through the grid. An ion accelerator section is disposed between the ion source and a target. The ion accelerator section accelerates ions that pass through the grid towards the target such that collisions of the ions with the target cause the target to generate and emit neutrons therefrom. The ion source, accelerator section and target are housed in a sealed tube and preferably the carbon nanotubes of the bundle are highly ordered with at least 106 carbon nanotubes per cm2 that extend in a direction substantially parallel to the central axis of the tube. The neutron generator provides gas ionization at much higher atomic to molecular ratio that the prior art, which allows for small compact size designs suitable for logging tools that are used in space-constrained downhole environments.

Owner:SCHLUMBERGER TECH CORP

Laser driven ion accelerator

InactiveUS6906338B2Thermometer detailsStability-of-path spectrometersIon accelerationIon accelerators

A system and method of accelerating ions in an accelerator to optimize the energy produced by a light source. Several parameters may be controlled in constructing a target used in the accelerator system to adjust performance of the accelerator system. These parameters include the material, thickness, geometry and surface of the target.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Linear ion accelerator

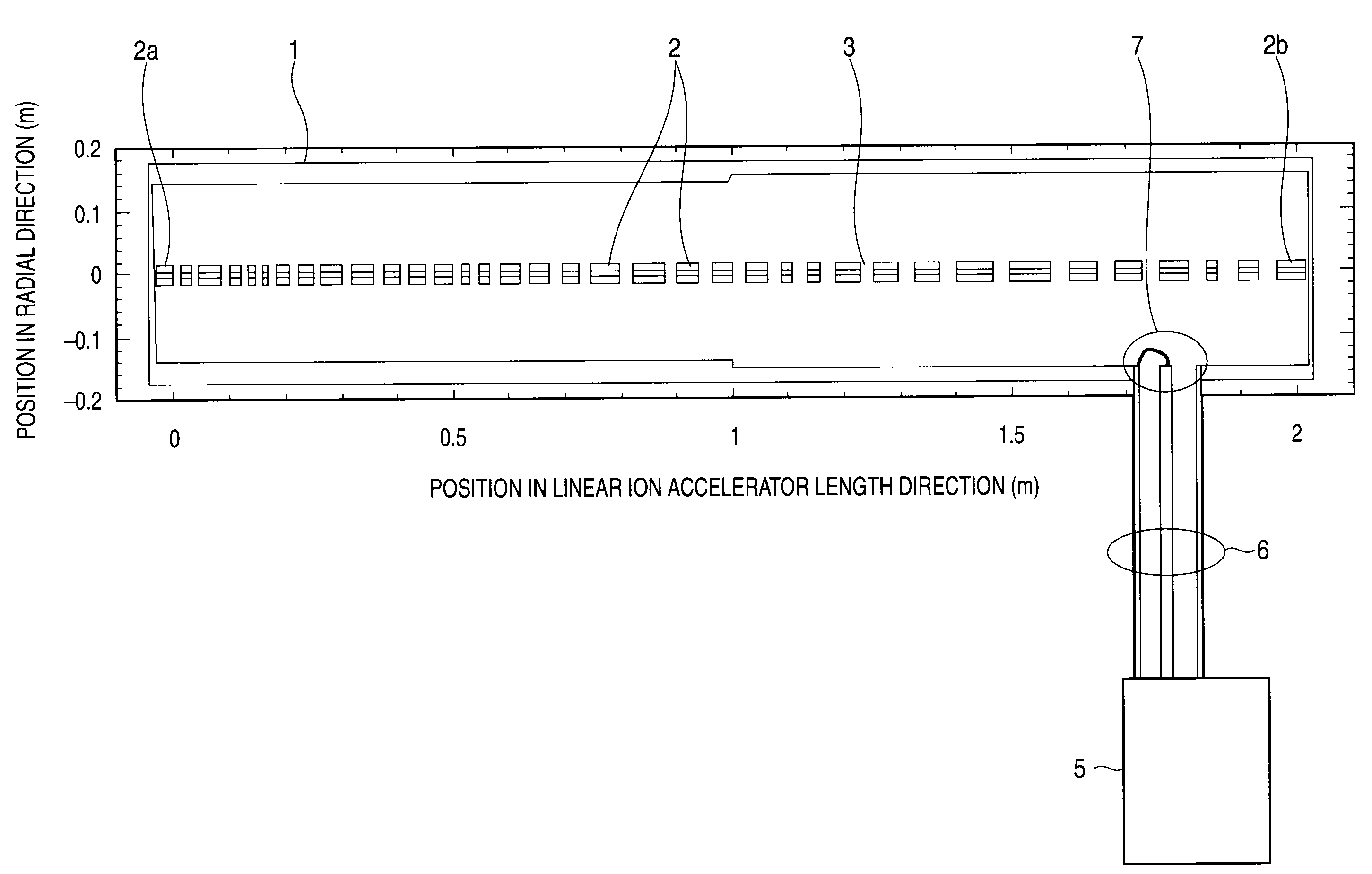

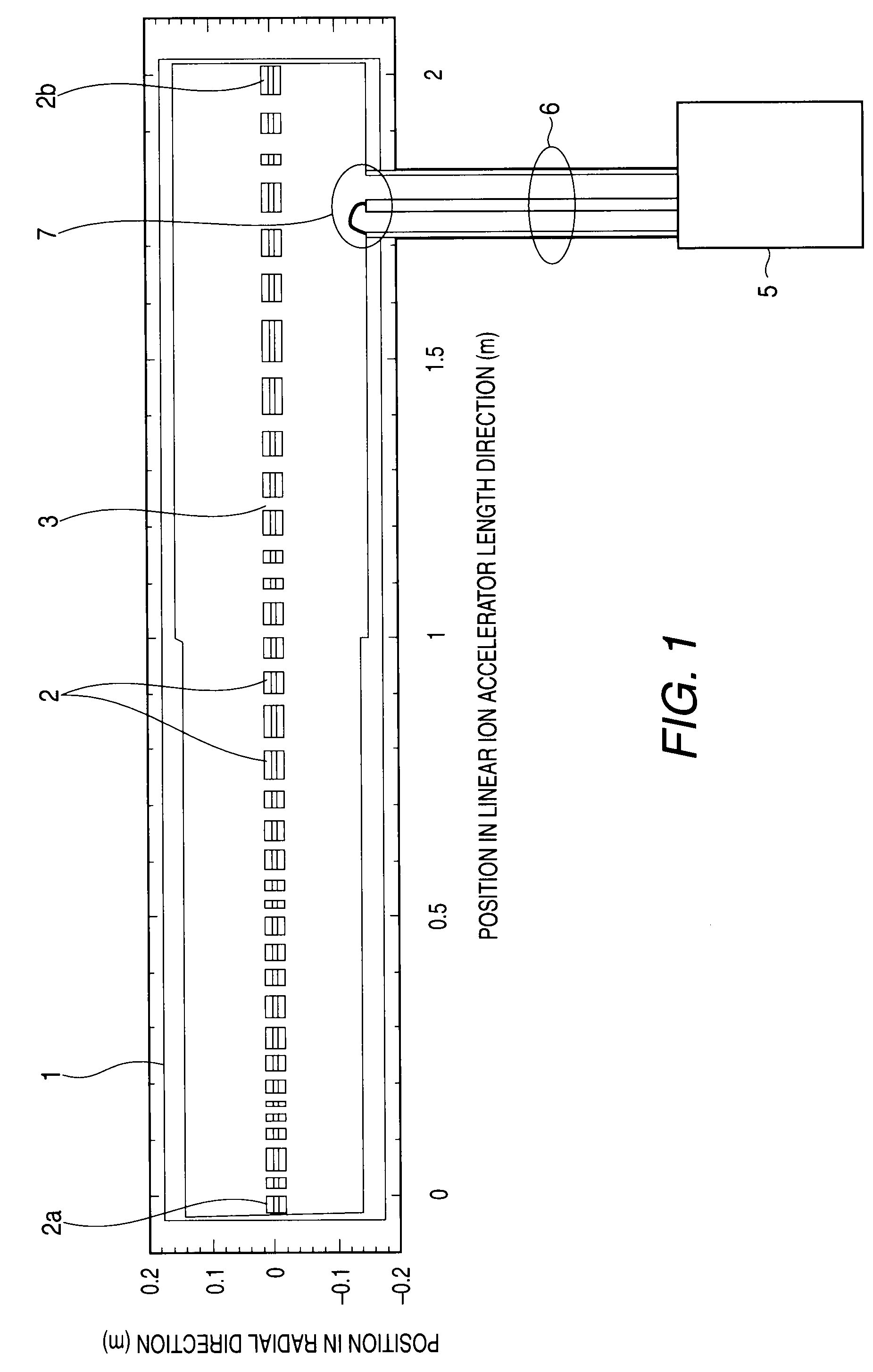

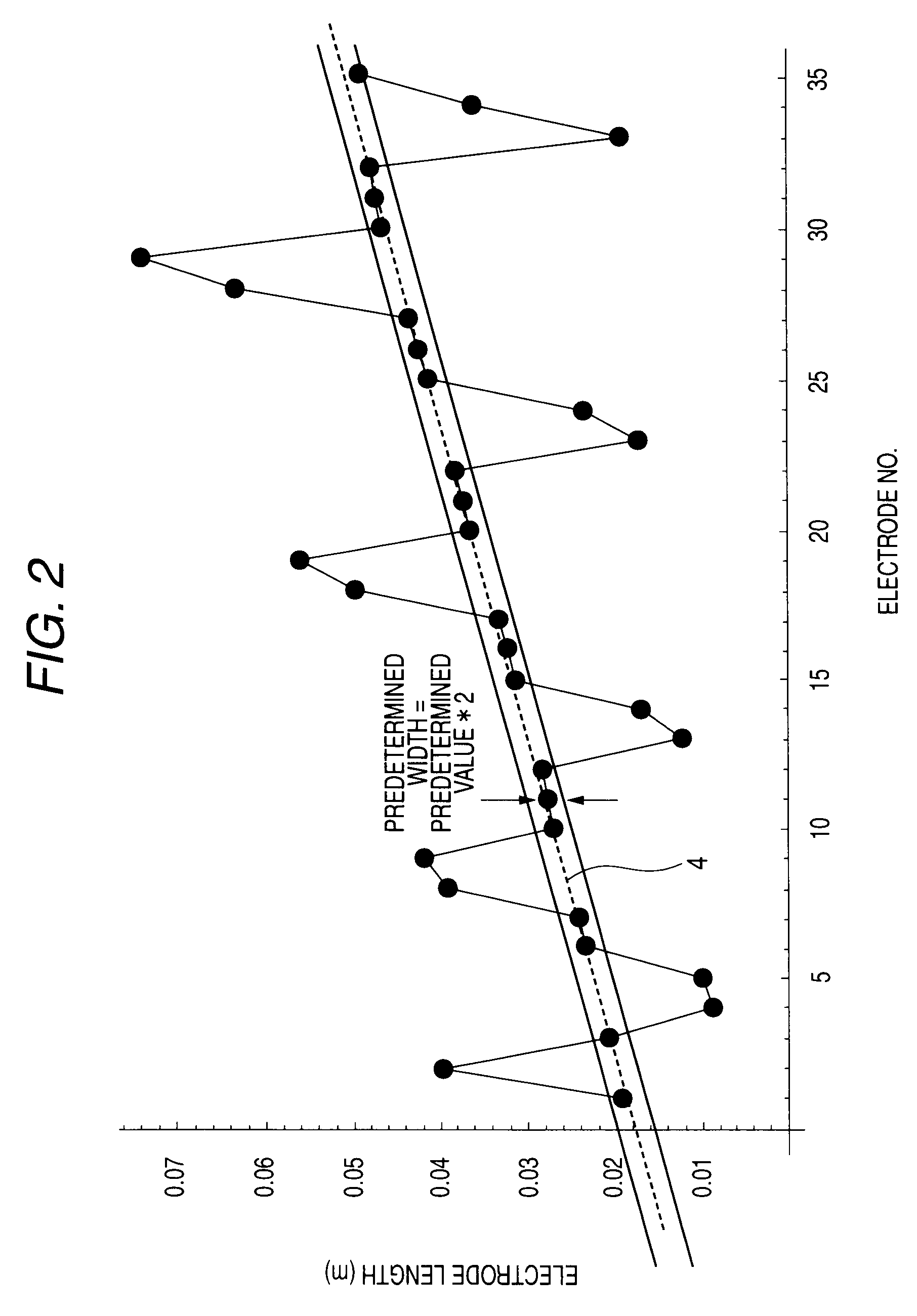

ActiveUS7609009B2Affect produced by the space charge effect is increasedEasy to divergeStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsIon beamIon acceleration

The electrode lengths of a plurality of electrodes linearly arranged in an acceleration cavity are proportional to the velocity of a traveling ion beam. Further, the electrode length is so designated that, in each half of a predetermined cycle in the ion beam direction of travel, the absolute value of a difference, relative to a length that is proportional to the beam traveling velocity is equal to or greater than a value corresponding to the phase width of the traveling ion beam, is provided for electrodes that do not exceed three units and that are fewer than electrodes allotted to half the predetermined cycle.

Owner:MITSUBISHI ELECTRIC CORP

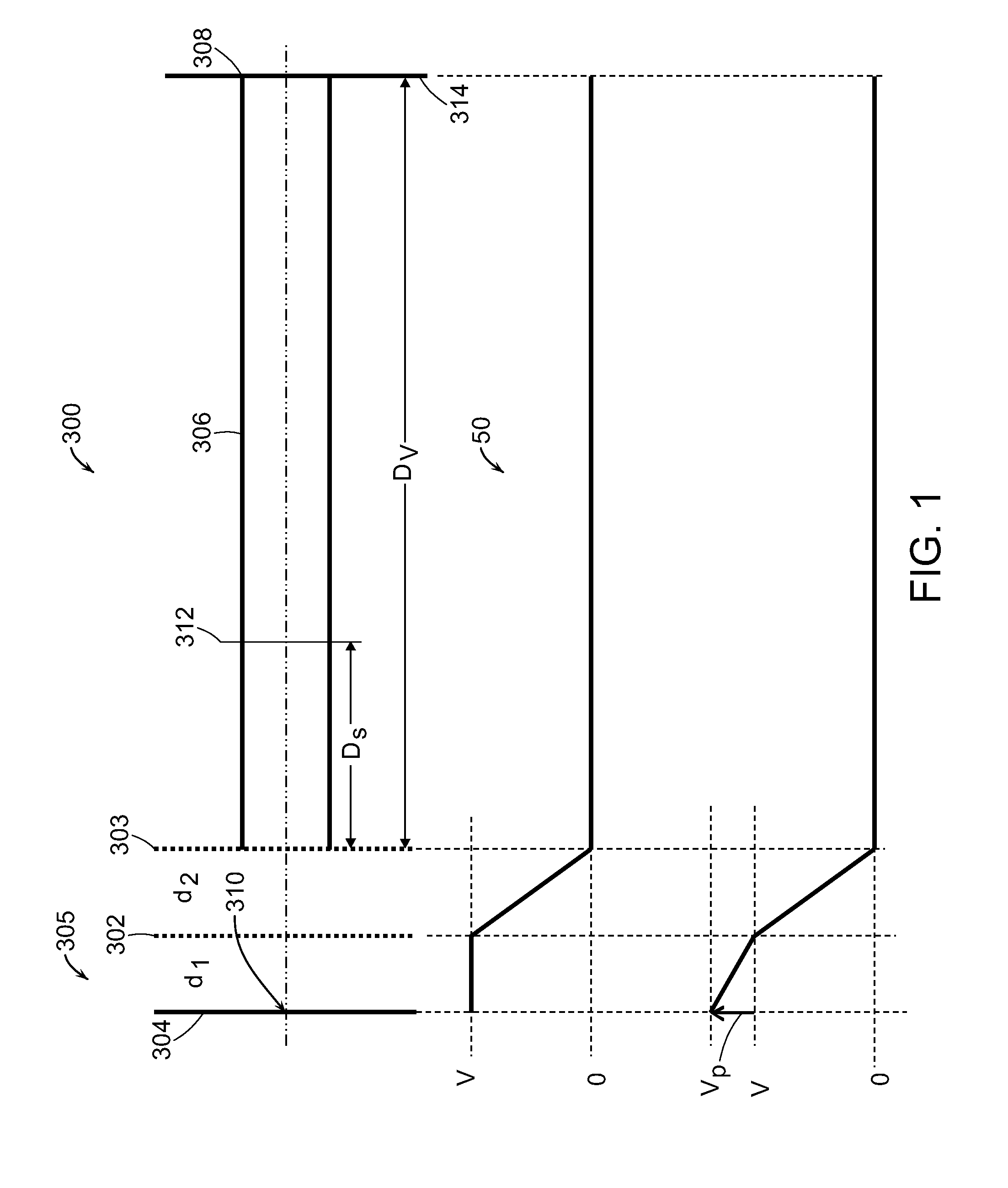

Ion Optical System For MALDI-TOF Mass Spectrometer

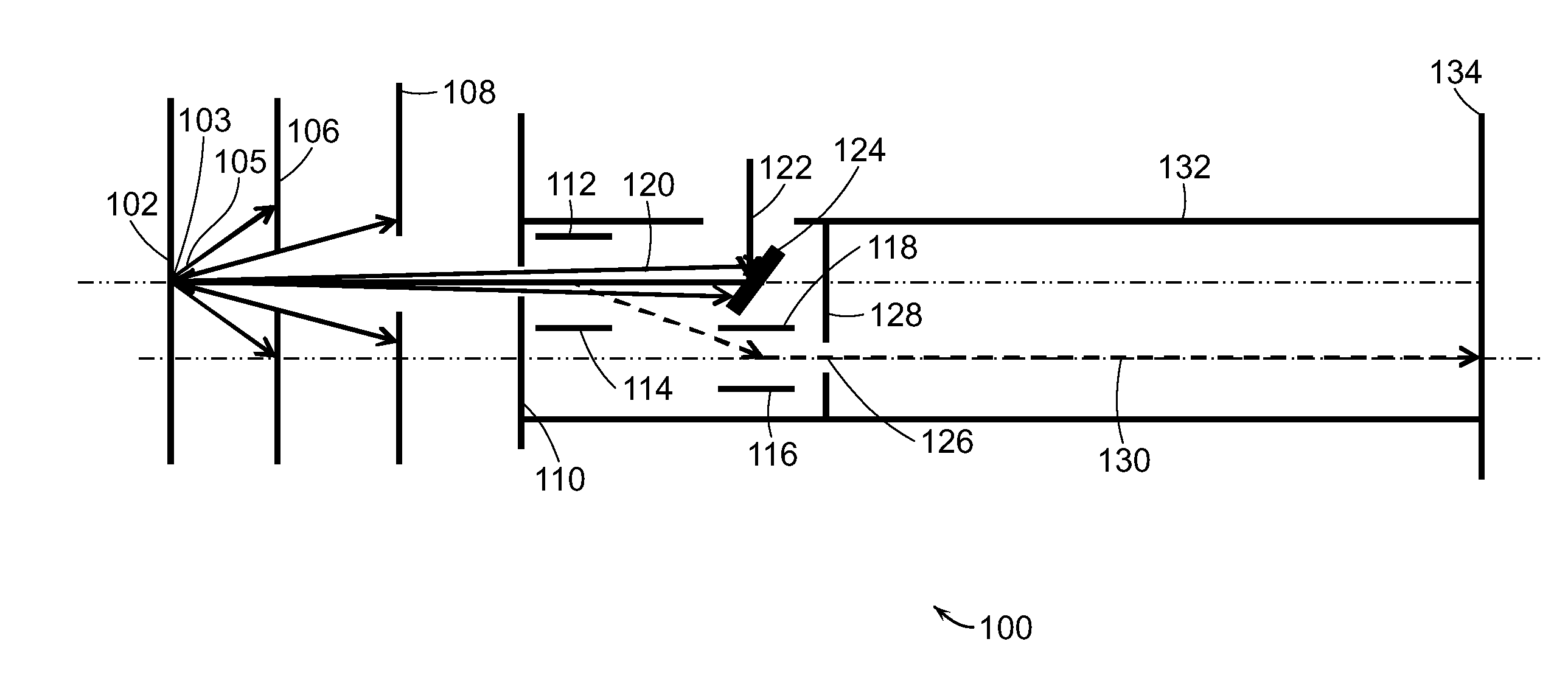

ActiveUS20150048245A1Sufficient massSufficient powerStability-of-path spectrometersTime-of-flight spectrometersElectricityMass analyzer

An ion accelerator for a time-of-flight mass spectrometer includes a pulsed ion accelerator positioned proximate to a sample plate and having an electrode that is electrically connected to the sample plate. An accelerator power supply generates an accelerating potential on the ion accelerator electrode that accelerates a pulse of ions generated from the sample positioned on the sample plate. An ion focusing electrode is positioned after the pulsed ion accelerator. A potential applied to the ion focusing electrode focuses the pulse of ions into a substantially parallel beam propagating in an ion flight path. A static ion accelerator is positioned proximate to the ion focusing electrode with an input that receives the pulse of ions focused by the ion focusing electrode. The static ion accelerator accelerating the focused pulse of ions.

Owner:VIRGIN INSTR CORP

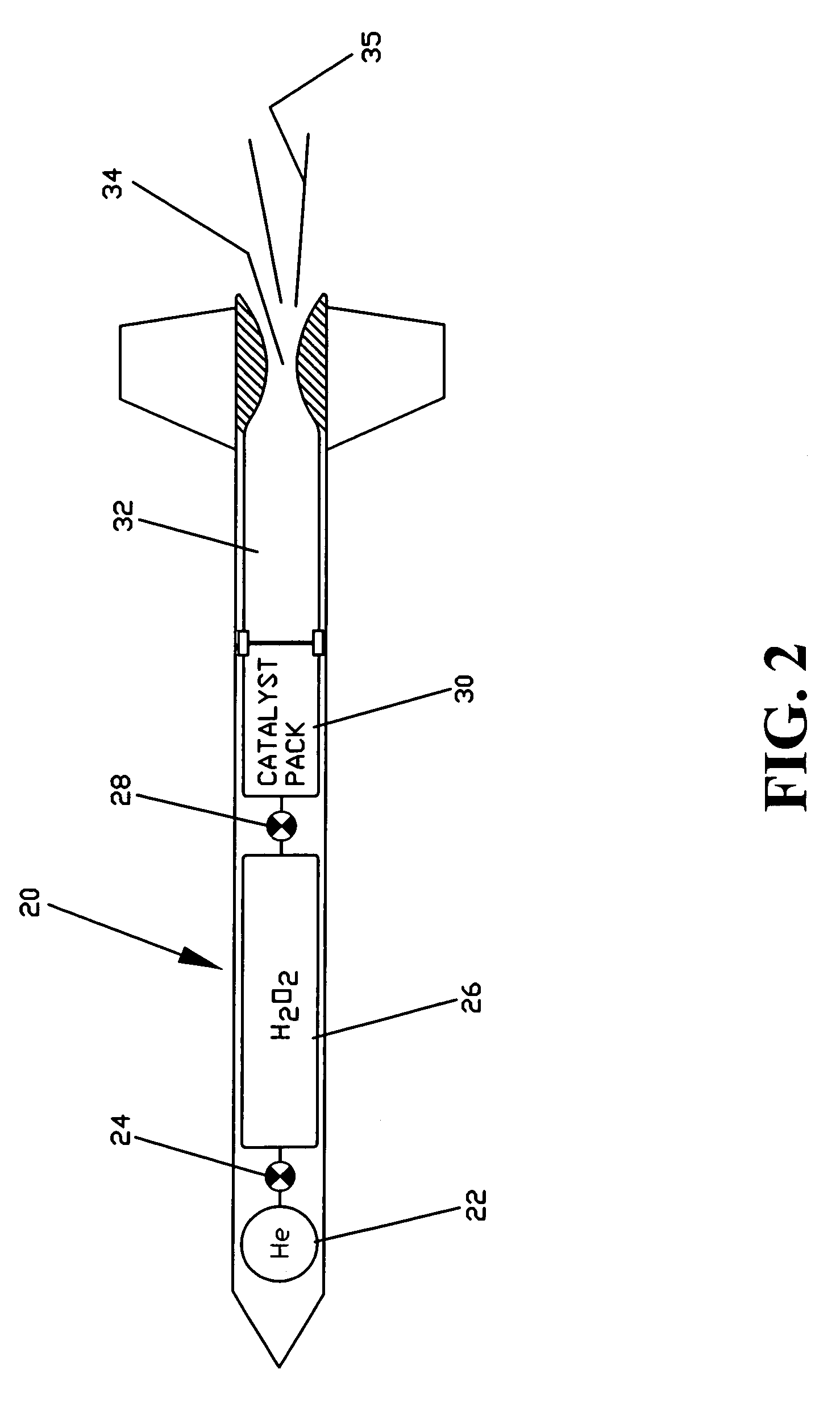

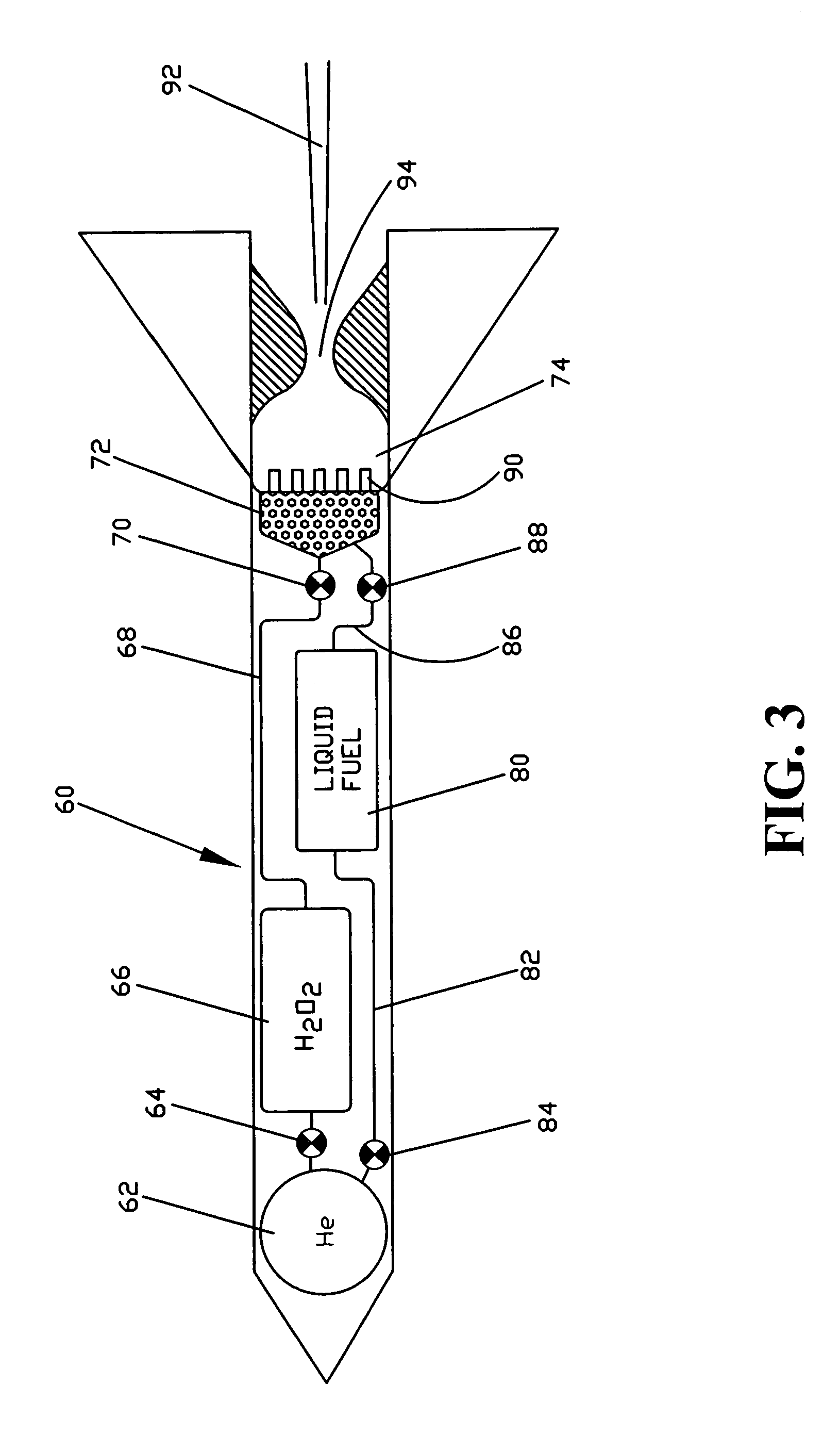

H2O2 decomposition catalyst

InactiveUS6991772B1Promote decompositionLower activation energyOxygen/ozone/oxide/hydroxideMolecular sieve catalystsCombustion chamberDecomposition

An activated catalyst for the rapid decomposition of H2O2 is provided wherein a porous high surface area catalyst base, e.g. a zeolite molecular sieve (ZMS) is impregnated or doped with a solution of metal cation salts and an ionic promoter, dried and calcined to form an activated catalyst. Such activated catalyst, in the form of a porous monolith or chunks, extrudate, pieces, pellets, or spheres, can be poured into and confined, in a tight pack, in a cavity of a rocket housing, downstream of a pressurized H2O2 tank. The H2O2 is flowed through the catalyst and undergoes rapid decomposition into steam and O2 and flows out the propellant nozzle of such rocket. Advantages of such activated catalyst are that it can be employed to rapidly decompose H2O2 to propel a) a mono-propellant rocket, b) a bipropellant rocket (having fuel and a combustion chamber) and c) a hybrid rocket (powered by H2O2 and fuel grain) and can also be used for a starter cartridge decomposition catalyst, a gas generator decomposition catalyst and the like. Another benefit of the activated catalyst of the invention is its low weight which is highly suitable in small flightweight rocket systems.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

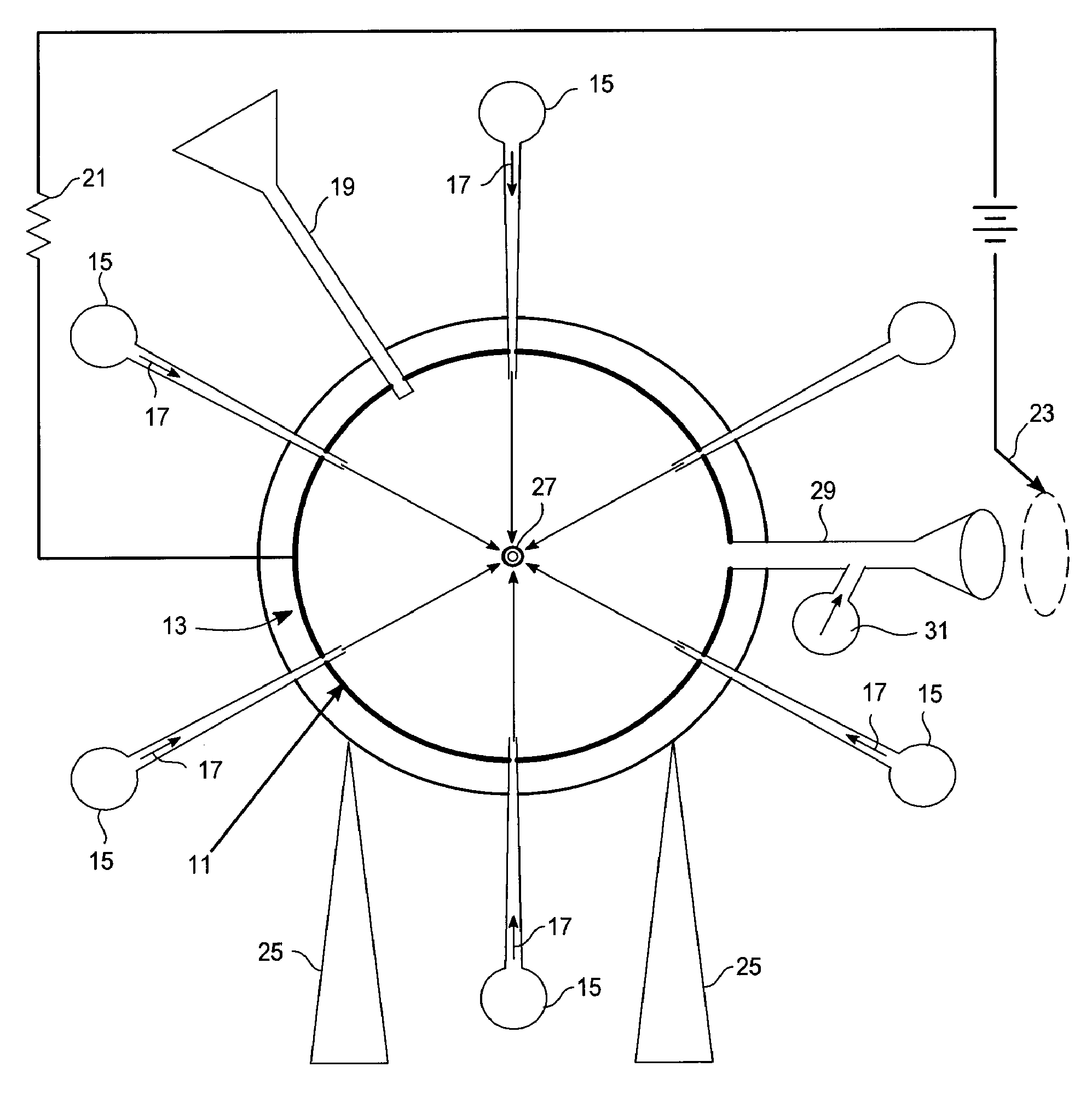

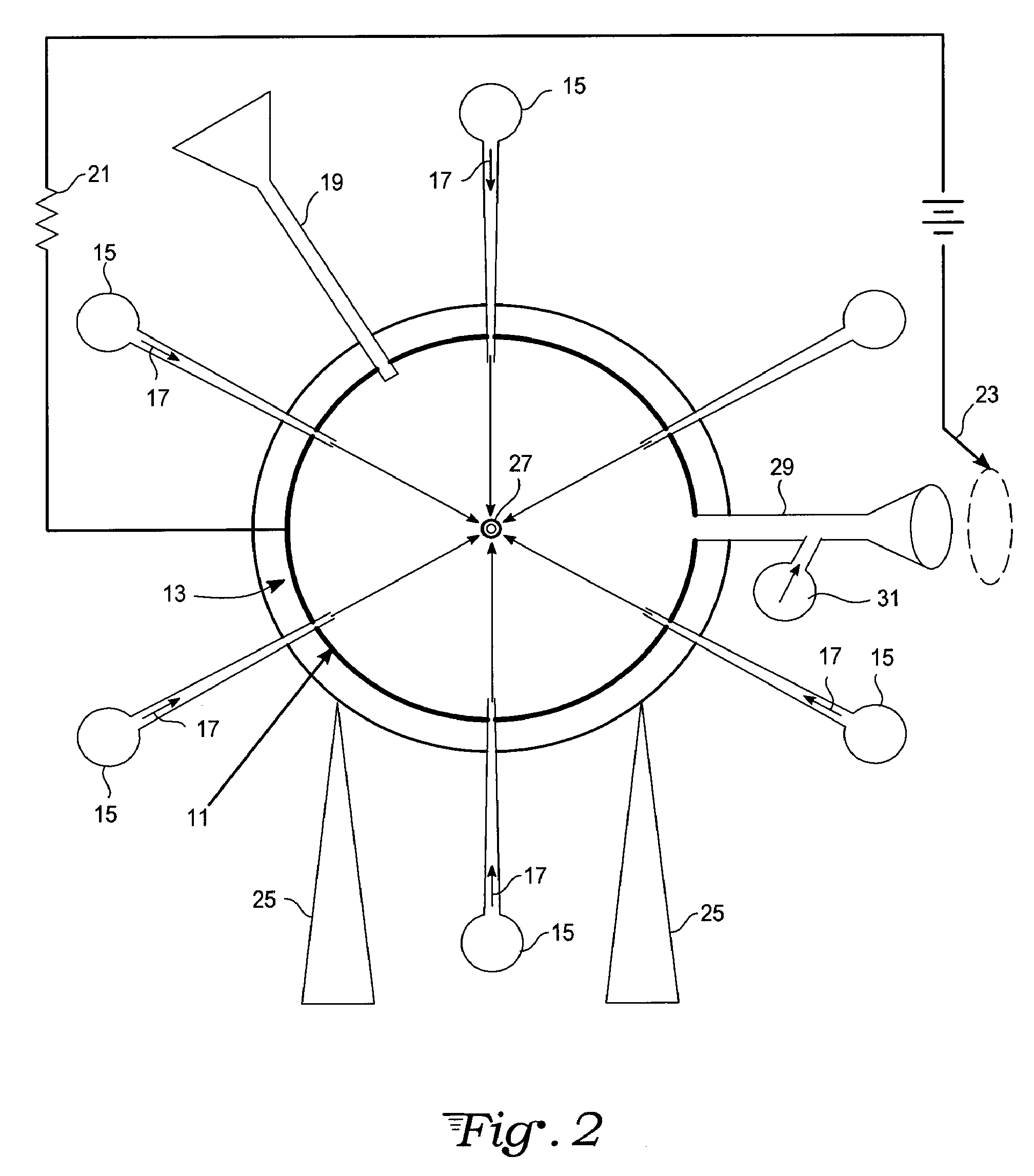

Thermonuclear plasma reactor for rocket thrust and electrical generation

InactiveUS20090000268A1Easy to triggerDownsize working reactionCosmonautic vehiclesNuclear energy generationHigh energyNuclear engineering

A reactor system produces plasma rocket thrust using alpha-initiated atomic fuel pellets without the need for a critical mass of fissionable material. The fuel pellets include an outer layer reactive material to alpha particles to generate neutrons (e.g., porous lead or beryllium), an under-layer of fissionable material (e.g., thorium or enriched uranium), and an optional inner core of fusion material (e.g., heavy water ice, boron hydride). The pellets are injected one at a time into a charged reaction chamber containing a set of alpha beam channels, possibly doubling as ion accelerators, all directed toward a common point. Alpha particles converging on each successive pellet initiate an atomic reaction in the fissionable under-layer, via a neutron cascade from the pellet outer layer, producing plasma that is confined within the chamber. This may be enhanced by atomic fusion of the optional inner core. The resulting high-energy plasma creates electrostatic pressure on the chamber and is allowed to exit the chamber through a port. An ion accelerator at the exhaust port of the chamber accelerates outgoing plasma ions, possibly with added reaction mass, to generate the rocket thrust. An electric circuit that includes the charged chamber may collect the electrons in the plasma to help power the ion accelerator(s).

Owner:YURASH GREG J

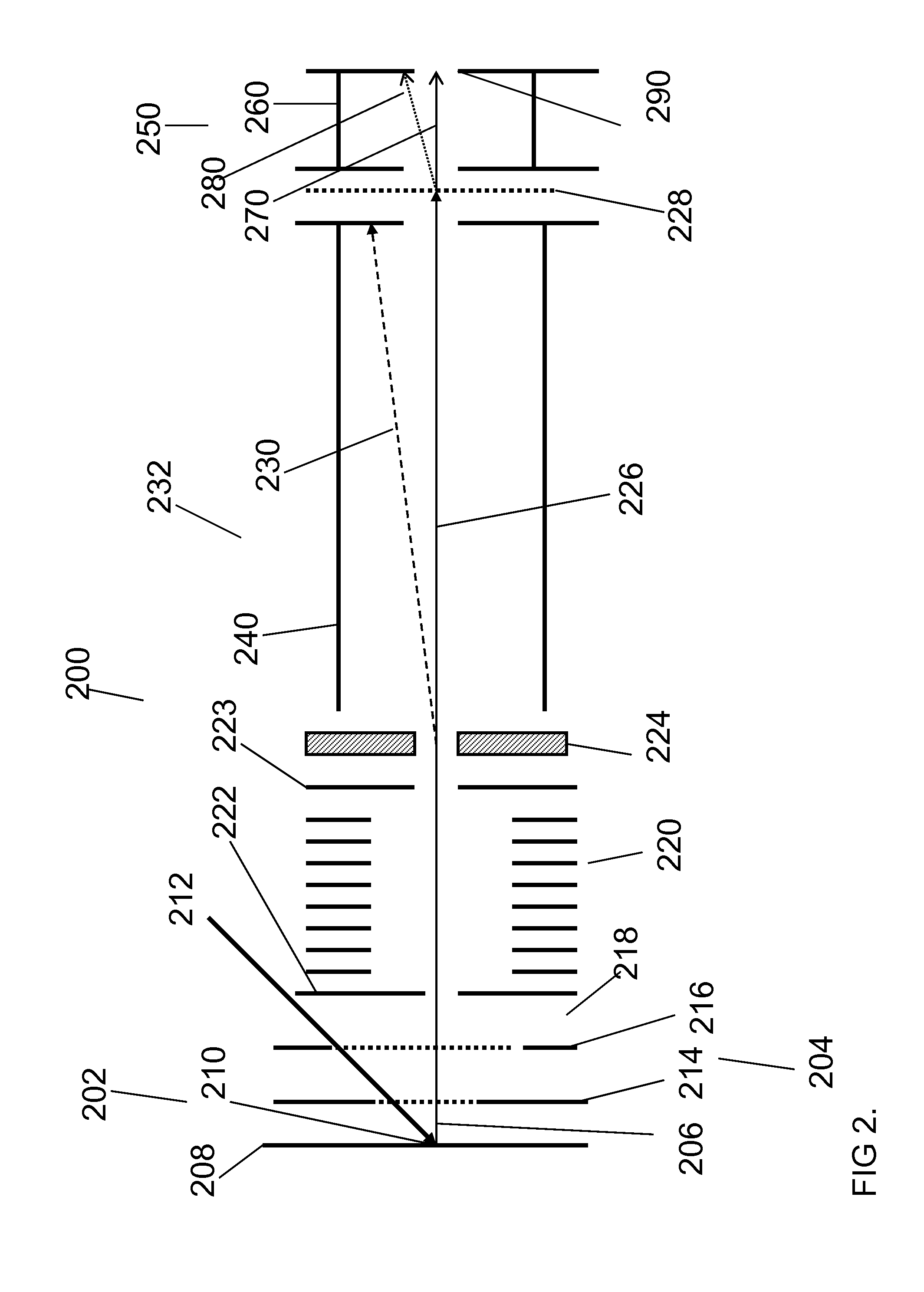

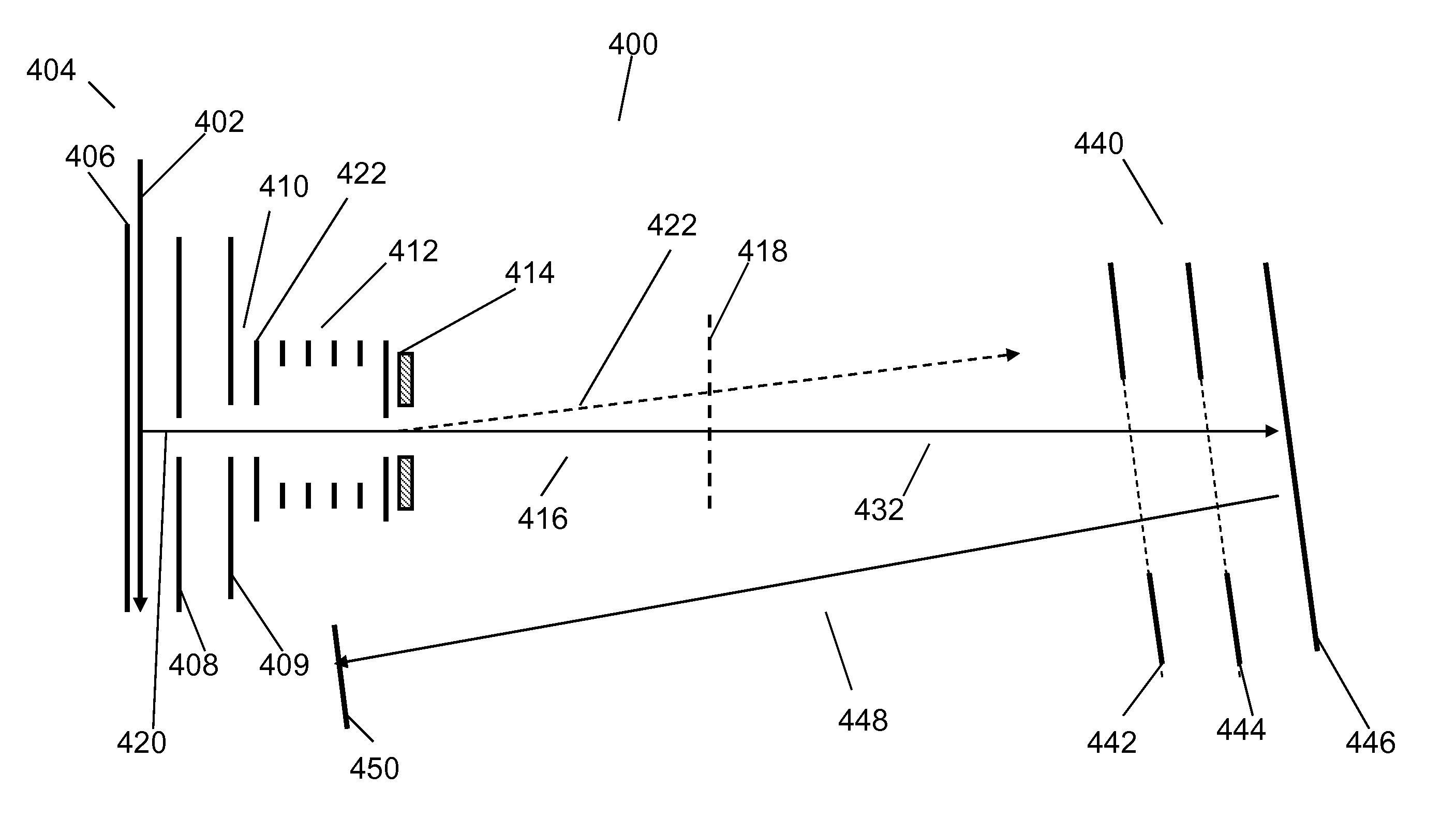

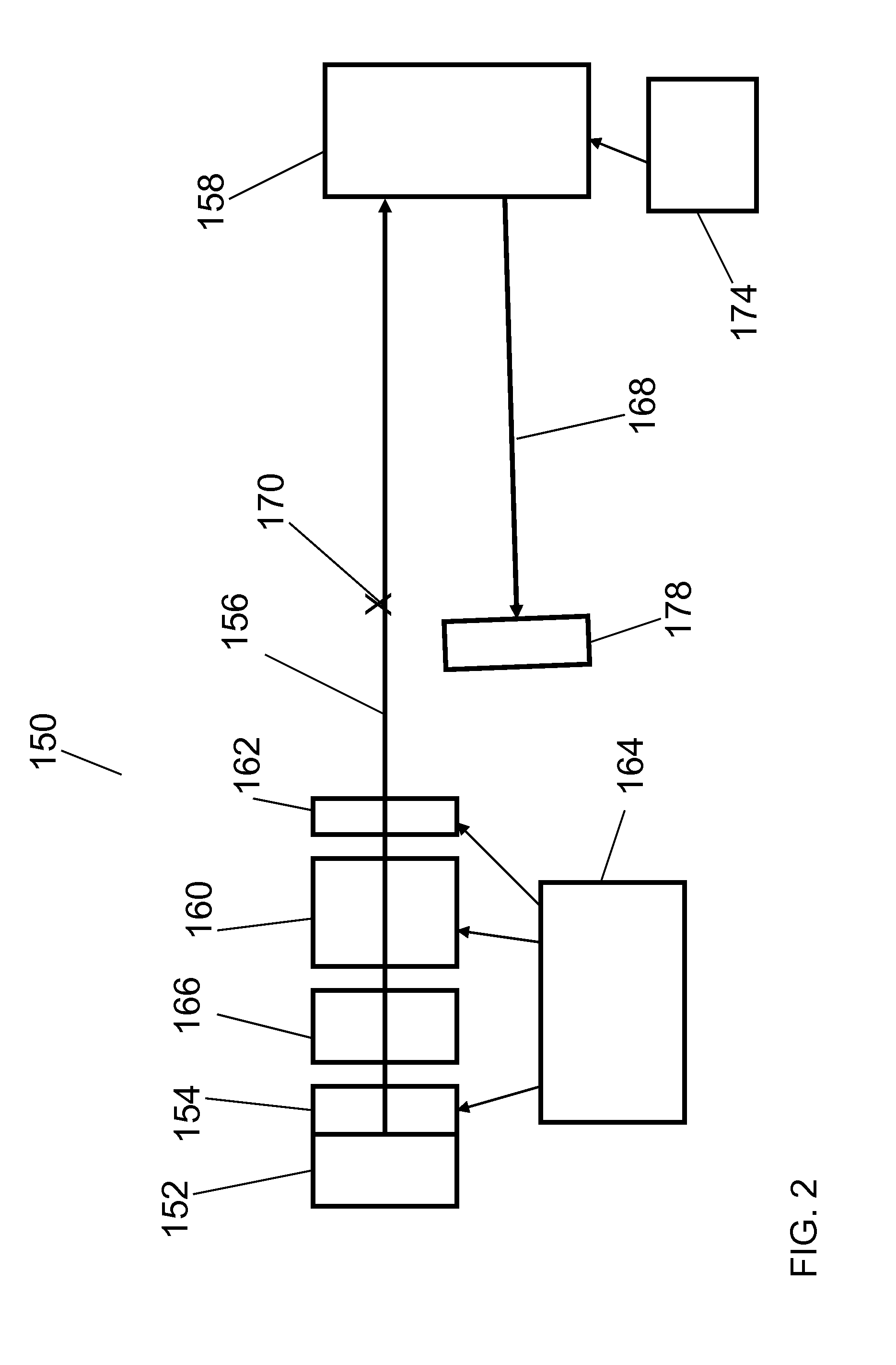

Multi-reflecting time-of-flight mass spectrometer with orthogonal acceleration

ActiveCN101366097AParticle separator tubesIsotope separationTime-of-flight mass spectrometryImage resolution

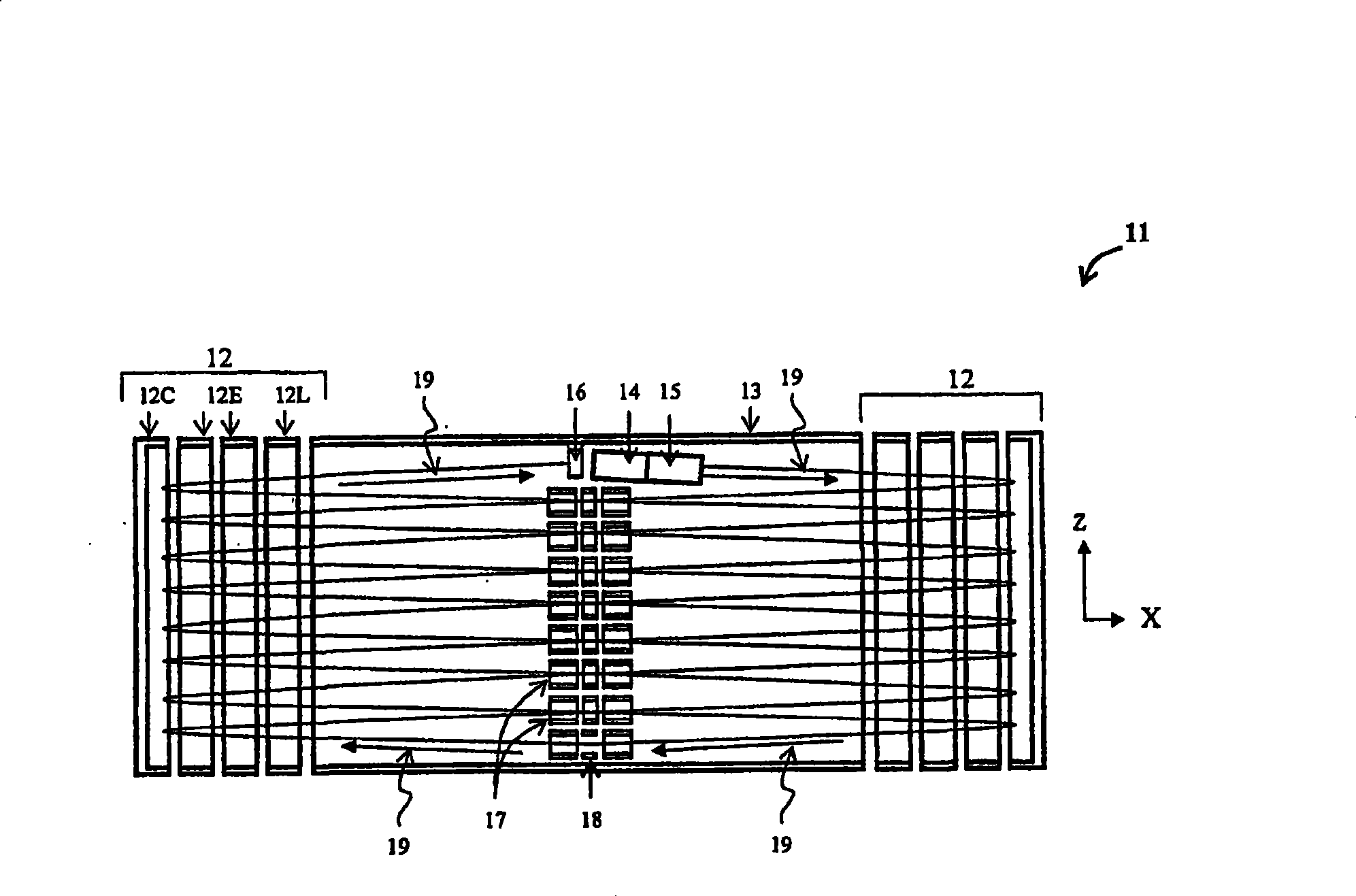

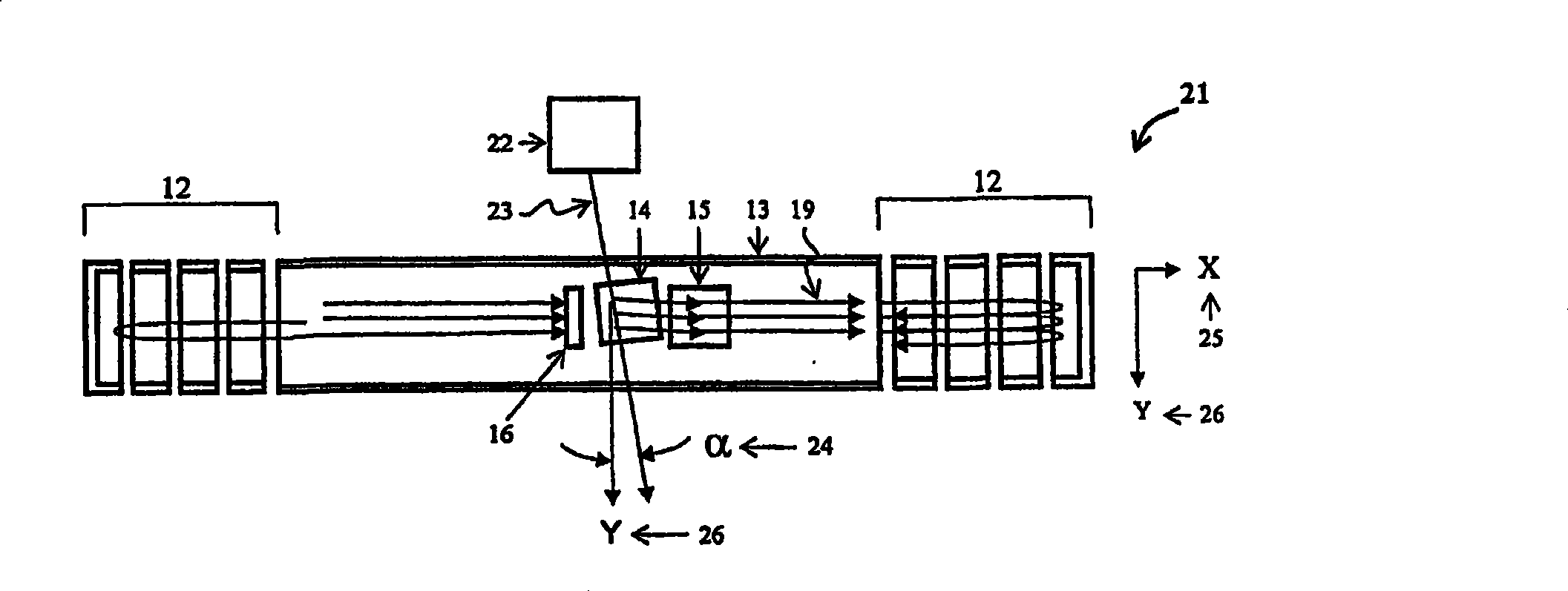

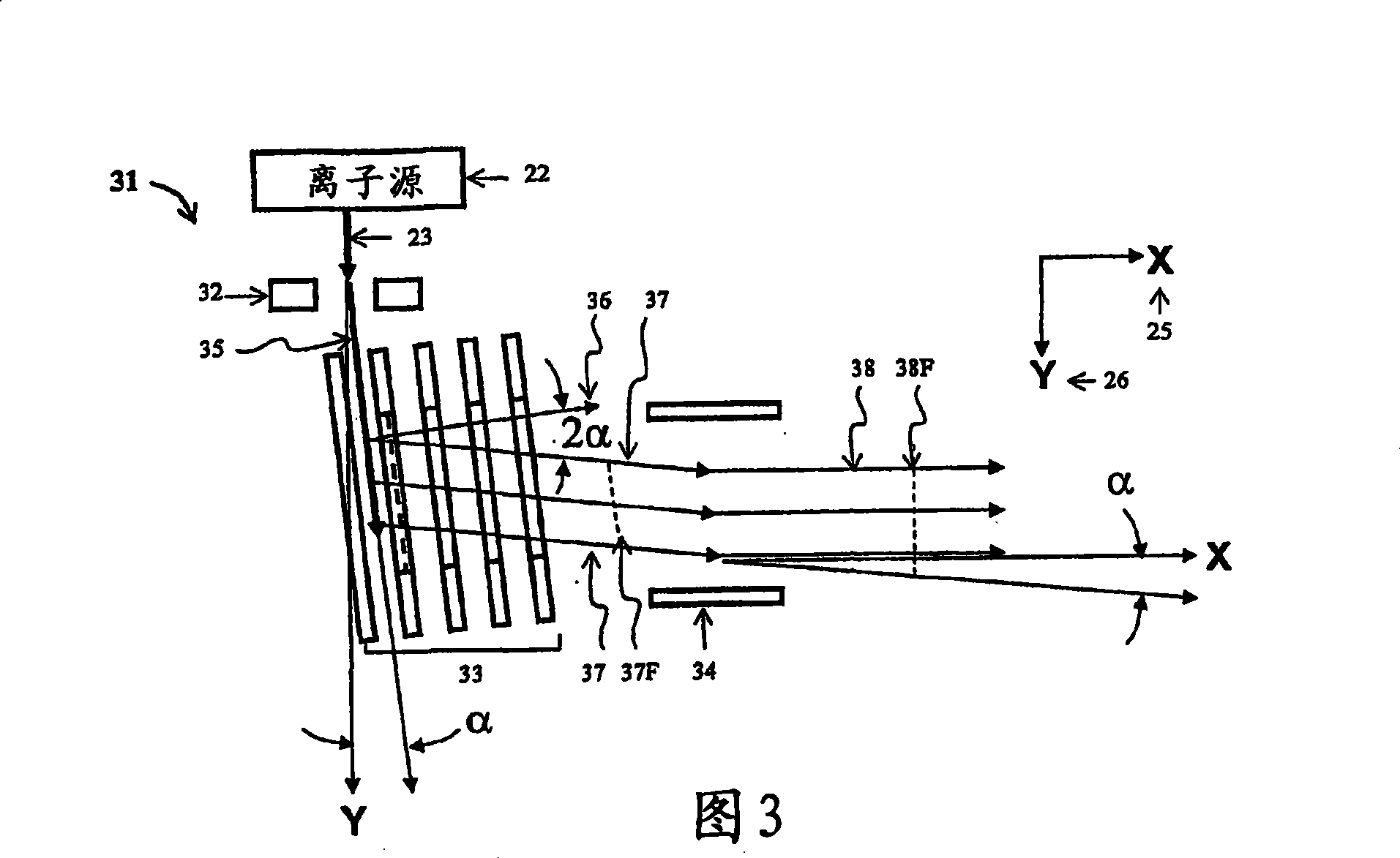

The disclosed apparatus includes a multi-reflecting time-of-flight mass spectrometer (MR-TOF MS) (11) comprising a pair of grid- free ion mirrors (12), a drift space (13), an orthogonal ion accelerator (14), an optional deflector (15), an ion detector (16), a set of periodic lenses (17), and an edge deflector (18). To improve the duty cycle of the ion injection at a low repetition rate dictated by a long flight in the MR-TOF MS, multiple measures may be taken. The incoming ion beam and the accelerator may be oriented substantially transverse to the ion path in the MR-TOF, while the initial velocity of the ion beam is compensated by tilting the accelerator and steering the beam for the same angle. To further improve the duty cycle of any multi-reflecting or multi-turn mass spectrometer, the beam may be time-compressed by modulating the axial ion velocity with an ion guide. The residence time of the ions in the accelerator may be improved by trapping the beam within an electrostatic trap. Apparatuses with a prolonged residence time in the accelerator provide improvements in both sensitivity and resolution.

Owner:LECO CORPORATION

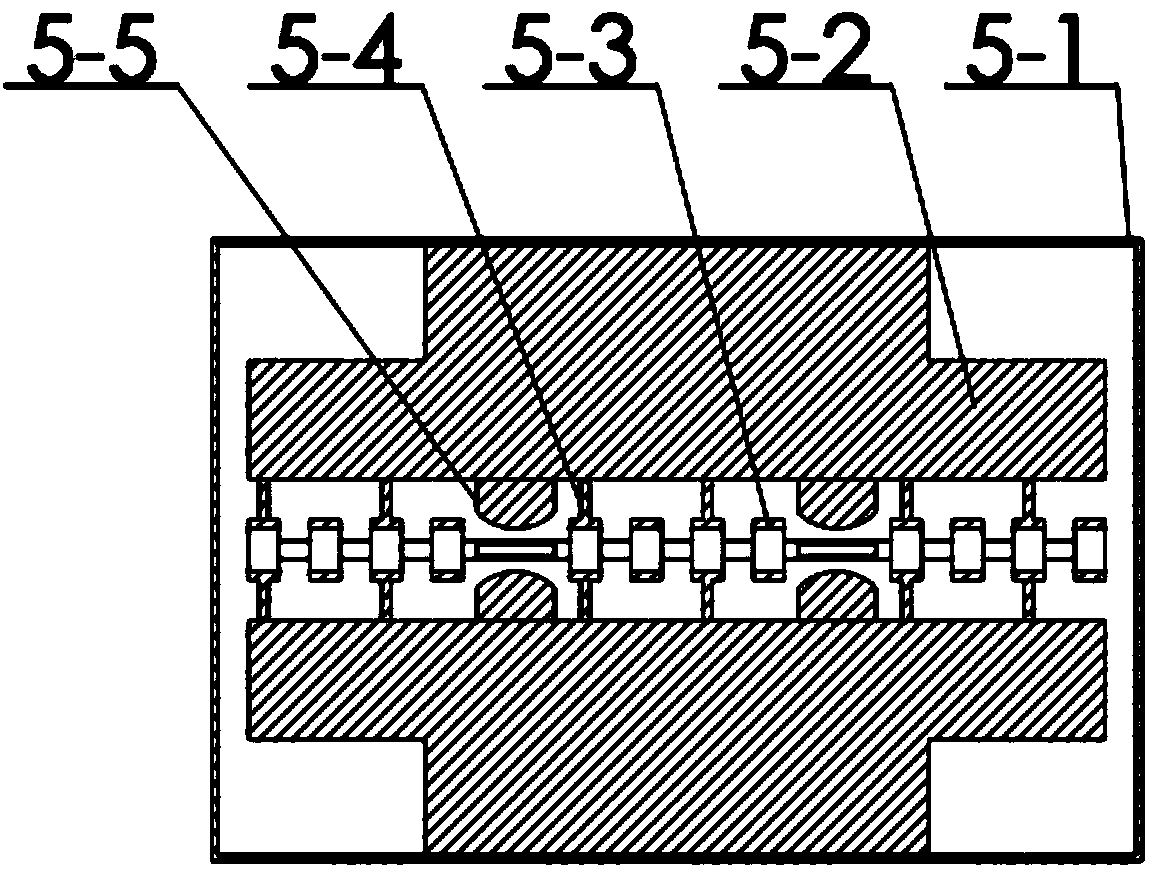

Ion accelerator injection device and using method

InactiveCN103906339AHigh shunt impedanceShorten the lengthAcceleratorsHigh frequency powerIon accelerators

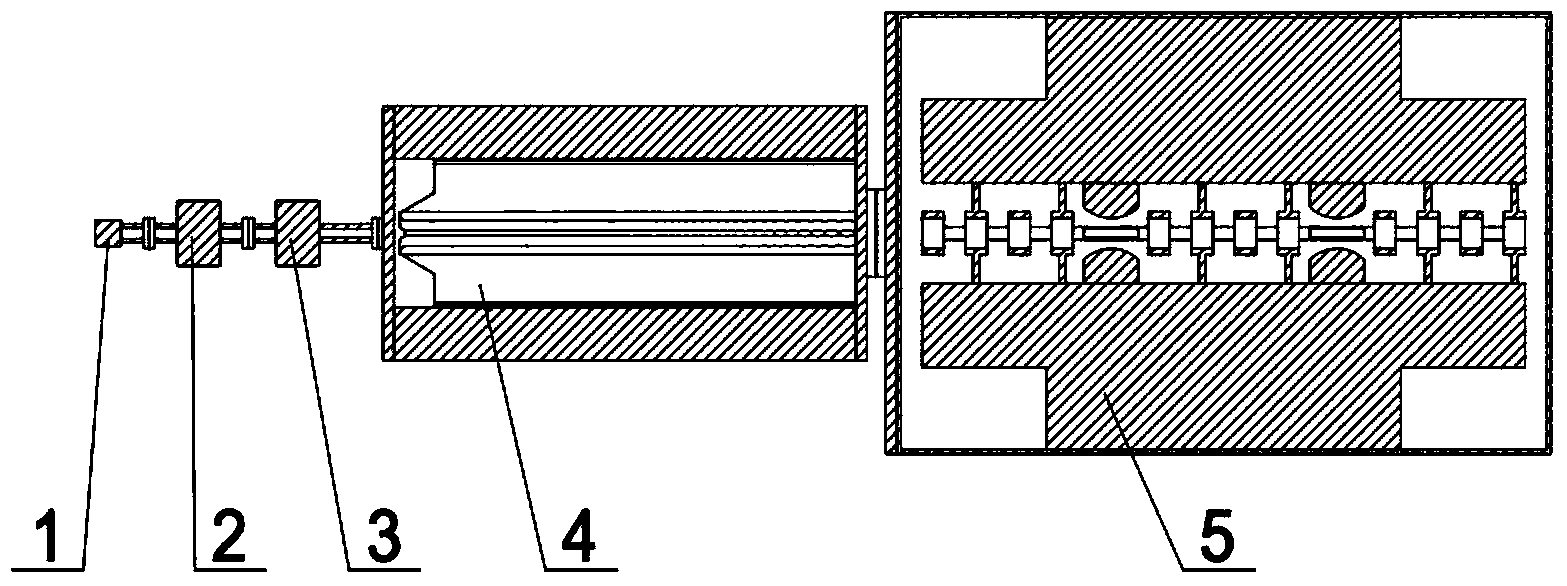

The invention relates to an ion accelerator injection device, and belongs to the technical field of nuclear energy. The ion accelerator injection device is characterized in that the ion accelerator injection device comprises an ion beam current ECR ion source, a first solenoid, a second solenoid, an RFQ linear accelerator and a mixed type ion accelerating device, wherein the ion beam current ECR ion source is used for generating high intensity, and the first solenoid and the second solenoid are connected with the RFQ linear accelerator and the mixed type ion accelerating device through vacuum pipelines. The RFQ linear accelerator and the mixed type ion accelerating device are connected through a flange. The ion accelerator injection device has the advantages that in the accelerating process of high intensity ion beam currents, the quality of the beam currents is made to be better due to the fact that the structure is more compact; the accelerating function and the transverse and longitudinal focusing function are combined in the same high-frequency structure by using the accelerating function of a mixed type DTL, cavity shunt impedance is high, and high-frequency power dissipation is lowered greatly; acceleration is carried out by using a zero phase, acceleration efficiency is higher, the length of a cavity can be reduced effectively, and effective accelerating gradients can be improved; an additional transmission matching section is not needed between an RFQ and the mixed type DTL, manufacturing cost can be lowered, and the length of the device can be shortened. The ion accelerator injection device is mainly applied to acceleration of high intensity low energy ion beam currents, and can be applied to injection devices of high-current accelerators, industrial accelerators and other application type accelerating devices.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

Method and apparatus for the analysis of samples

InactiveUS20100181473A1Time-of-flight spectrometersSamples introduction/extractionMaterial removalCompound (substance)

The present invention relates to an apparatus and method for the analysis of ions in a mass spectrometer comprising; a means to remove material from the sample at a defined specific point, a means to change either discretely or continuously the said defined point of material removal, at least one ionisation means, at least one ion accelerator, at least one energy selective means, a time focus means, a pulse bunching means and a detection means. Said invention allows the mass of an to be analysed with respect to multiple positions on a sample of a material providing a method and apparatus that allows the effective three dimensional mapping of the sample in terms of its constituent parts, their corresponding distribution in those three dimensions in relation to each other and other points of interest on the said sample and also to retain important chemical information by permitting the analysis of whole and intact molecules present on the surface of or within the material sample.

Owner:IONOPTIKA

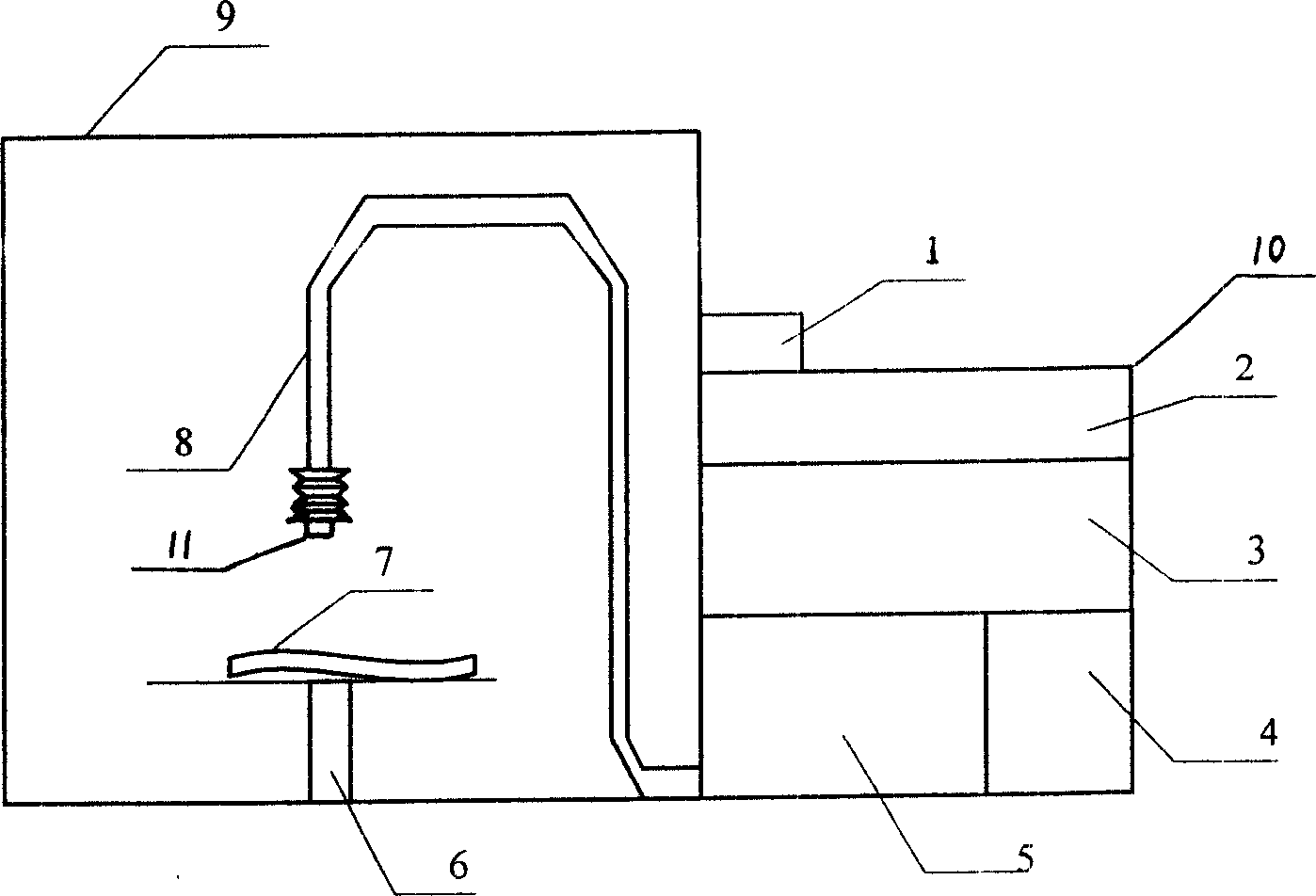

Automobile interior ornament flocking method

InactiveCN1579645AAvoid shieldingOvercome the defect that only flat products can be flockedPretreated surfacesCoatingsEngineeringIon accelerators

The flocking method of the automobile inner ornament is as follows: process the surface, gelatinize, flock, put the pieces to be flocked on the turntable platform of the flocking maneuvering box, add fluff into the hopper of the flocking machine and power on the flocking machine. With the running of the briar dressing dish in the charging basket, the fluff is added into the charging system inside the flocking machine, is charged with positive charge, is accelerated by the ion accelerator and blast system, circumgyrates in the screwed pipeline and is erupted out equably along the exit direction of the screwed pipeline. We wave the nozzles right and left to make sure the fluff sprayed equably onto the pieces to be flocked, sweep it broadways and vertically and clean the fluff on the surface of the pieces to be flocked with air pressure gun between once and three times. After being solidified and cleaned, it can be packed. It can flock any shape, has equable flocking, good flocking effect and high flocking efficiency and doesn't affect the effect of the appearance of the pieces to be flocked.

Owner:于庆华

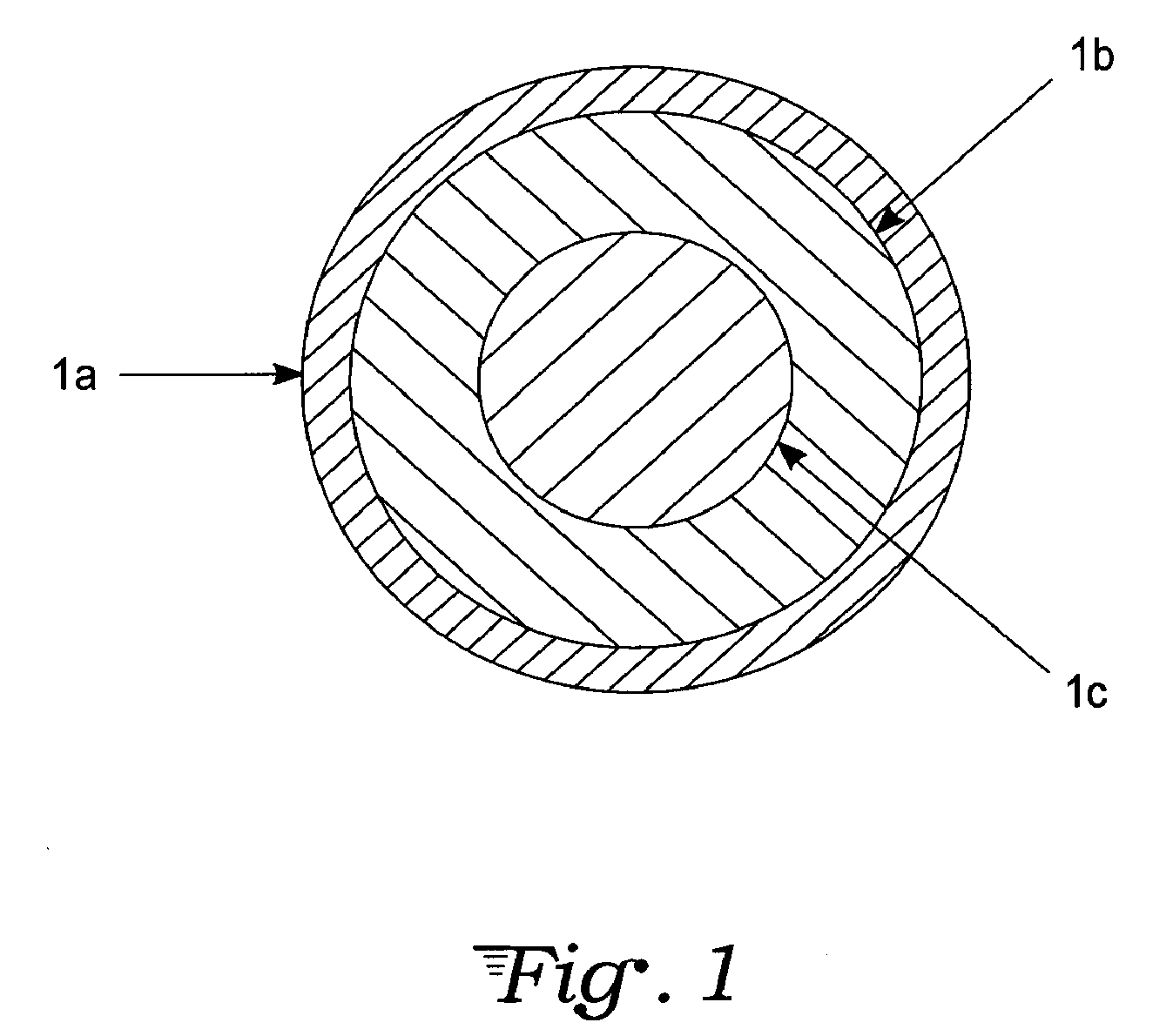

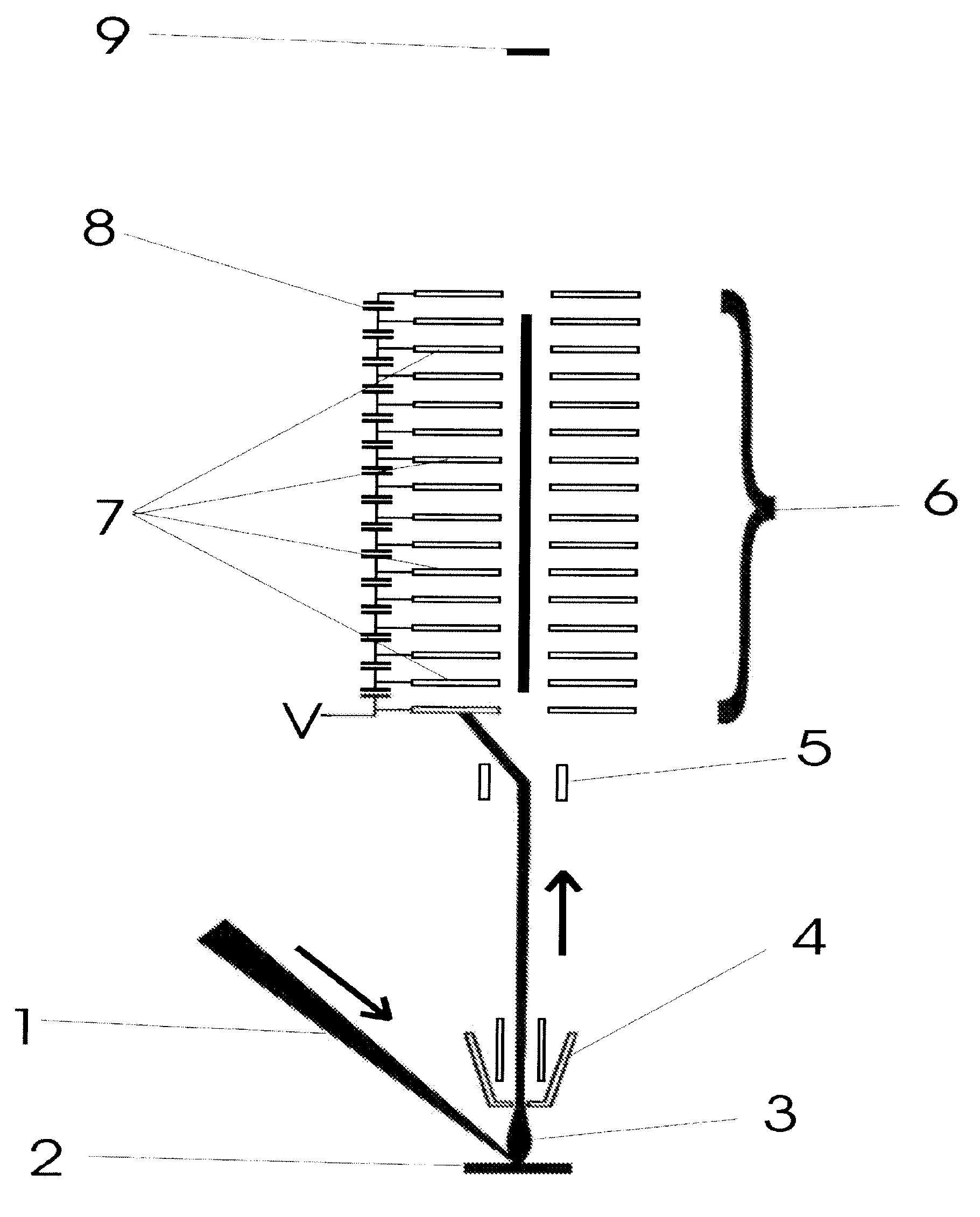

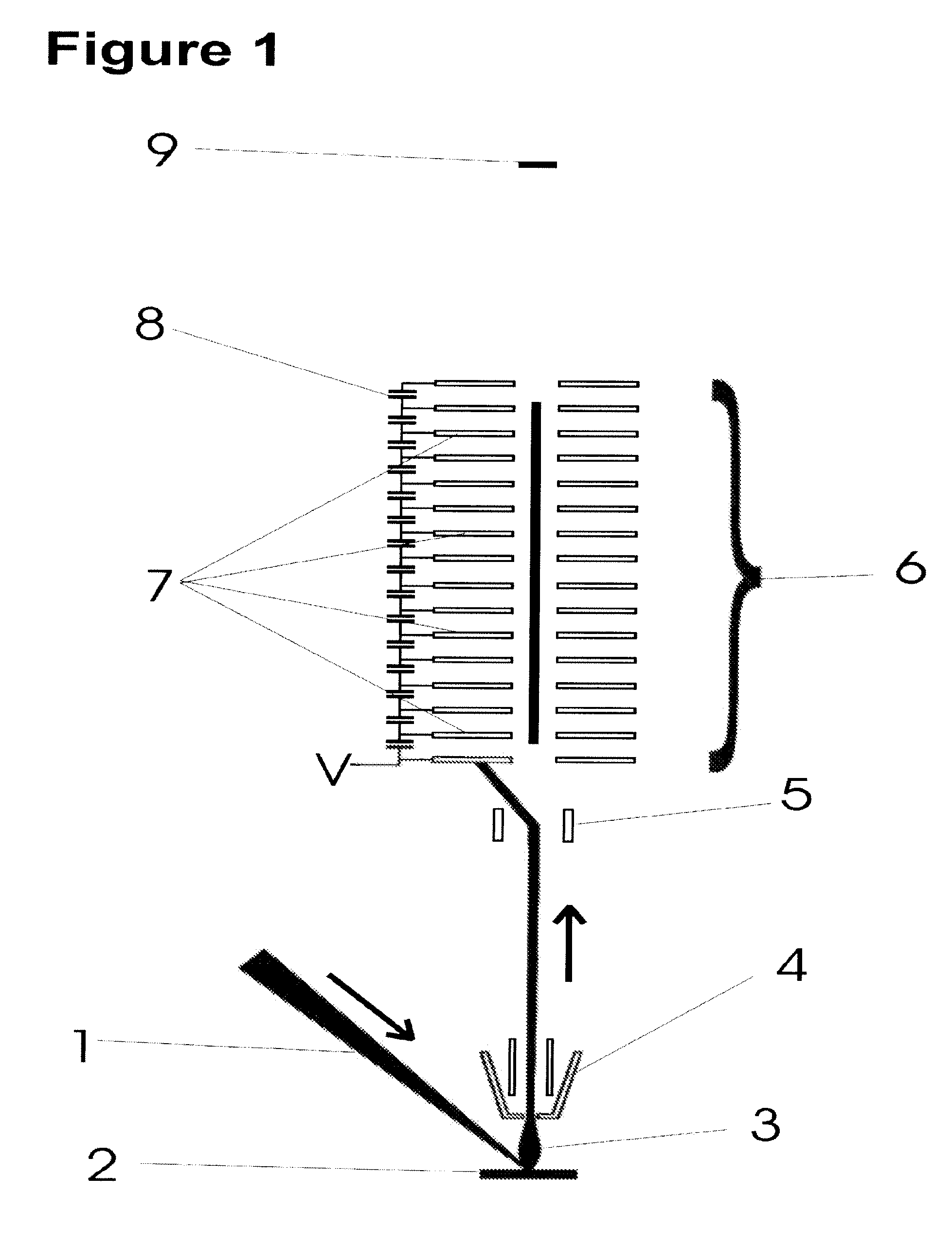

Neutron generator

InactiveUS20110169492A1Low efficiencyLow atomic to molecular ion ratio of ionNanotechElectric discharge tubesPower gridIonization

A neutron generator includes an ion source disposed in a pressurized environment containing an ionizable gas. The ion source includes a substrate with a bundle of carbon nanotubes extending therefrom. The ends of the nanotubes are spaced from a grid. Ion source voltage supply circuitry supplies a positive voltage potential between the substrate and the grid of the ion source to cause ionization of the ionizable gas and emission of ions through the grid. An ion accelerator section is disposed between the ion source and a target. The ion accelerator section accelerates ions that pass through the grid towards the target such that collisions of the ions with the target cause the target to generate and emit neutrons therefrom. The ion source, accelerator section and target are housed in a sealed tube and preferably the carbon nanotubes of the bundle are highly ordered with at least 106 carbon nanotubes per cm2 that extend in a direction substantially parallel to the central axis of the tube. The neutron generator provides gas ionization at much higher atomic to molecular ratio that the prior art, which allows for small compact size designs suitable for logging tools that are used in space-constrained downhole environments.

Owner:SCHLUMBERGER TECH CORP

Polyester alkali decrement and one-bath-dyeing one-step low-temperature processing method

ActiveCN103590271ALower glass transition temperatureReduce alkali reduction processing efficiencyDyeing processDisperse dyeAccelerant

The invention discloses a polyester alkali decrement and one-bath-dyeing one-step low-temperature processing method. The method comprises the steps: carrying out alkali decrement and one-bath-dyeing one-step processing on polyester by using a dipping process, and dissolving sodium hydroxide, a cation accelerant, a carrier, a dispersing agent and a disperse dye into a dye liquid, wherein the dye liquid is prepared from water, the concentration of the carrier is 4-15g / L, the concentration of the sodium hydroxide is 2-4g / L, and the concentration of the cation accelerant is 1*10<-5> to 10*10<-5>mol / L; placing a polyester fabric into the dye liquid according to the bath ratio of 1: (10-100); then, heating to 90-100 DEG C at the speed of 0.5-2 DEG C / min, preserving the heat for 20-100min; taking out the polyester fabric after the heat preservation is ended, washing the polyester fabric 2-5 times by using tap water, and then, carrying out reduction clearing at the temperature of 70-80 DEG C and the bath ratio of 1:50 for 10min by using 2g / L sodium hydroxide and 2g / L sodium hydrosulfite; next, taking out the fabric, and washing 2-6 times by using water; and finally, drying the fabric at the temperature of 70-80 DEG C. By using the method, the polyester alkali decrement and dyeing processing flow is shortened, the alkali decrement processing temperature is reduced, the consumptions of the sodium hydroxide and the cation accelerant are reduced, the production efficiency is increased, the energy sources are saved, the process is simple, no special requirement for the polyester fabric and equipment are needed, and the large-scale production can be realized by using conventional equipment, so that the method has a wide application prospect.

Owner:绍兴通盛印染有限公司

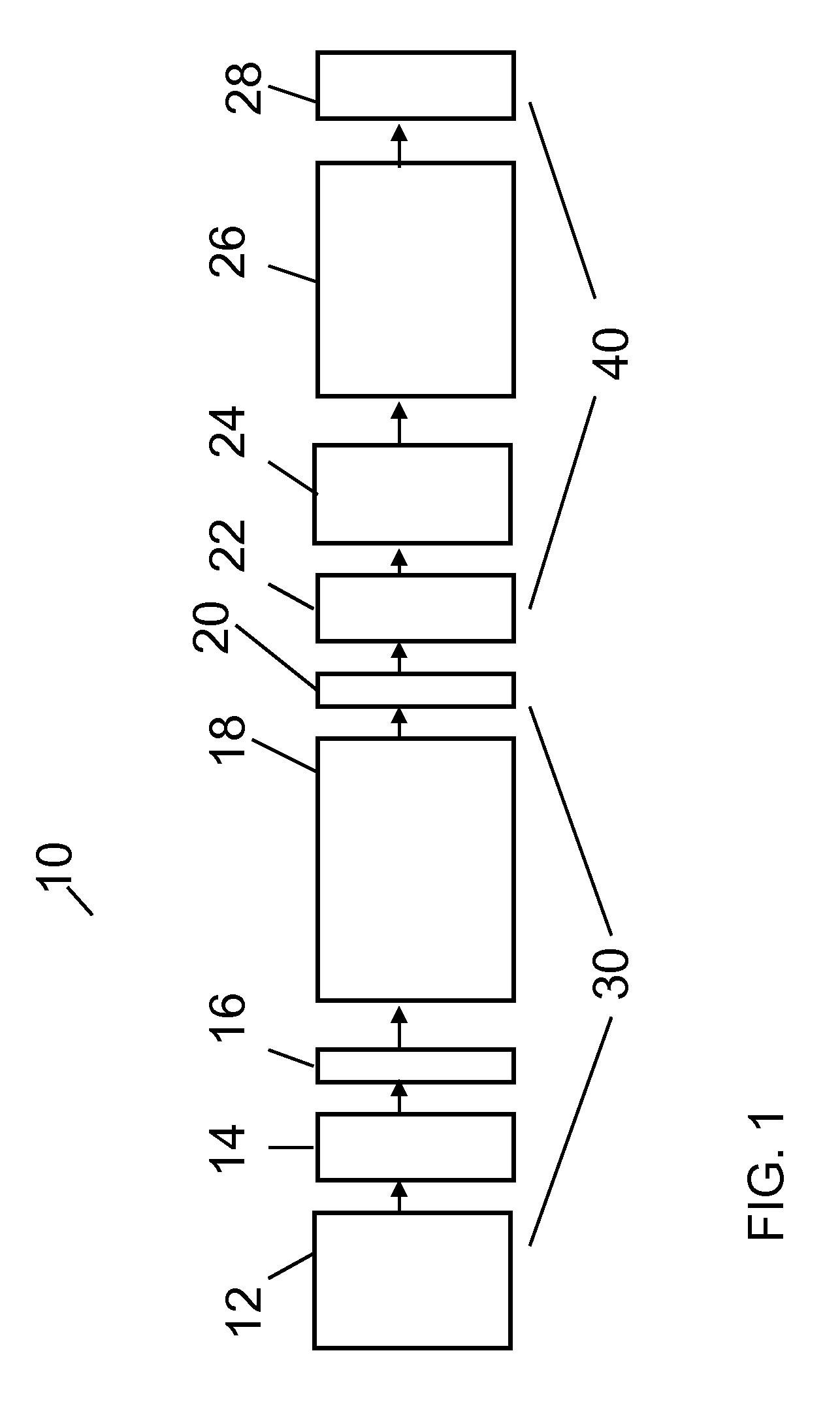

Tandem time-of-flight mass spectrometry with simultaneous space and velocity focusing

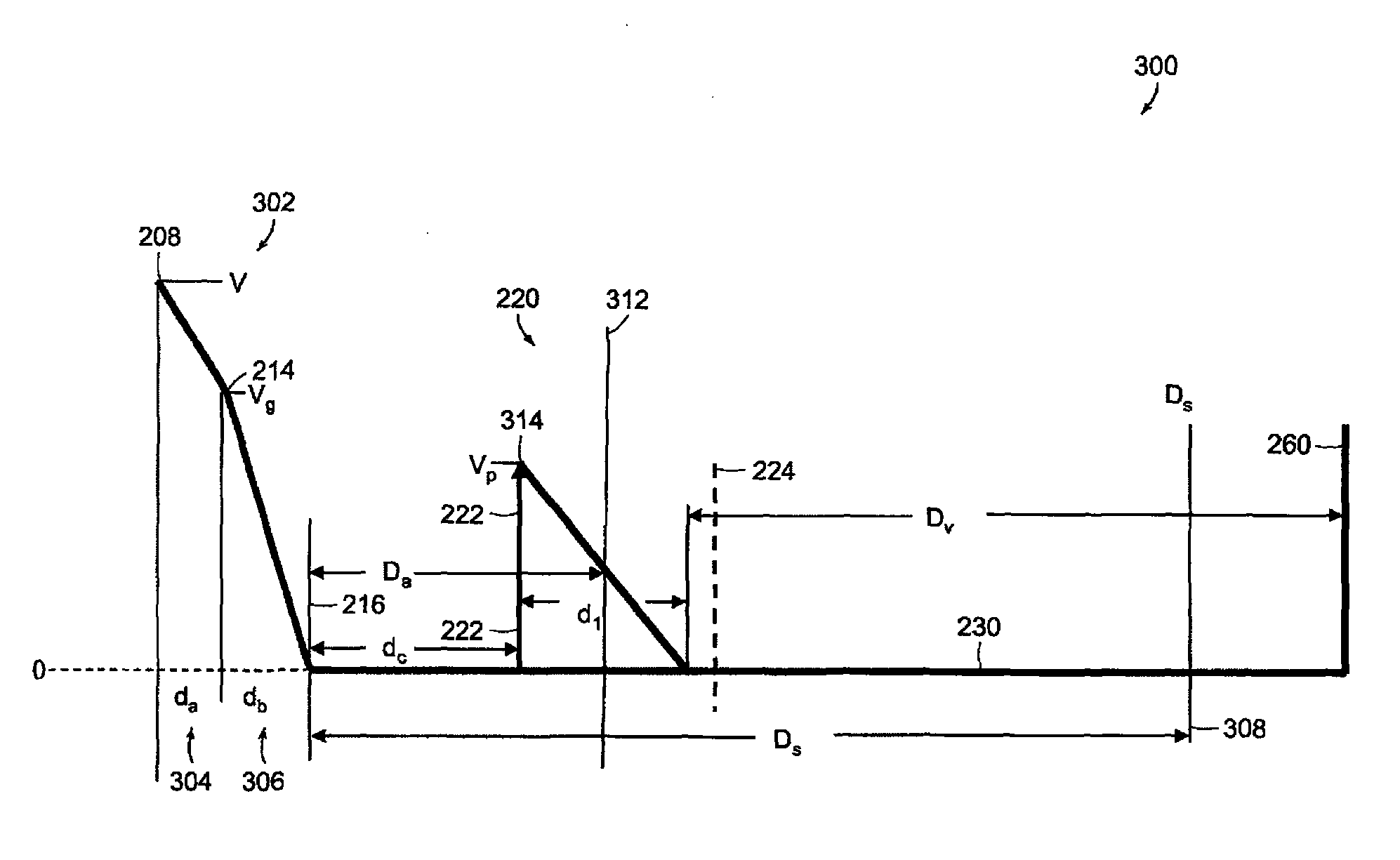

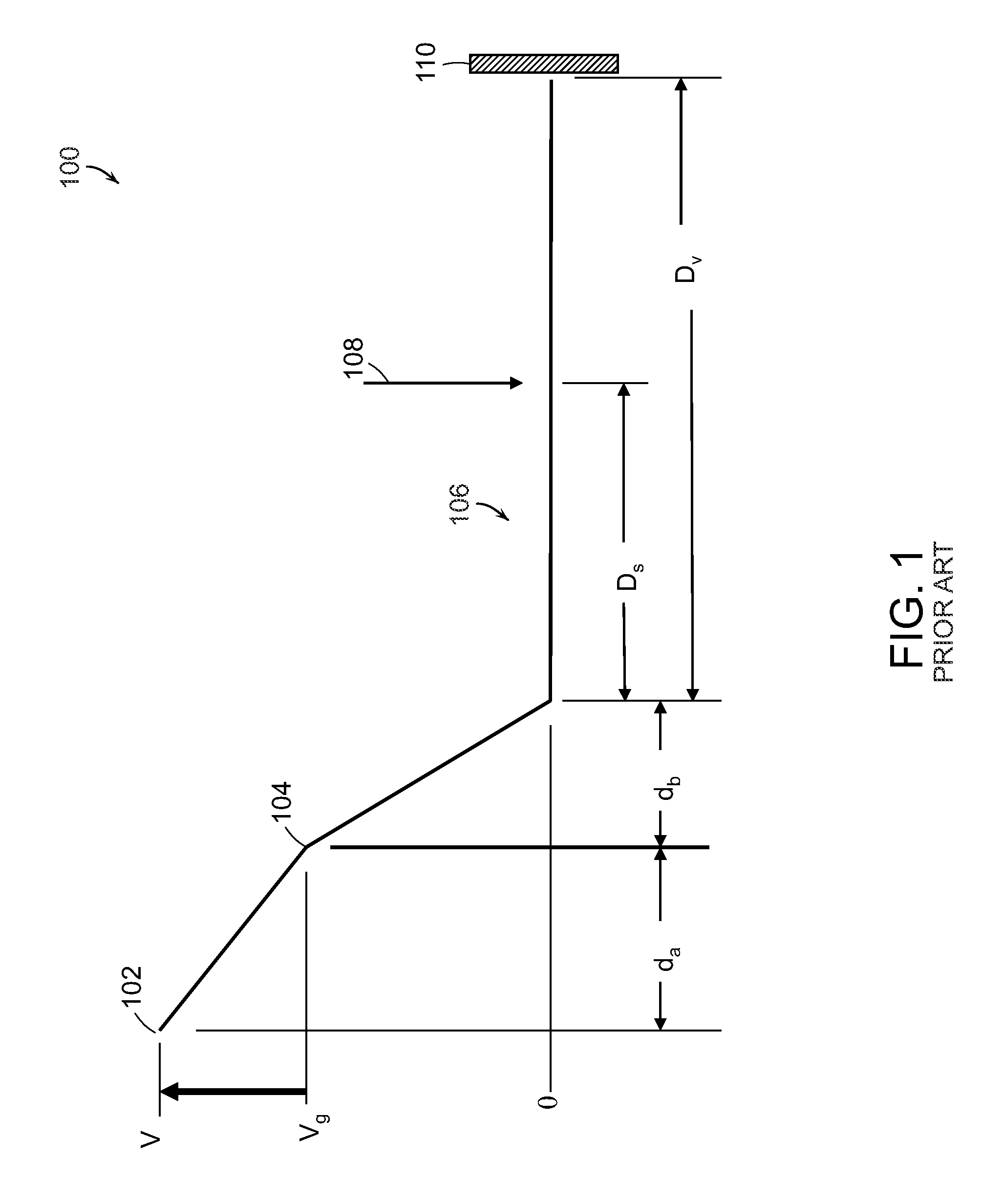

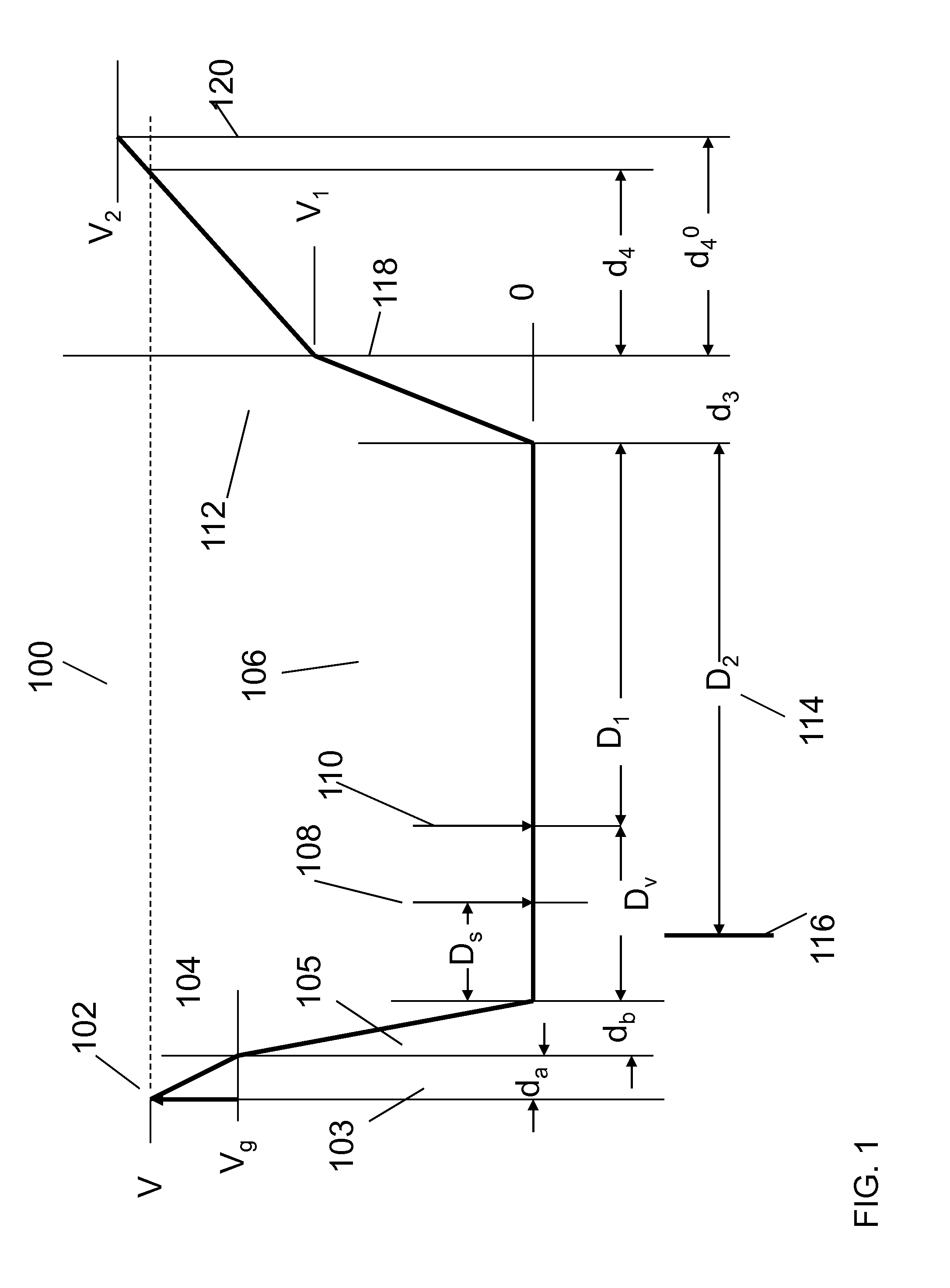

InactiveUS8847155B2Increase speedImprove utilizationTime-of-flight spectrometersIsotope separationTime-of-flight mass spectrometryIon beam

A tandem TOF mass spectrometer includes a first TOF mass analyzer that generates an ion beam comprising a plurality of ions and that selects a group of precursor ions from the plurality of ions. A pulsed ion accelerator accelerates and refocuses the selected group of precursor ions. An ion fragmentation chamber is positioned to receive the selected group of precursor ions that is refocused by the pulsed ion accelerator. At least some of the selected group of precursor ions is fragmented in the ion fragmentation chamber. A second TOF mass analyzer receives the selected group of precursor ions and ion fragments thereof from the ion fragmentation chamber and separates the ion fragments and then detects a fragment ion mass spectrum.

Owner:VIRGIN INSTR CORP

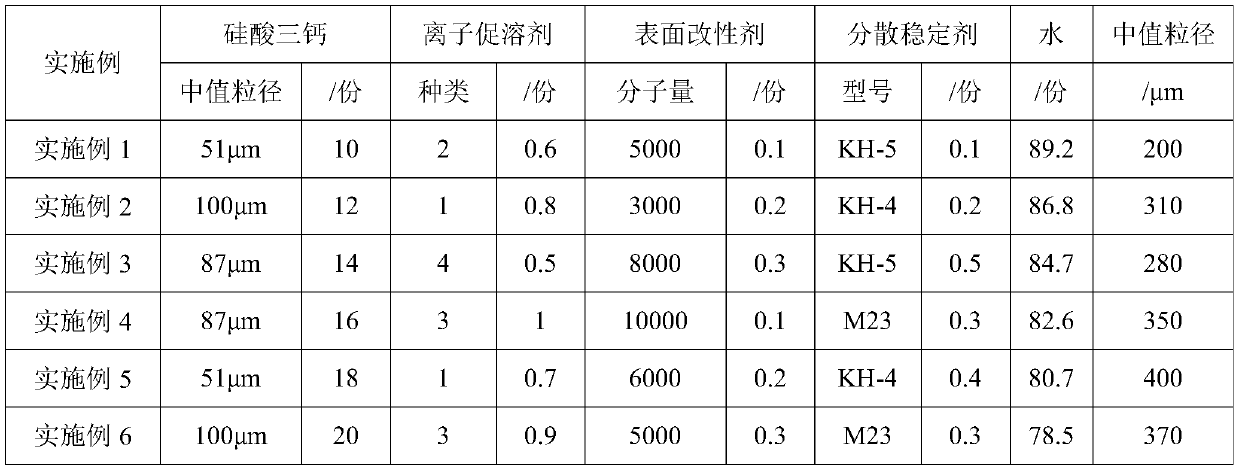

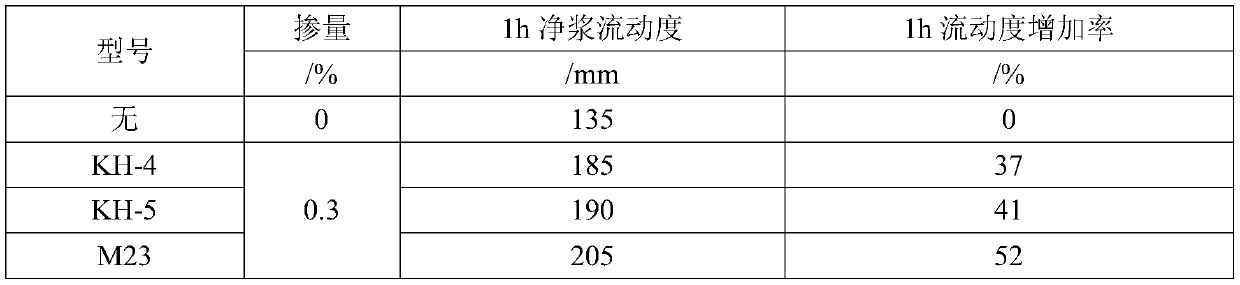

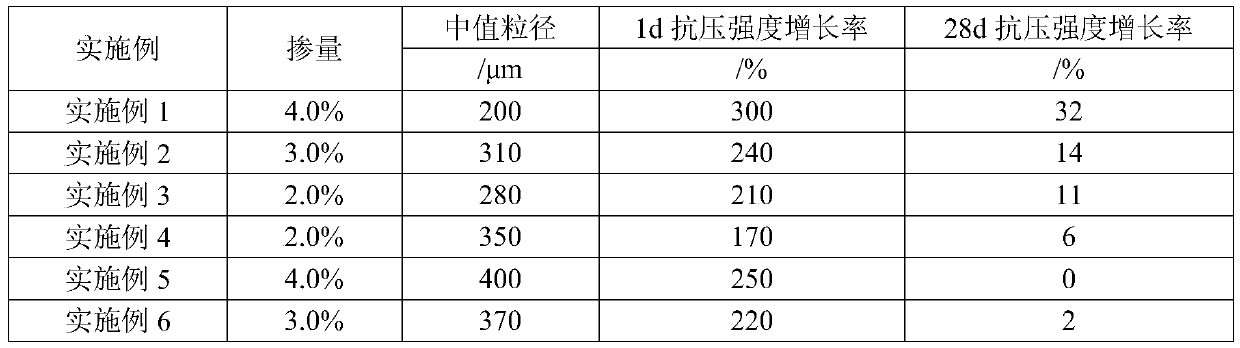

C-S-H gel nanocrystal nucleus early strength agent, preparation method and application thereof

ActiveCN110330257AAccelerated nucleation growthImprove pore structureIon acceleratorsNucleation growth

The invention provides a C-S-H gel nanocrystal nucleus early strength agent, a preparation method and application thereof. The C-S-H gel nanocrystal nucleus early strength agent is mainly prepared from the following components by weight through wet milling process: 10-20 parts of tricalcium silicate, 0.5-1 part of an ion promoter, 0.1-0.3 part of a surface modifier, 0.1-0.5 part of a dispersion stabilizer, and 78.5-89.2 parts of water. The C-S-H gel nanocrystal nucleus early strength agent provided by the invention utilizes the crystal nucleus induction effect of nano form C-S-H gel to accelerate the nucleation growth of hydration products at the early stage of hydration, and can achieve the early strength purpose from the two aspects of by improving the pore structure and inducing nucleation.

Owner:WUHAN UNIV OF TECH

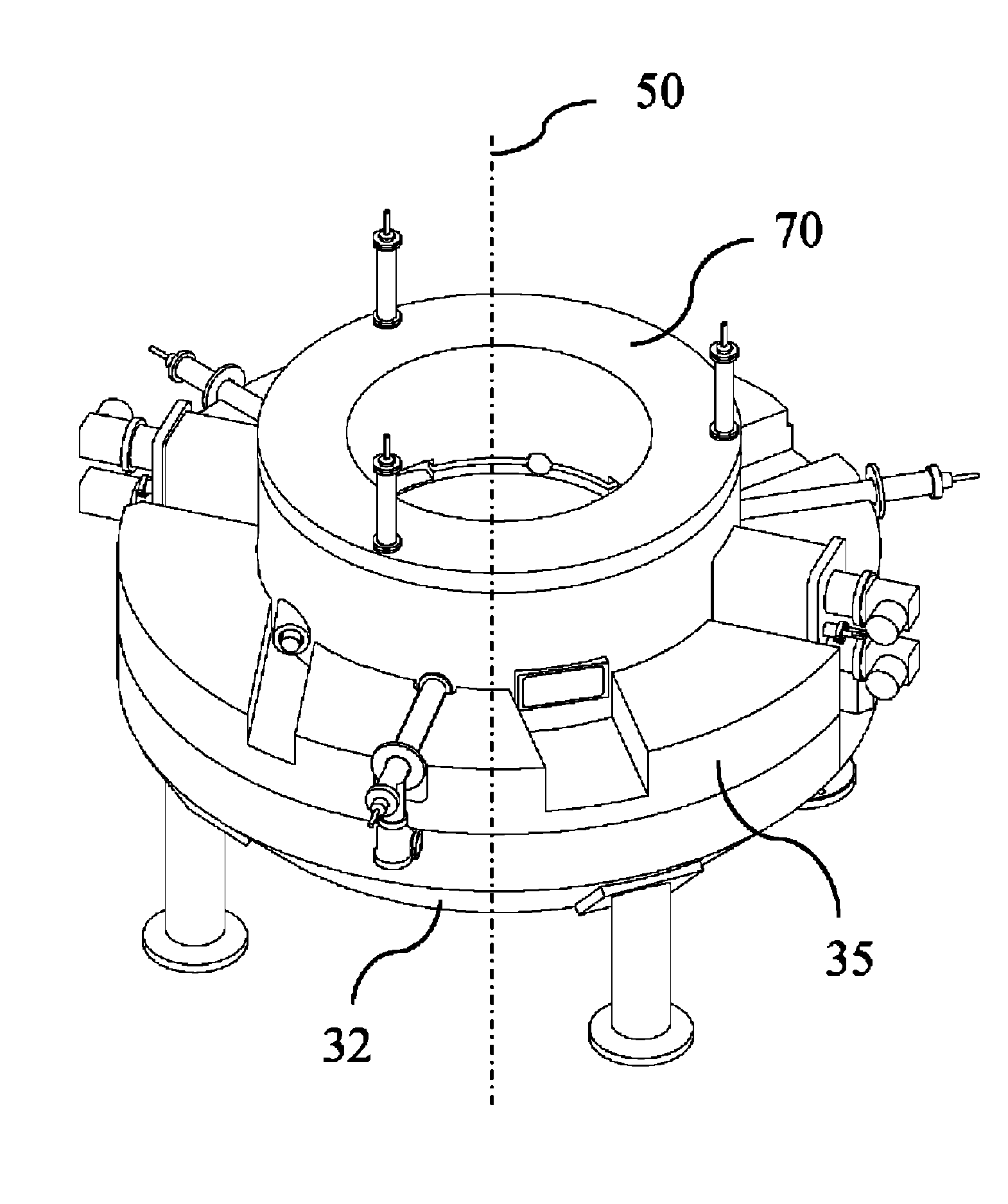

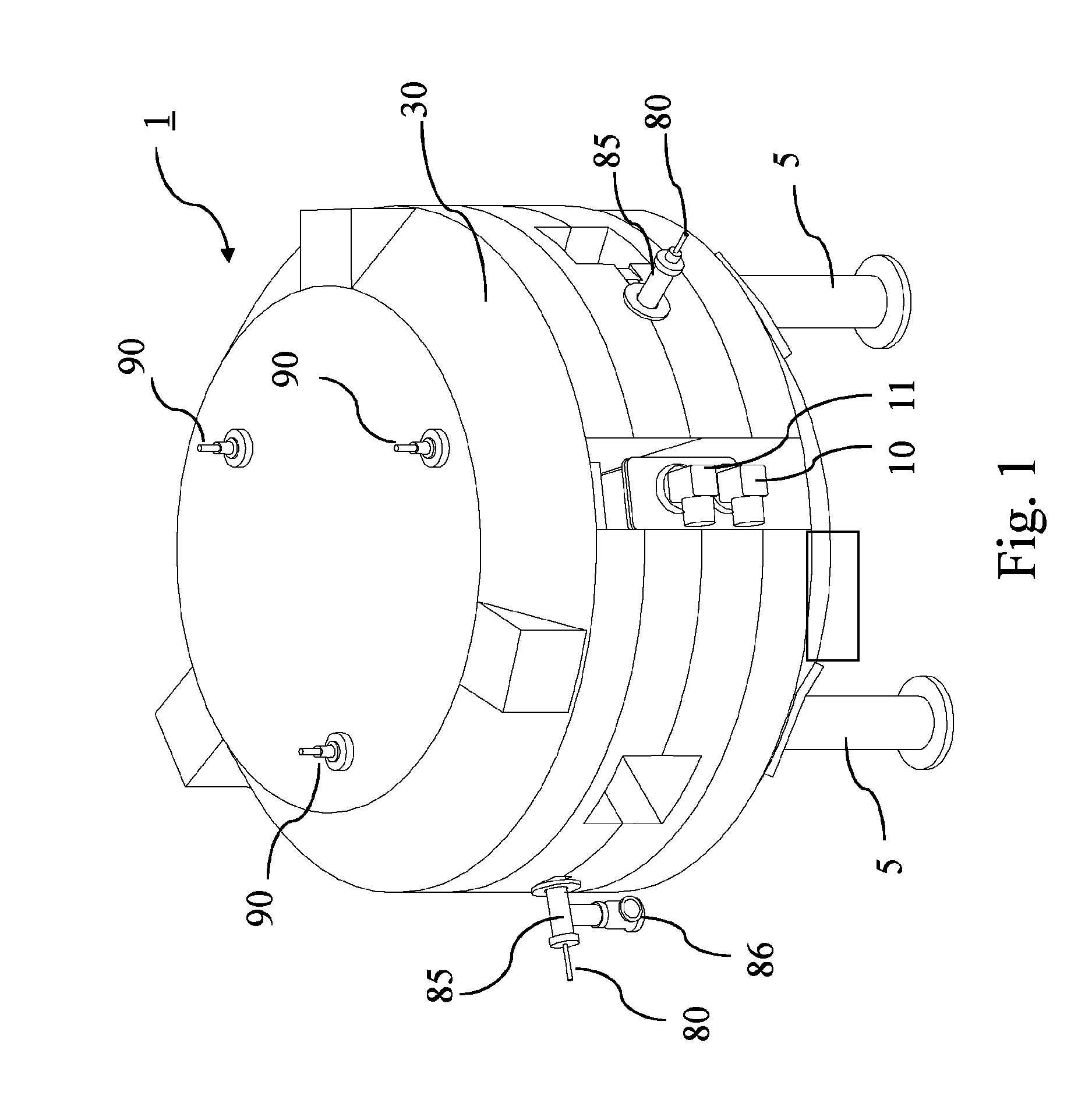

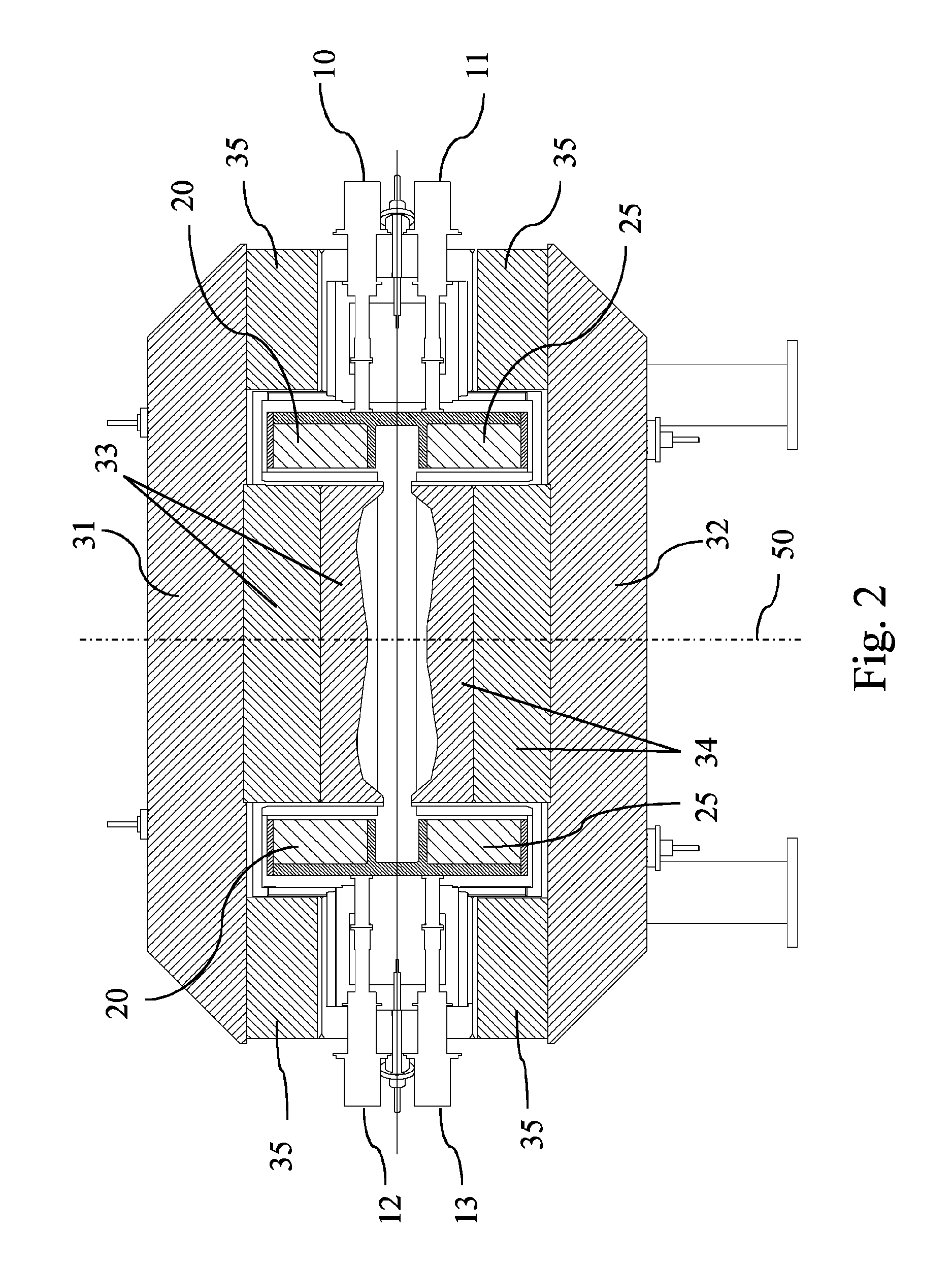

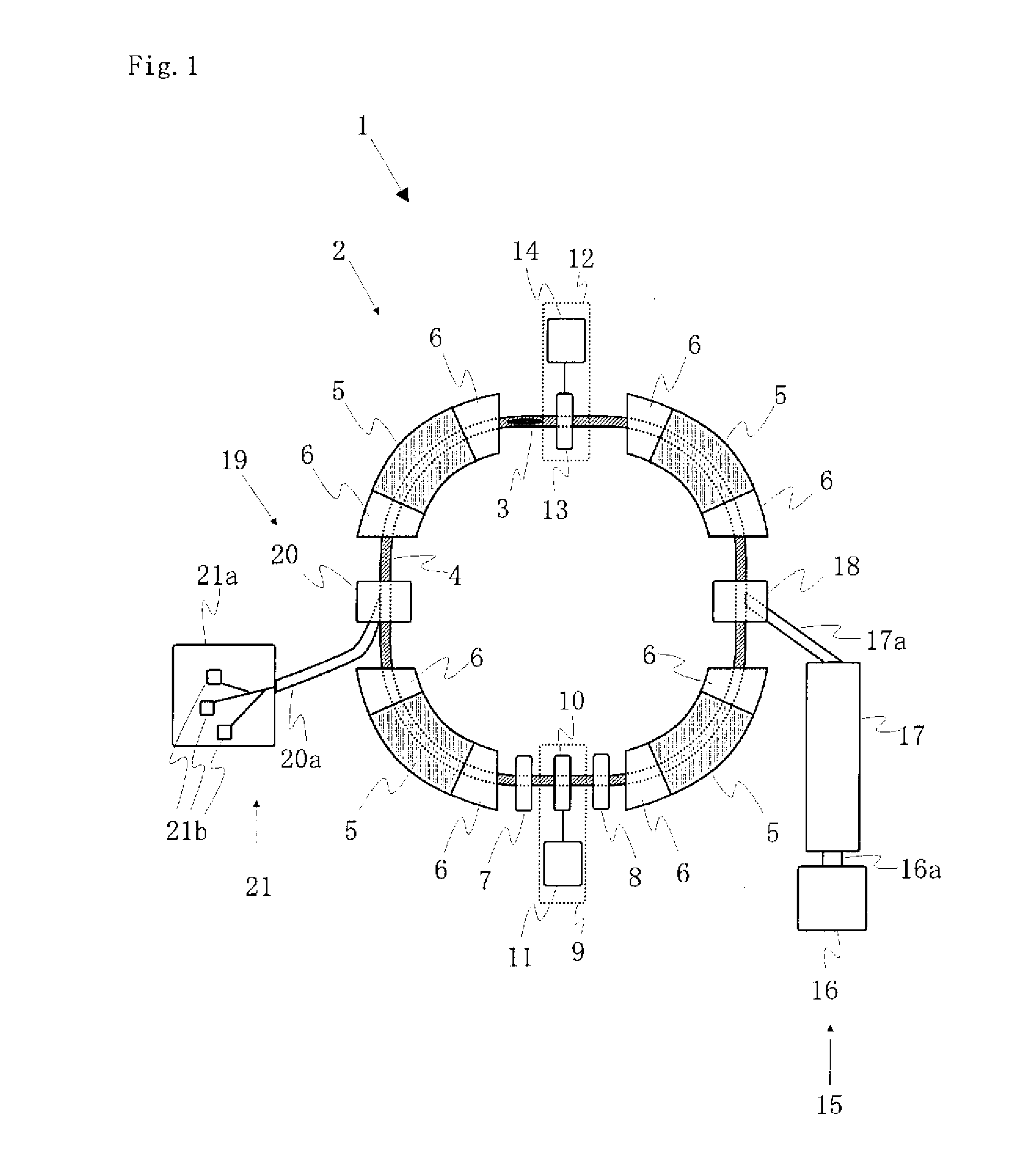

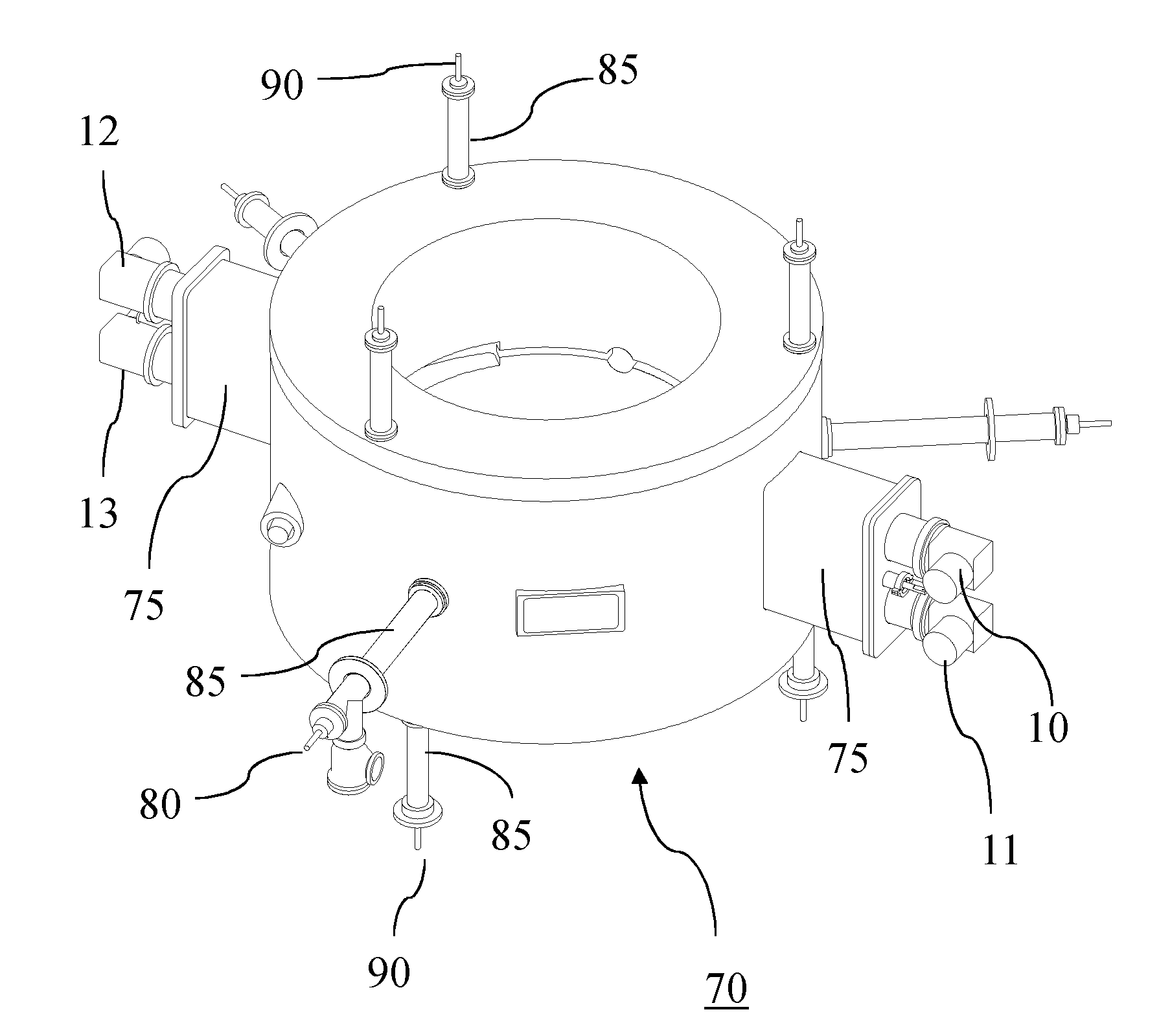

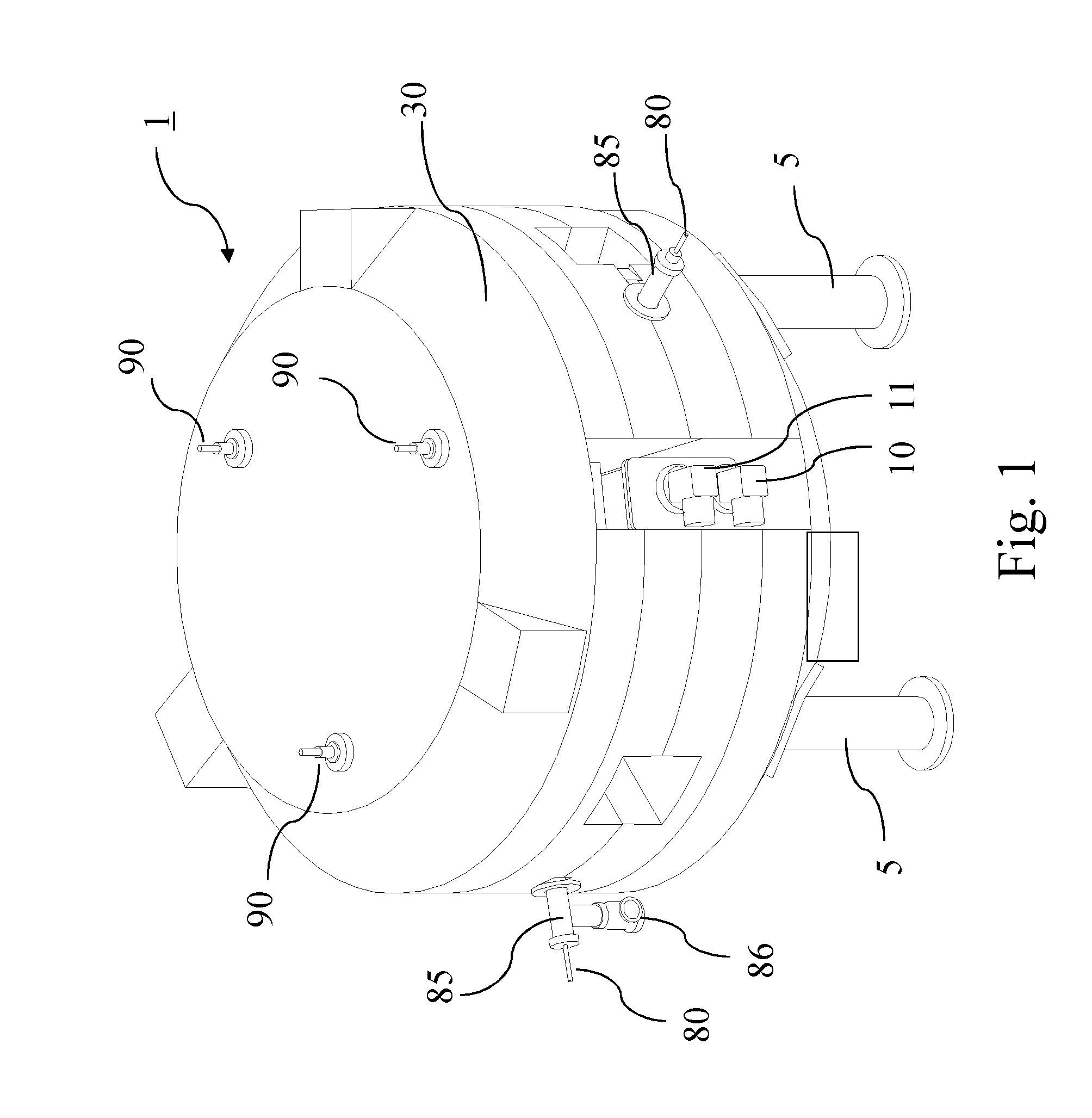

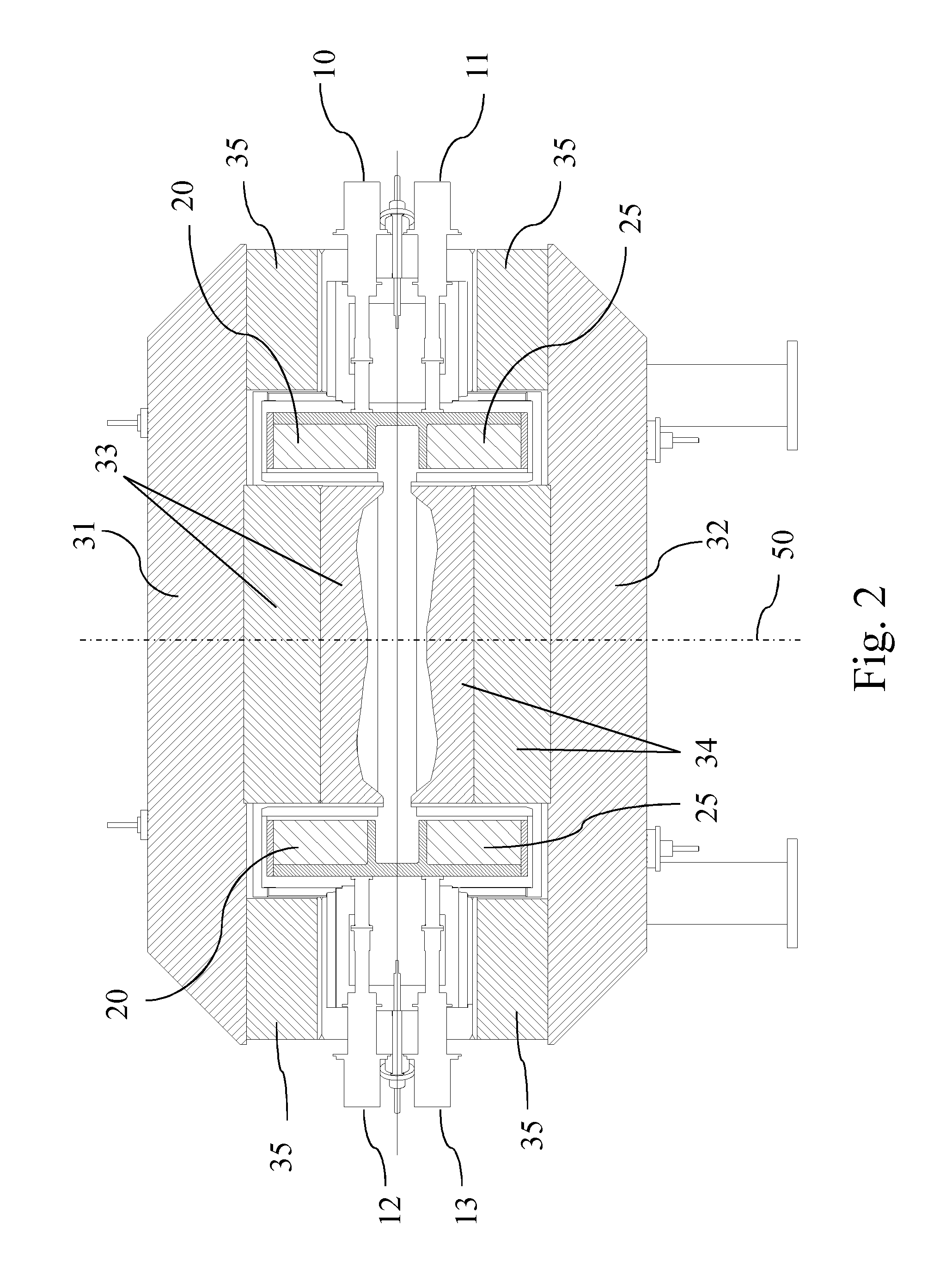

Magnetic structure for circular ion accelerator

A magnet structure for use in a circular ion accelerator, such as e.g. a synchrocyclotron comprises a cold-mass structure including superconducting magnetic coils (20, 25), at least one dry cryocooler unit (10, 11, 12, 13) coupled with the cold-mass structure for cooling the latter and a magnetic yoke structure (30) with a return yoke (35) configured radially around said coils (20, 25). The return yoke (35) comprises an opening in which said dry cryocooler unit (10, 11, 12, 13) is received so as to be in thermal contact with said cold-mass structure.

Owner:ION BEAM APPL

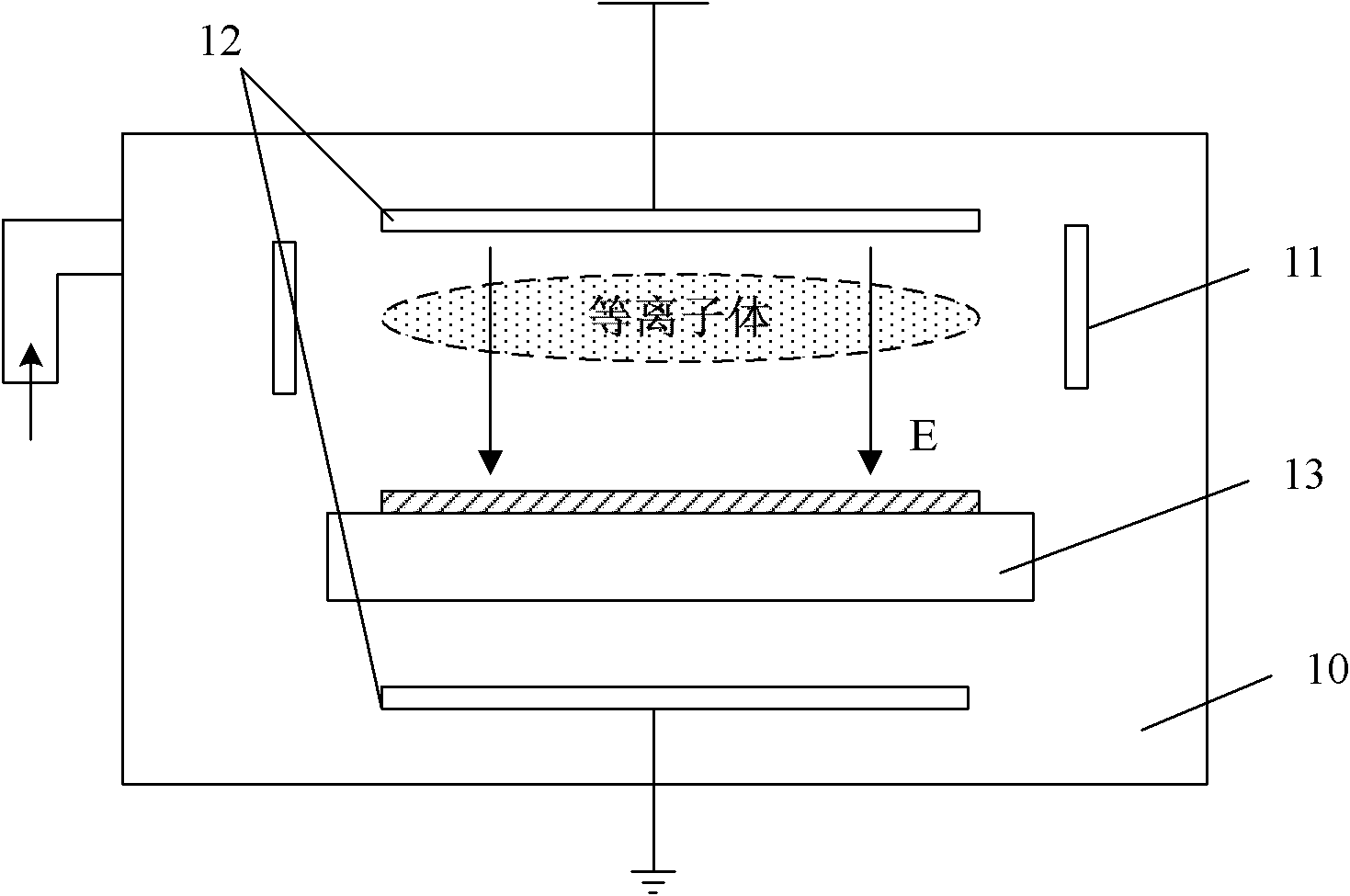

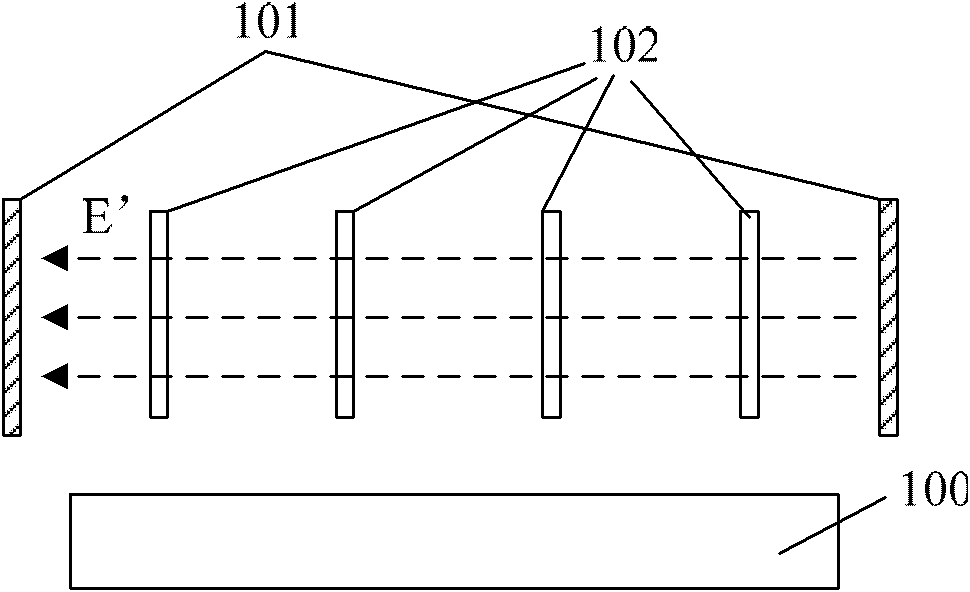

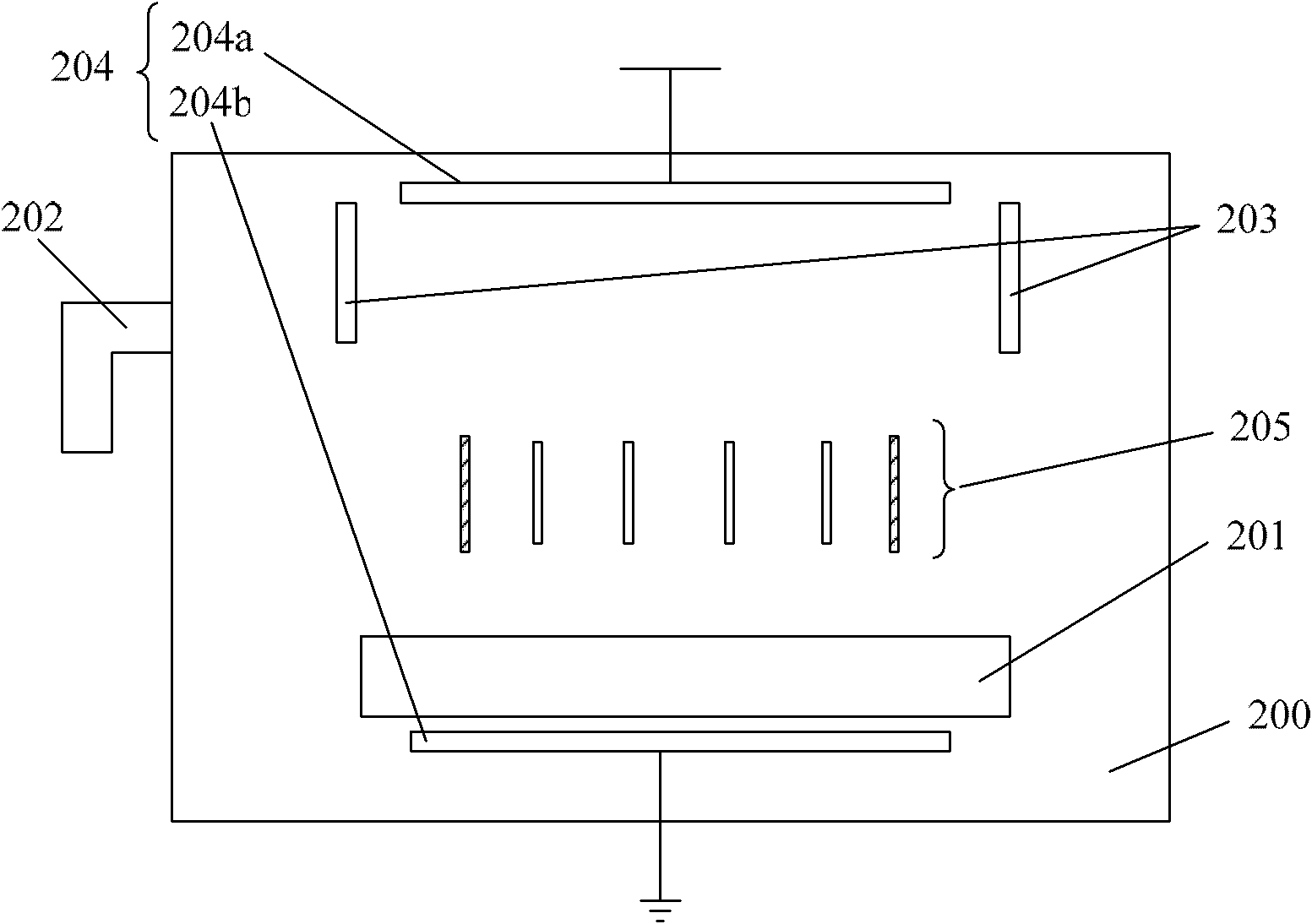

Plasma cleaning device

ActiveCN102486986AReduce throughputPrecise control of bombardment intensityElectric discharge tubesSemiconductor/solid-state device manufacturingIon bombardmentPlasma generator

The invention provides a plasma cleaning device which comprises a plasma chamber, a base, a plasma generator, an ion accelerator and a filter, wherein the base is arranged in the plasma chamber and used for bearing a workpiece to be cleaned, the plasma generator is used for generating plasmas, the ion accelerator is used for generating an accelerating field for accelerating ions in the plasmas to form an ion beam, the filter is arranged on the path of the ion beam and is used for deflecting the movement direction of ions in the ion beam through a deflection field and filtering ions shot to the workpiece to be cleaned so as to reduce throughput of ions in the ion beam and further accurately control the intensity of ion bombardment; therefore dielectric surface property shifting or thickness loss caused by excessive ion beam bombardment can be avoided.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

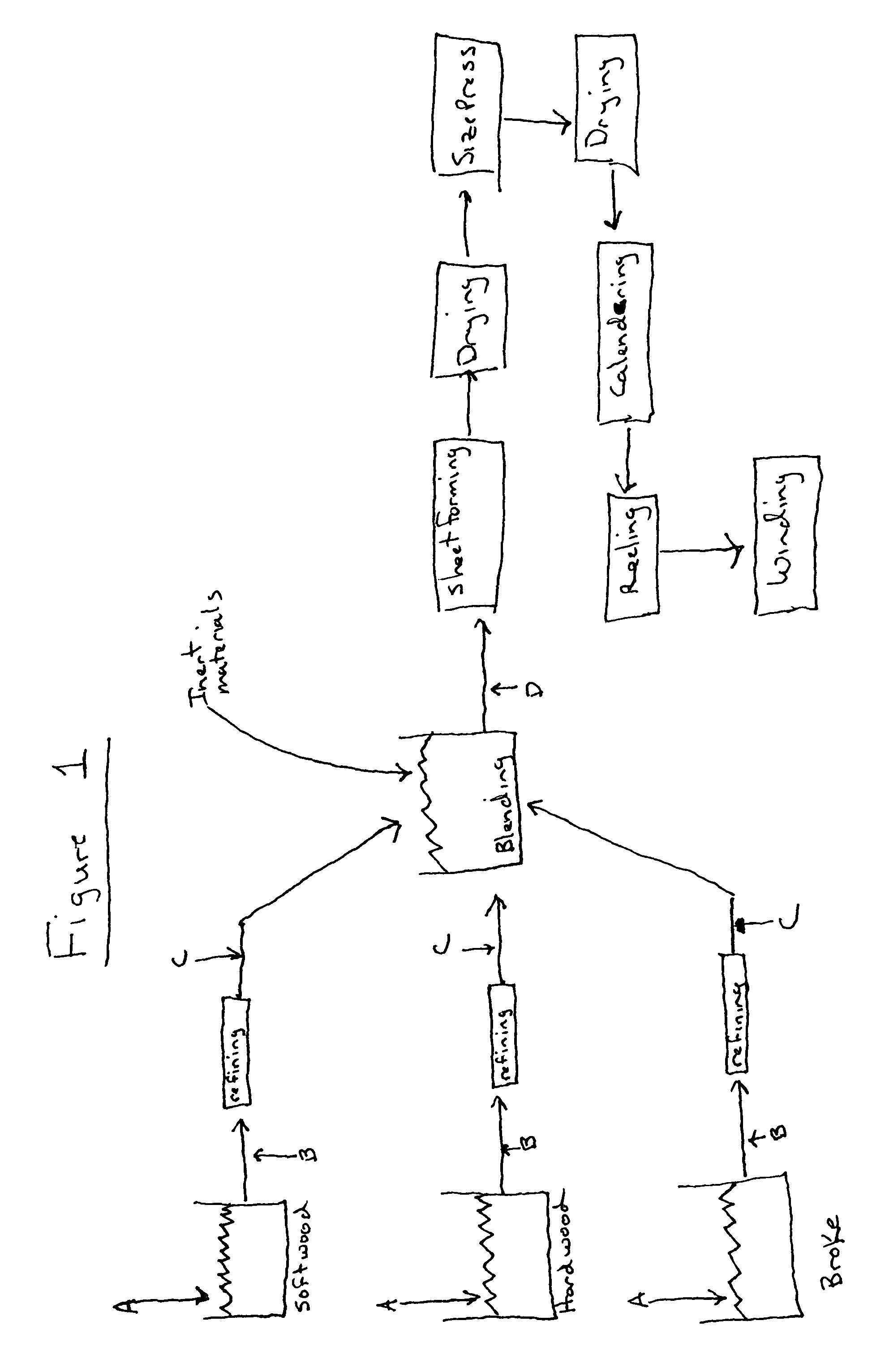

Paper substrates useful in wallboard tape applications

ActiveUS7789996B2Natural cellulose pulp/paperWater-repelling agents additionPulp and paper industryCellulose fiber

This invention relates to paper products and / or substrates suitable for being made and / or converted into wallboard tape; which also may be known as joint tape and / or drywall tape, having a pH of at least 7.0 and containing a plurality of cellulose fibers, a wet strength additive, an alkaline sizing agent, and an anionic promoter, as well as methods of making and using the same.

Owner:INT PAPER CO

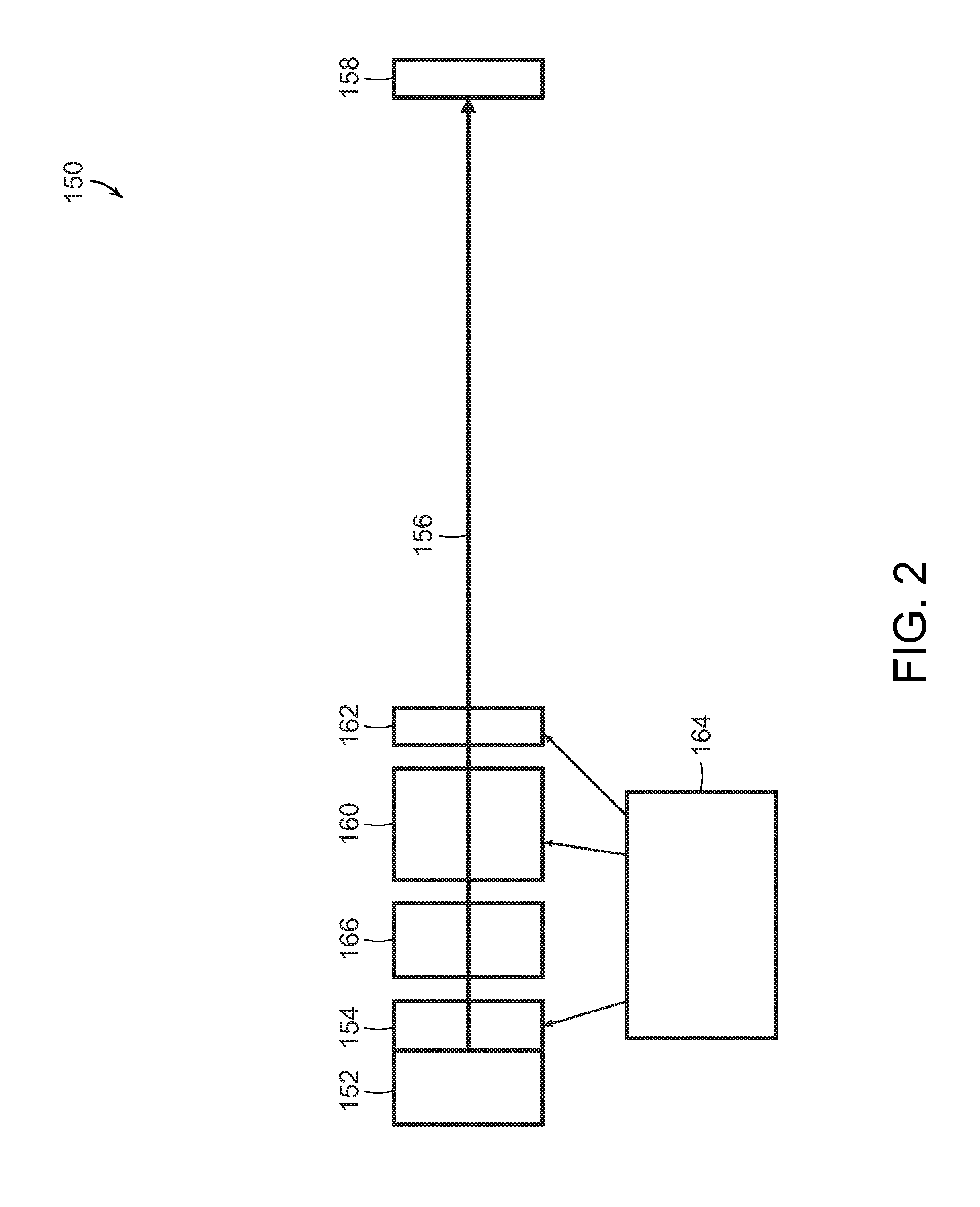

Tandem TOF Mass Spectrometer With Pulsed Accelerator To Reduce Velocity Spread

InactiveUS20110049350A1Increase speedImprove utilizationTime-of-flight spectrometersIsotope separationIon beamMass-to-charge ratio

A tandem TOF mass spectrometer includes a pulsed ion source that generates a pulse of precursor ions from a sample to be analyzed. A first pulsed ion accelerator accelerates and refocuses a predetermined group of precursor ions. A first timed ion passes the predetermined group of precursor ions and rejects substantially all other ions. An ion fragmentation chamber fragments at least some of the precursor ions in the predetermined group. A second timed ion selector selects a predetermined range of masses centered on each precursor in the predetermined group and rejects substantially all other ions. A second pulsed ion accelerator accelerates and refocuses the selected precursor ions and fragments thereof. An ion mirror generates a reflected ion beam. An ion detector detects precursor ions and fragments, wherein a flight time from the second pulsed ion accelerator to the ion detector is dependent on a mass-to-charge ratio of the selected precursor ions and fragments thereof and nearly independent of an initial velocity distribution of ions in the pulse of ions.

Owner:VIRGIN INSTR CORP

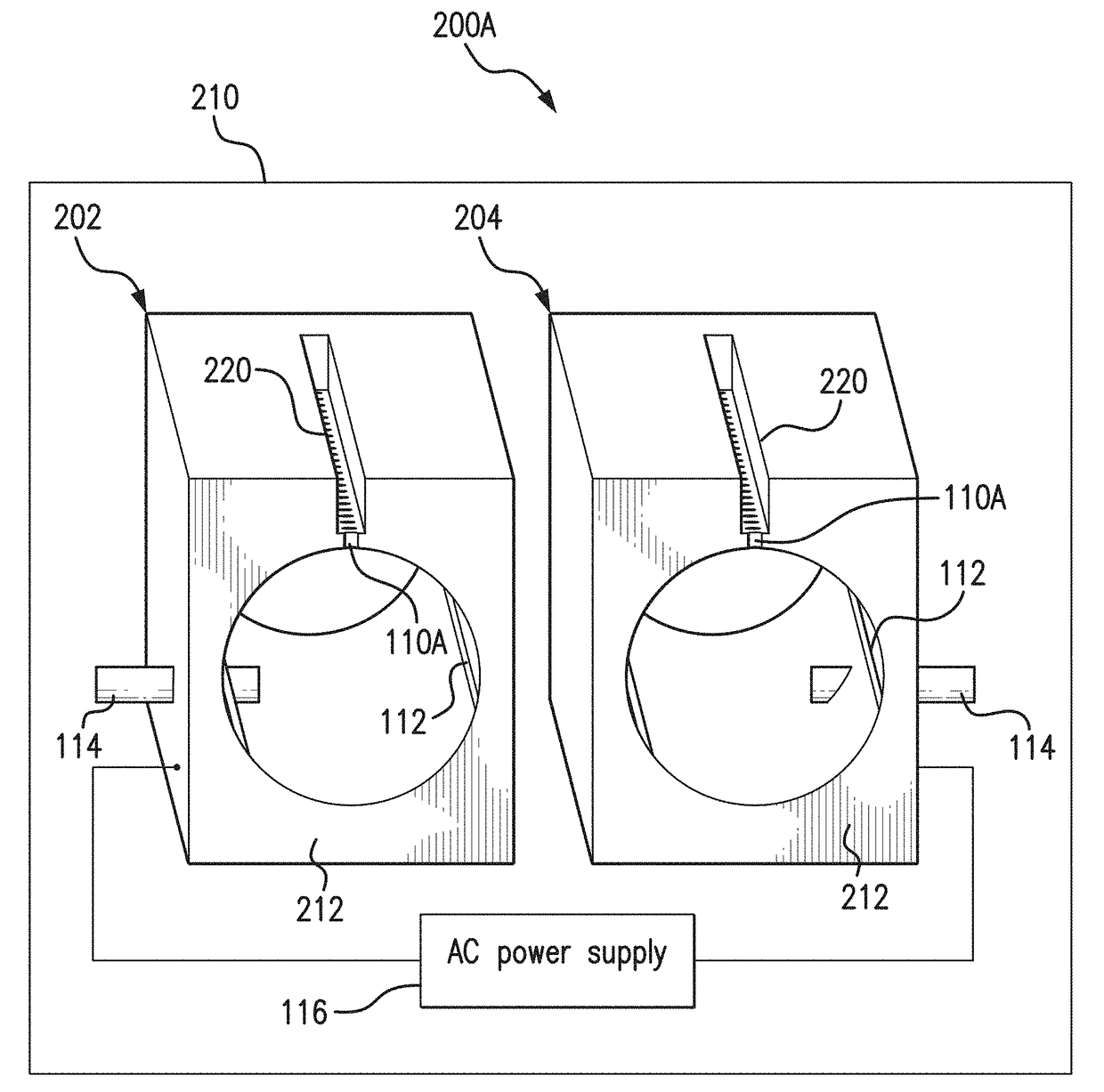

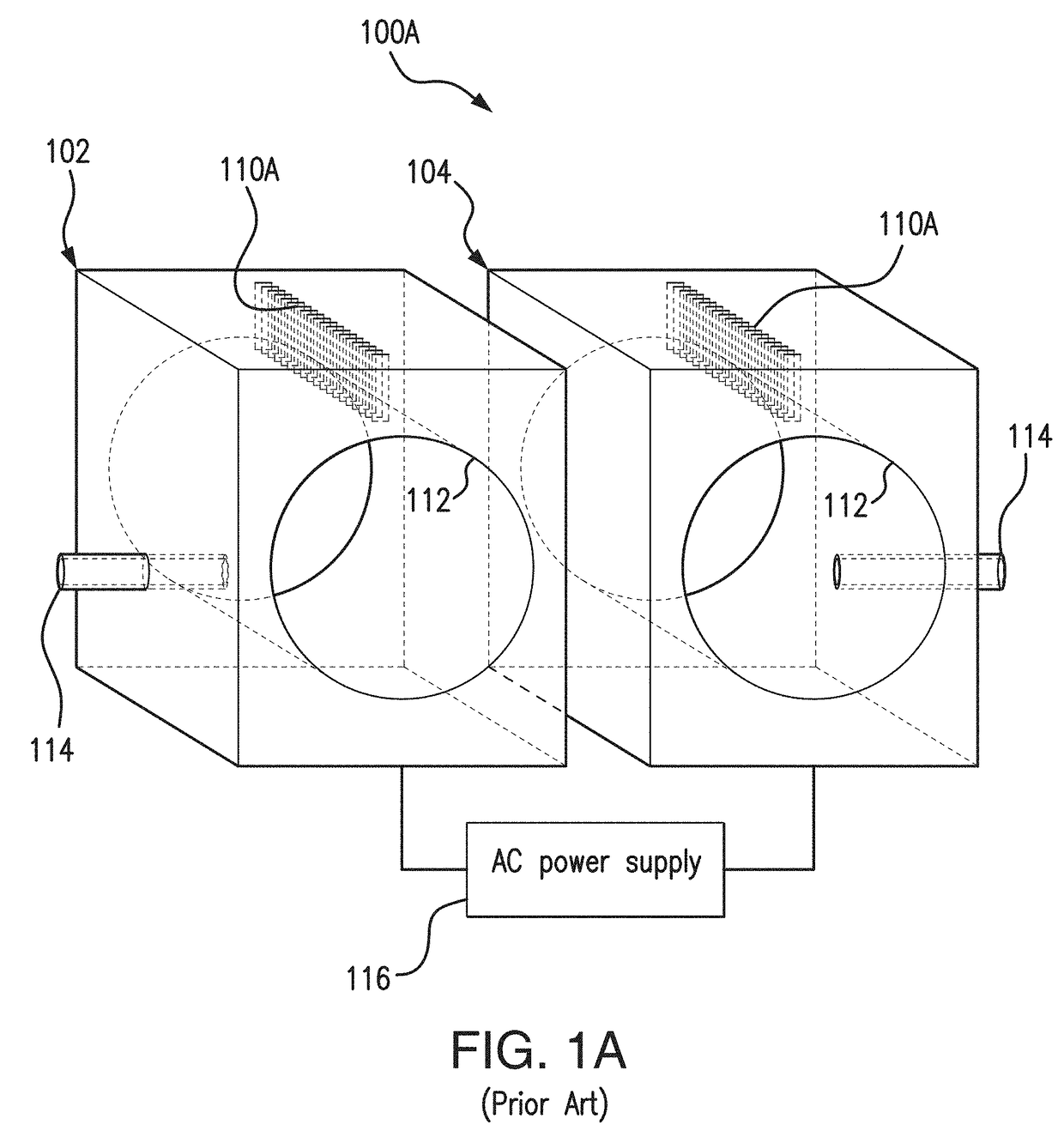

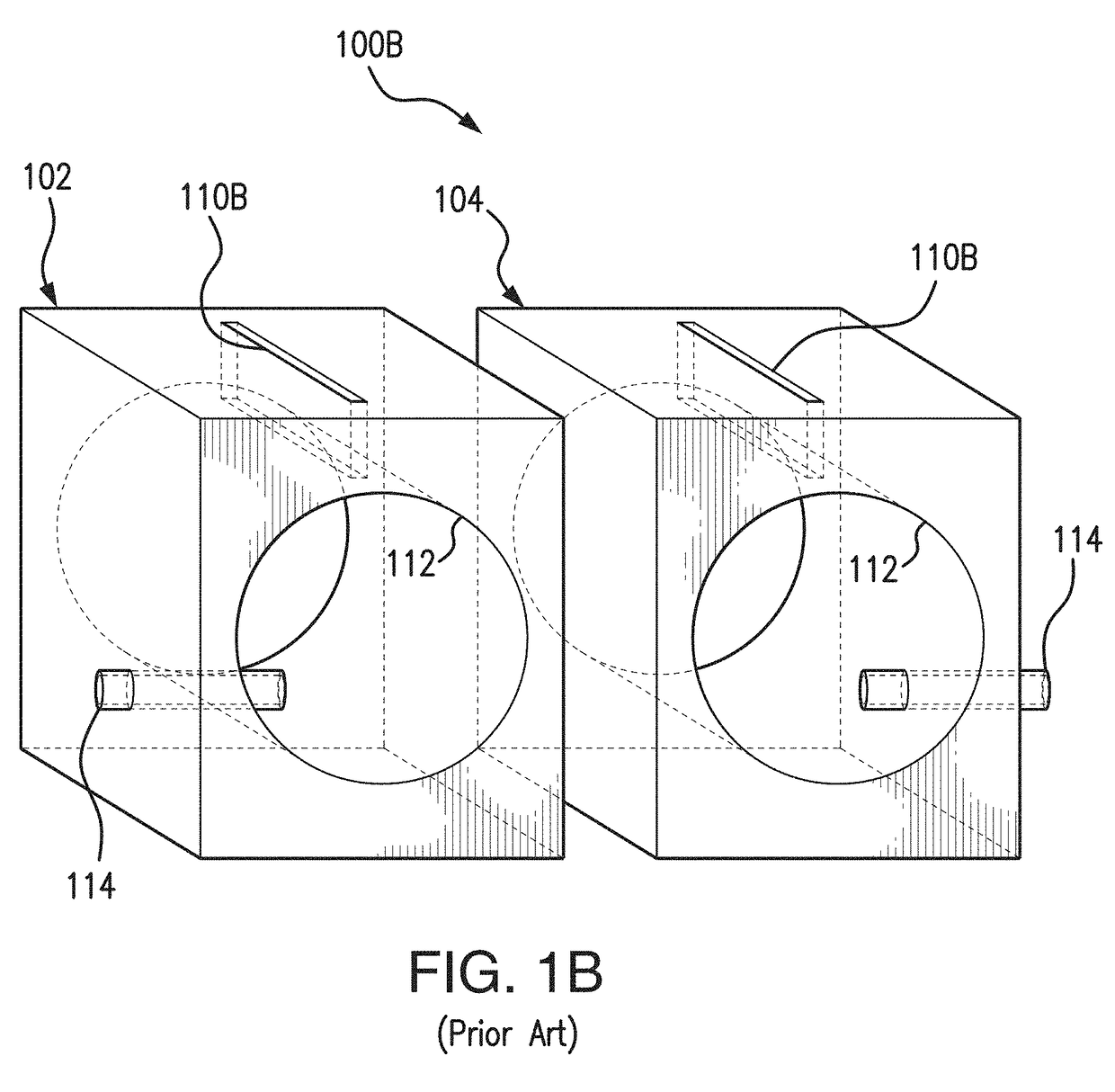

Hollow cathode ion source

An ion source includes a chamber. The ion source further includes a first hollow cathode having a first hollow cathode cavity and a first plasma exit orifice and a second hollow cathode having a second hollow cathode cavity and a second plasma exit orifice. The first and second hollow cathodes are disposed adjacently in the chamber. The ion source further includes a first ion accelerator between and in communication with the first plasma exit orifice and the chamber. The first ion accelerator forms a first ion acceleration cavity. The ion source further includes a second ion accelerator between and in communication with the second plasma orifice and the chamber. The second ion accelerator forms a second ion acceleration cavity. The first hollow cathode and the second hollow cathode are configured to alternatively function as electrode and counter-electrode to generate a plasma. Each of the first ion acceleration cavity and the second ion acceleration cavity are sufficient to enable the extraction and acceleration of ions.

Owner:ASAHI GLASS CO LTD +2

Terylene alkali deweighting processing method

InactiveCN103757885ALower glass transition temperaturePromote hydrolysisFibre typesDisperse dyeIon accelerators

The invention discloses a terylene alkali deweighting processing method. The method comprises the steps: carrying out alkali deweighting processing of terylene with sodium hydroxide by adopting a dipping process, dissolving sodium hydroxide, a cationic accelerant and a terylene dispersion dye dyeing carrier in water to prepare an alkali liquid, putting a terylene fabric into the alkali liquid with the alkali deweighting bath ratio of 1:5-100, then heating up to 70-90 DEG C at a heating-up rate of 0.5-2 DEG C / min, carrying out heat preservation for 30-100 min, after finishing heat preservation, taking out the terylene fabric, carrying out full water washing for a plurality of times with tap water, and then drying at the temperature of 80 DEG C. The method reduces the alkali deweighting processing temperature, saves energy, and decreases the using amounts of sodium hydroxide and the cationic accelerant; and quality indexes of the prepared terylene fabric are consistent to those of a fabric processed by conventional alkali deweighting. The method has the advantages of simple process and easy operation, has no special requirements on the terylene fabric and equipment, can be used for large-scale production by utilizing conventional equipment, and has a wide application prospect.

Owner:HENAN INST OF ENG

Linear time-of-flight mass spectrometry with simultaneous space and velocity focusing

InactiveUS8461521B2Removed volatility barrierTime-of-flight spectrometersIsotope separationTime-of-flight mass spectrometryMass analyzer

A time-of-flight mass spectrometer includes an ion source that generates ions. A two-field ion accelerator receives the ions generated by the ion source and generates an electric field that accelerates the ions through an ion flight path. A pulsed ion accelerator generates an accelerating electric field that focuses the ions to a focal plane where the ion flight time to the focal plane for an ion of predetermined mass-to-charge ratio is substantially independent to first order of an initial velocity of the ions prior to acceleration. An ion detector is positioned at the focal plane to detect ions. The two-field ion accelerator generates electric fields that cause the ion flight time to the ion detector for an ion of predetermined mass-to-charge ratio to be substantially independent to first order of both the initial position and the initial velocity of the ions prior to acceleration.

Owner:VIRGIN INSTR CORP

Reflector Time-of-Flight Mass Spectrometry with Simultaneous Space and Velocity Focusing

InactiveUS20120145889A1Removed volatility barrierEasy to useTime-of-flight spectrometersIsotope separationMass analyzerReflectron

A time-of-flight mass spectrometer includes an ion source that generates ions. A two-field ion accelerator accelerates the ions through an ion flight path. A pulsed ion accelerator focuses the ions to a first focal plane where the ion flight time is substantially independent to first order of an initial velocity of the ions prior to acceleration. An ion reflector focuses ions to a second focal plane where the ion flight time is substantially independent to first order of an initial velocity of the ions prior to acceleration. An ion detector positioned at the second focal plane detects the ions. The two-field ion accelerator and the ion reflector cause the ion flight time to the ion detector for the ion of predetermined mass-to-charge ratio to be substantially independent to first order of both the initial position and the initial velocity of the ions prior to acceleration.

Owner:VIRGIN INSTR CORP

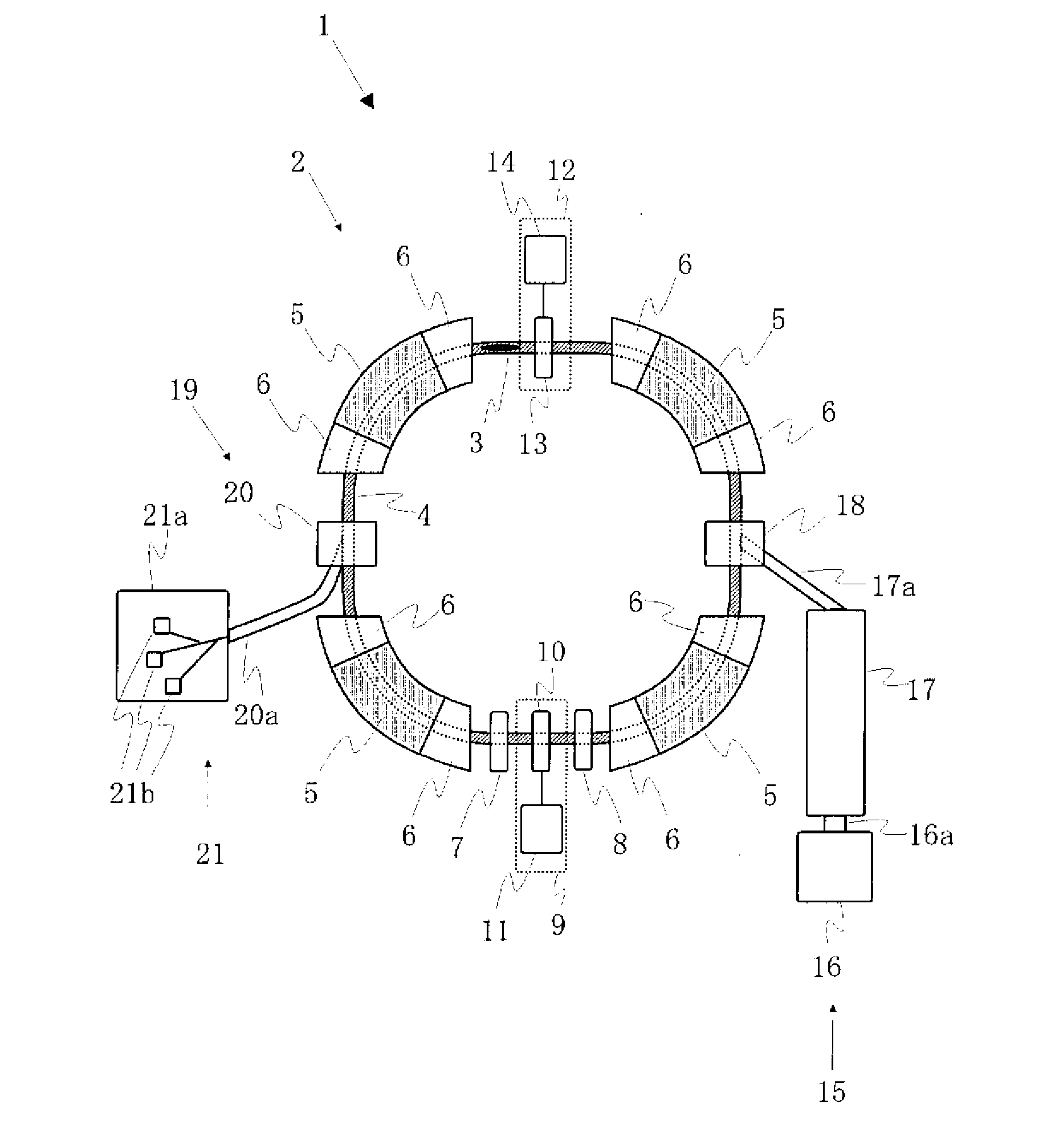

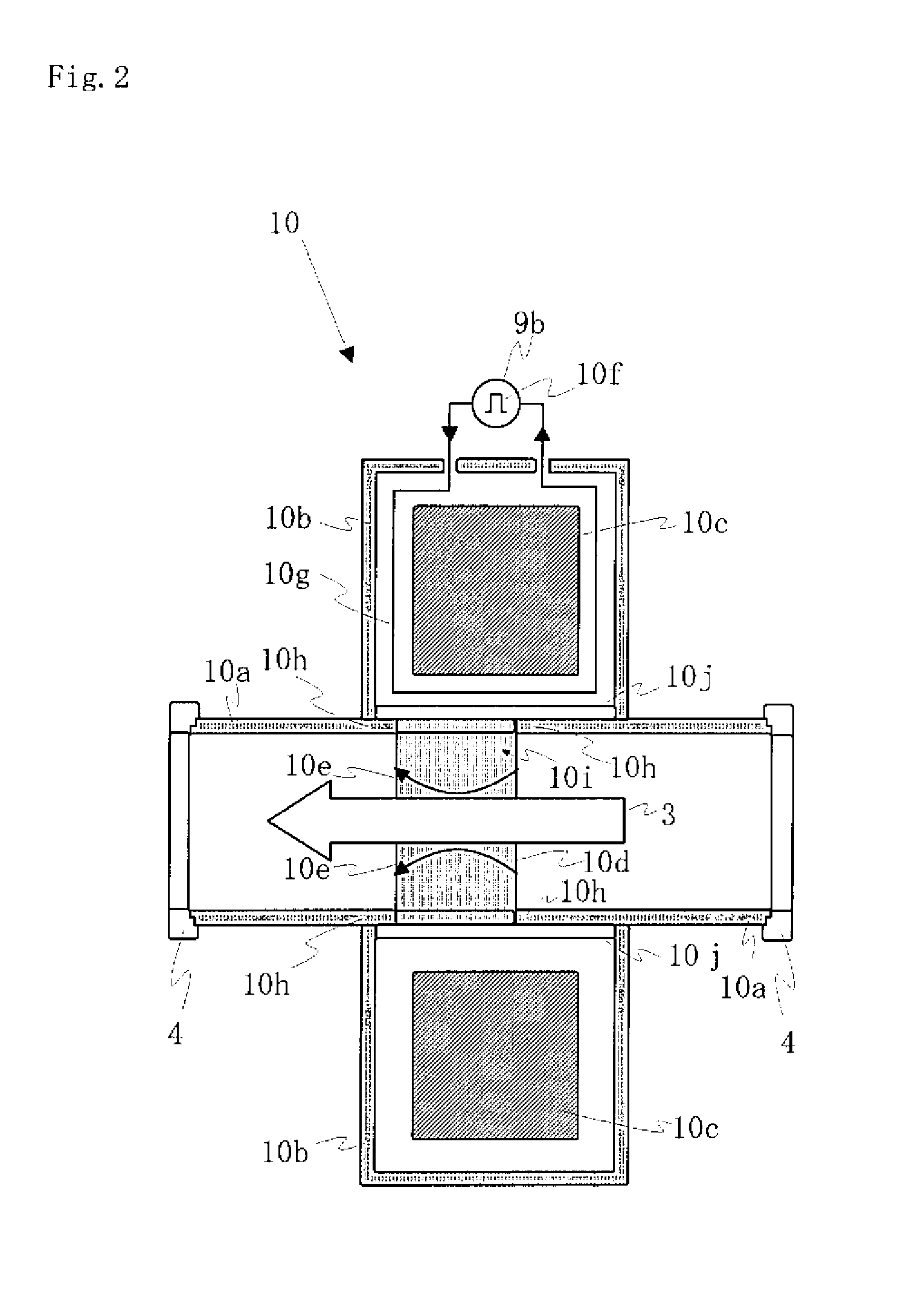

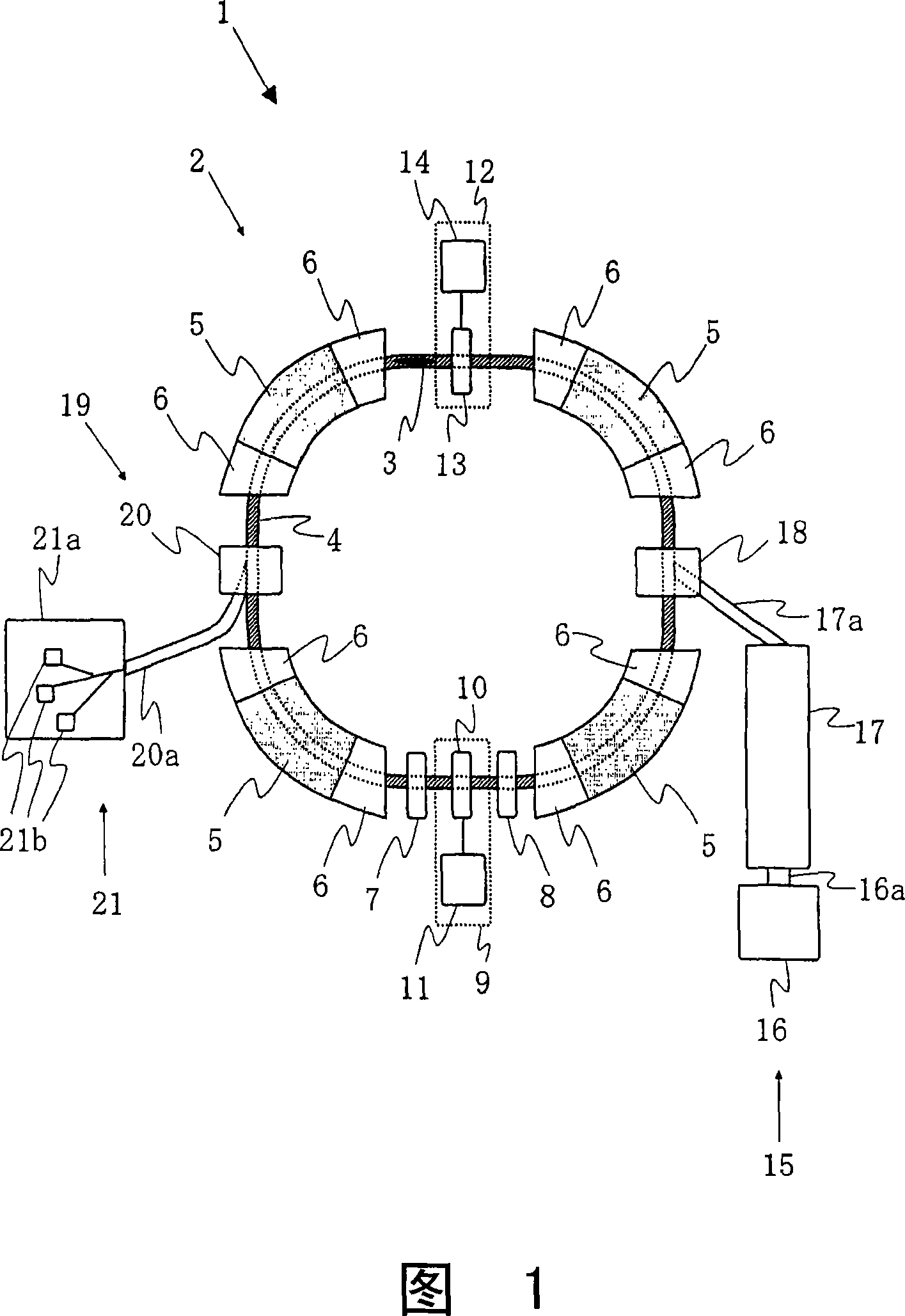

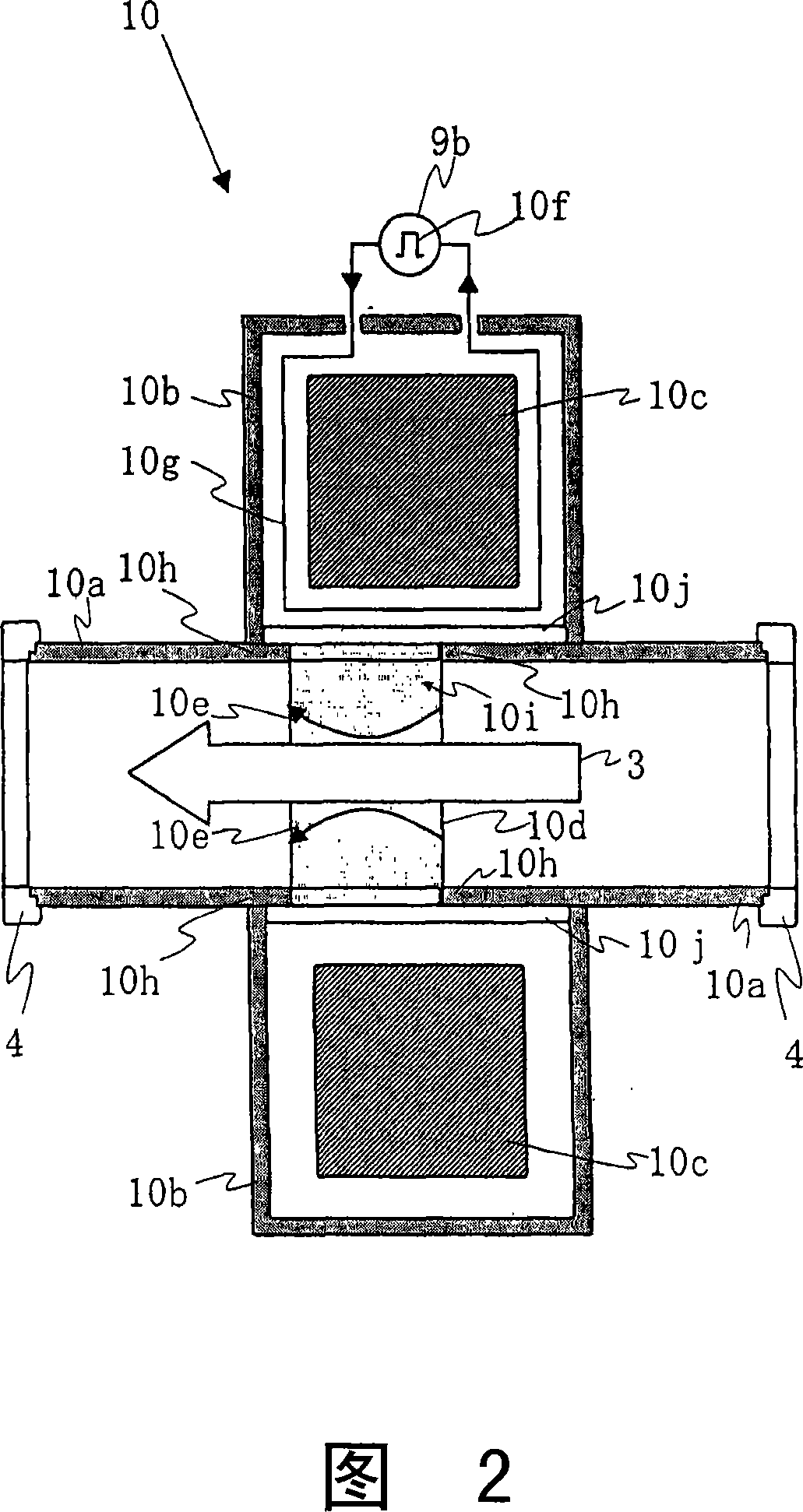

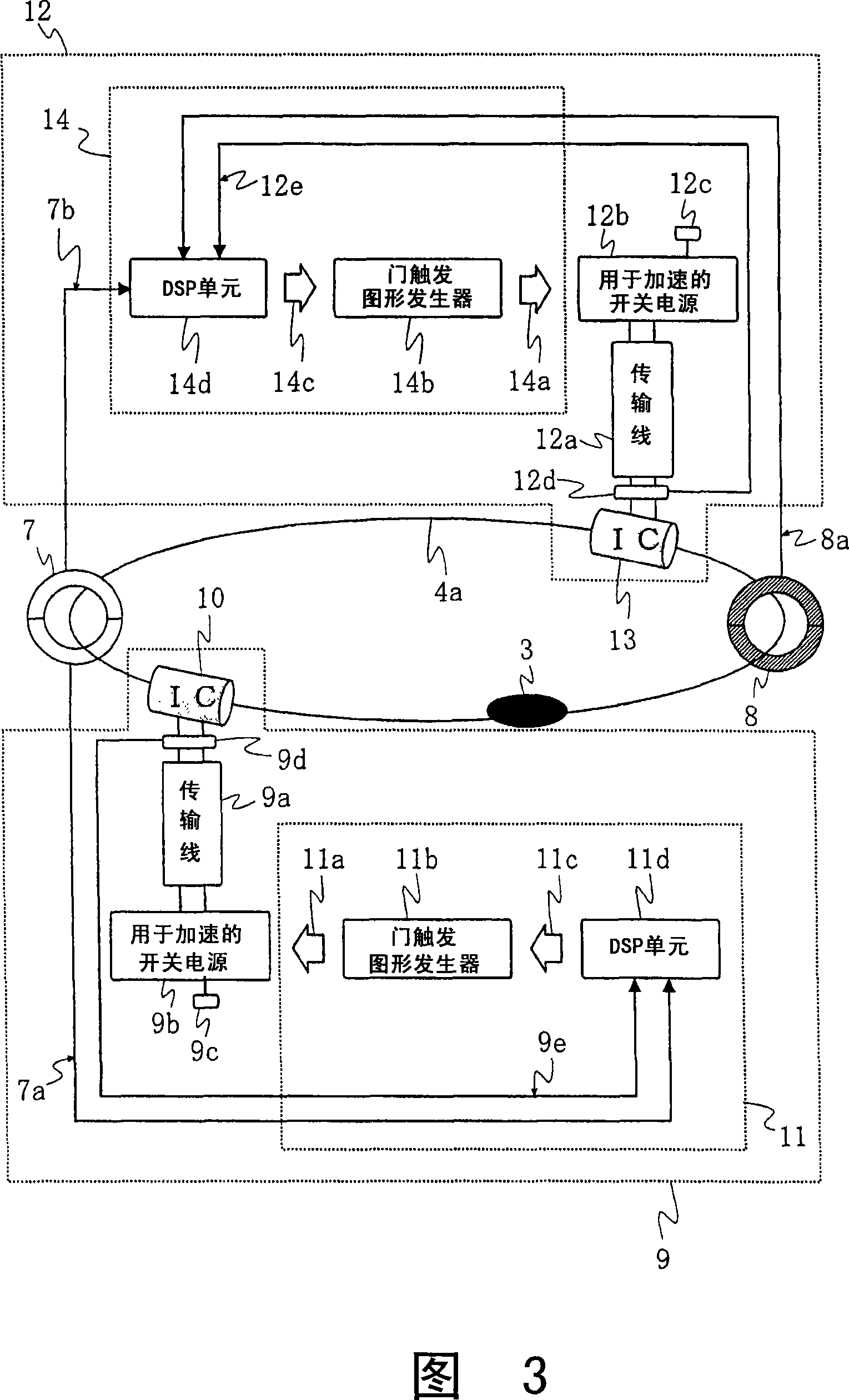

All-ion accelerator and control method of the same

ActiveUS20090195194A1Prevent proliferationMagnetic induction acceleratorsMagnetic resonance acceleratorsIon beamSynchrotron

It is an object of the present invention to provide an accelerator that can accelerate by itself all ions up to any energy level allowed by the magnetic fields for beam guiding, and provides an all-ion accelerator in which with trigger timing and a charging time of an induced voltage applied to an ion beam injected from a preinjector by induction cells for confinement and acceleration used in an induction synchrotron, digital signal processors for confinement and acceleration and pattern generators for confinement and acceleration generate gate signal patterns for confinement and acceleration on the basis of a passage signal of the ion beam and an induced voltage signal for indicating the value of the induced voltage applied to the ion beam, and intelligent control devices for confinement and acceleration perform feedback control of on / off of the induction cells for confinement and acceleration.

Owner:HIGH ENERGY ACCELERATOR RESEARCH ORGANIZATION

All-species ion accelerator and control method thereof

An accelerator capable of accelerating all-species ions to an arbitrary energy level on the same accelerator. An all-species ion accelerator which uses the generating timing and applying time of an induction voltage applied, by a confining and accelerating induction acceleration cell used in an induction acceleration synchrotron, to an ion beam injected by a front-end accelerator to generate a confining and accelerating gate signal pattern by a confining and accelerating digital signal processor and a confining and accelerating pattern generator based on an ion beam passing signal, a position signal and an induction voltage signal used to recognized an induction voltage value applied to an ion beam, and feedback-controls the one / off of the confining and accelerating induction acceleration cell by a confining and accelerating intelligent control device.

Owner:HIGH ENERGY ACCELERATOR RESEARCH ORGANIZATION

EUV collector debris management

InactiveUS8075732B2Decorative surface effectsSemiconductor/solid-state device manufacturingEtchingHalogen

A method and apparatus that may comprise an EUV light producing mechanism utilizing an EUV plasma source material comprising a material that will form an etching compound, which plasma source material produces EUV light in a band around a selected center wavelength comprising: an EUV plasma generation chamber; an EUV light collector contained within the chamber having a reflective surface containing at least one layer comprising a material that does not form an etching compound and / or forms a compound layer that does not significantly reduce the reflectivity of the reflective surface in the band; an etchant source gas contained within the chamber comprising an etchant source material with which the plasma source material forms an etching compound, which etching compound has a vapor pressure that will allow etching of the etching compound from the reflective surface. The etchant source material may comprises a halogen or halogen compound. The etchant source material may be selected based upon the etching being stimulated in the presence of photons of EUV light and / or DUV light and / or any excited energetic photons with sufficient energy to stimulate the etching of the plasma source material. The apparatus may further comprise an etching stimulation plasma generator providing an etching stimulation plasma in the working vicinity of the reflective surface; and the etchant source material may be selected based upon the etching being stimulated by an etching stimulation plasma. There may also be an ion accelerator accelerating ions toward the reflective surface. The ions may comprise etchant source material. The apparatus and method may comprise a part of an EUV production subsystem with an optical element to be etched of plasma source material.

Owner:ASML NETHERLANDS BV

Magnetic Structure For Circular Ion Accelerator

ActiveUS20130270451A1Improve cooling effectStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsThermal contactIon acceleration

A magnet structure for use in a circular ion accelerator, such as e.g. a synchrocyclotron comprises a cold-mass structure including superconducting magnetic coils (20, 25), at least one dry cryocooler unit (10, 11, 12, 13) coupled with the cold-mass structure for cooling the latter and a magnetic yoke structure (30) with a return yoke (35) configured radially around said coils (20, 25). The return yoke (35) comprises an opening in which said dry cryocooler unit (10, 11, 12, 13) is received so as to be in thermal contact with said cold-mass structure.

Owner:ION BEAM APPL

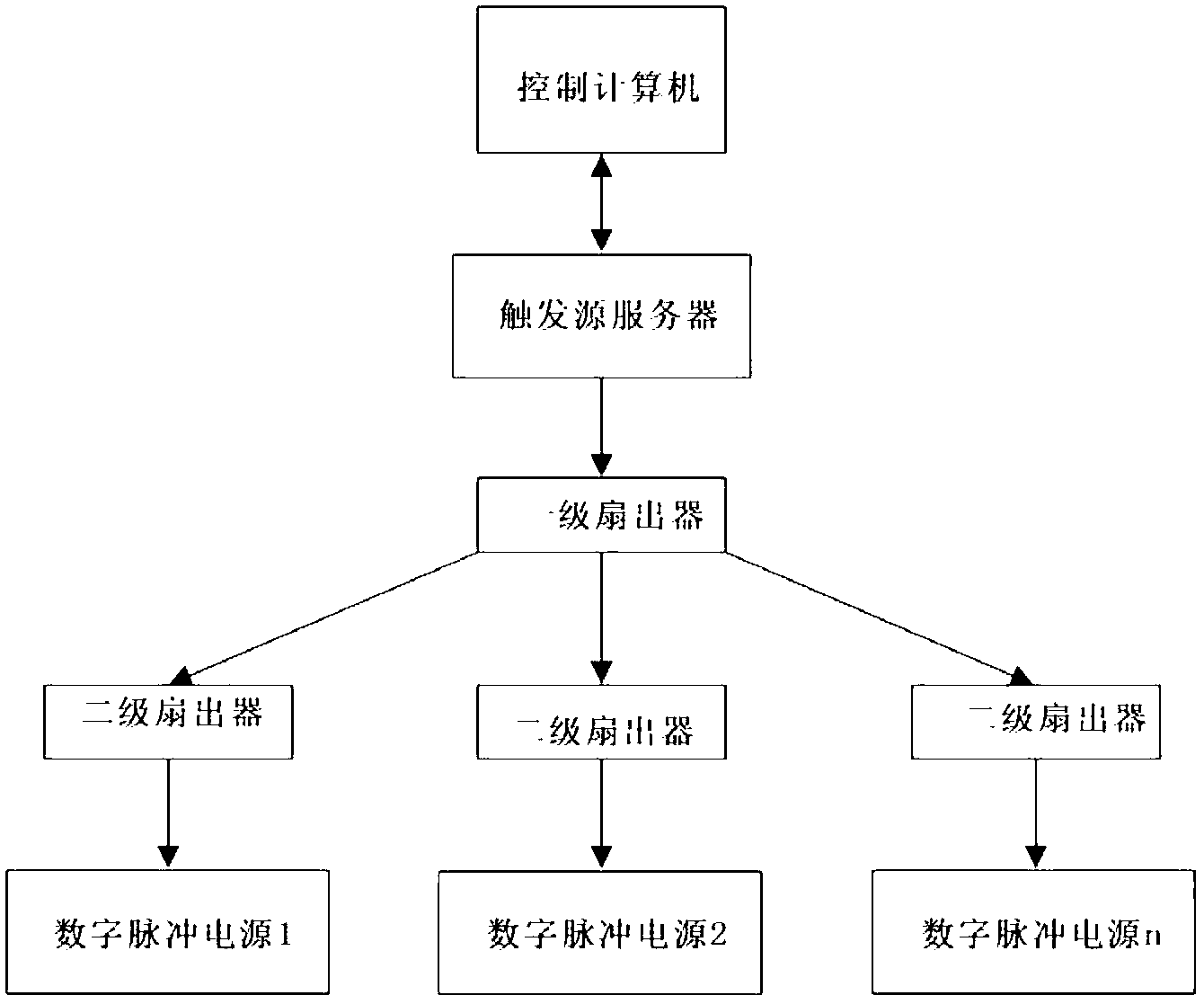

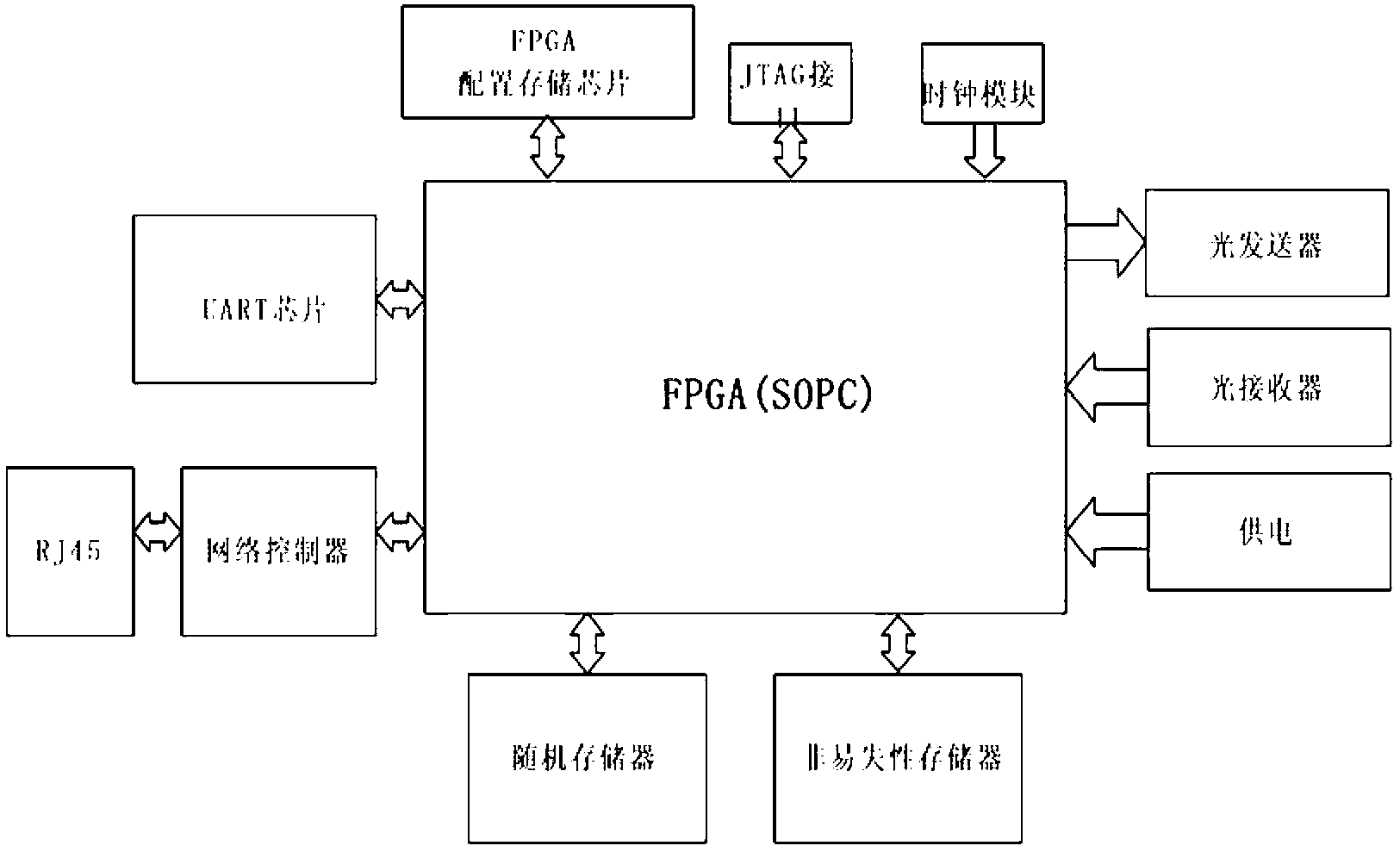

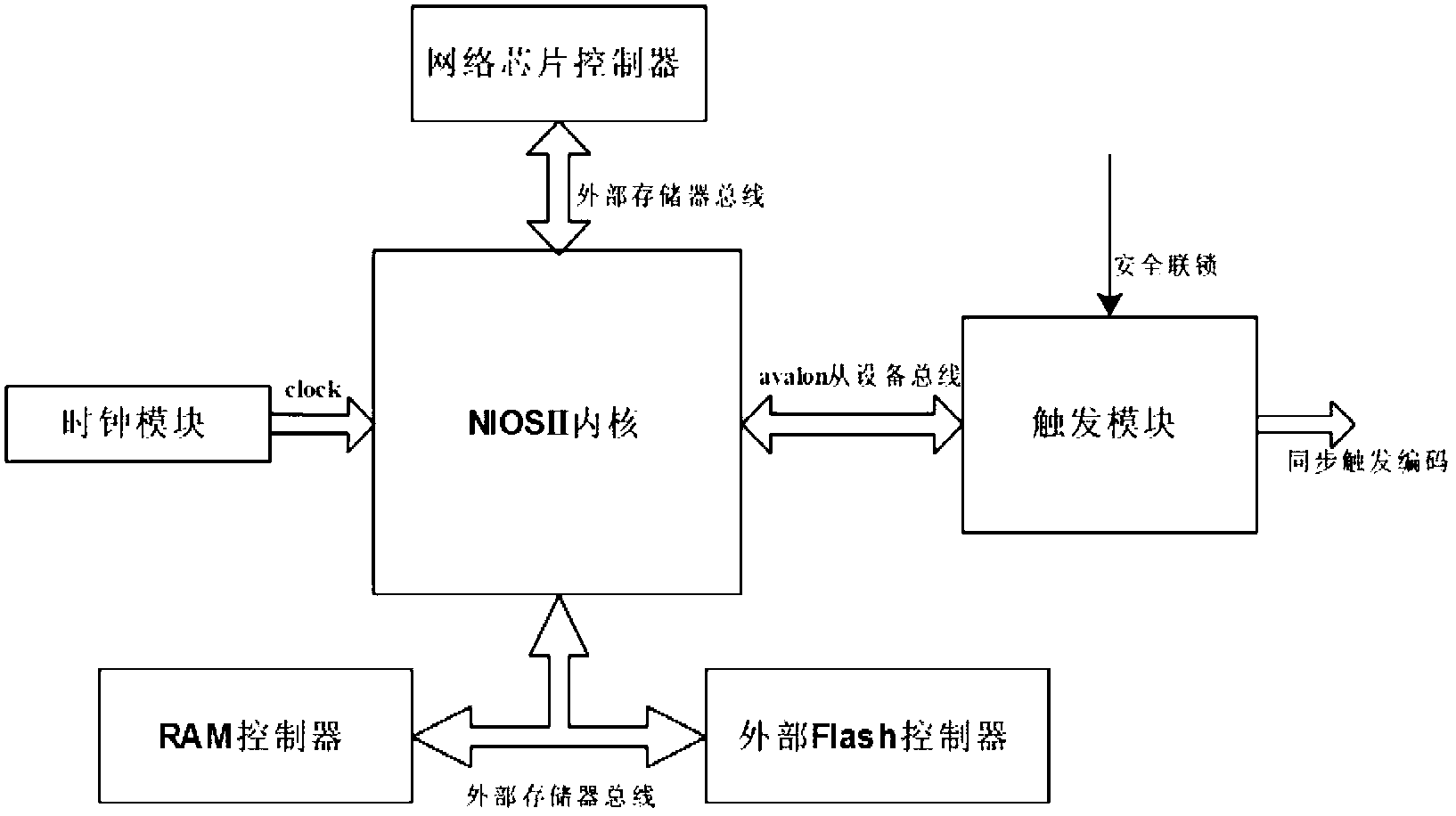

Digital pulse power supply synchronous timing trigger system

ActiveCN103064328AMeet the requirements of flexible timing and synchronous startHighly integratedProgramme controlComputer controlRemote controlComputer module

The invention relates to a digital pulse power supply synchronous timing trigger system for achieving a remote synchronous timing trigger control with many sets of digital pulse power supply.. The digital pulse power supply synchronous timing trigger system is characterized in that the trigger system comprises a trigger source server and the trigger source server is mutually connected with a control computer, the hardware of the trigger source server is a field programmable gata array (FPGA). The trigger source server is connected with a first-level fan-out machine which is respectively connected with multichannel second fan-out machines without time differences. The second fan-out machine is connected with a digital pulse power supply module. The digital pulse power supply synchronous timing trigger system achieves the synchronous starting or the grouped synchronous starting control of ion accelerator digital pulse power supply or related industry many sets of digital pulse power supply according to the setting time series. And the digital pulse power supply synchronous timing trigger system meets the requirements that the digital pulse power in the relevant fields can be started flexible timing synchronization under the remote control method.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

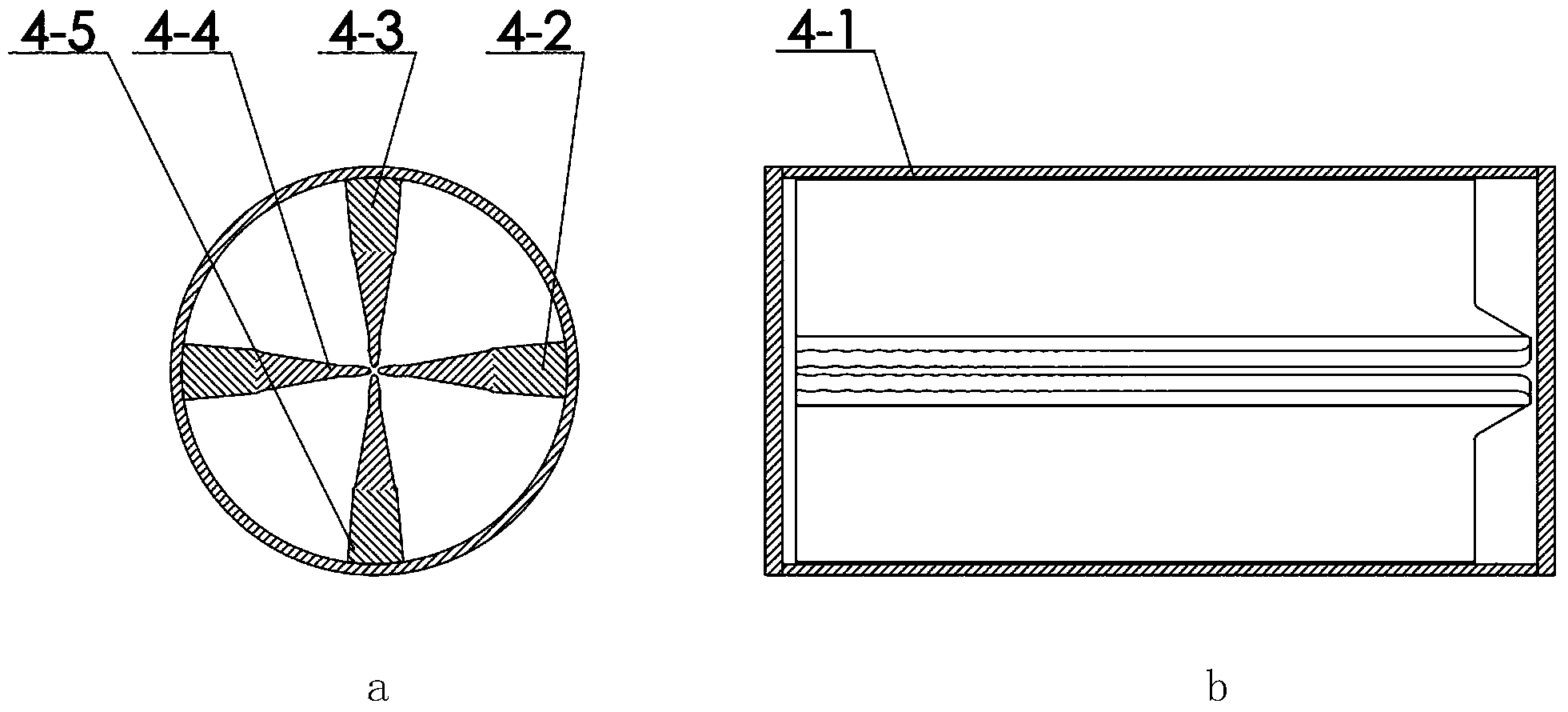

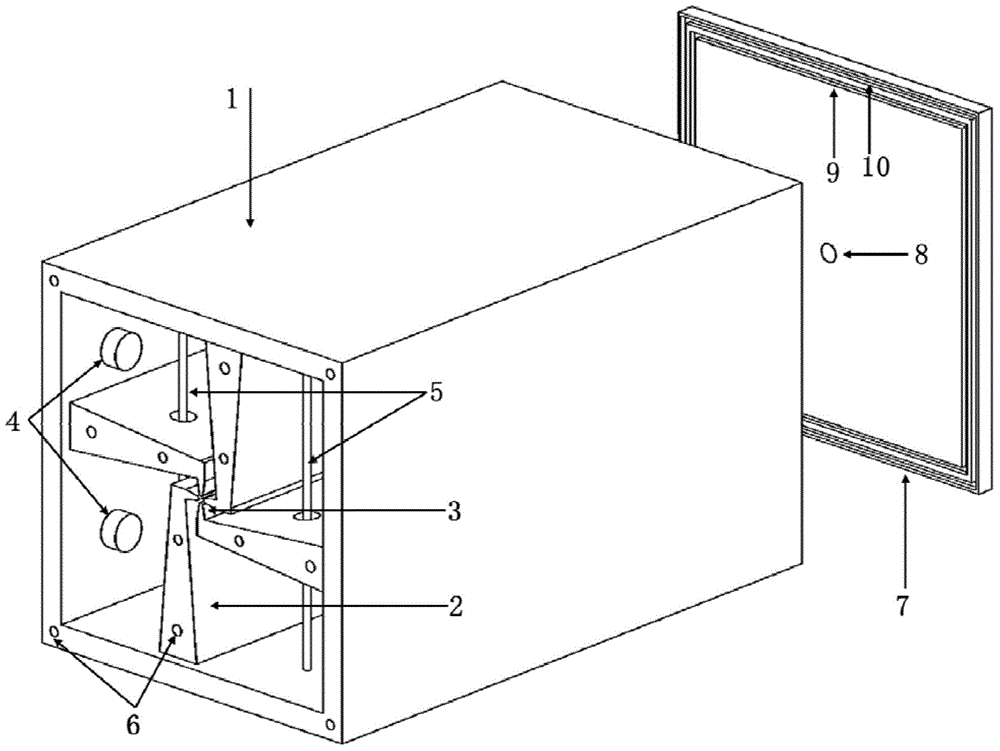

Bent wing-type radio-frequency quadrupole accelerator

The invention relates to the technical field of an acceleration mechanism of an ion accelerator, in particular to a bent wing-type radio-frequency quadrupole accelerator. The bent wing-type radio-frequency quadrupole accelerator is characterized by comprising a cavity, wherein four wings are arranged in the cavity, end plates are respectively arranged at the two ends of the cavity, a beam hole is arranged at the central position of each end plate, the central line of the two beam holes and the central axis of the cavity are on the same straight line, and a Pi-model stabilization rod and a tuner for adjusting frequency are further arranged on the cavity. By bending wings at pole head parts, the cross section size of the cavity is greatly reduced on the condition of no change on the total transverse length of the wings, and the bent wing-type radio-frequency quadrupole accelerator is very suitable for low-frequency beams; and meanwhile, due to the compatibility with the advantages of simplicity and effectiveness of a cooling system of the traditional four-wing radio-frequency quadrupole acceleration mechanism, the bent wing-type radio-frequency quadrupole accelerator is very suitable for a continuous-wave working state. Obvious advantages are shown on the aspects of reduction on processing difficulty of the radio-frequency quadrupole accelerator, reduction on engineering cost, improvement on running reliability and stability of a device and the like.

Owner:科近泰基新技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com