Automobile interior ornament flocking method

A technology for automotive interior parts and flocking, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc. and other problems, to achieve uniform color and brightness, graceful and gorgeous appearance, and easy cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

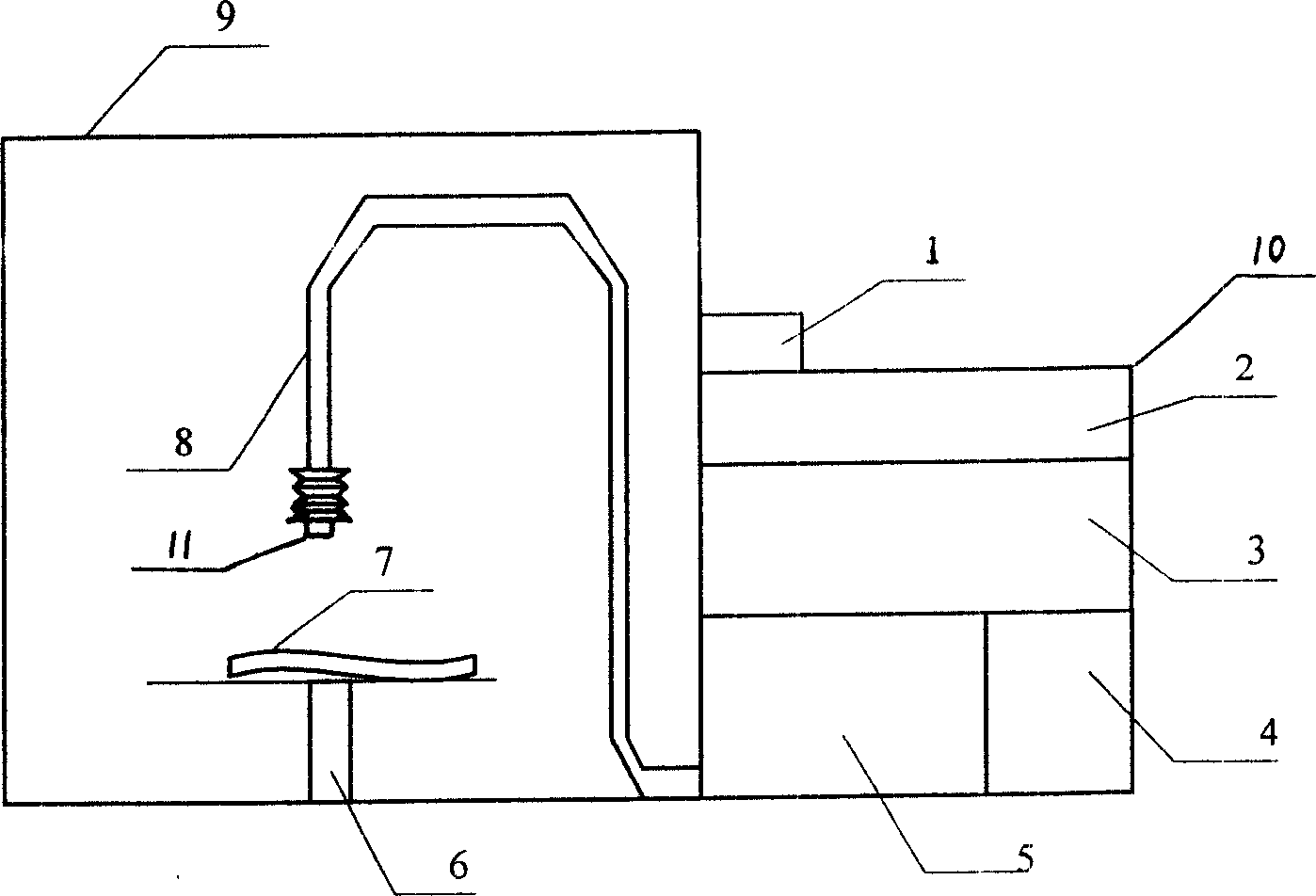

Image

Examples

Embodiment Construction

[0019] 1. Surface treatment, for the surface of automobile interior parts that need flocking, such as the outer surface of the A, B, and C pillar guards, the outer surface of the door panel, the outer surface of the instrument panel, the outer surface of the coat rack, the surface of the door frame sealing strip, As well as the surface of car glove box, glove box, radio box, center console, etc., use 60-360 mesh emery cloth or sandpaper repeatedly to make the surface of the flocked area become a rough surface to increase the bonding surface area. At the same time, an embedded groove structure is formed to enhance the bonding strength, and the roughness of the polishing requires visual inspection of the surface to lose its original gloss. For materials with poor wettability with oil stains on the surface, use a rag to wipe the surface with acetone or xylene for degreasing treatment;

[0020] 2. Glue, use brushing or spraying method to apply glue, mix the purchased adhesive accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pile length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com