Magnetic structure for circular ion accelerator

a circular ion accelerator and magnet structure technology, applied in the direction of accelerators, magnetic resonance accelerators, electrical devices, etc., can solve the problems of increasing the magnetic stray field, reducing the efficiency of the yoke structure, and prolonging the down time period of the cyclotron operation. , to achieve the effect of increasing the refrigeration capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

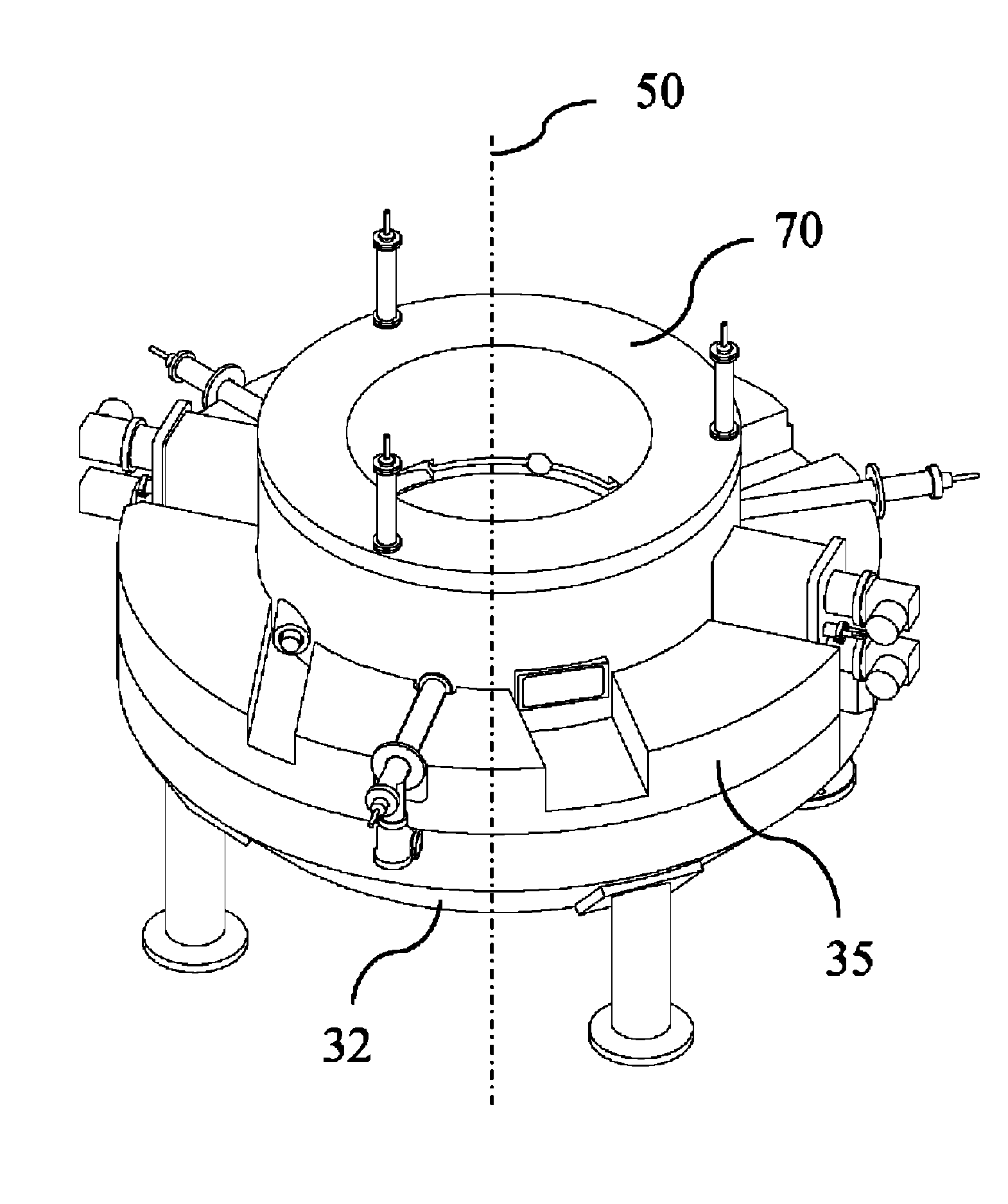

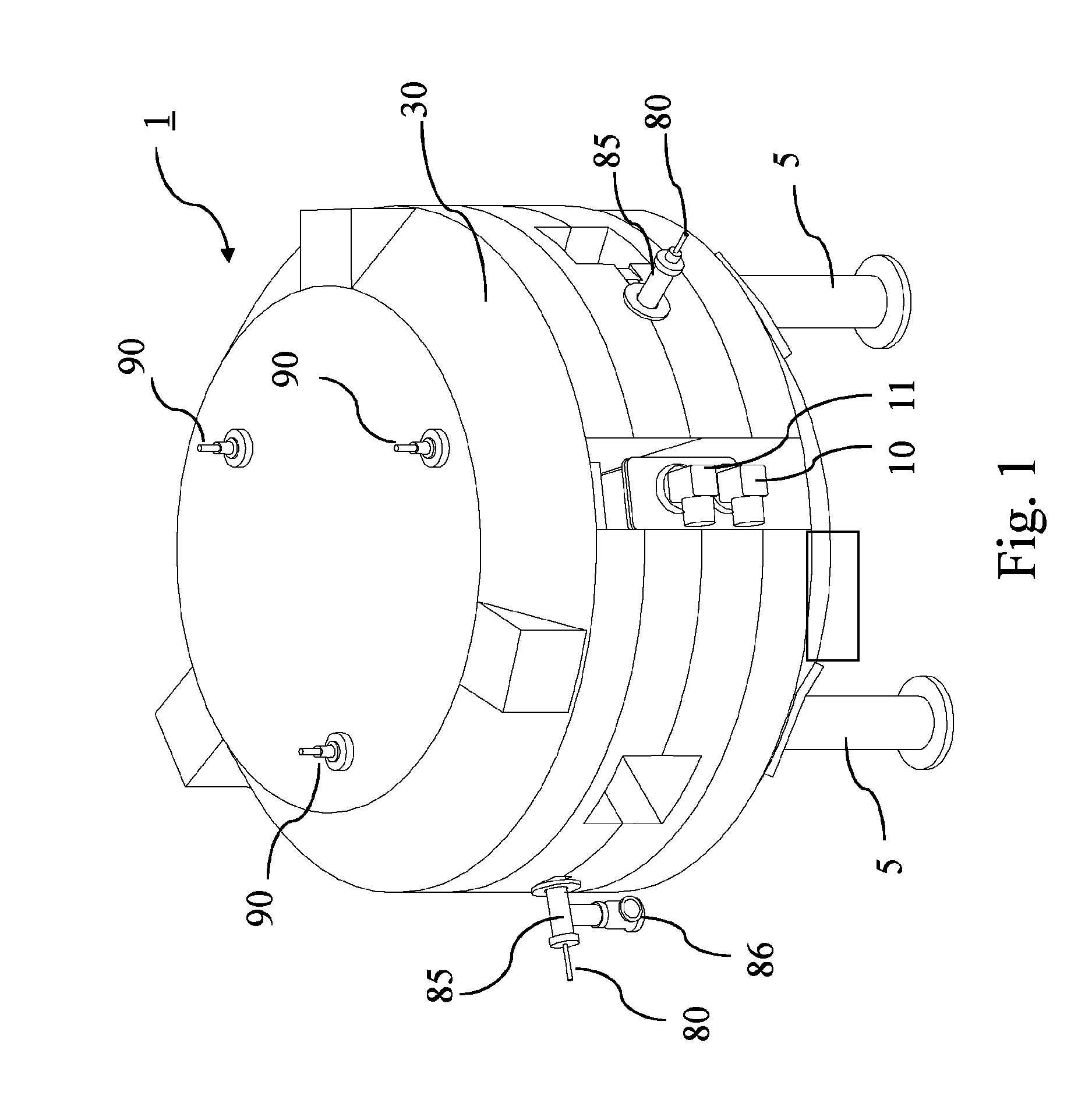

[0028]FIG. 1 shows, as an illustration of the invention, a three dimensional view of a preferred embodiment of a synchrocyclotron 1 comprising a magnetic structure according to the invention. It will be noted that, for the sake of clarity, the representation of the synchrocyclotron 1 is only schematic, and that not all its parts and details are shown. The major part of the magnetic structure that is visible from the outside of the synchrocyclotron is a magnetic yoke structure 30, which is usually made of ferromagnetic iron. The synchrocyclotron with its magnetic structure is supported on the floor by several feet 5.

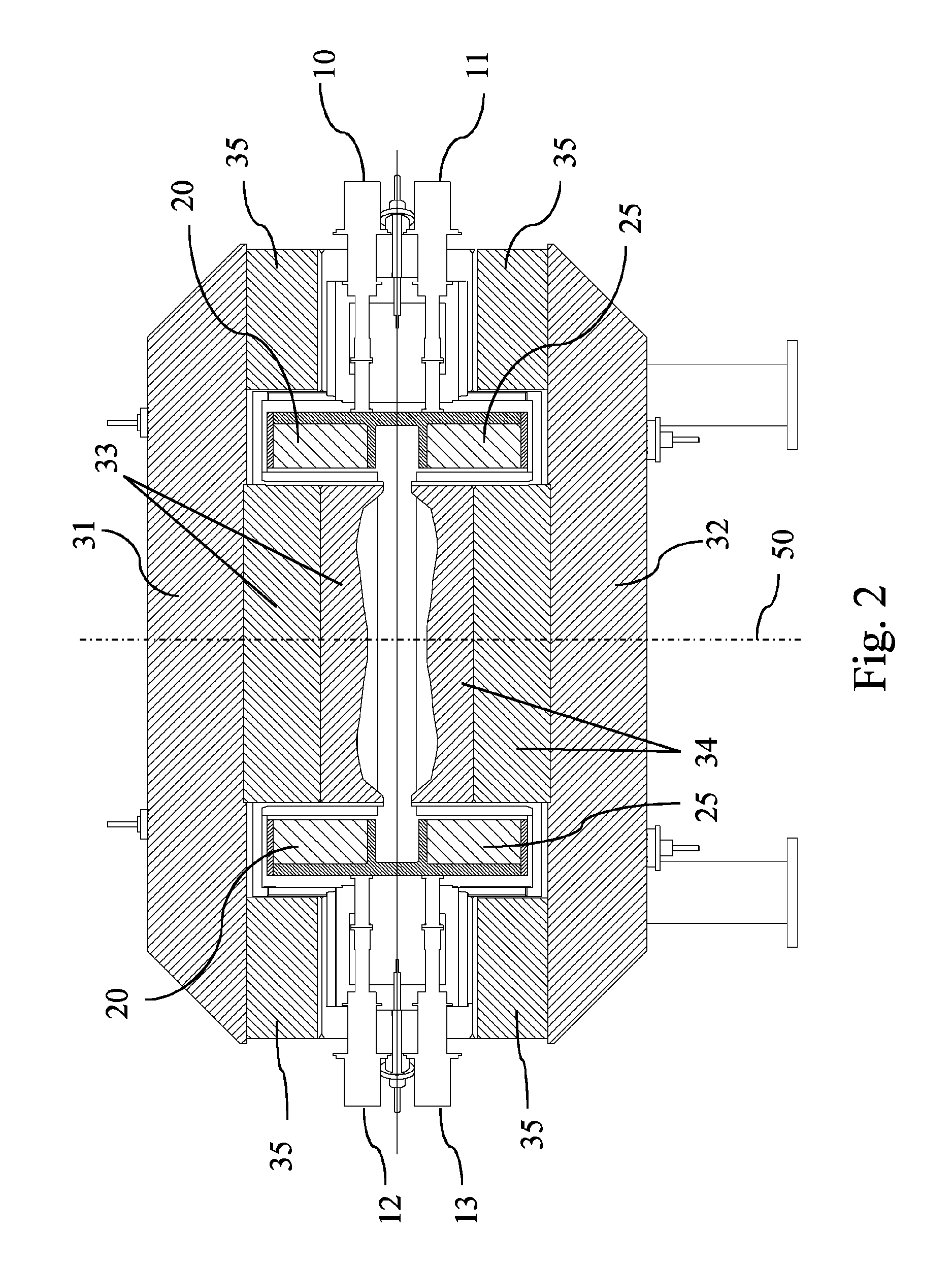

[0029]FIG. 2 is a schematic sectional view illustrating a preferred embodiment of magnetic structure according to the invention. The magnetic structure comprises two circular superconducting magnetic coils 20, 25. These coils have an annular shape and are superimposed symmetrically with regard to a median plane of the synchrocyclotron 1. To fix the ideas, it will be noted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com