Patents

Literature

39results about How to "Low material performance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Additive manufacturing of three-dimensional articles

ActiveUS20150165524A1Short manufacturing timeQuality improvementHydrogenAdditive manufacturing apparatusLaser additive manufacturingSupport surface

The present invention relates to a method for forming a three-dimensional article through successively depositing individual layers of powder material that are fused together so as to form the article, the method comprising the step of heating a first portion of a support surface while depositing a layer of powder material on a second portion of the support surface.

Owner:ARCAM AB

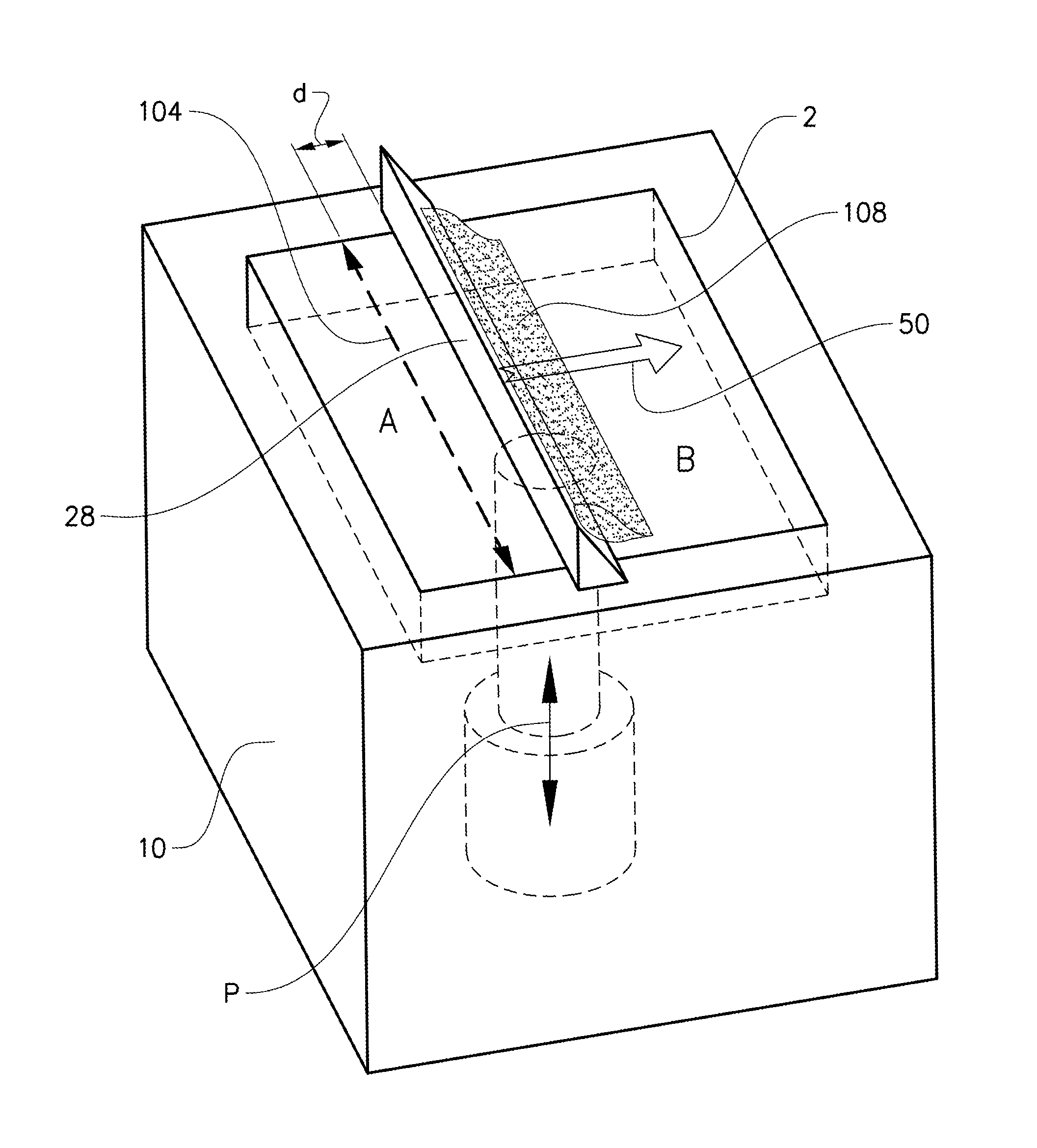

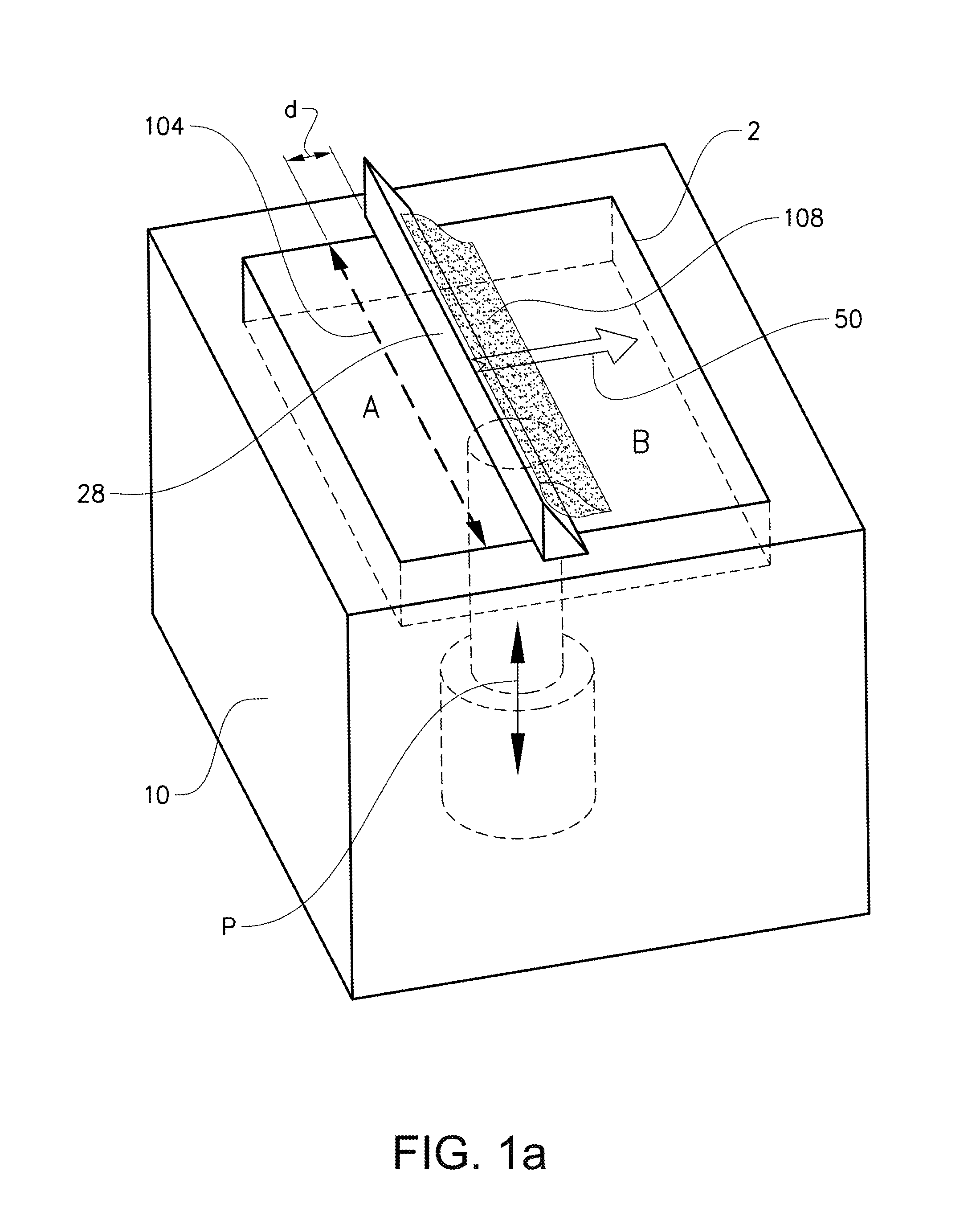

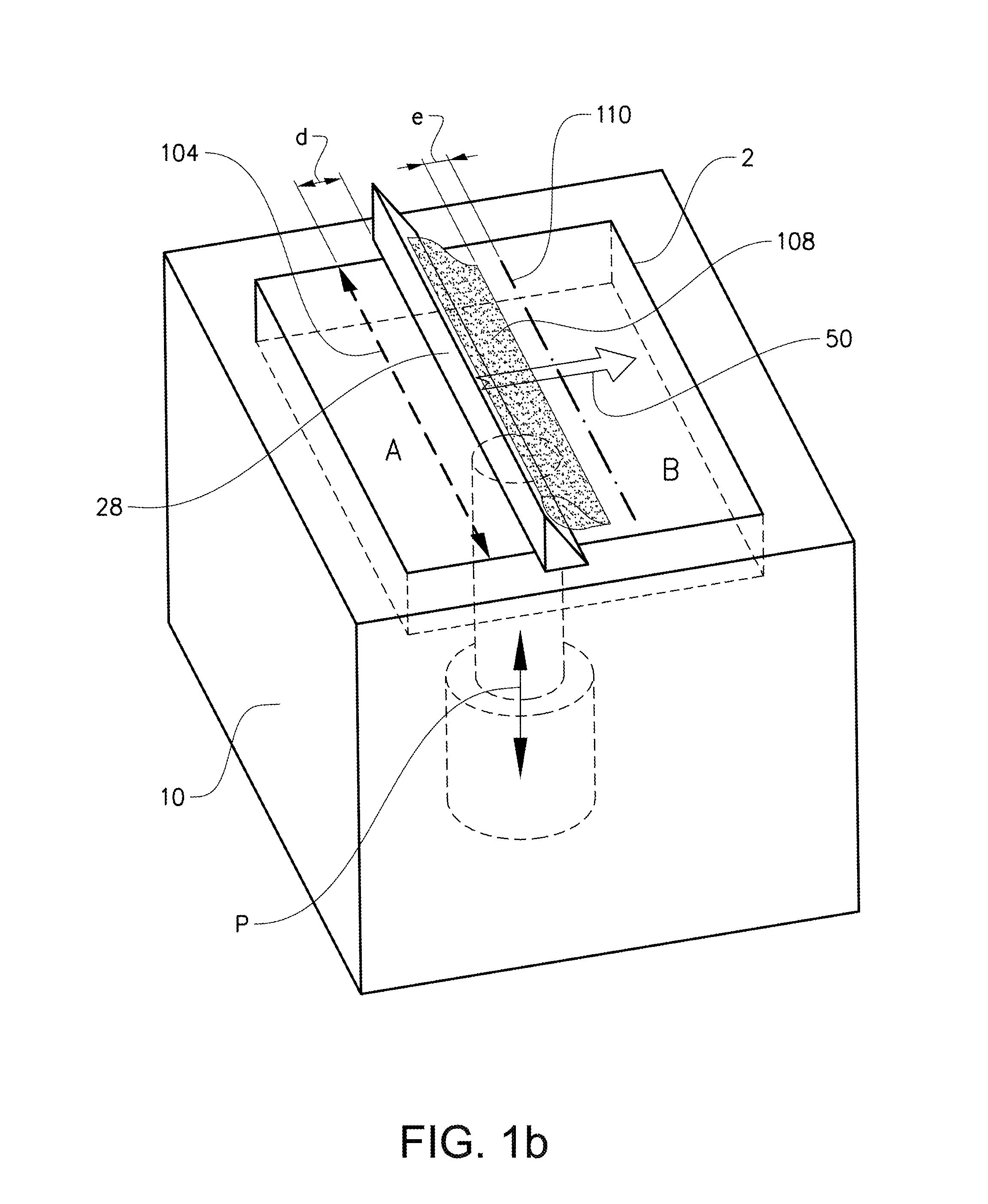

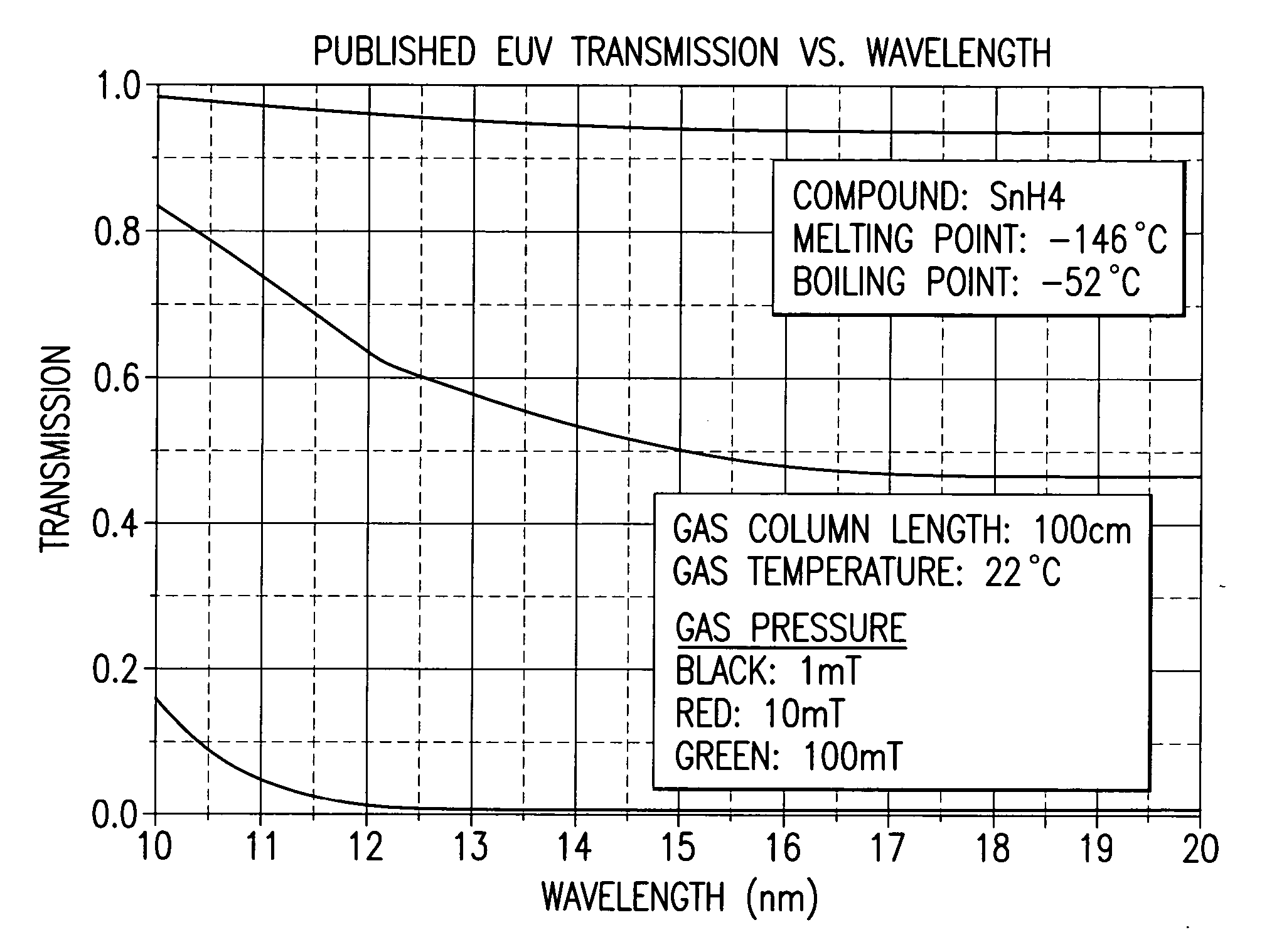

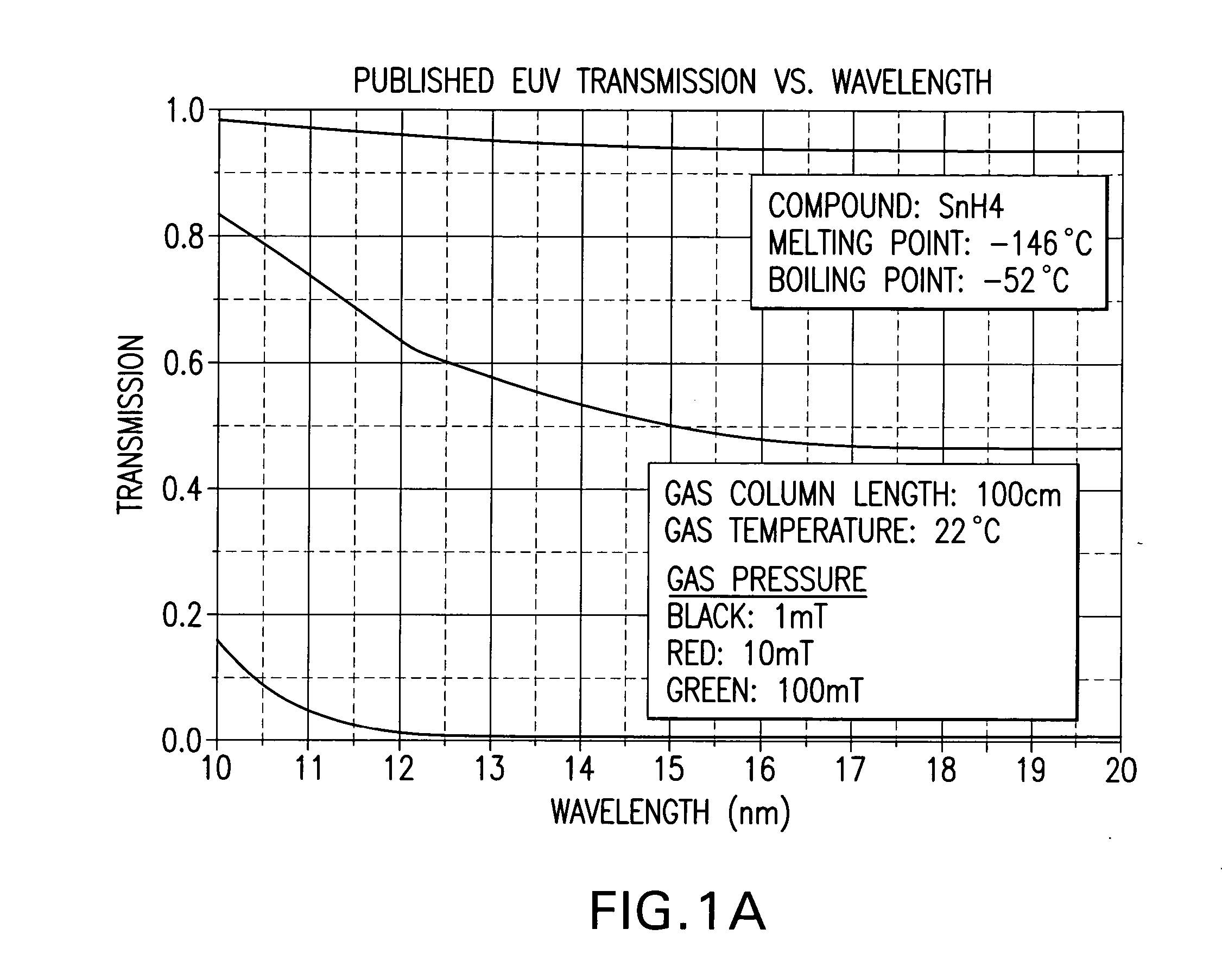

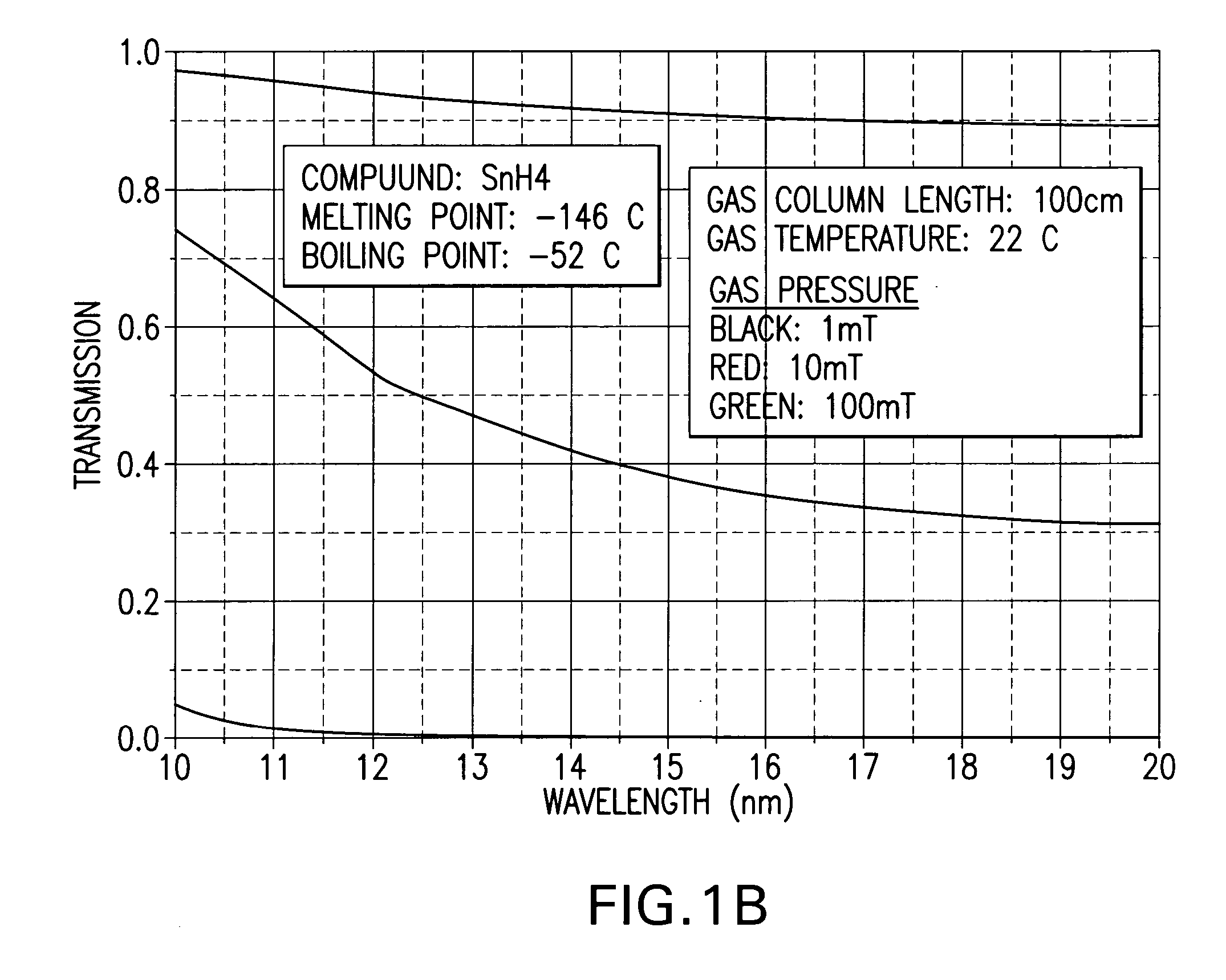

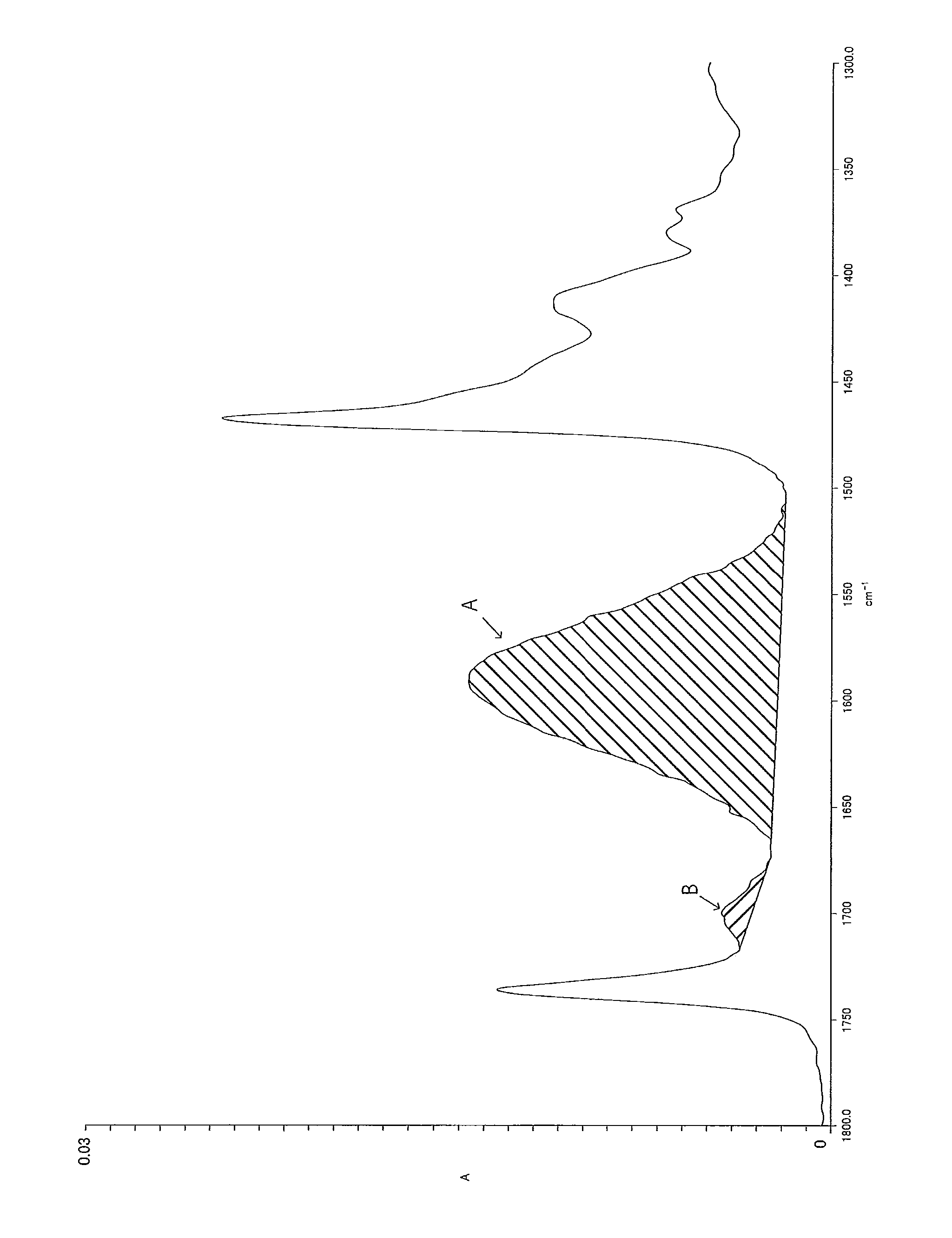

EUV collector debris management

InactiveUS20060091109A1Reduce reflectivityLow material performance requirementsDecorative surface effectsSemiconductor/solid-state device manufacturingEtchingSource material

A method and apparatus that may comprise an EUV light producing mechanism utilizing an EUV plasma source material comprising a material that will form an etching compound, which plasma source material produces EUV light in a band around a selected center wavelength comprising: an EUV plasma generation chamber; an EUV light collector contained within the chamber having a reflective surface containing at least one layer comprising a material that does not form an etching compound and / or forms a compound layer that does not significantly reduce the reflectivity of the reflective surface in the band; an etchant source gas contained within the chamber comprising an etchant source material with which the plasma source material forms an etching compound, which etching compound has a vapor pressure that will allow etching of the etching compound from the reflective surface. The etchant source material may comprises a halogen or halogen compound. The etchant source material may be selected based upon the etching being stimulated in the presence of photons of EUV light and / or DUV light and / or any excited energetic photons with sufficient energy to stimulate the etching of the plasma source material. The apparatus may further comprise an etching stimulation plasma generator providing an etching stimulation plasma in the working vicinity of the reflective surface; and the etchant source material may be selected based upon the etching being stimulated by an etching stimulation plasma. There may also be an ion accelerator accelerating ions toward the reflective surface. The ions may comprise etchant source material. The apparatus and method may comprise a part of an EUV production subsystem with an optical element to be etched of plasma source material.

Owner:ASML NETHERLANDS BV

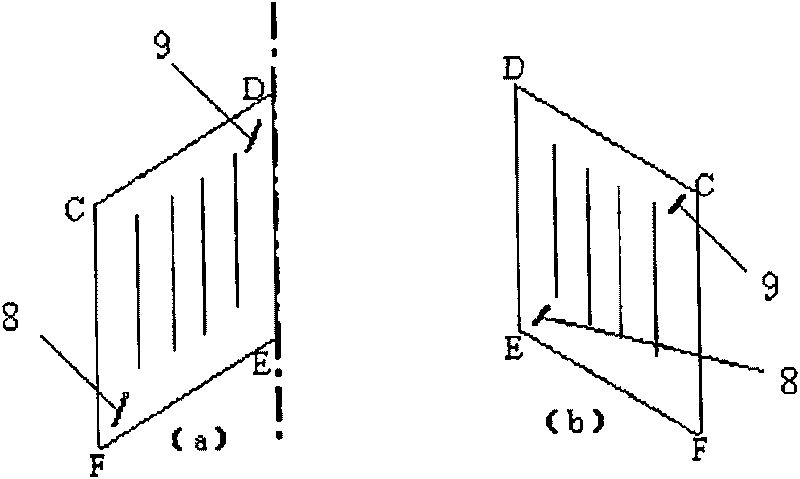

Bidirectional vacuum prepressing blowing filling soft soil foundation treatment method

InactiveCN101235634AIncrease the depth of reinforcementIncrease laying thicknessSoil preservationVacuum pumpingCofferdam

The invention discloses a bidirectional vacuum pre-pressing hydraulically-filled soft ground treatment process, which comprises the following steps that building sealing walls and embedding vacuum pipes on the bottom of a coffer-dam, paving sand cushion with appropriate thickness whose inner portion is provided with filter strainers and vacuum tubes, and the surface is covered with earth-work cloth, building plastic drainage plates whose one section which is exposed on the surface of earth is vertically tied on a bamboo frame upwards, hydraulically filling sands to height mark, installing vacuum-pumping devices, and paving vacuum films. And the process is finished after the design consolidation degree is reached on the earth through starting the vacuum-pumping pump. The process increases the reinforcing treatment depth of vacuum pre-pressing, shortens the construction cycle of hydraulically-filled earth-building project, and saves vacuum film material.

Owner:NANJING UNIV OF SCI & TECH

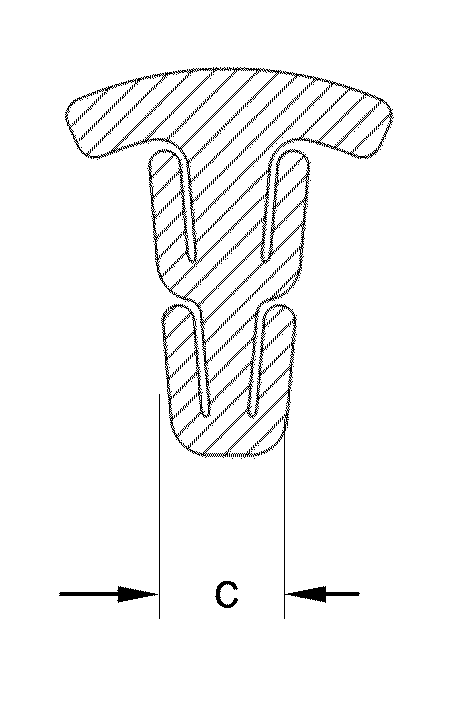

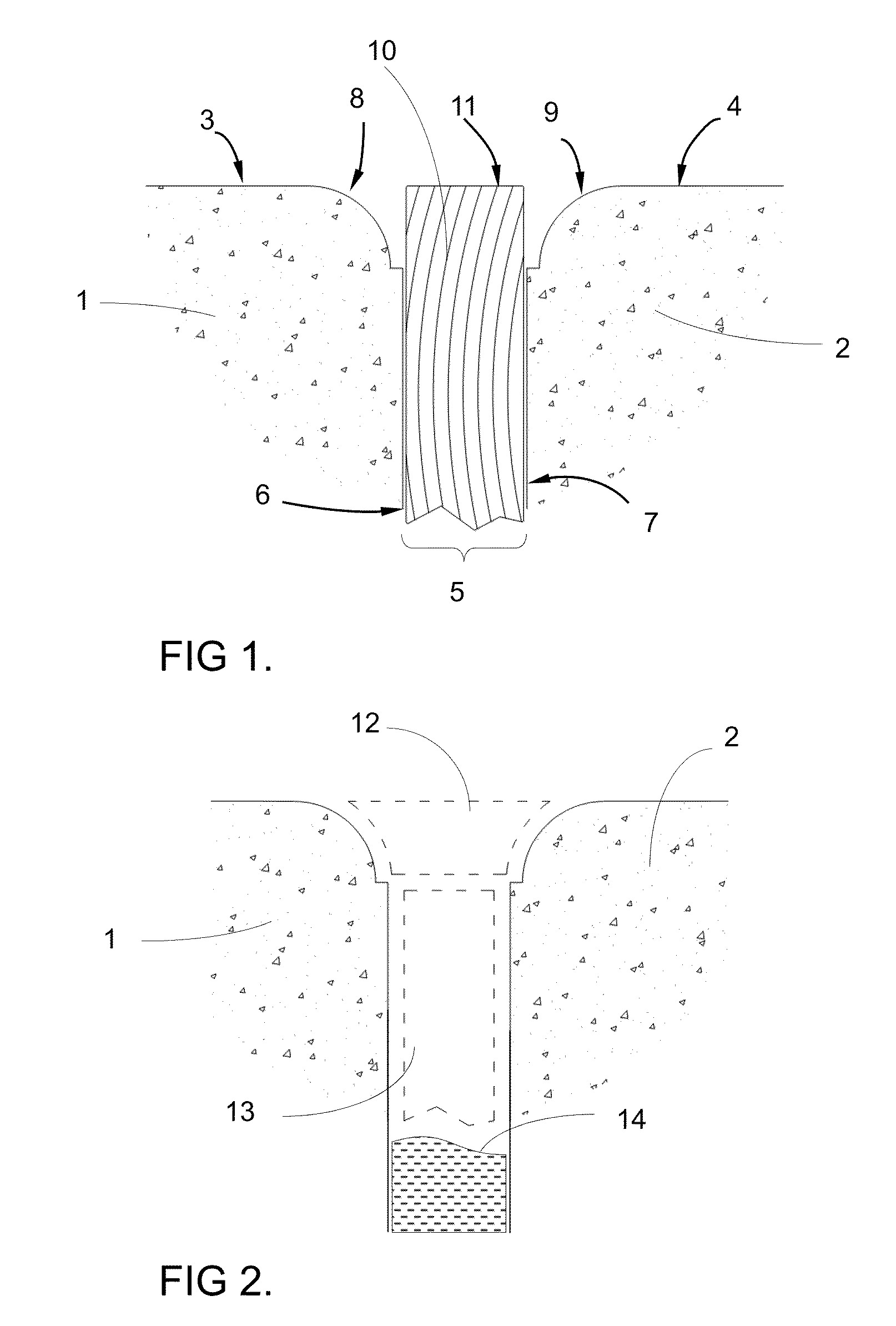

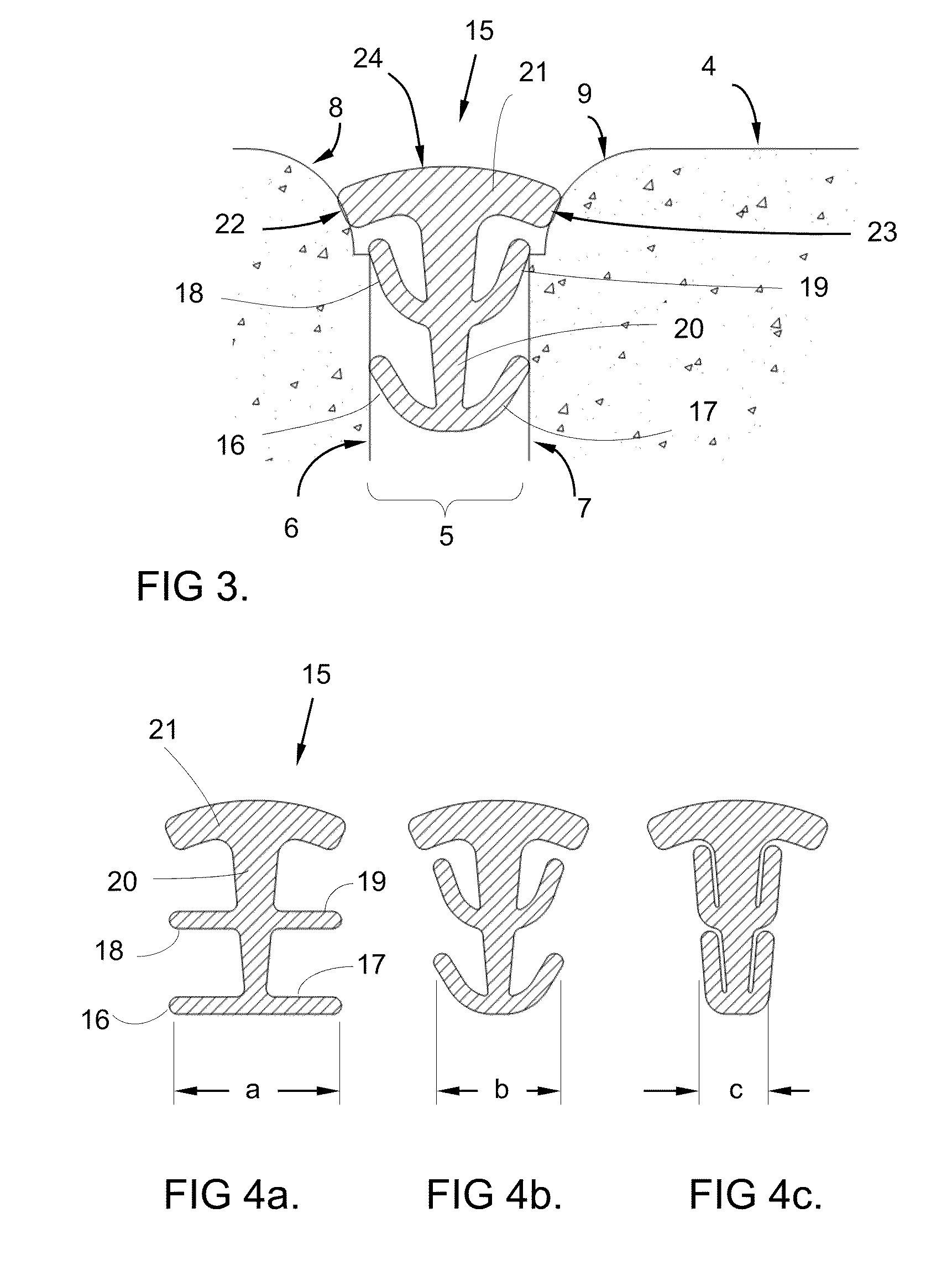

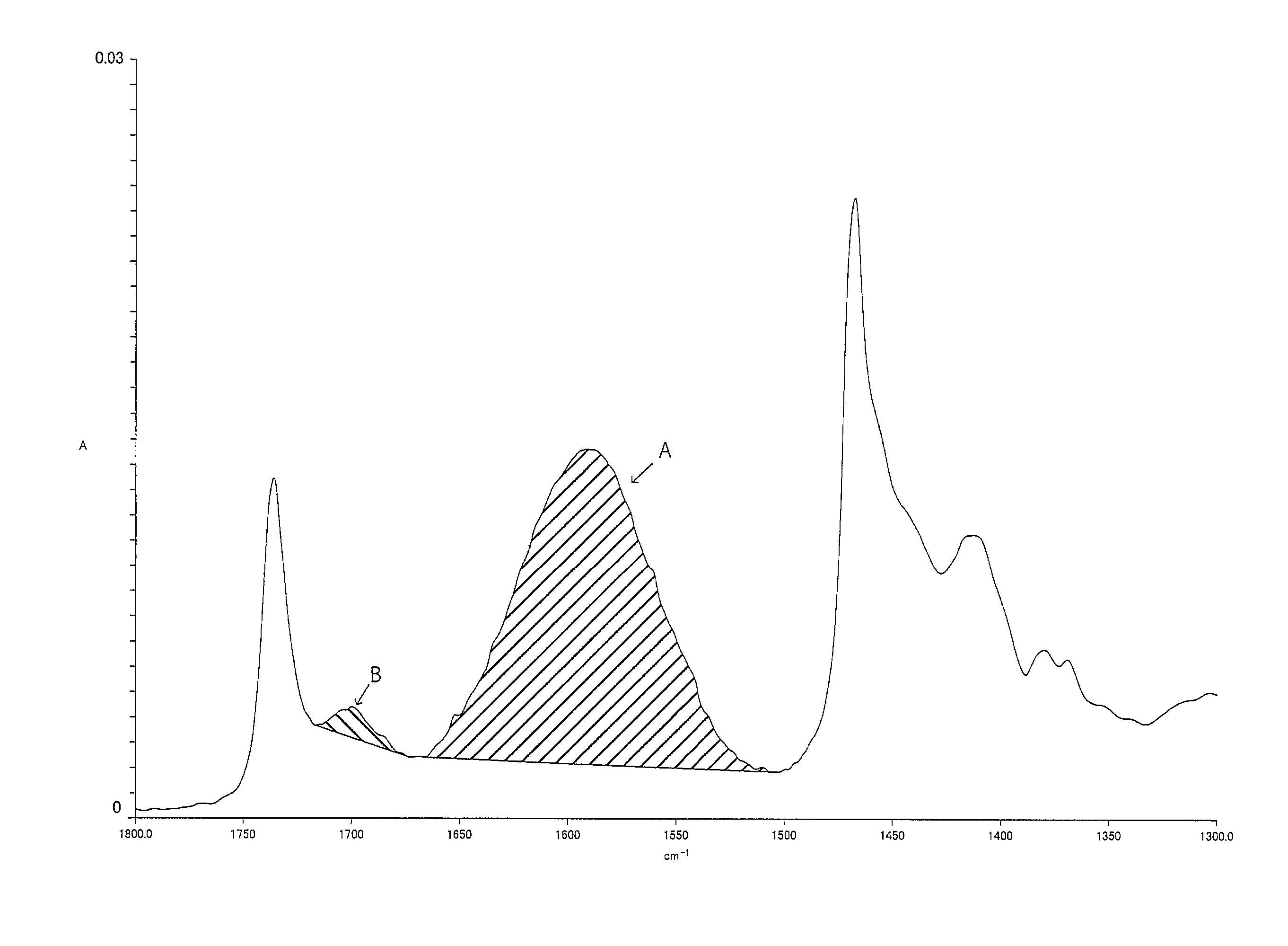

Compliant trim for concrete slabs

InactiveUS8132380B2Easy assessment processEasy to put inBuilding repairsBuilding material handlingCivil engineeringEngineering

Owner:WILKES JR ROBERT DAVID

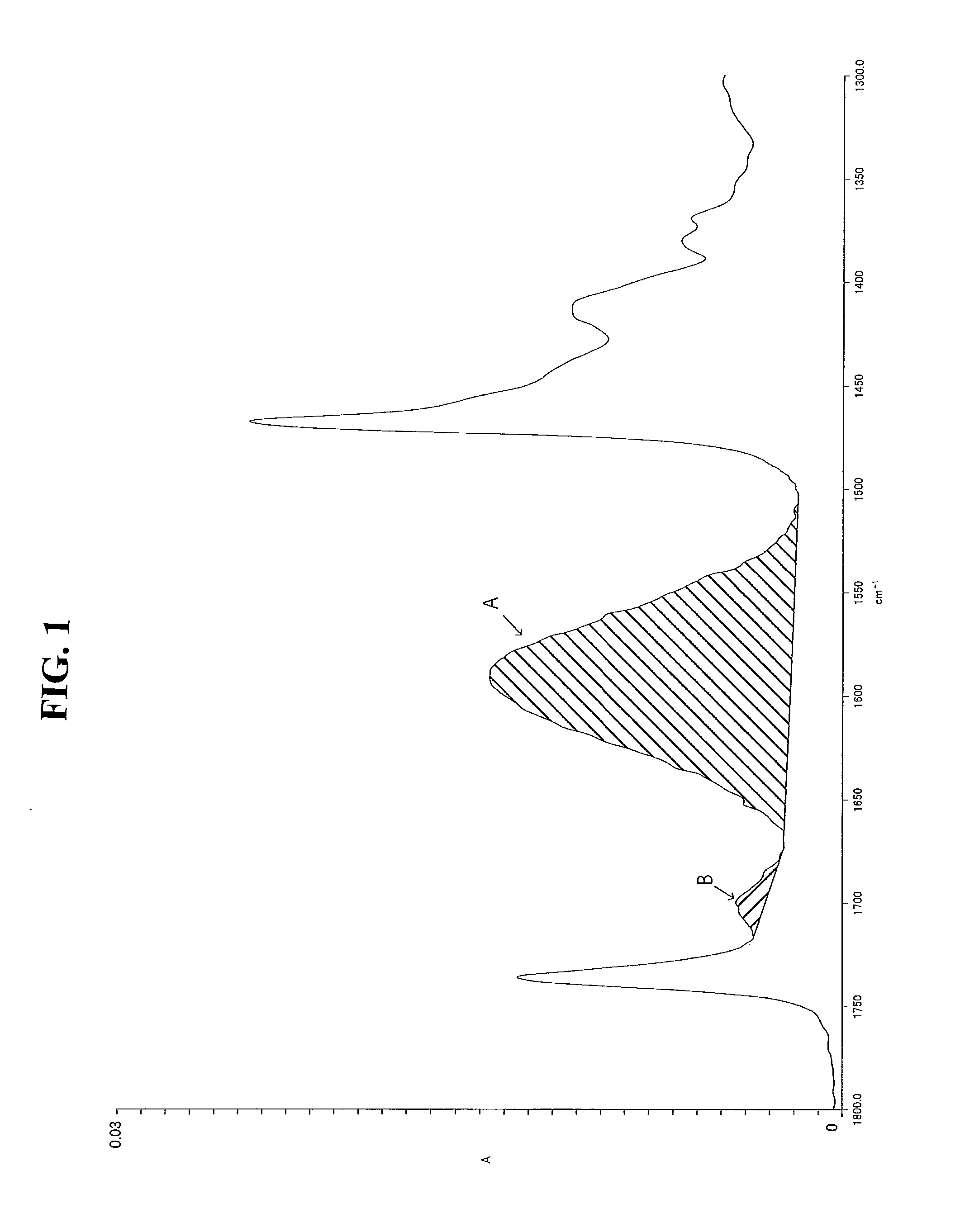

Golf ball resin composition and golf ball using the same

ActiveUS20110092312A1Increase elasticityGood fluidityFibre treatmentSynthetic resin layered productsCarboxylic acidEngineering

An object of the present invention is to provide a golf ball resin composition that comprises an ionomer resin with an excellent resilience and fluidity. Another object of the present invention is to provide a golf ball excellent in the resilience without lowering the durability significantly in a golf ball using the ionomer resin for the intermediate layer. The present invention provides a golf ball resin composition comprising, 100 parts by mass of (A) an ionomer resin consisting of a metal ion-neutralized product of a ternary copolymer composed of ethylene, α,β-unsaturated carboxylic acid having 3 to 8 carbon atoms and α,β-unsaturated carboxylic acid ester, and from 25 parts to 100 parts by mass of (B) a metal salt of a fatty acid having 18 to 30 carbon atoms. The golf ball of the present invention is not limited, as long as it comprises a constituent member formed from the golf ball resin composition of the present invention.

Owner:SUMITOMO RUBBER IND LTD

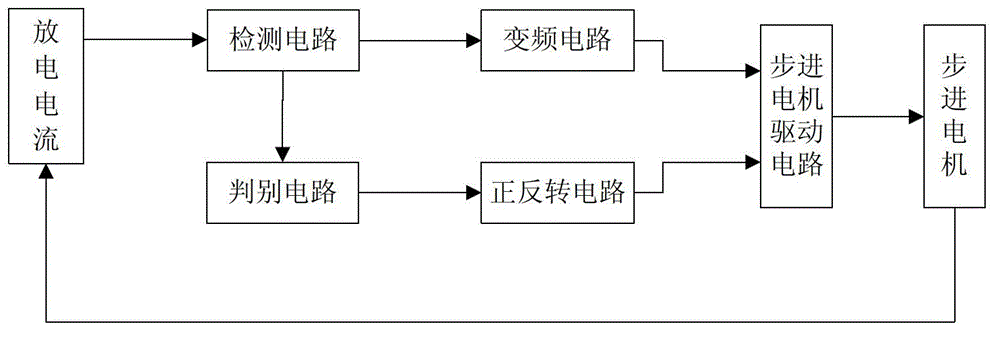

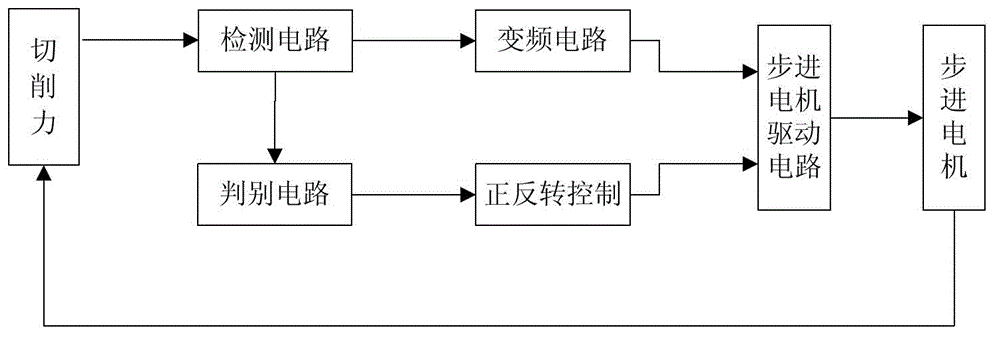

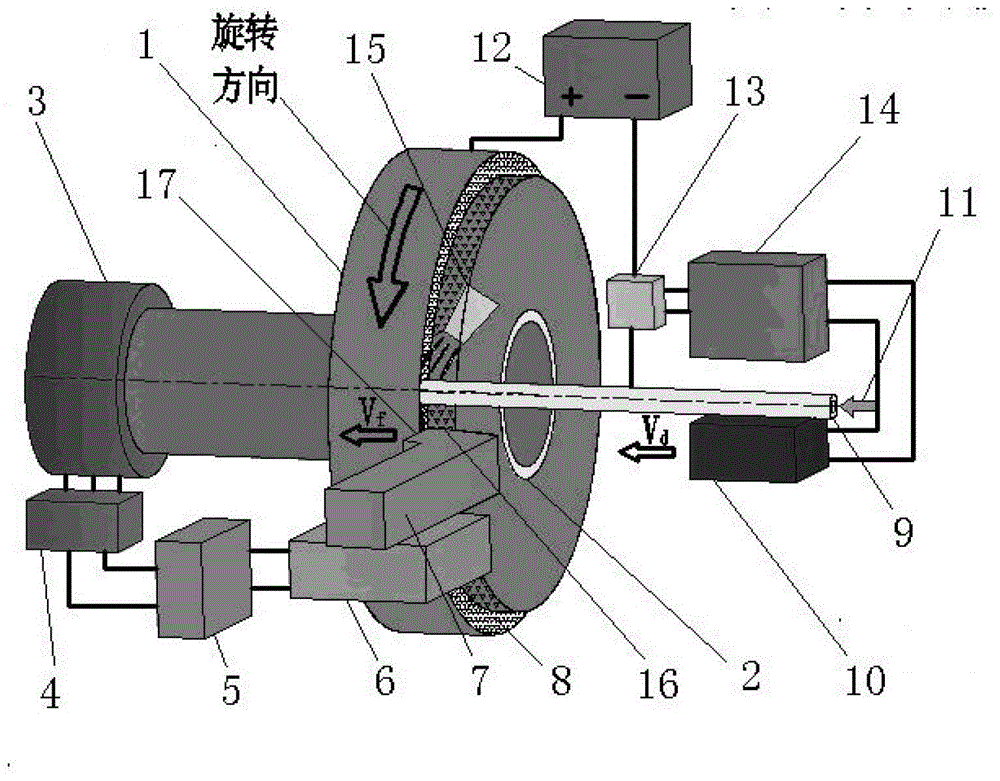

Electric spark induction controllable erosion and mechanical finishing compound cutting dual-servo feeding processing system

ActiveCN102974902AHigh removal rateSolve the problem of low processing efficiencyControl systemCutting force

The invention discloses an electric spark induction controllable erosion and mechanical finishing compound cutting dual-servo feeding processing system which is characterized by comprising an electric spark induction erosion electrode servo feeding control system (1) using an erosion state as a sampling basis and a mechanical finishing tool automatic feeding regulating system (2) using a cutting force as a sampling basis, wherein the electric spark induction erosion electrode servo feeding control system controls the feeding of an induction erosion electrode, ensures that the electric spark induction erosion in a machining region is controllably, efficiently and stably carried out, and forms an erosion product and a softened layer through controllable erosion; and the mechanical finishing tool automatic feeding regulating system ensures that the erosion product and the softened layer which are generated by erosion are cut and removed without cutting a base body material, so that the tool loss is reduced, the finished surface quality is ensured and the processing efficiency is increased. According to the invention, the processing efficiency of a metal material difficult in processing can be remarkably increased, the finished surface quality is increased, and the finished surface is final mechanized surface due to the mechanical finishing function of a tool.

Owner:南京航浦机械科技有限公司

Multi-piece golf ball

A multi-piece golf ball excellent in resilience and controllability includes a core composed of a center and an envelope layer covering the center and at least one cover covering the core, wherein the center is formed from a center composition containing (A) at least one resin component selected from the group consisting of (a-1) a binary copolymer composed of an olefin and an α,β-unsaturated carboxylic acid having 3 to 8 carbon atoms, (a-2) an ionomer resin consisting of a metal ion-neutralized product of the binary copolymer, (a-3) a ternary copolymer composed of the binary copolymer components and an β,β-unsaturated carboxylic acid ester, and (a-4) an ionomer resin consisting of a metal ion-neutralized product of the ternary copolymer components and (B) a basic metal salt of a fatty acid, and wherein the envelope layer is formed from a rubber composition.

Owner:SUMITOMO RUBBER IND LTD

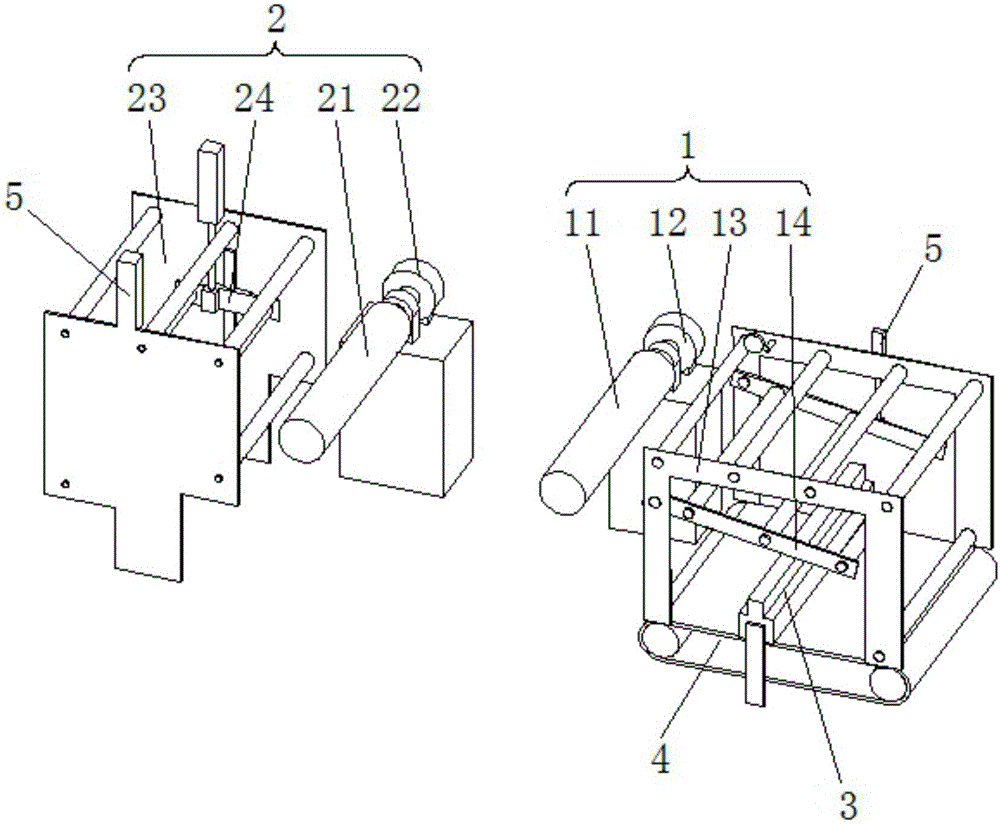

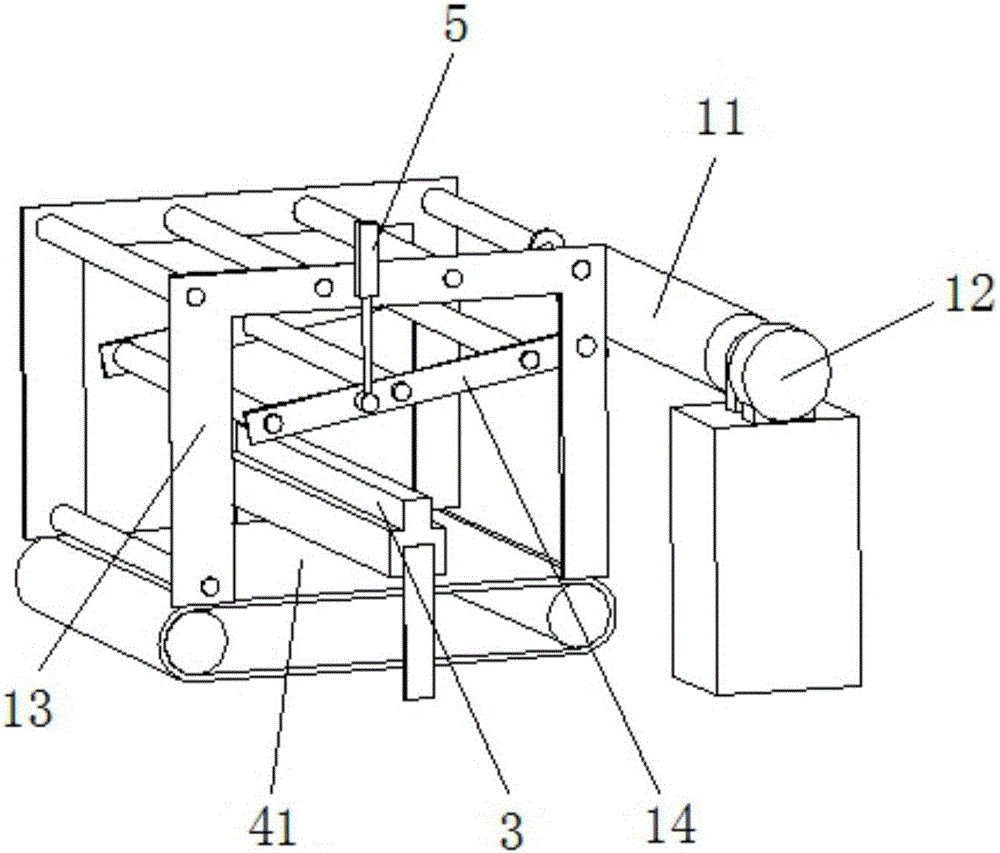

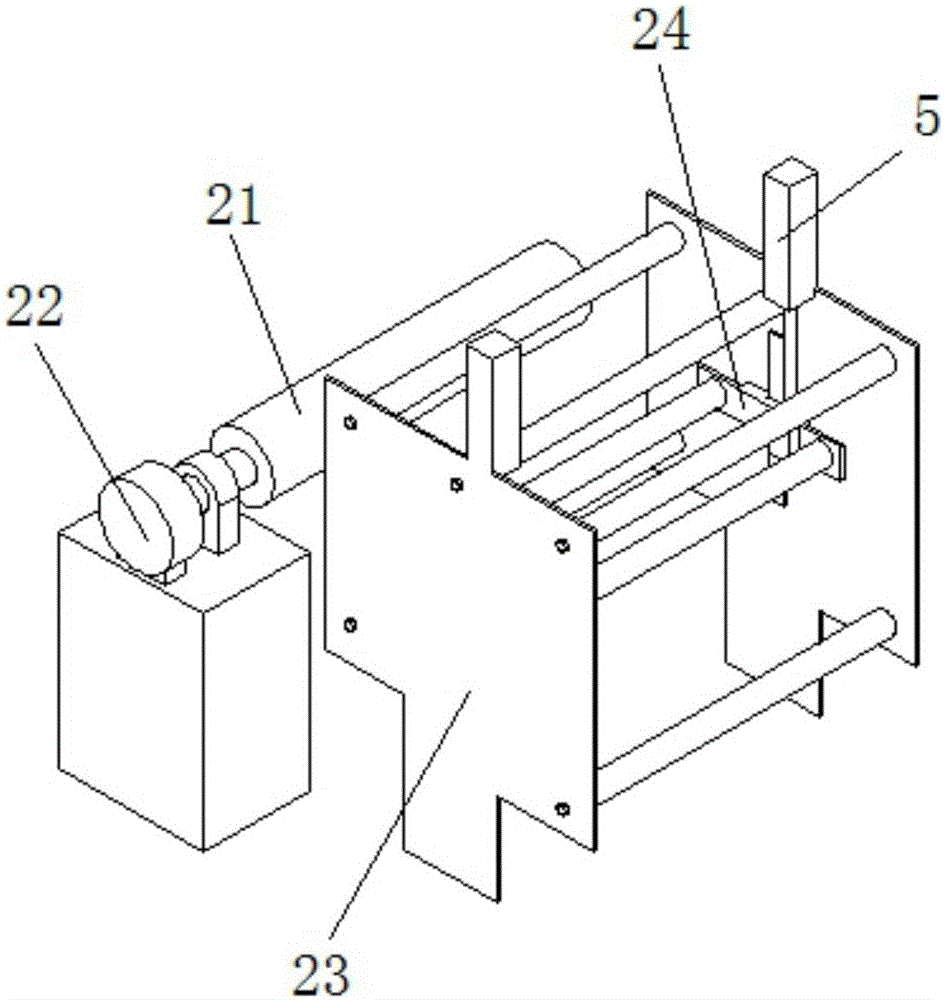

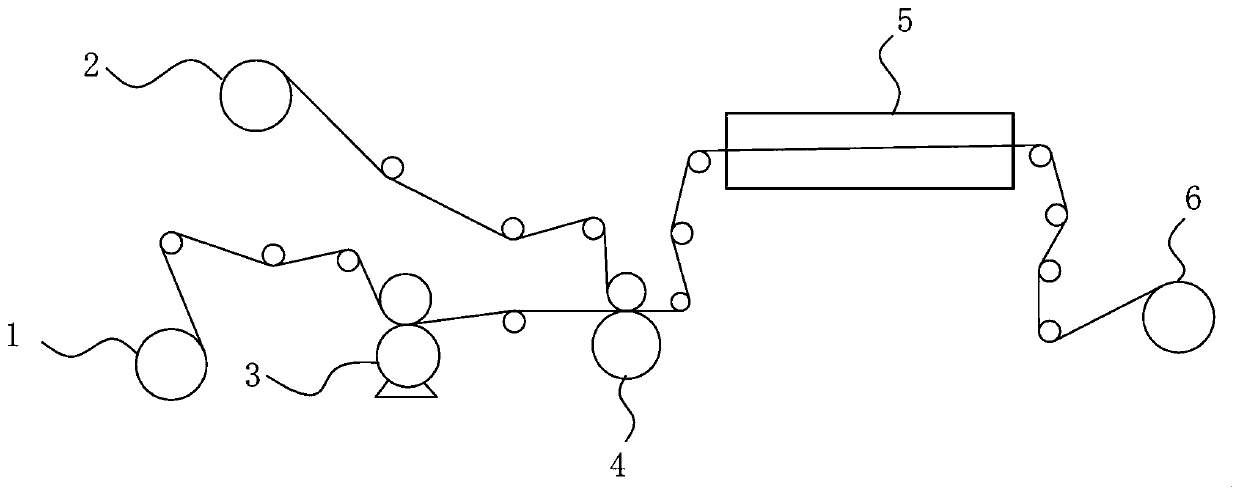

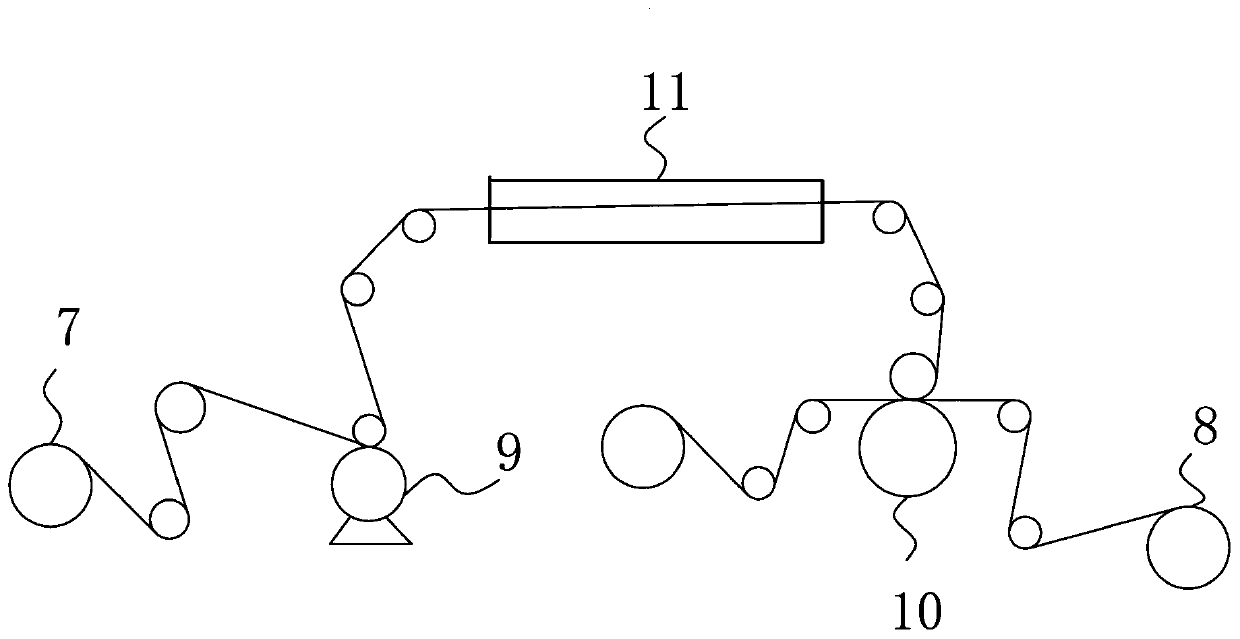

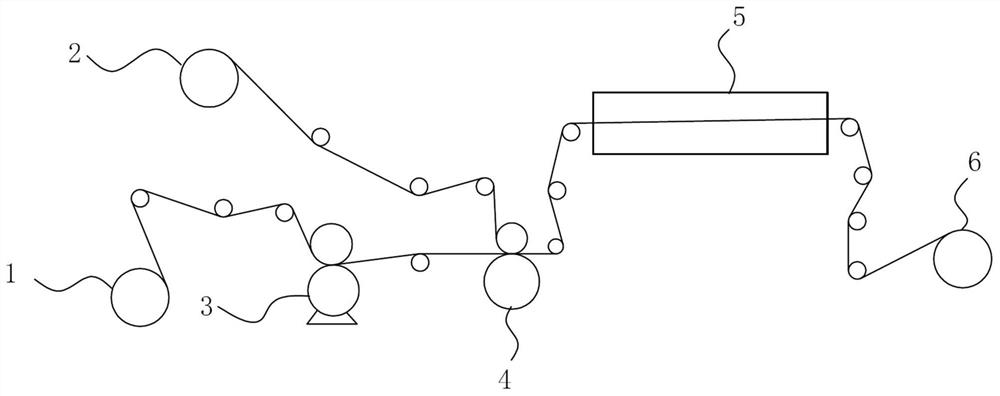

Bag-making device used for full-automatic bag-making machine and bag-making method thereof

ActiveCN105109098AIntelligent tension controlLow material performance requirementsBox making operationsPaper-makingEngineeringMagnetic particle clutch

The invention relates to a bag-making device used for a full-automatic bag-making machine and a bag-making method thereof. The device has a hot blade, an unwinding mechanism, and a rolling mechanism. The output shaft of an unwinding magnetic powder clutch in the unwinding mechanism is fixedly connected with an unwinding roller. An unwinding rack is provided with a plurality of guiding rollers. One end of an unwinding floating frame is rotatably connected with the unwinding rack. The unwinding floating frame is provided with a plurality of guiding rollers. The unwinding rack is fixedly provided with a push rod device which is rotatably connected with the other end of the unwinding floating frame. The output shaft of a rolling magnetic powder clutch in the rolling mechanism is fixedly connected with a wind-up roller. A rolling rack is provided with a plurality of guiding rollers. A rolling floating frame is arranged on the rolling rack. The rolling floating frame is provided with a plurality of guiding rollers. The rolling rack is fixedly provided with a push rod device connected with the rolling floating frame. The bag-making device solves problems that a common film in a common film bag-making process used for a full-automatic bag-making machine easily melts and deforms, and the device reduces production cost.

Owner:CHANGZHOU SHUANGHE PACKING CO LTD

Multi-piece golf ball

ActiveUS20130172114A1Strong alkalineEfficiently neutralizedGolf ballsSolid ballsThermoplastic elastomerCarboxylic acid

A multi-piece golf ball includes a core composed of a center, an envelope layer and at least one cover. The center is formed from a composition containing at least one resin component and a basic metal salt of a fatty acid. The resin component is selected from a binary copolymer composed of an olefin and an α,β-unsaturated carboxylic acid, an ionomer resin consisting of a metal ion-neutralized product of a binary copolymer composed of an olefin and an α,β-unsaturated carboxylic acid, a ternary copolymer composed of an olefin, an α,β-unsaturated carboxylic acid and an α,β-unsaturated carboxylic acid ester, and an ionomer resin consisting of a metal ion-neutralized product of a ternary copolymer composed of an olefin, an α,β-unsaturated carboxylic acid and an α,β-unsaturated carboxylic acid ester. The envelope layer is formed from a composition containing a thermoplastic resin and / or a thermoplastic elastomer as a resin component.

Owner:SUMITOMO RUBBER IND LTD

Golf ball resin composition and golf ball using the same

ActiveUS9080031B2Increase elasticitySpeed up neutralizationFibre treatmentSynthetic resin layered productsIonomerPolymer science

An object of the present invention is to provide a golf ball resin composition that comprises an ionomer resin with an excellent resilience and fluidity. Another object of the present invention is to provide a golf ball excellent in the resilience without lowering the durability significantly in a golf ball using the ionomer resin for the intermediate layer. The present invention provides a golf ball resin composition comprising, 100 parts by mass of (A) an ionomer resin consisting of a metal ion-neutralized product of a ternary copolymer composed of ethylene, α,β-unsaturated carboxylic acid having 3 to 8 carbon atoms and α,β-unsaturated carboxylic acid ester, and from 25 parts to 100 parts by mass of (B) a metal salt of a fatty acid having 18 to 30 carbon atoms. The golf ball of the present invention is not limited, as long as it comprises a constituent member formed from the golf ball resin composition of the present invention.

Owner:SUMITOMO RUBBER IND LTD

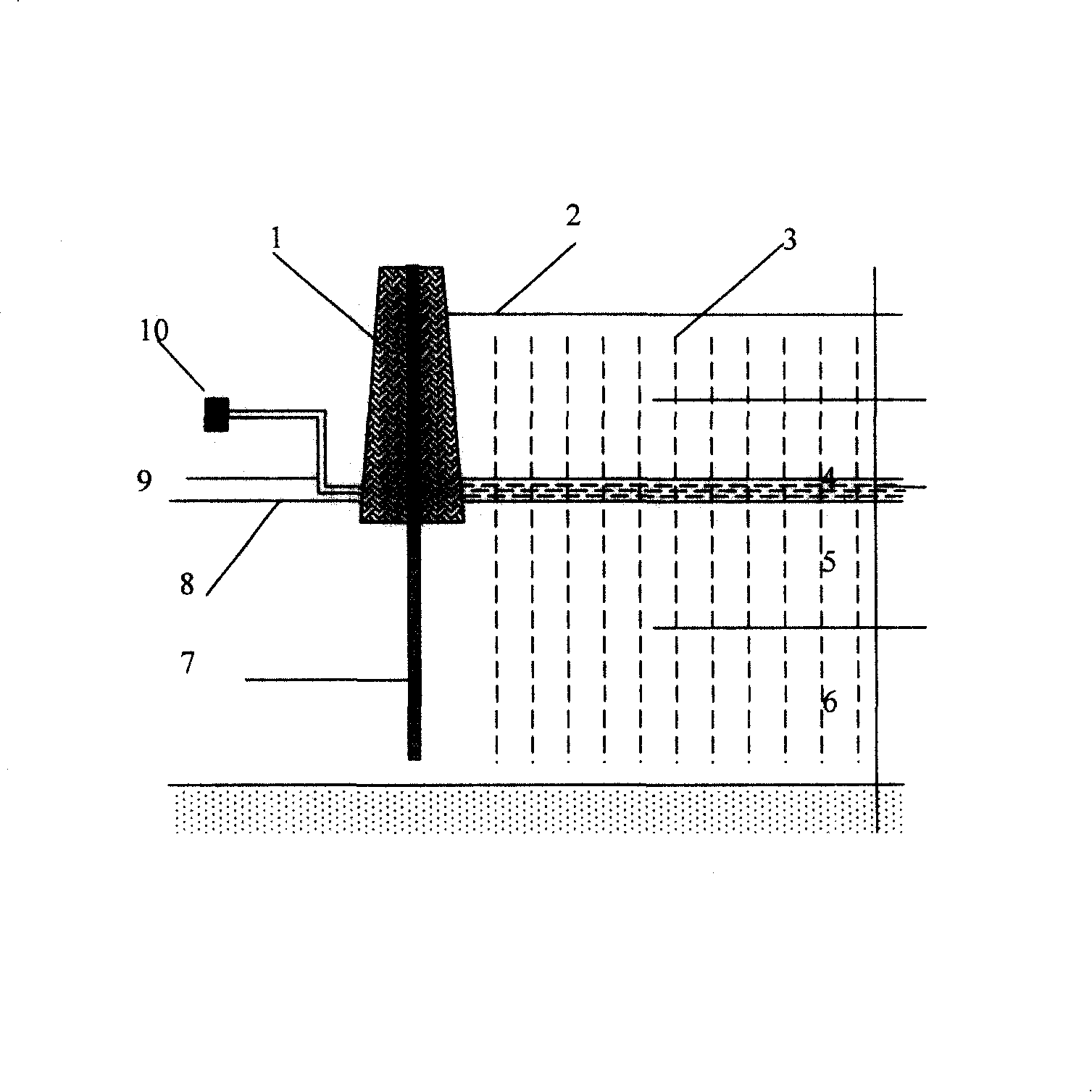

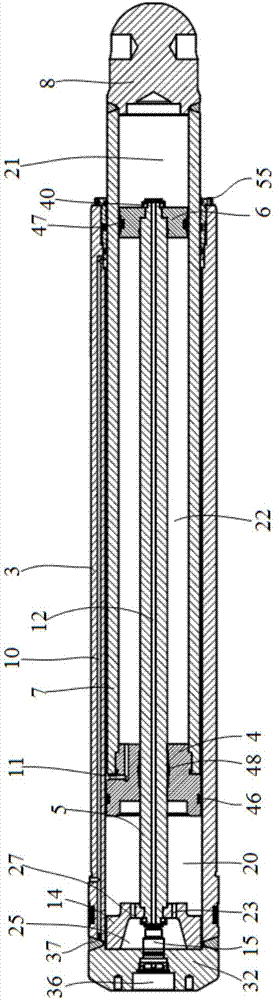

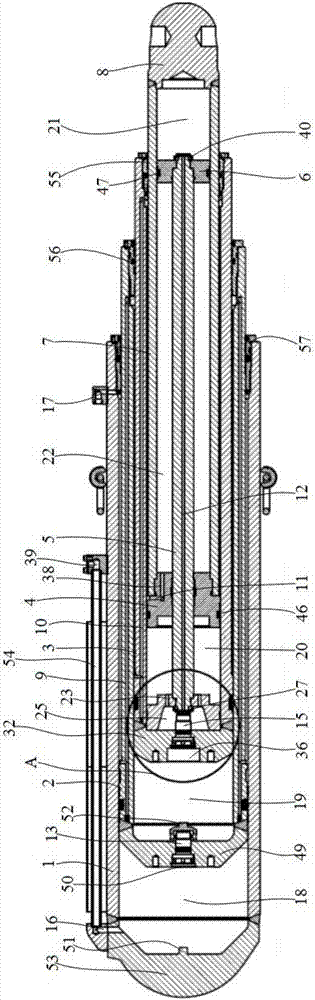

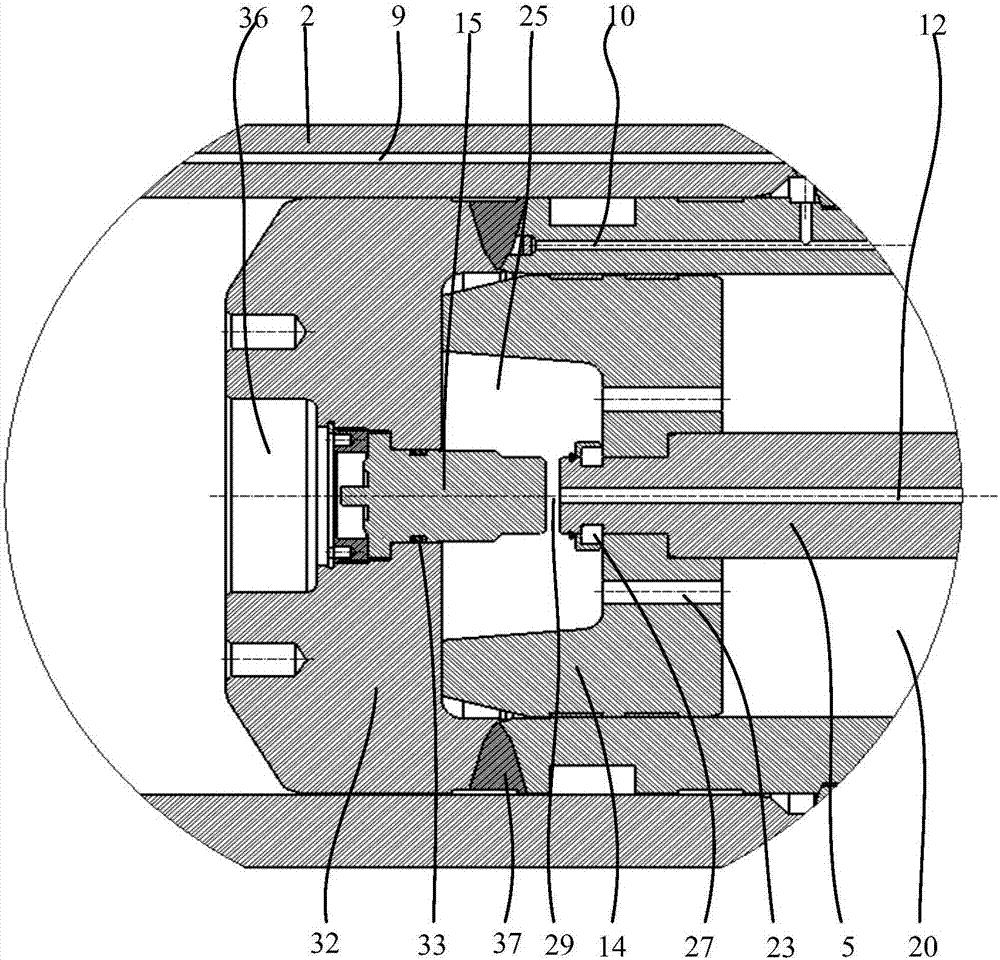

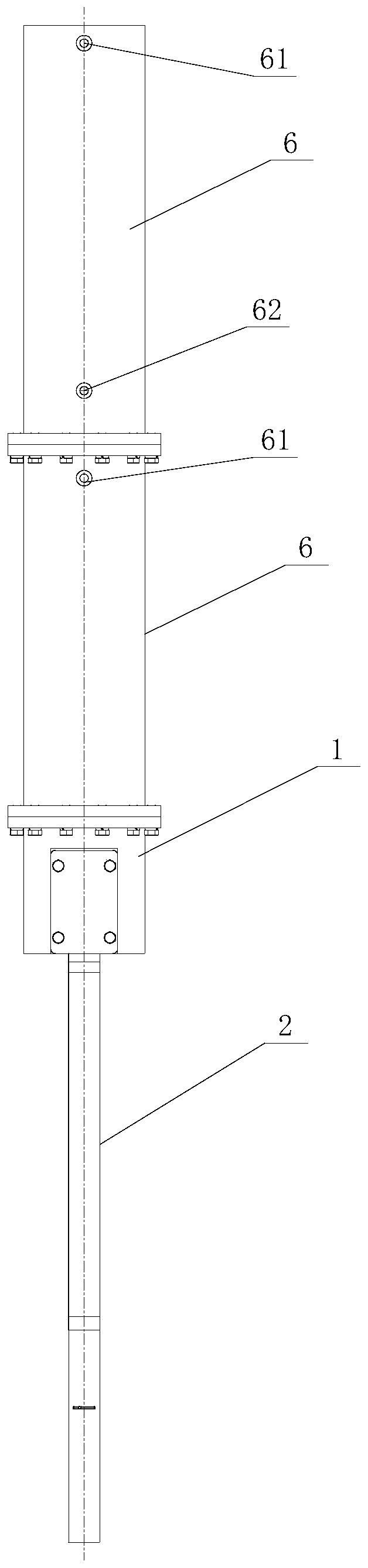

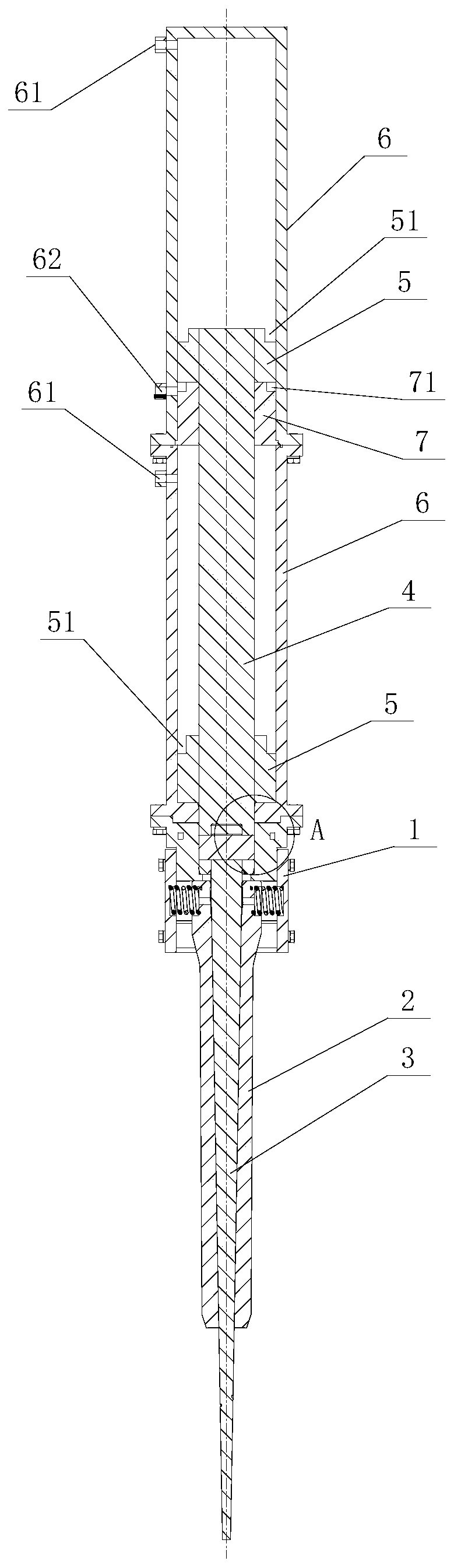

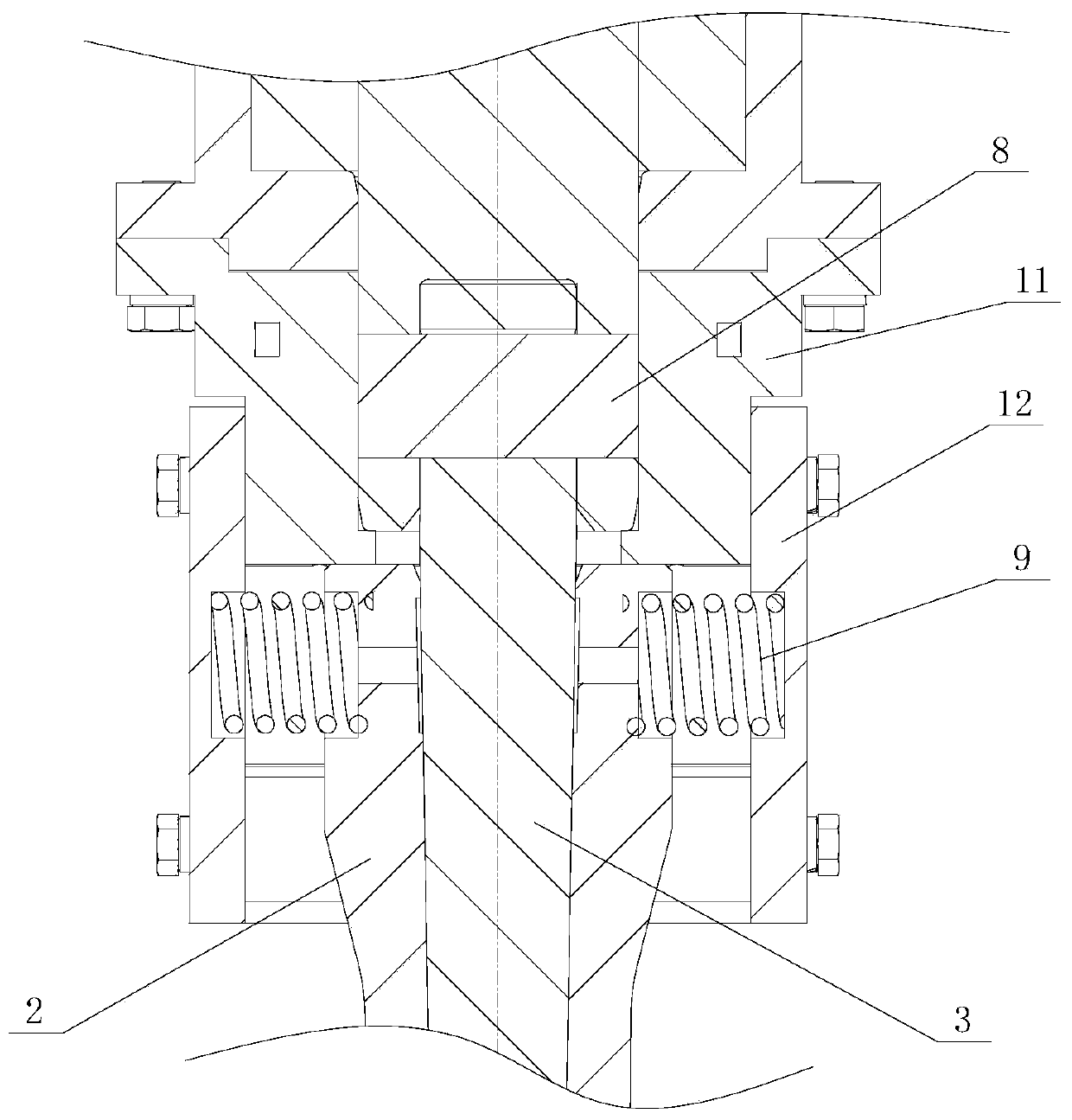

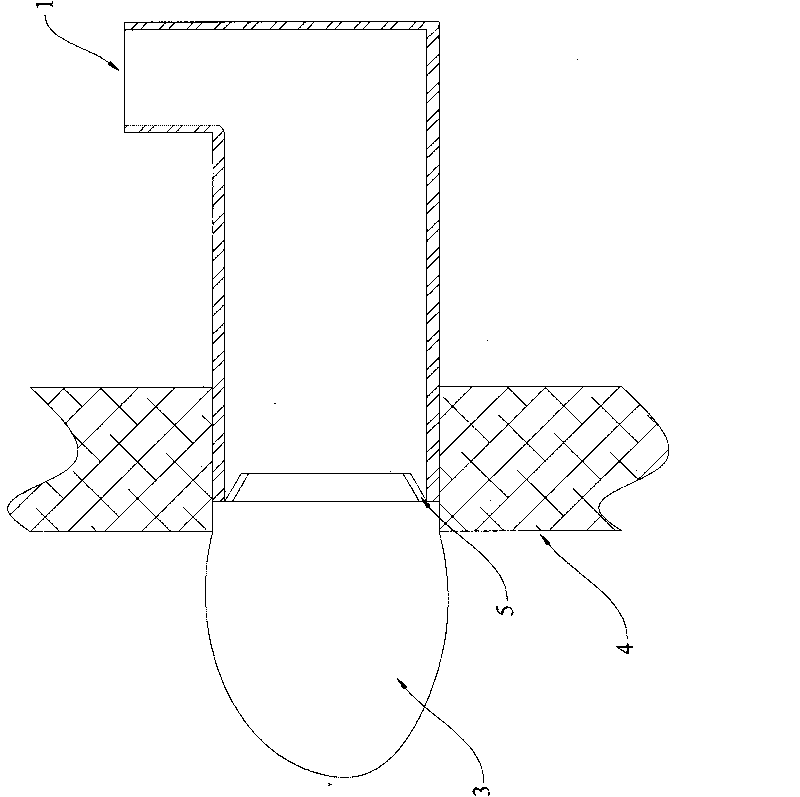

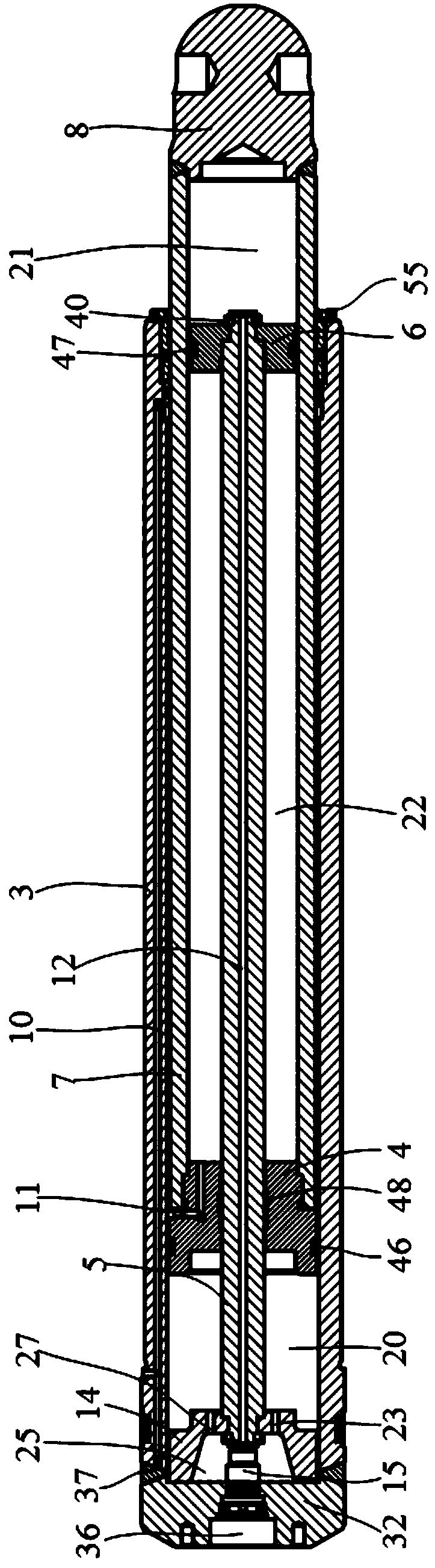

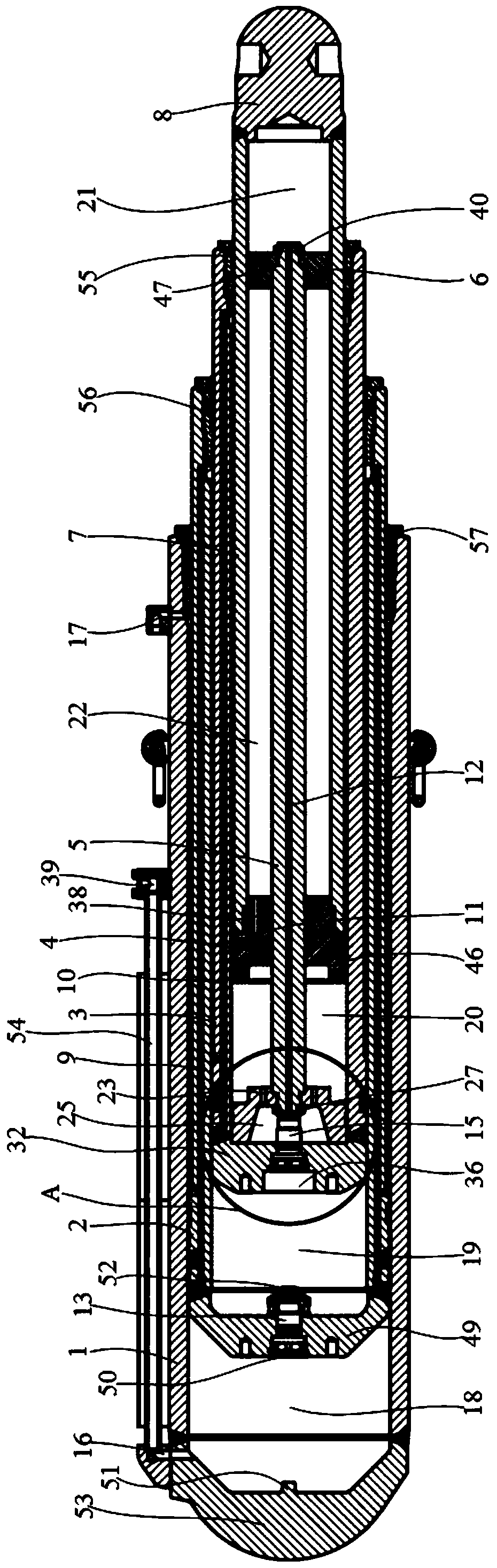

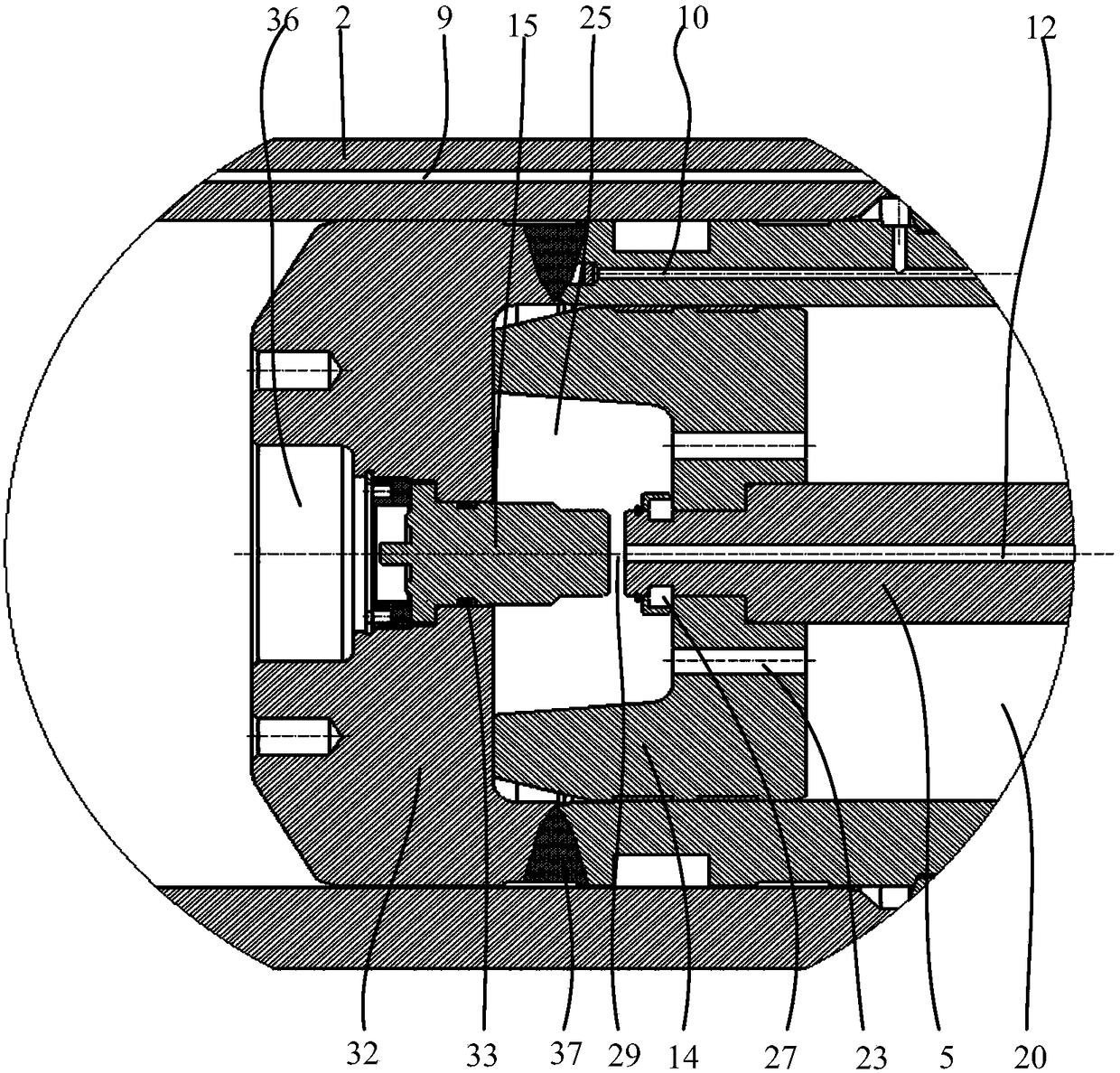

Double-action hydraulic mechanism, multi-grade retractable hydraulic mechanism and hydraulic bracket

InactiveCN107387491AIncrease the expansion ratioLow material performance requirementsFluid-pressure actuatorsCylinder blockPiston rod

The invention discloses a double-action hydraulic mechanism, a multi-grade retractable hydraulic mechanism and a hydraulic bracket and belongs to the technical field of hydraulic pressure. The double-action hydraulic mechanism comprises a first cylinder body 3, a second cylinder body 7, a first guide sleeve 4, a second guide sleeve 14, a piston rod 5, a piston 6, a first valve seat 32 and a first valve 25. The multi-grade retractable hydraulic mechanism comprises an outermost-side cylinder body 1, a plurality of middle cylinder bodies 2, the double-action hydraulic mechanism provided by the invention, a second valve seat 49 and a second valve 13. The hydraulic bracket comprises the multi-grade retractable hydraulic mechanism provided by the invention and a column head 8. The double-action hydraulic mechanism, the multi-grade retractable hydraulic mechanism and the hydraulic bracket, provided by the invention, have a relatively large contraction ratio; and the double-action hydraulic mechanism is introduced so that performance requirements on materials of a sealing part and a cylinder barrel are reduced.

Owner:CATERPILLAR ZHENGZHOU

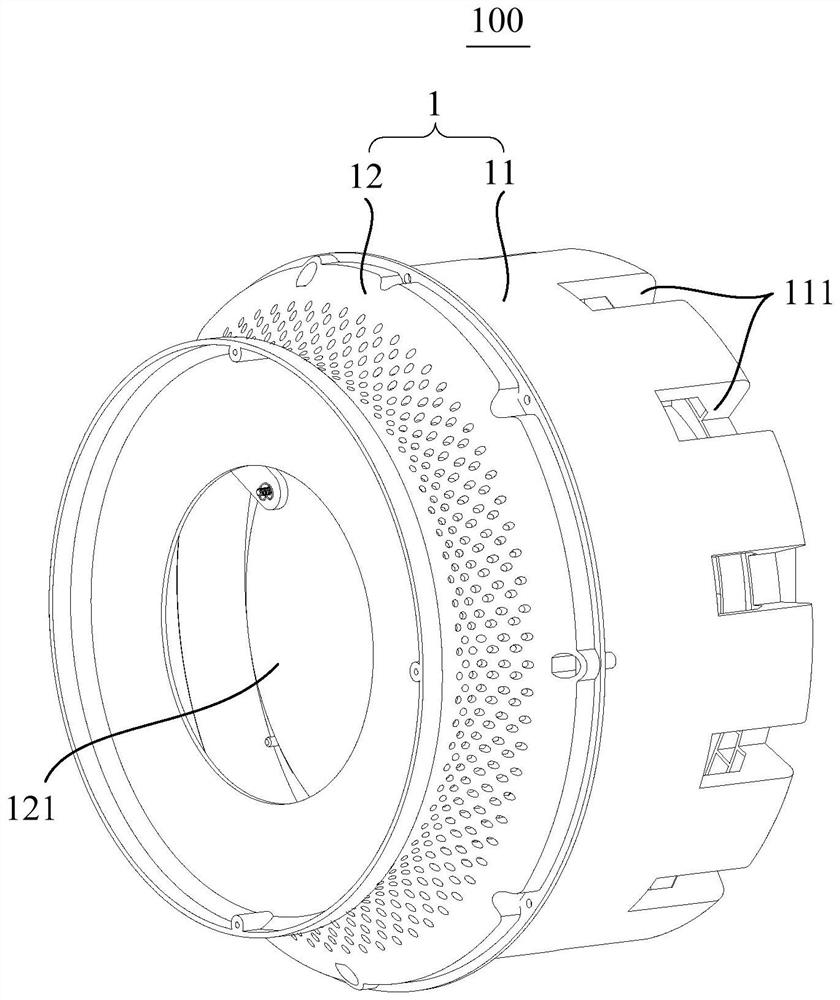

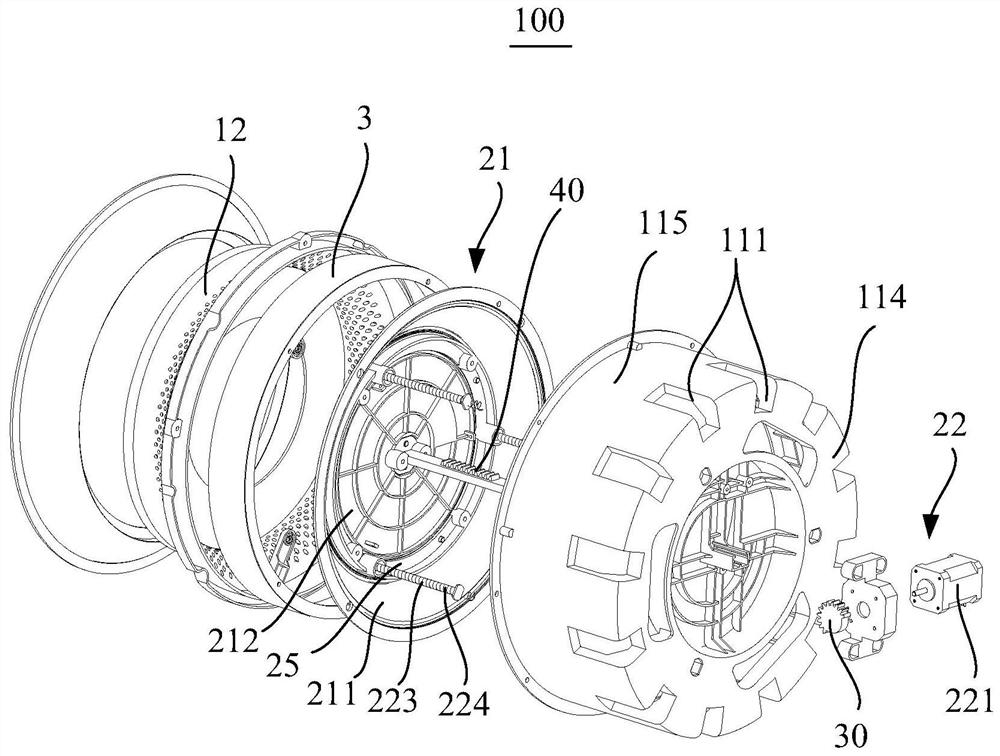

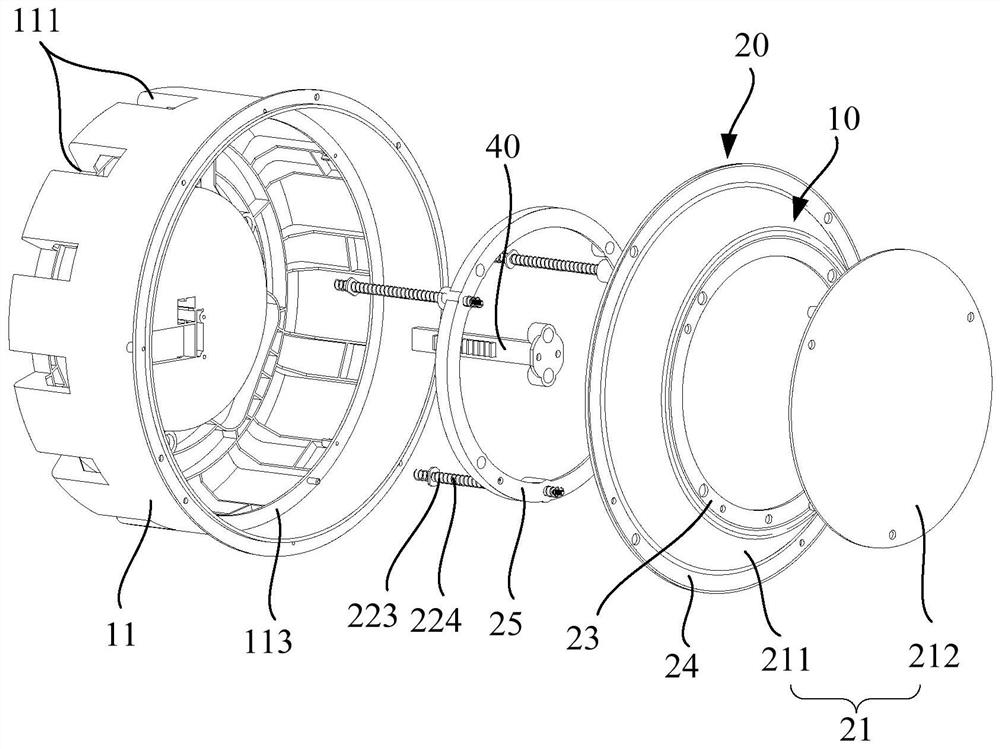

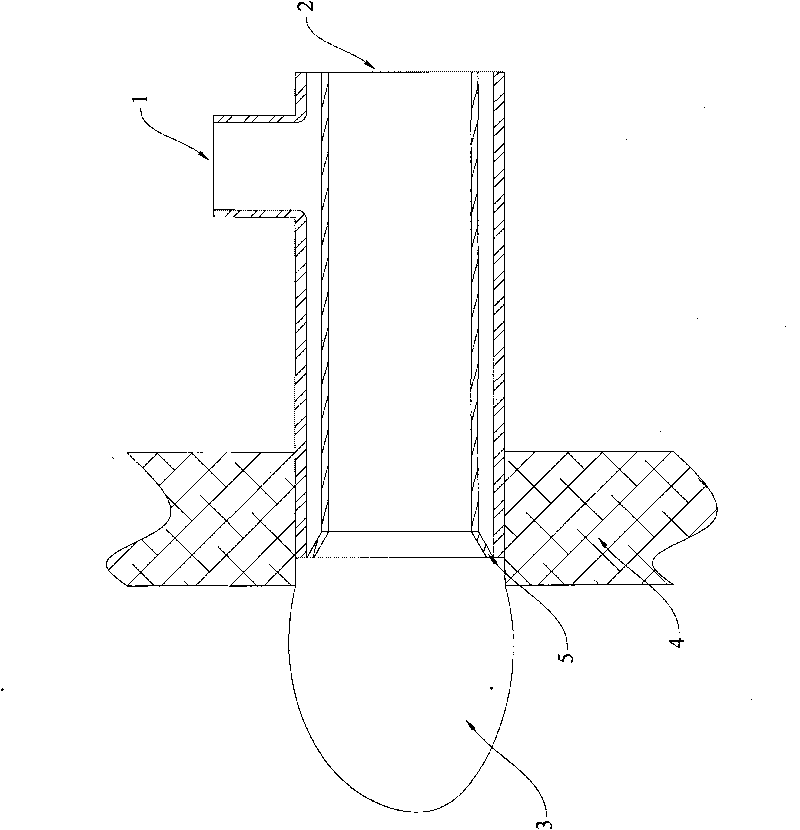

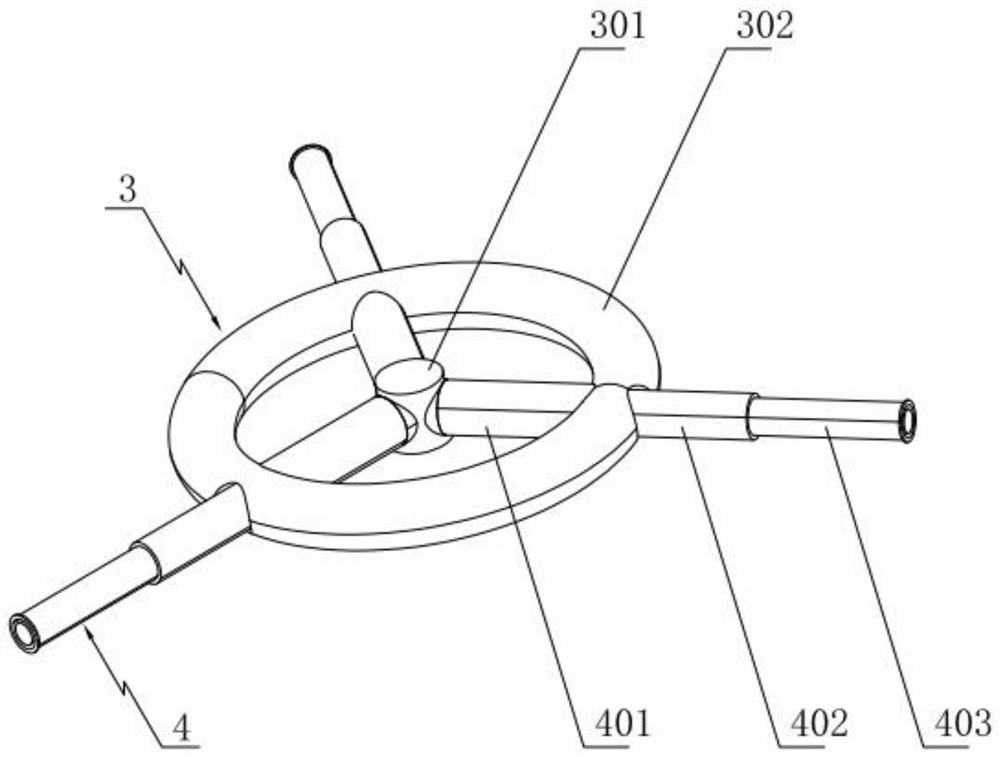

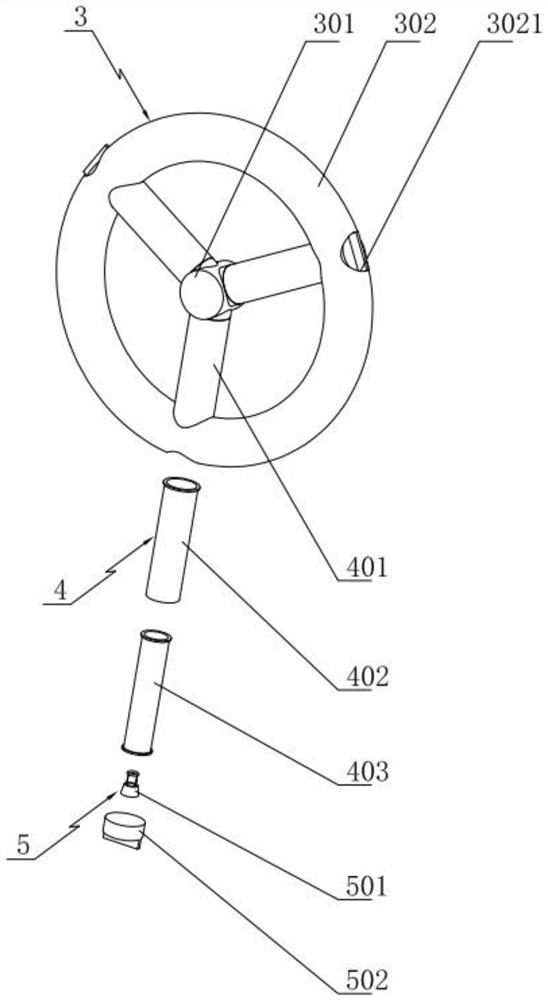

Vortex ring generating device, air conditioner indoor unit and air conditioner

PendingCN112747365AWide range of radiationEasy to moveLighting and heating apparatusHeating and ventilation casings/coversPhysicsBlow out

The invention discloses a vortex ring generating device, an air conditioner indoor unit and an air conditioner. The vortex ring generating device comprises a shell and a vortex ring generating portion; the shell comprises an air duct and a flow collecting piece, the air duct is provided with an air outlet, the flow collecting piece is installed at the air outlet, an air supply outlet communicating with the air duct is formed in the flow collecting piece, and an air passing area of the air supply outlet is smaller than that of the air outlet; and the vortex ring generating portion comprises a push plate assembly and a driving device, the push plate assembly is arranged in the shell and comprises a flexible part and a push plate connected to the flexible part, the flexible part is connected to the peripheral wall face of the shell, the push plate is arranged towards the air supply outlet, and the driving device drives the push plate to reciprocate in the shell so as to periodically drive airflow to be blown out of the air supply outlet. The vortex ring generating portion of the vortex ring generating device is simple in structure, high in sealing performance, high in reliability and low in cost.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Double-cylinder force-increased splitter

PendingCN111058848ASimple structureLight structureDisloding machinesFluid-pressure actuatorsEngineeringCylinder block

The invention discloses a double-cylinder force-increased splitter. The splitter comprises a base, a splitting block, a wedge block, a piston rod, a pair of pistons and a pair of cylinder bodies, wherein the pair of cylinder bodies are connected in series, one of the cylinder bodies is connected with one end of the base, and the other end of the base is connected with the splitting block; the pairof pistons are arranged in inner cavities of the corresponding cylinder bodies in a sleeved mode, and the two ends of the piston rods are connected with the corresponding pistons; and the wedge blockis arranged in the splitting block in a penetrating mode and connected with the piston rod, force application oil inlets are formed in the ends, far away from the base, of the pair of cylinder bodies, and a reset oil inlet is formed in the end, close to the base, of one cylinder body far away from the base. The double-cylinder force-increased splitter has the advantages of being simple in structure, flexible to use, capable of improving splitting accuracy, beneficial to weight reduction and capable of avoiding hydraulic oil leakage.

Owner:湖南烈岩科技有限公司

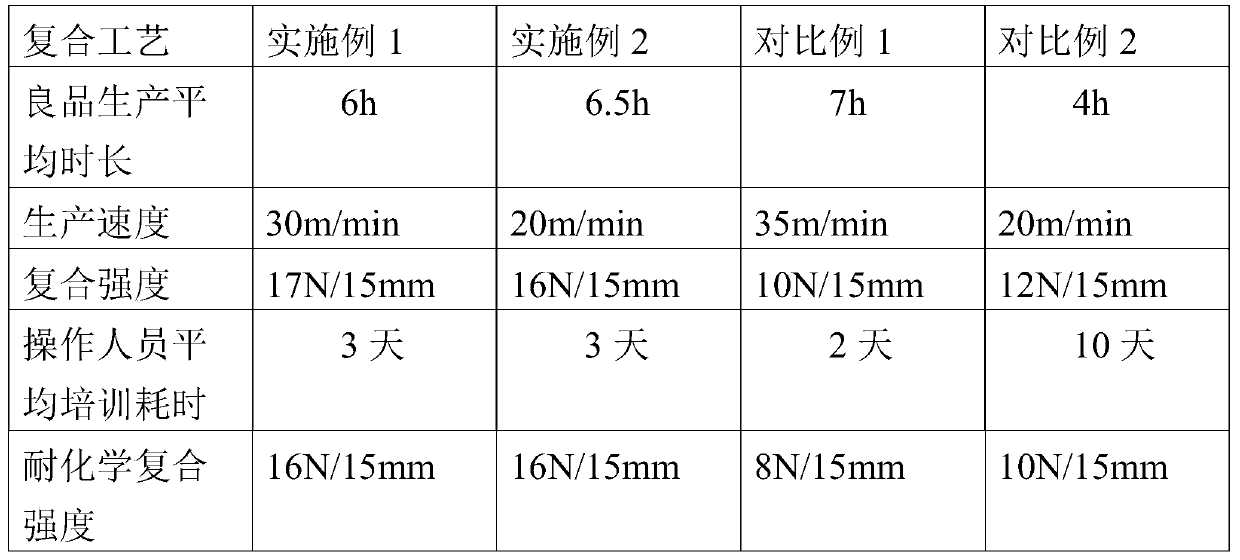

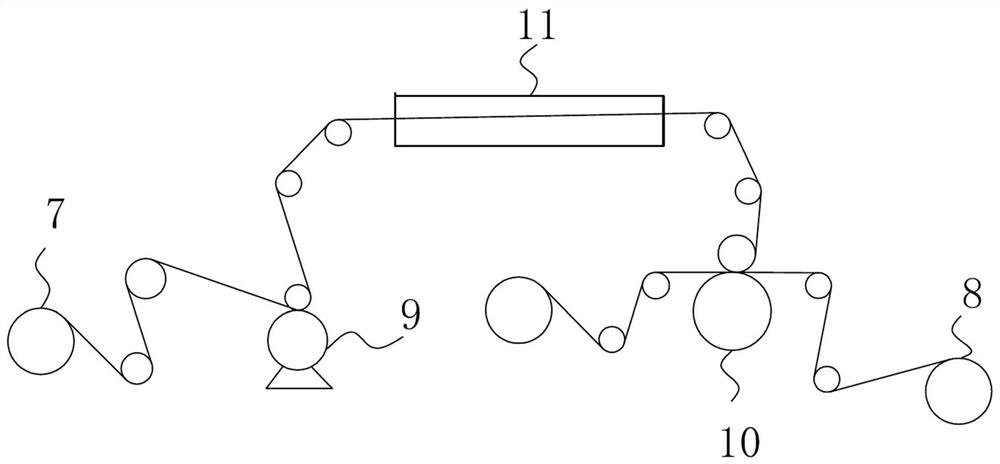

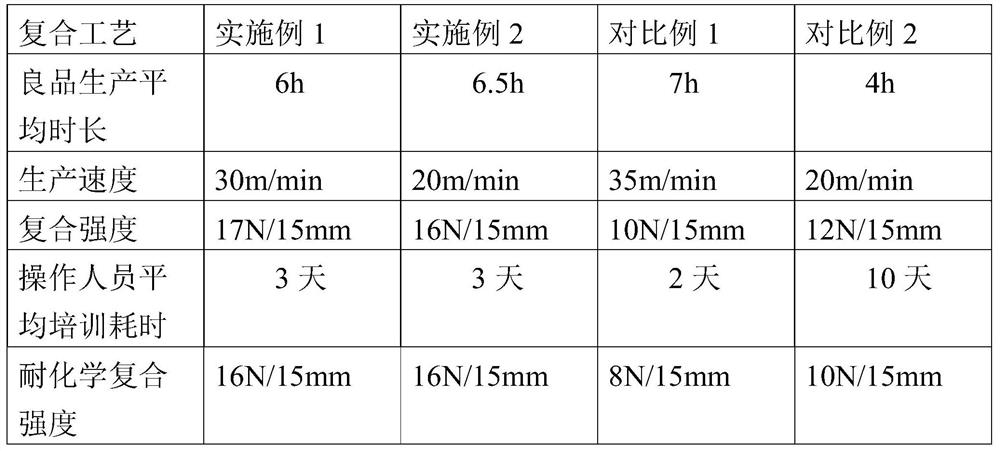

Preparation method of aluminum-plastic composite film

ActiveCN110077091ALower requirementLow material performance requirementsLaminationLamination apparatusComposite strengthComposite film

The invention provides a preparation method of an aluminum-plastic composite film. A bonding mode of a bonding layer of the aluminum-plastic composite film is chemical reaction, and composite strengthis obviously improved and chemical corrosion resistance is better when the bonding mode is compared with a partially physical bonding mode of two traditional composite technologies; the production technology of the aluminum-plastic composite film has a substantially reduced requirement for equipment and raw materials, has an obviously reduced requirement for operation quality for workers and guarantees that interference in the production is reduced, and stability of batch production is improved; the production speed of the method is obviously increased as compared with that of a thermal technology, and production efficiency is improved.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

Golf ball resin composition and golf ball

A golf ball resin composition that is excellent in resilience includes (A) at least one resin component selected from the group consisting of (a-1) a binary copolymer composed of an olefin and an α,β-unsaturated carboxylic acid having 3 to 8 carbon atoms, (a-2) an ionomer resin consisting of a metal ion-neutralized product of a binary copolymer composed of an olefin and an α,β-unsaturated carboxylic acid having 3 to 8 carbon atoms, (a-3) a ternary copolymer composed of an olefin, an α,β-unsaturated carboxylic acid having 3 to 8 carbon atoms and an α,β-unsaturated carboxylic acid ester, and (a-4) an ionomer resin consisting of a metal ion-neutralized product of a ternary copolymer composed of an olefin, an α,β-unsaturated carboxylic acid having 3 to 8 carbon atoms and an α,β-unsaturated carboxylic acid ester, and (B) a basic metal salt of a fatty acid.

Owner:SUMITOMO RUBBER IND LTD

Multi-piece golf ball

Owner:SUMITOMO RUBBER IND LTD

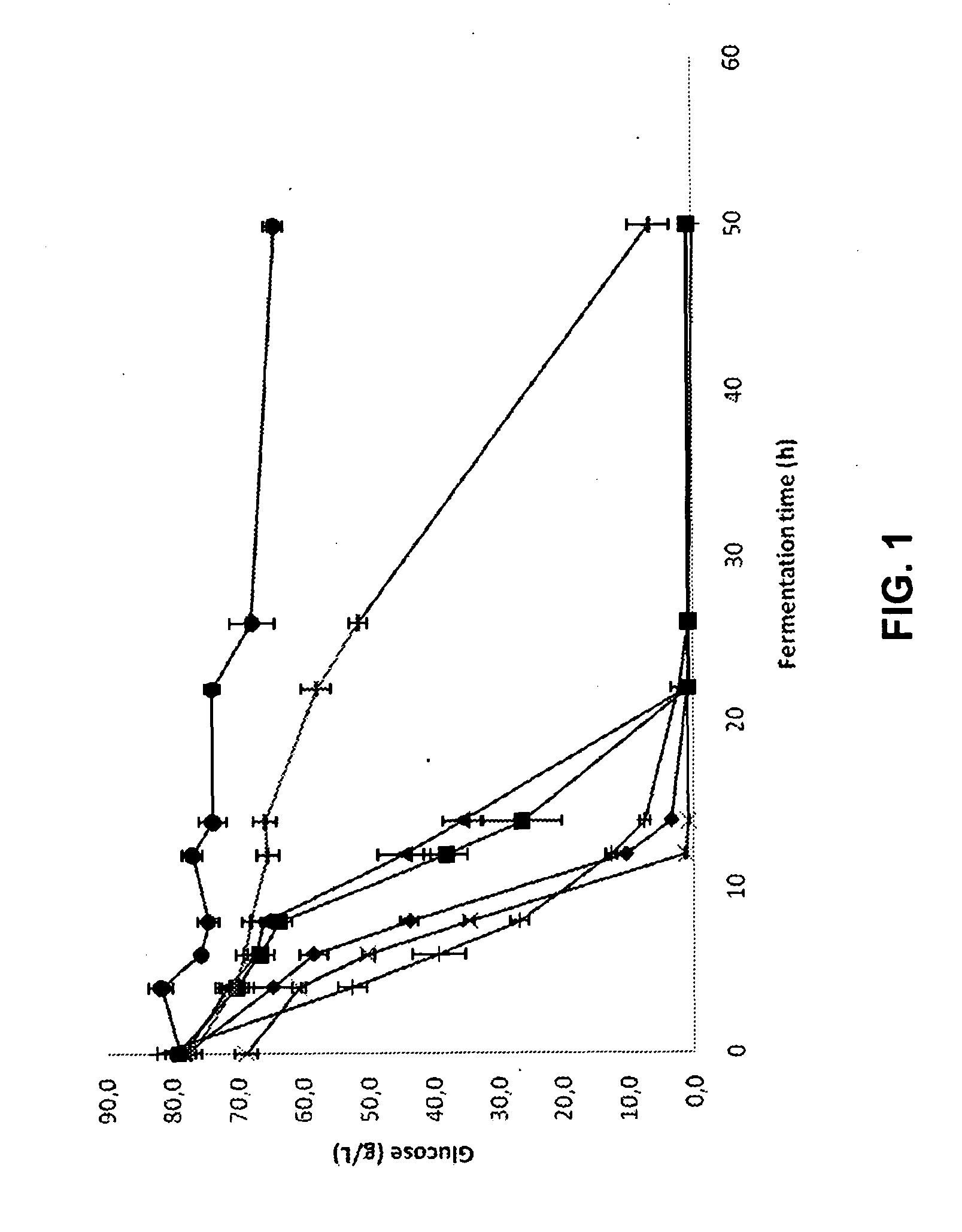

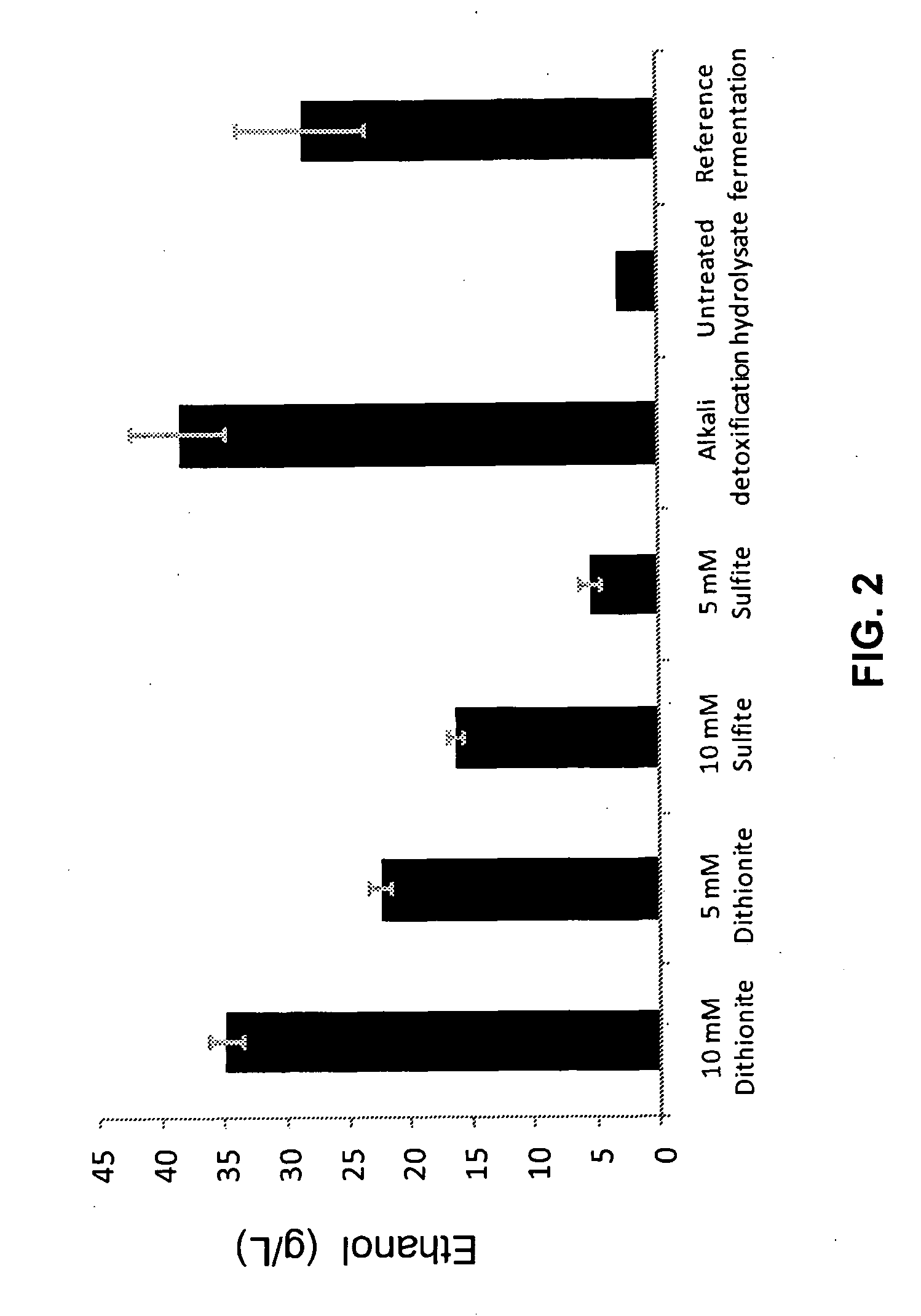

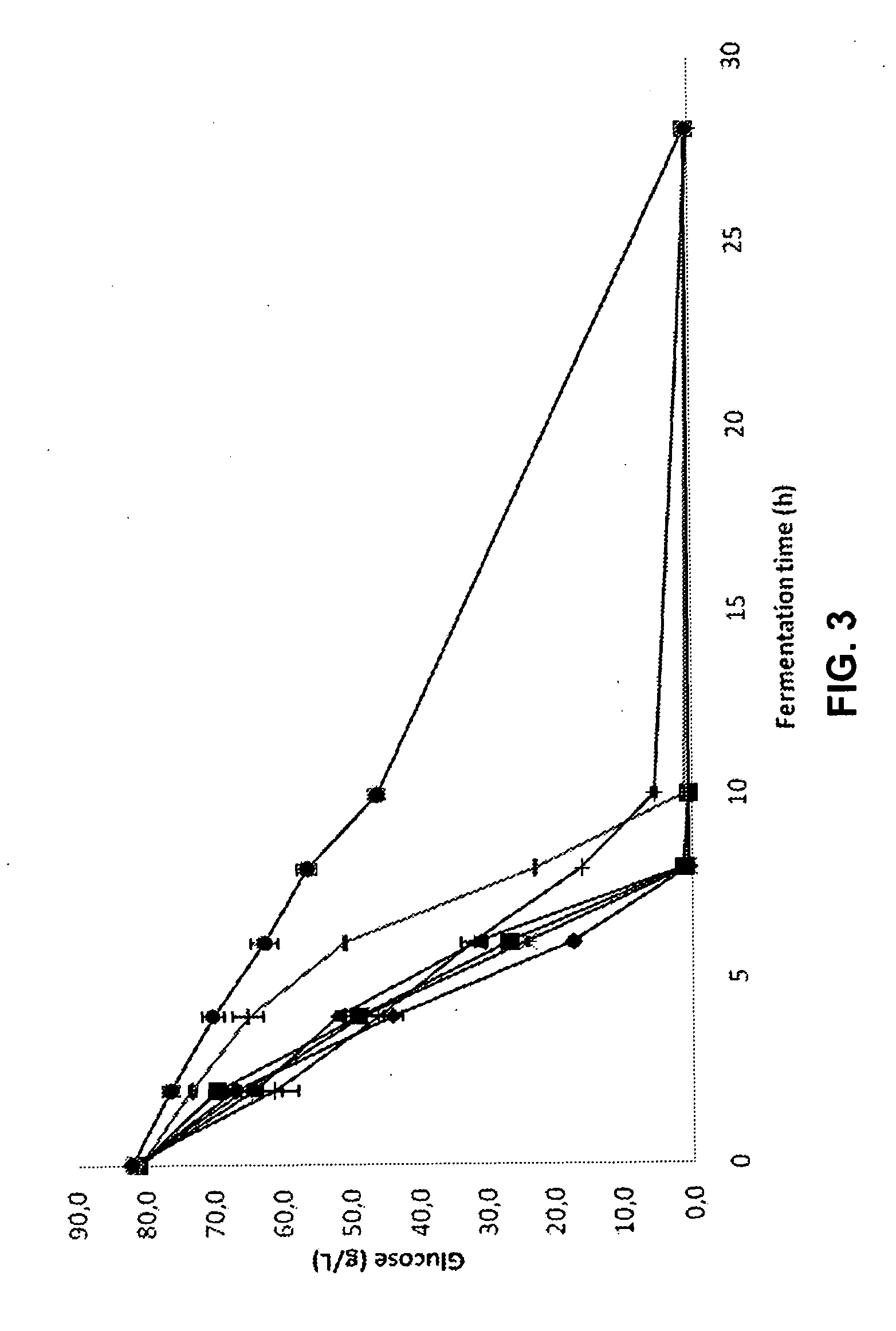

Detoxification with Reducing Agents

ActiveUS20130011894A1Reduce inhibitionLow material performance requirementsBiofuelsFermentationCelluloseDithionous acid

The present invention provides a method for decreasing the fermentation inhibition in a process for producing a target chemical from a pretreated cellulosic material, the process comprising enzymatic hydrolysis of the pretreated cellulosic material and fermentation of hydrolysed material, wherein the fermentation inhibitory properties of the material subjected to fermentation is decreased by an addition of at least one reducing agent to the pretreated material or hydrolysed material. Moreover, the present invention provides the use of dithionite for decreasing the fermentation inhibitory properties of a material being subjected to simultaneous enzymatic hydrolysis and fermentation.

Owner:SEKAB E TECH

Multi-piece golf ball

A multi-piece golf ball excellent in resilience and controllability includes a core composed of a center and an envelope layer covering the center and at least one cover covering the core, wherein the center is formed from a center composition containing (A) at least one resin component selected from the group consisting of (a-1) a binary copolymer composed of an olefin and an α,β-unsaturated carboxylic acid having 3 to 8 carbon atoms, (a-2) an ionomer resin consisting of a metal ion-neutralized product of the binary copolymer, (a-3) a ternary copolymer composed of the binary copolymer components and an β,β-unsaturated carboxylic acid ester, and (a-4) an ionomer resin consisting of a metal ion-neutralized product of the ternary copolymer components and (B) a basic metal salt of a fatty acid, and wherein the envelope layer is formed from a rubber composition.

Owner:SUMITOMO RUBBER IND LTD

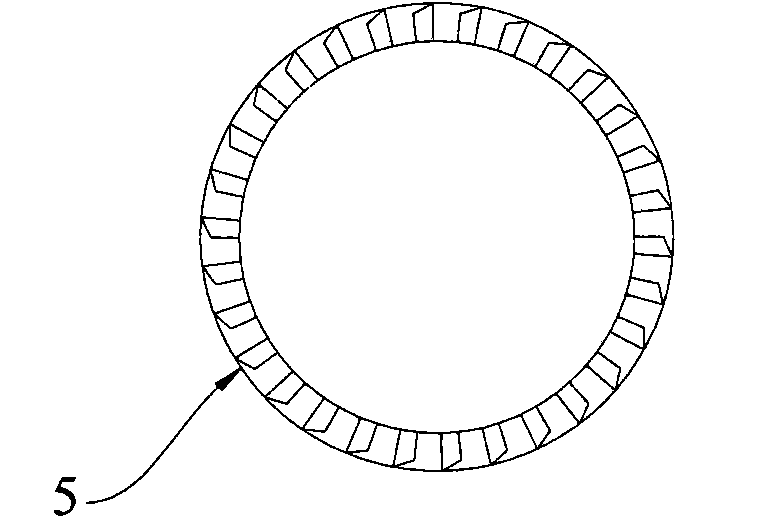

Rotational flow mixing device for coal distillation furnace

InactiveCN101760213AActs as a gasketImprove securityDirect heating destructive distillationCold airDistillation

The invention discloses a rotational flow mixing device for a coal distillation furnace, which comprises a gas pipeline and rotational flow vanes, wherein the gas pipeline introduces cold air or hot flue gas into a mixing chamber; a plurality of the rotational flow vanes are arranged along the peripheral direction of a gas outlet of the gas pipeline, and a plurality of vane structures form a certain angle with the flowing direction of airflow; and a plane where the gas outlet of the gas pipeline is positioned is positioned outside a plane where the inner wall of the mixing chamber is positioned. In the rotational flow mixing device, the pipe mouth is provided with the rotational flow vanes, because gas generates rotational flow at the outlet, local low air pressure is formed at the pipe mouth and has the function of a sealing gasket on the gas in the mixing chamber, and the safety of the device is greatly improved.

Owner:北京嘉德信达投资有限公司 +1

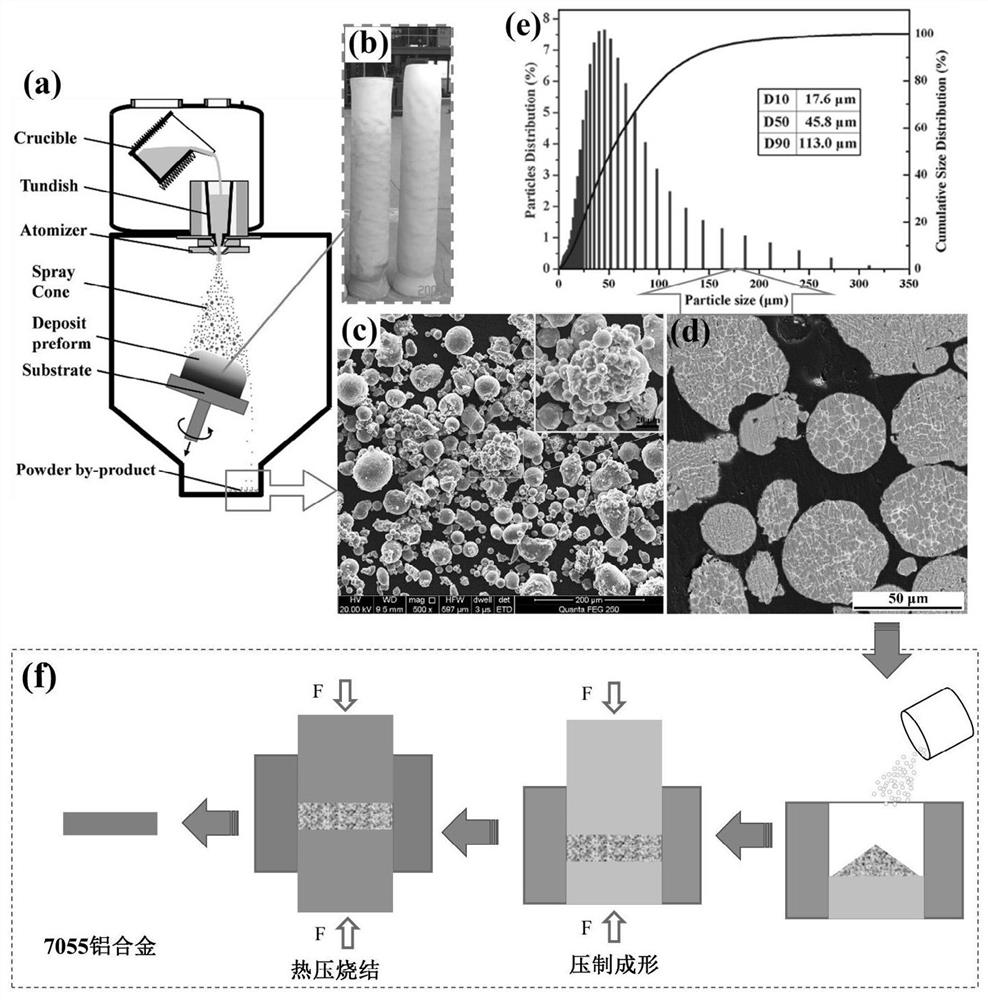

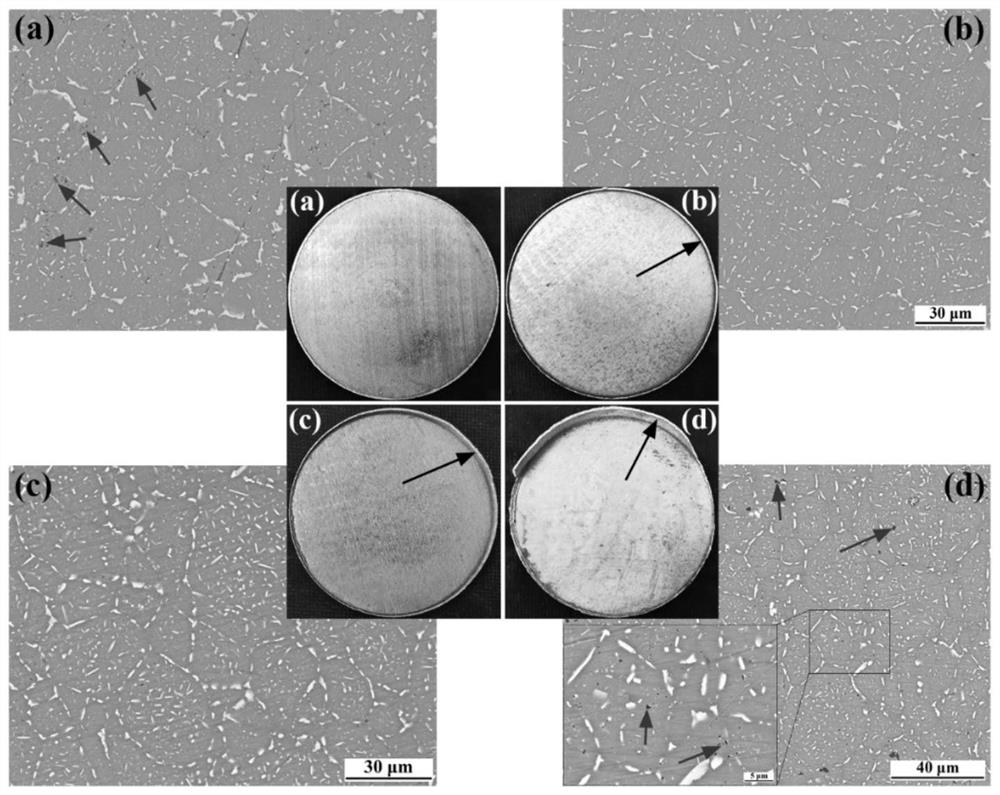

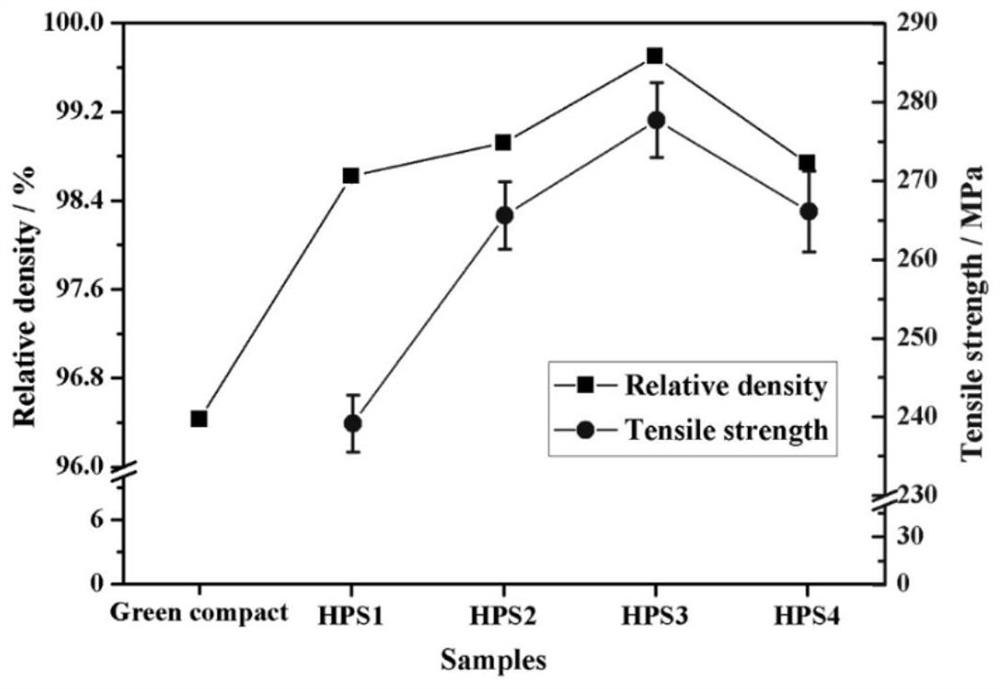

Comprehensive utilization method of powder by-products generated in spray forming process and product application

The invention provides a comprehensive utilization method of powder by-products generated in the spray forming process. The method comprises the steps that powder by-products are pressed, formed and sintered directly; the powder by-products mainly from extra powder generated in the spray forming green part preparation process, and are named as powder by-products in order to differ from a spray forming green part; according to the pressing forming, a hydraulic single column press or a four-column hydraulic press is adopted for loading the powder by-products into a steel mold to be formed, and agreen body is prepared; according to sintering, a vacuum hot pressing furnace is adopted for performing sintering densification, an alloy is prepared, and therefore the powder by-products are comprehensively utilized. According to the comprehensive utilization method of powder by-products generated in the spray forming process, the preparation technological process is short, the cost is low, operation is easy, convenient and flexible, the prepared materials have the structure and performance advantages of being fine in grain, uniform in structure, free of segregation and high in strength. Themethod can effectively achieve comprehensive utilization of powder by-products, the material utilization rate is increased, and the certain economic benefits are obtained.

Owner:CENT SOUTH UNIV

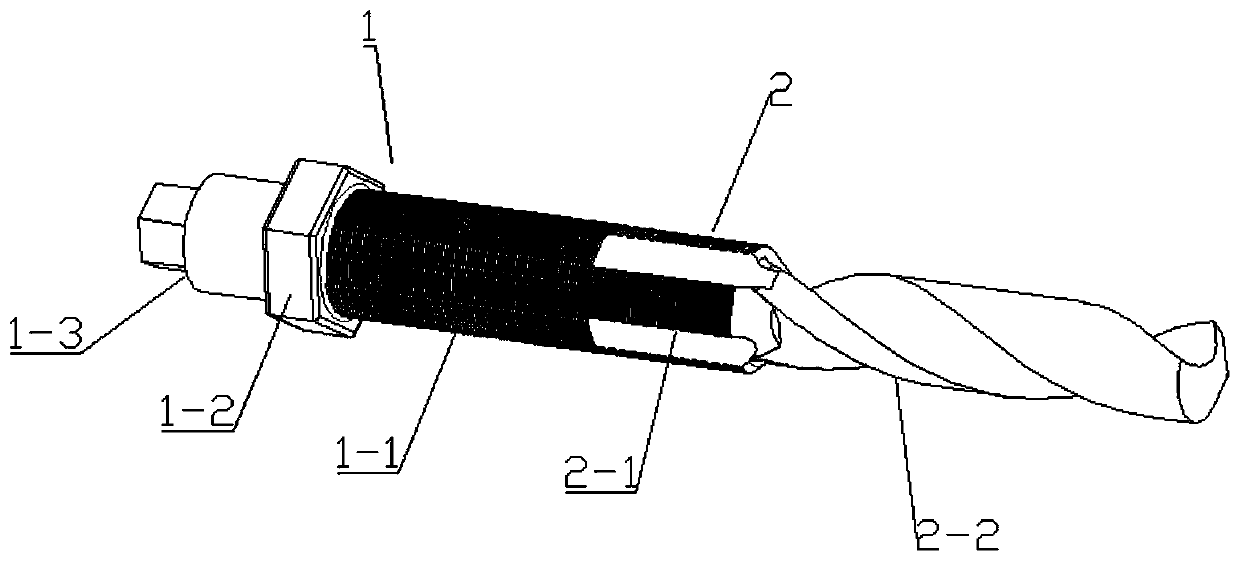

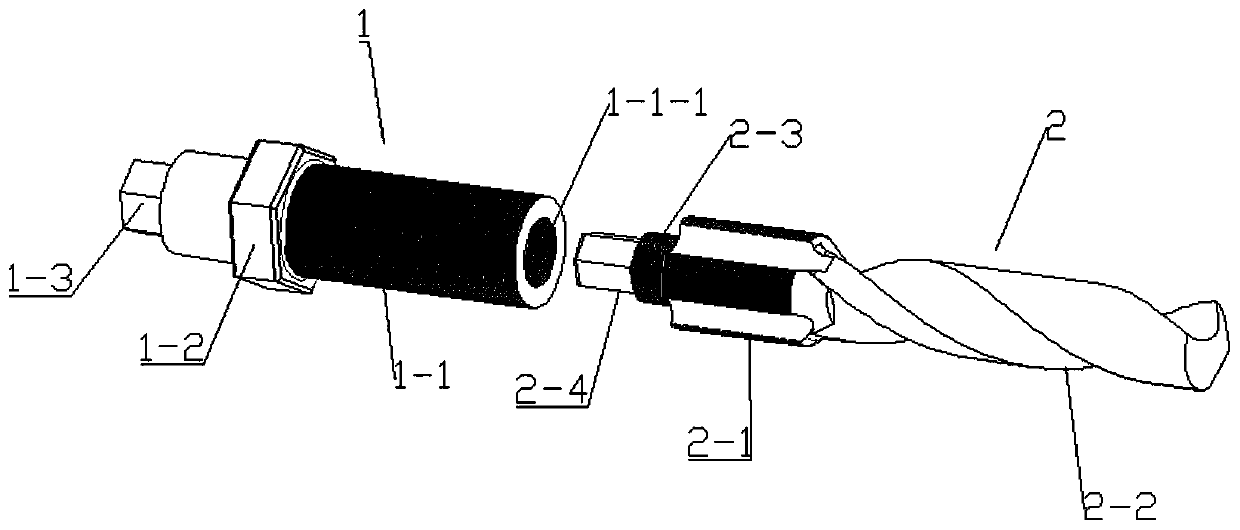

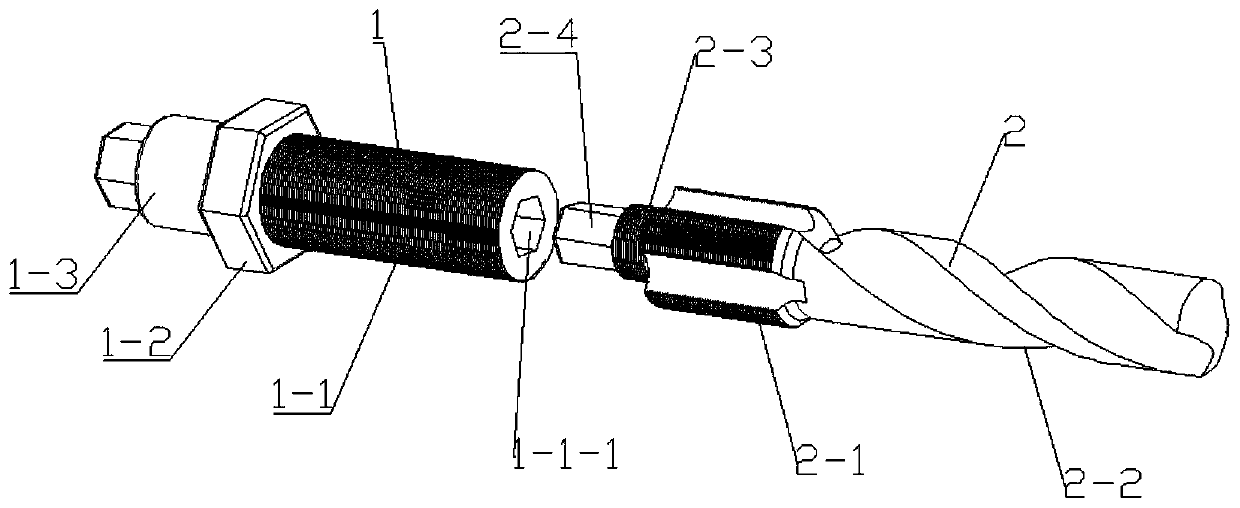

Novel self-tapping drill assembling bolt

PendingCN111219402AImprove adaptabilityReduce waste of resourcesThread cutting toolsTransportation and packagingDrill holeManufacturing engineering

The invention discloses a novel self-tapping drill assembling bolt which comprises a fixed bolt and a tapping and drilling rod body, wherein the tapping and drilling rod body comprises a tap screw rodand a drill rod integrally formed; the fixed bolt comprises a screw rod; one end of the screw rod and the free end of the tap screw rod are assembled and connected; a hexagon nut and a first connector extending in the length direction of the screw rod are fixedly arranged at the other end of the screw rod; the tail end of the first connector is arranged to be a polygonal prism structure matched with drilling equipment, or a third mounting groove hole matched with the drilling equipment is formed in the free end surface of the first connector; an external thread matched with a threaded groovehole tapped by the tap screw rod is formed in the outer surface of the fixed bolt; and the fixed bolt and the free end of the tap screw rod are assembled and connected to be adapted to the requirementof a thicker workpiece to flexibly select or cut the fixed bolt with proper length, so that suitability of the fixed bolt is improved; and after drilling, tapping and fastening are finished at one time, the tapping and drilling rod body can be dismantled from the fixed bolt, so that resource waste of the tapping and drilling rod body is reduced.

Owner:JIANGSU AWD FASTENER

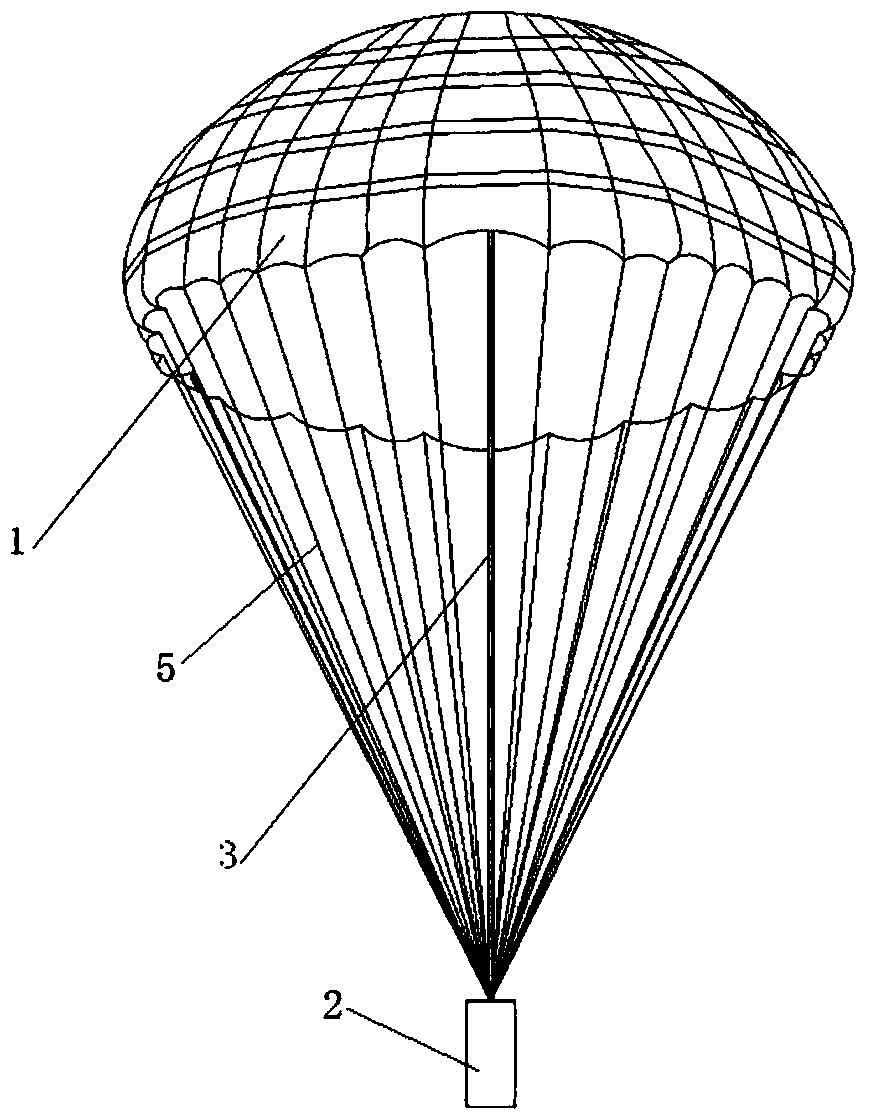

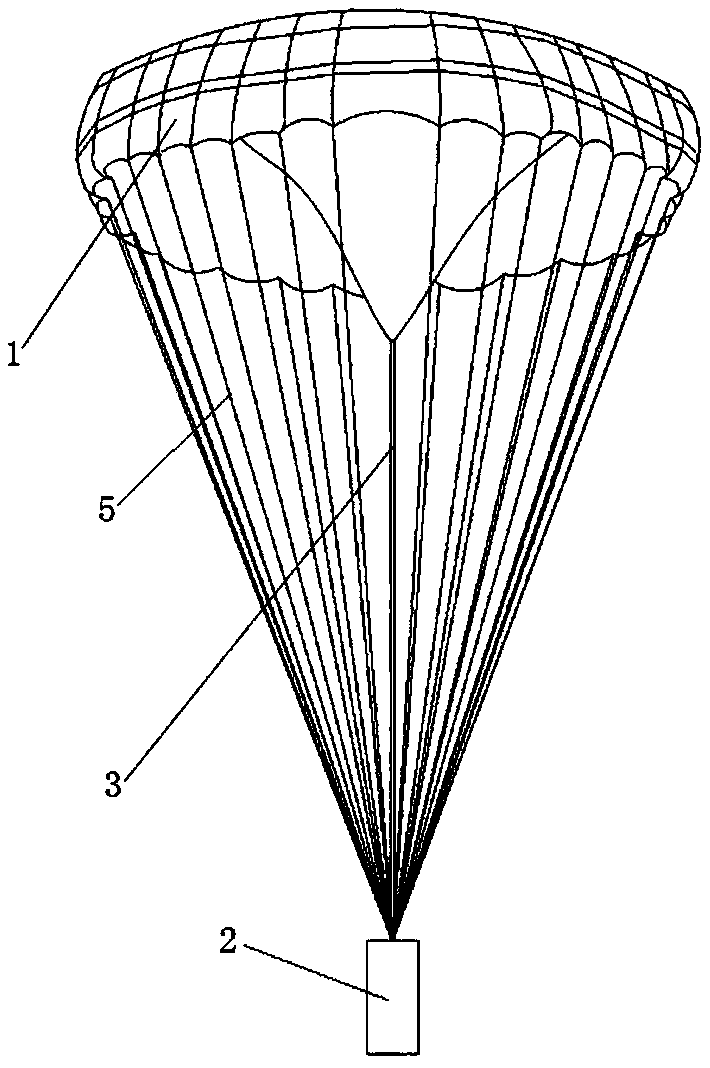

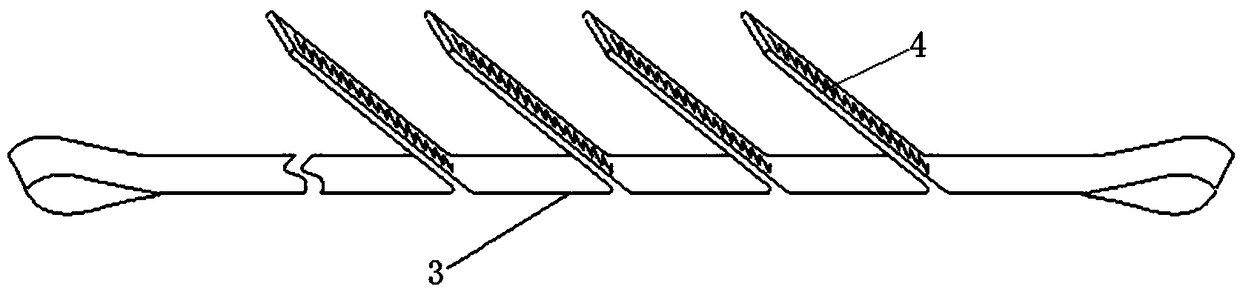

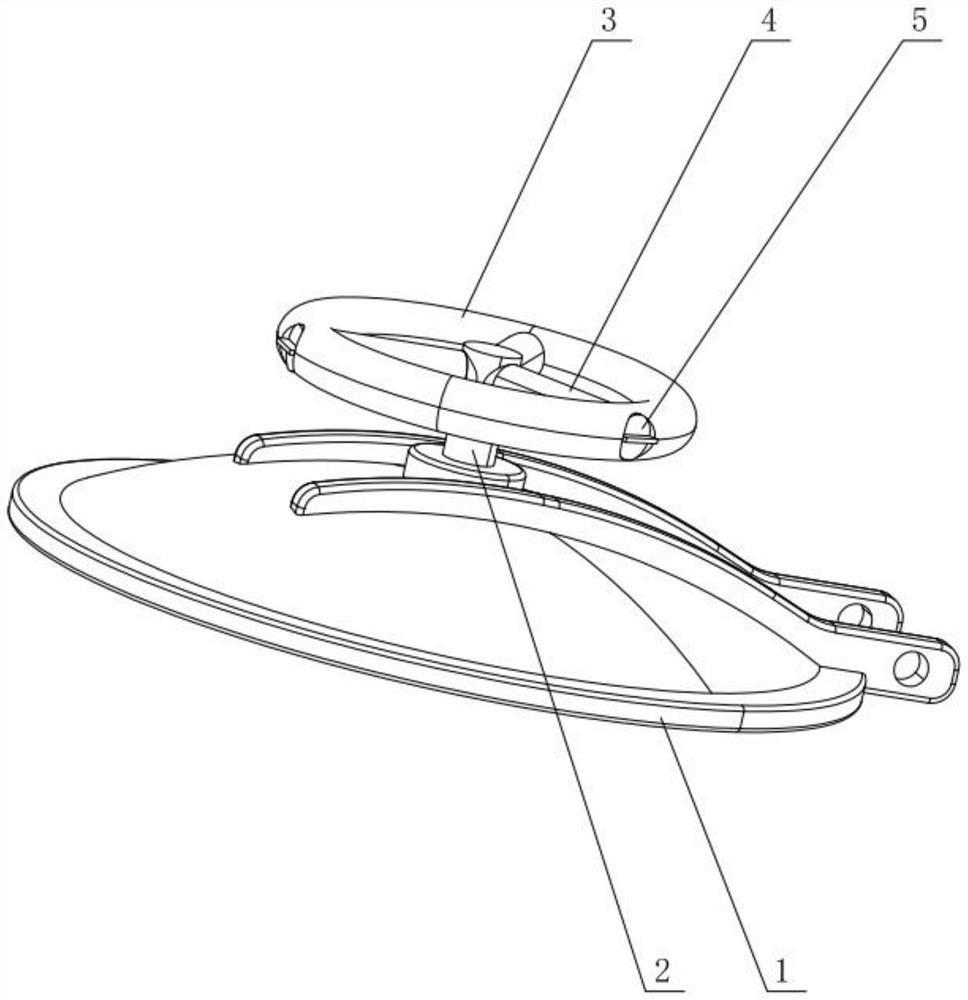

Powerful rope-controlled cushioning parachute

InactiveCN109229393AExtended inflation timeLow material performance requirementsParachutesTime extensionEngineering

A powerful rope-controlled cushioning parachute includes parachutes and lifts, A circumferential parachute rope is connected between the parachute and the lifting object, a center rope is connected between the top center of the parachute and the lifting object, and a folding section is arranged on the center rope. During the parachute descending and unfolding, the center rope is pulled by the tension between the parachute and the lifting object, the folding section is gradually unfolded, and the center rope is longer, so that the parachute can be fully unfolded. To achieve full-area deploymentof parachute inflation time prolonged, reduce parachute impact, reduce parachute material performance requirements, improve the safety of air-dropped materials.

Owner:AEROSPACE LIFE SUPPORT IND LTD

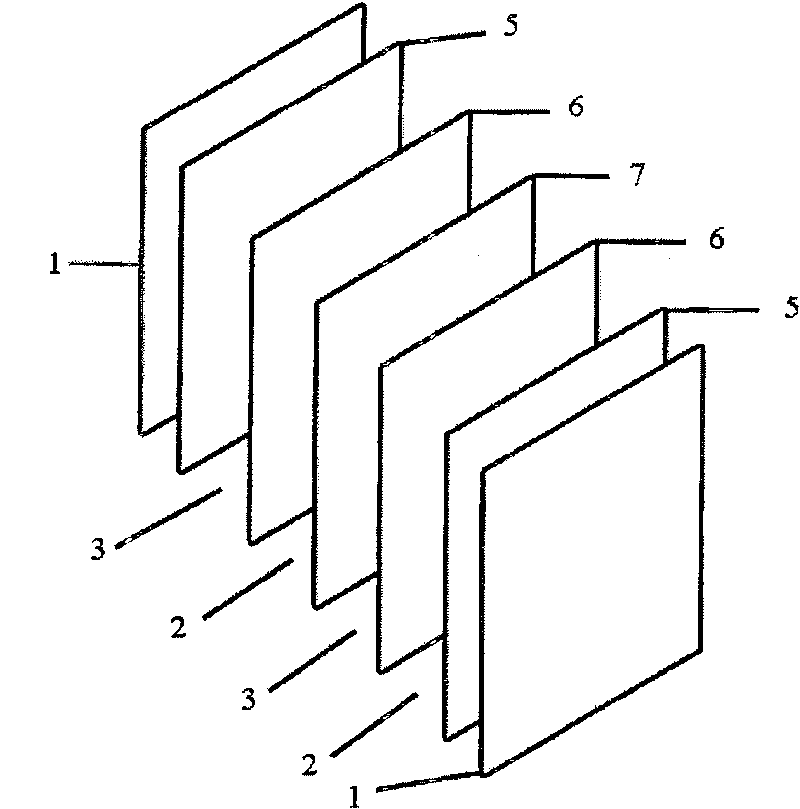

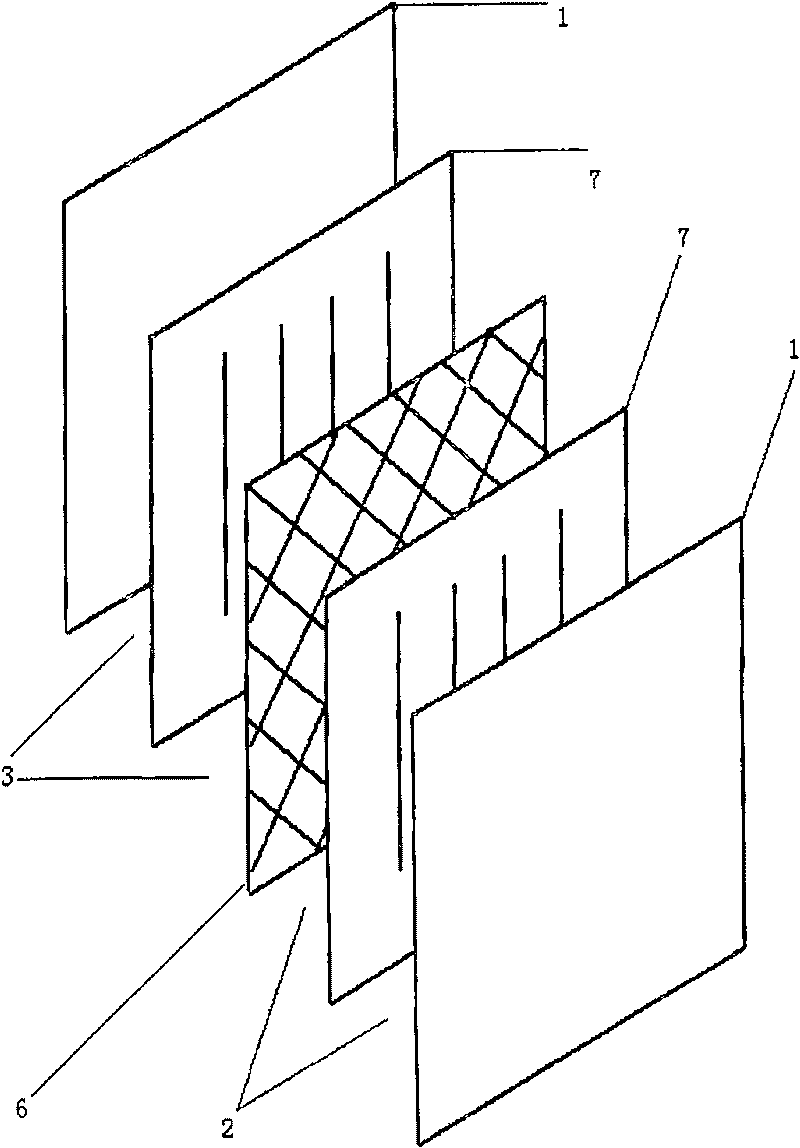

Liquid stream battery stack

InactiveCN101252200BSmall self-dischargeReduce manufacturing costElectrolyte moving arrangementsRegenerative fuel cellsFlow cellElectrical polarity

The invention provides a flow cell stack, comprising two endplates, a diaphragm, and two bipolar plates, the flow cell stack is separated into an anode electrolyte area and a cathode electrolyte areathrough the diaphragm between the two endplates, each area is provided with a bipolar plate which has the same polarity with the electrolyte of the corresponding area and the same polarity at both sides; two poles of the same bipolar plate are connected in parallel; an inlet of each bipolar plate is arranged at the same position below the bipolar plate, and an outlet of each bipolar plate is arranged at the same position above the bipolar plate. The flow cell stack is simple in structure, can reduce the requirement on the performance of the material of the bipolar plate effectively, particularly the requirement on the compactness of the bipolar plate so as to reduce the production cost effectively; meanwhile, the flow cell stack can effectively decrease the self-discharging and reduction of efficiency of the cell caused by the crossing between the anode electrolyte and the cathode electrolyte in the cell stack and prolong the service life of the cell, is suitable to be an update of theprior flow cell stack, particularly to be used on a cell stack which needs large current discharging.

Owner:CENT SOUTH UNIV +1

Polyamic acid resin in reach-approved solvent system for wire coating applications

PendingUS20210395458A1Reduce molecular weightLow material performance requirementsPlastic/resin/waxes insulatorsPowdery paintsPolymer sciencePolyamide

The present invention discloses a polyamic acid resin composition in a REACH-approved solvent system for use in wire coating applications. The polyamic acid resin composition comprises a molecular weight greater than 8,000 grams per mole, more preferably greater than 20,000 grams per mole. The REACH-approved solvent system comprising a primary REACHapproved solvent with one or more optional secondary REACH-approved co-solvents. The secondary REACH-approved co-solvent can be reactive or non-reactive with dianhydride. The present invention also discloses the elimination of solvents in polyamic acid resin to produce a REACH-approved polyamic acid resin powder.

Owner:KANEKA AMERICAS HLDG

A kind of preparation method of aluminum-plastic composite film

ActiveCN110077091BLower requirementLow material performance requirementsLaminationLamination apparatusComposite strengthChemical reaction

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

Double-acting hydraulic mechanism, multi-stage telescopic hydraulic mechanism and hydraulic support

InactiveCN107387491BIncrease the expansion ratioLow material performance requirementsFluid-pressure actuatorsCylinder blockPiston rod

The invention discloses a double-action hydraulic mechanism, a multi-grade retractable hydraulic mechanism and a hydraulic bracket and belongs to the technical field of hydraulic pressure. The double-action hydraulic mechanism comprises a first cylinder body 3, a second cylinder body 7, a first guide sleeve 4, a second guide sleeve 14, a piston rod 5, a piston 6, a first valve seat 32 and a first valve 25. The multi-grade retractable hydraulic mechanism comprises an outermost-side cylinder body 1, a plurality of middle cylinder bodies 2, the double-action hydraulic mechanism provided by the invention, a second valve seat 49 and a second valve 13. The hydraulic bracket comprises the multi-grade retractable hydraulic mechanism provided by the invention and a column head 8. The double-action hydraulic mechanism, the multi-grade retractable hydraulic mechanism and the hydraulic bracket, provided by the invention, have a relatively large contraction ratio; and the double-action hydraulic mechanism is introduced so that performance requirements on materials of a sealing part and a cylinder barrel are reduced.

Owner:CATERPILLAR ZHENGZHOU

Textile reinforcement suitable for being used in a method for impregnation by a thermoplastic resin

InactiveUS20190153636A1Low softening pointLow material performance requirementsOrnamental textile articlesLayered productsYarnPolyresin

The invention relates to a textile reinforcement suitable for being used in a method for impregnation by a thermoplastic impregnation resin, with a view to producing composite parts, including at least one set of substantially parallel high-tenacity yarns, and a sewing yarn sewn through the one or more sets, characterized in that the sewing yarn includes filaments which have a melting temperature higher than the melting temperature of said thermoplastic impregnation resin, and filaments made from a thermoplastic material, which can be mixed into the impregnation resin, and which have a melting temperature lower than the implementation temperature of said thermoplastic impregnation resin.

Owner:CHOMARAT TEXTILES INDS

A fast and labor-saving opening and closing handle mechanism for pressure-resistant hatch covers

ActiveCN111186530BIncrease the arm of actionOperating force is smallUnderwater vesselsVessel hatches/hatchwaysStructural engineeringMechanical engineering

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

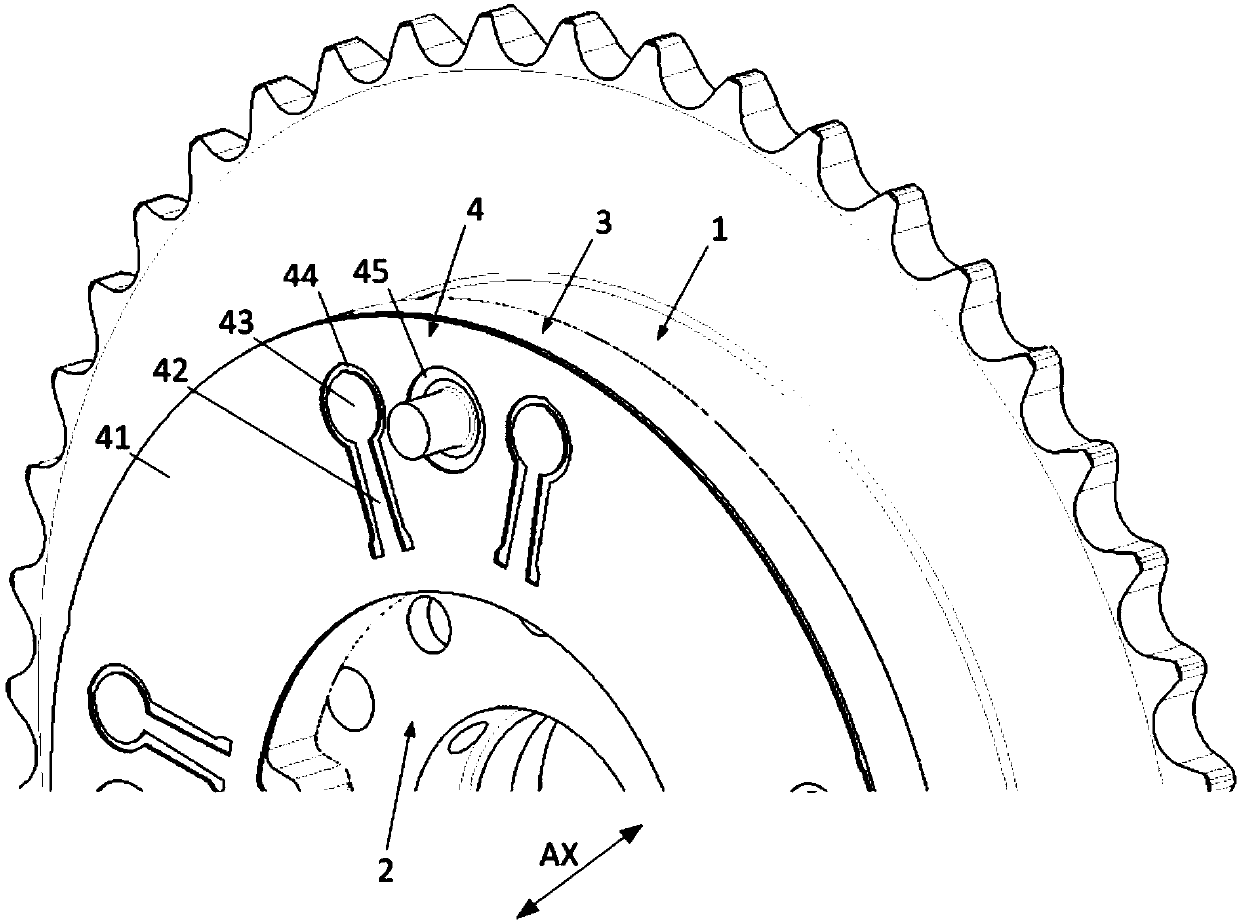

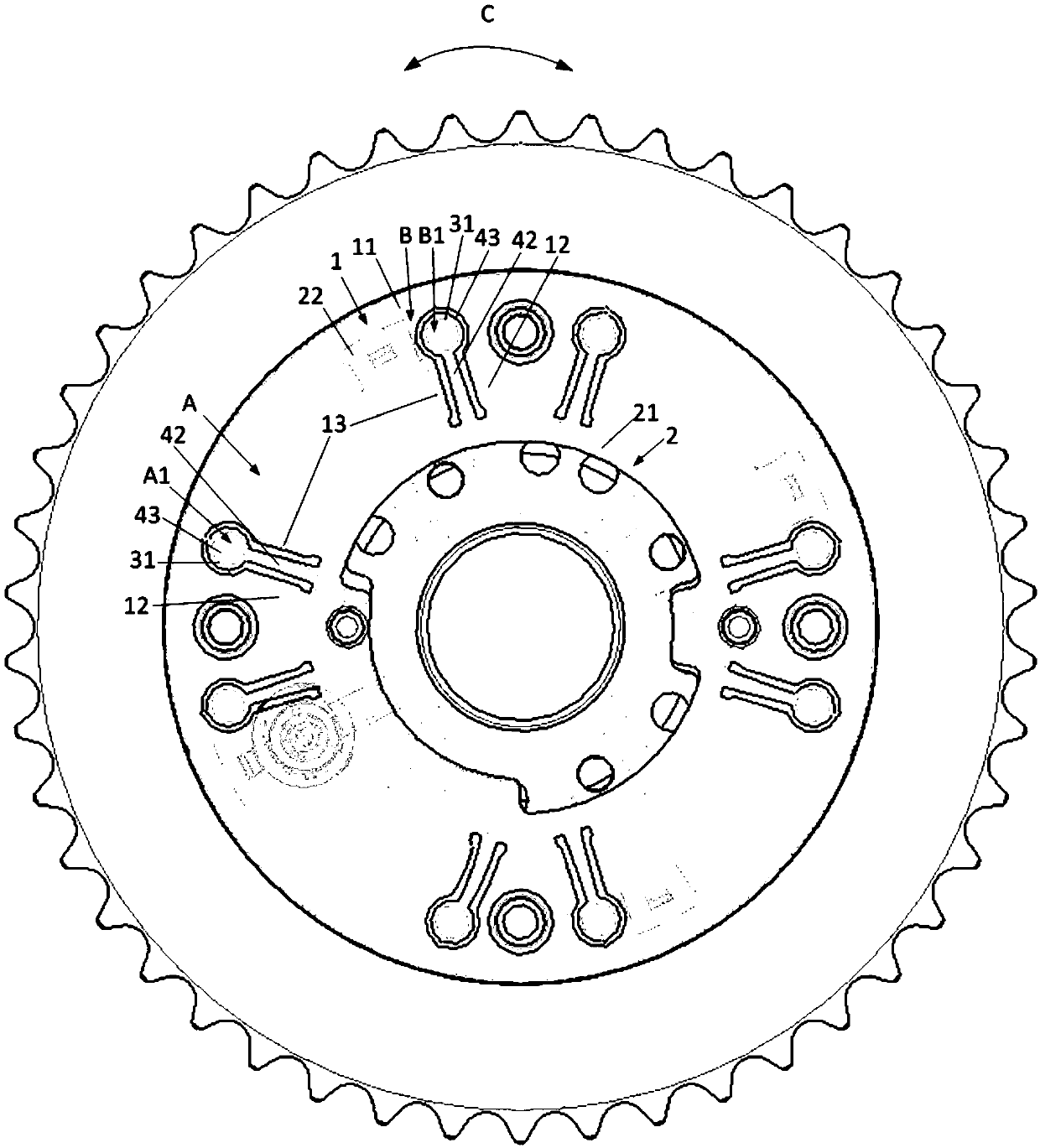

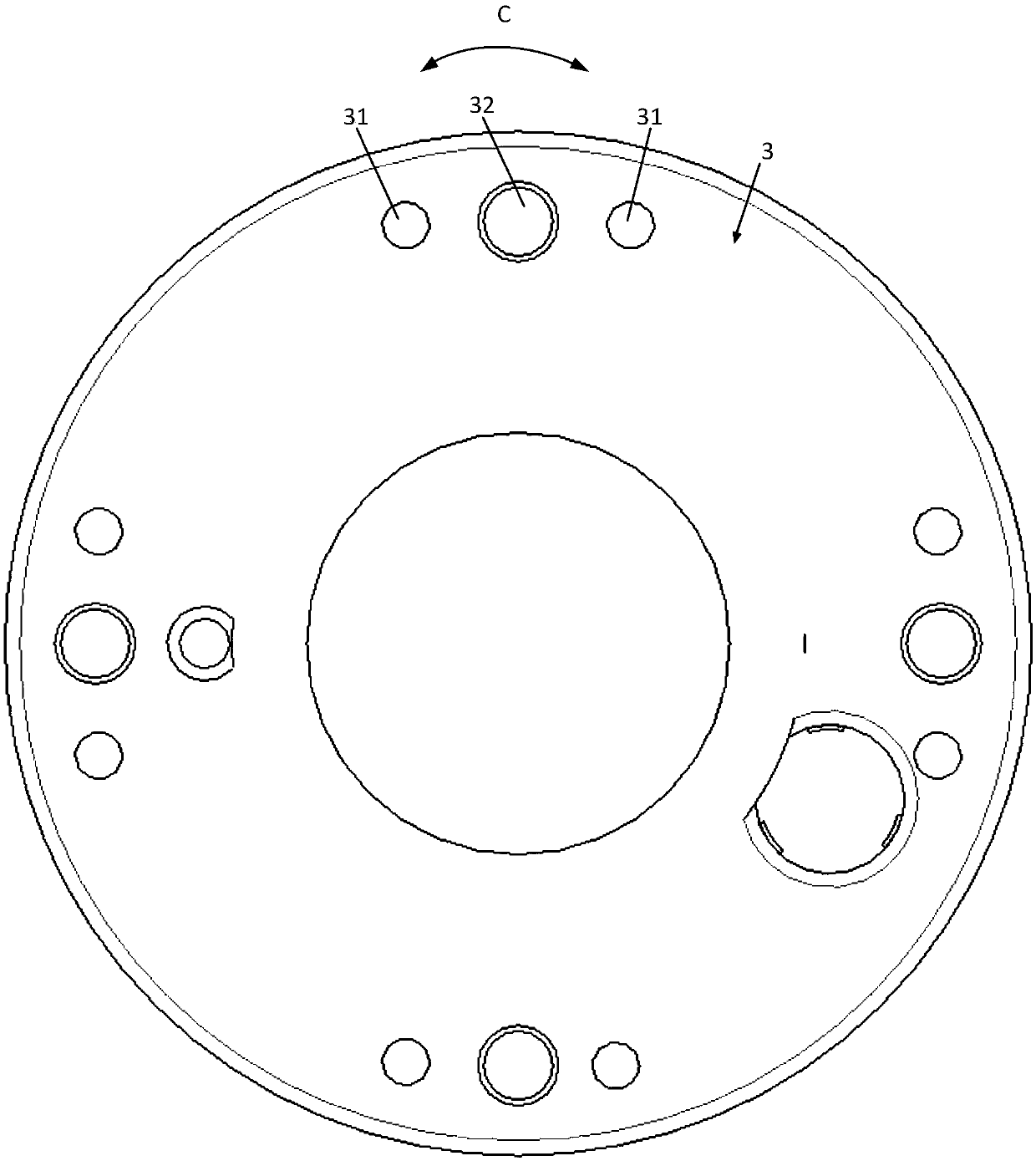

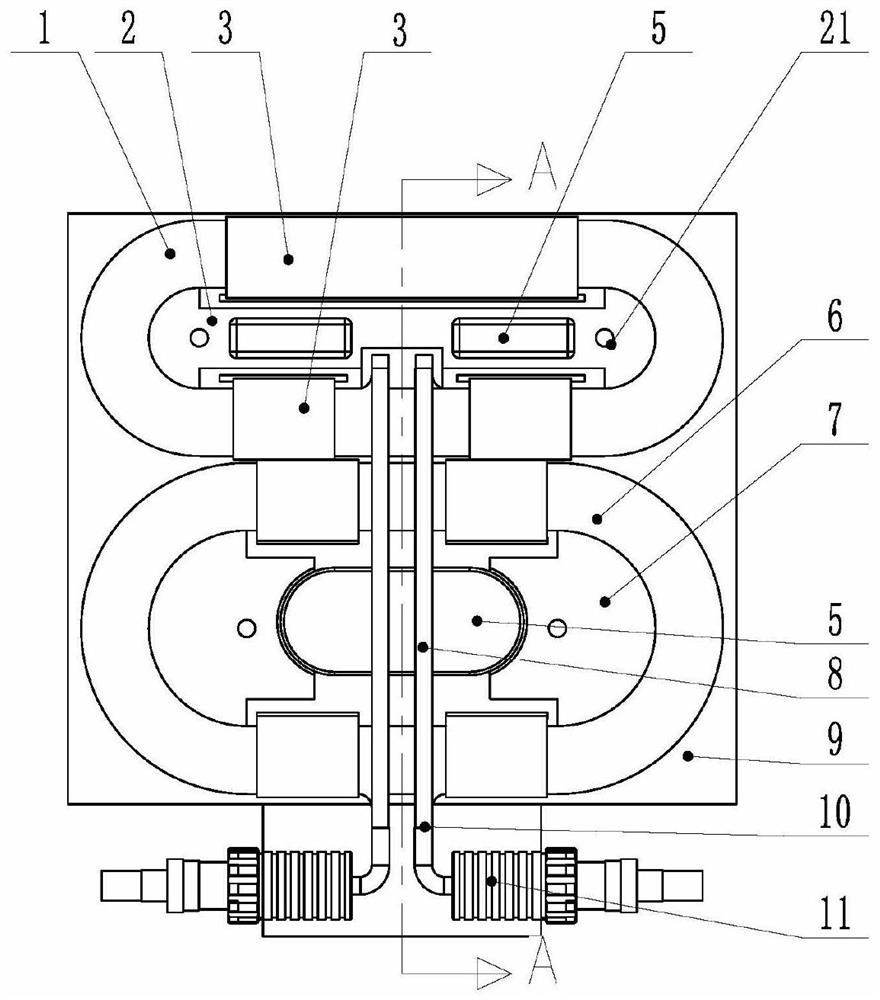

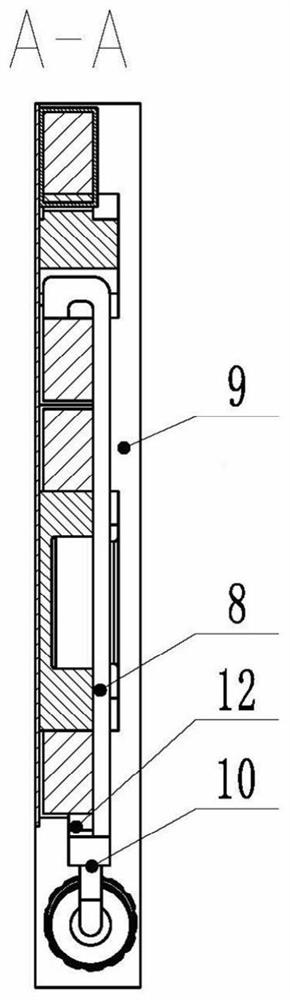

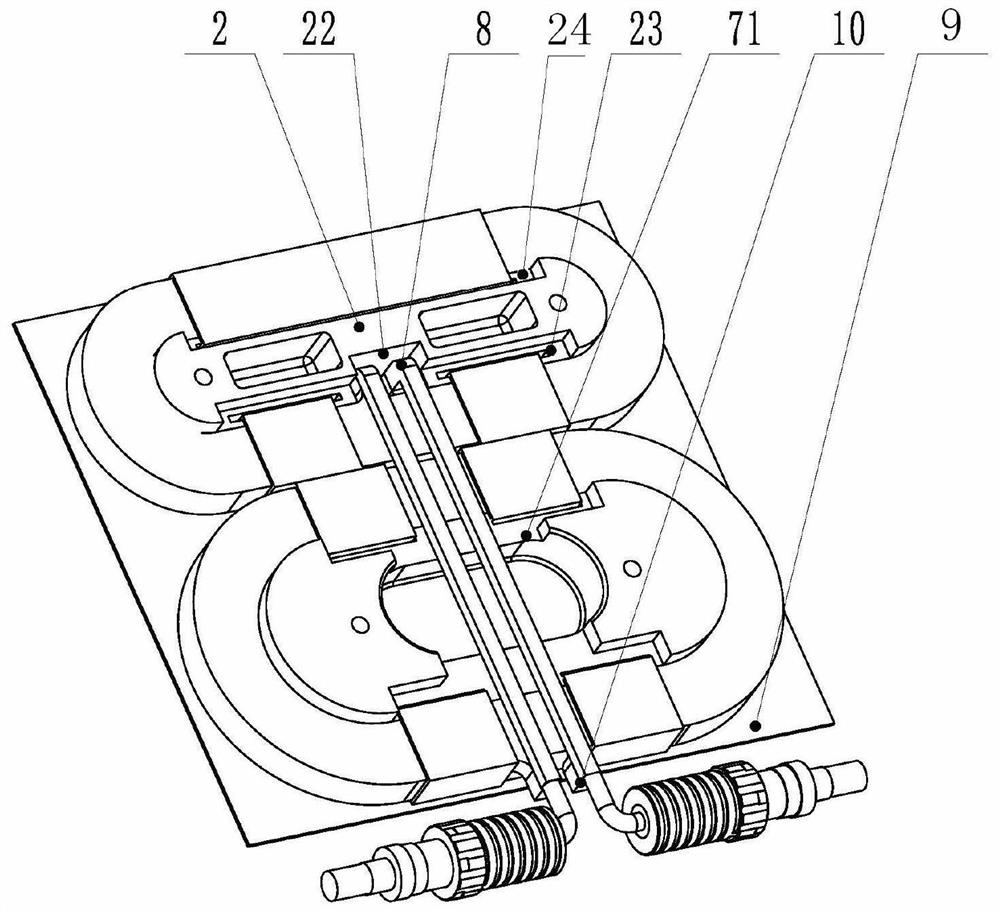

Camshaft phaser

ActiveCN110836133AImprove reliabilityReduce loadValve arrangementsMachines/enginesEngineeringControl valves

The invention relates to camshaft phaser. The camshaft phaser comprises a stator, a rotor and a sealing cover, wherein a plurality of oil chambers distributed in the circumferential direction are formed among the stator, the rotor and the sealing cover; and a plurality of through holes extending in the axial direction and penetrating through the sealing cover are formed in the sealing cover, eachoil chamber communicates with at least one through hole correspondingly, and each through hole is provided with a control valve enabling the through hole to open / close, so that the control valves control the through holes to open only when the oil pressure in the oil chambers is greater than a predetermined value. In this way, the camshaft phaser can control the oil pressure in the oil chambers inside the camshaft phaser, and high oil pressure is eliminated, so that the reliability of the camshaft phaser is improved; and in addition, by controlling the oil pressure, the load borne by the partsof the camshaft phaser is reduced, and the requirements for material performance such as tensile strength and fatigue strength of related parts are reduced so that the manufacturing cost can be saved.

Owner:SCHAEFFLER TECH AG & CO KG

Suspension propelling and guiding integrated module and maglev track system

ActiveCN113517772AMeet structural strength requirementsStable structurePropulsion systemsMagnetic holding devicesEngineeringMechanical engineering

The invention relates to the technical field of high-speed maglev traffic, and discloses a suspension propelling and guiding integrated module and a maglev track system. The module comprises an upper coil, an upper coil framework, a lower coil, a lower coil framework, a binding structure, a high-voltage connector and a shell, wherein the upper coil, the upper coil framework, the lower coil, the lower coil framework and the binding structure are all arranged in the shell, and the upper coil and the lower coil are correspondingly arranged on the upper coil framework and the lower coil framework respectively and bound through the binding structure. Two upper coil outgoing lines of the upper coil are led out from the innermost layer of the upper coil through a first outgoing line groove of the upper coil framework and are vertically led out to the bottom connecting part through a second outgoing line groove in the upper surface of the lower coil framework; the two lower coil outgoing lines of the lower coil are led out from the outer side of the lower coil to the bottom connecting position and are connected with the two upper coil outgoing lines respectively to form two connecting points, and each connecting point is connected with one high-voltage connector. Therefore, the structural strength requirement of the integrated coil can be met, and the structure is more reliable.

Owner:HIWING TECH ACAD OF CASIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com