Double-action hydraulic mechanism, multi-grade retractable hydraulic mechanism and hydraulic bracket

A hydraulic mechanism, double-acting technology, applied in the hydraulic field, can solve the problems of small expansion ratio, high material performance requirements of seals and hydraulic cylinders, and achieve the effect of increasing the expansion ratio and reducing the material performance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

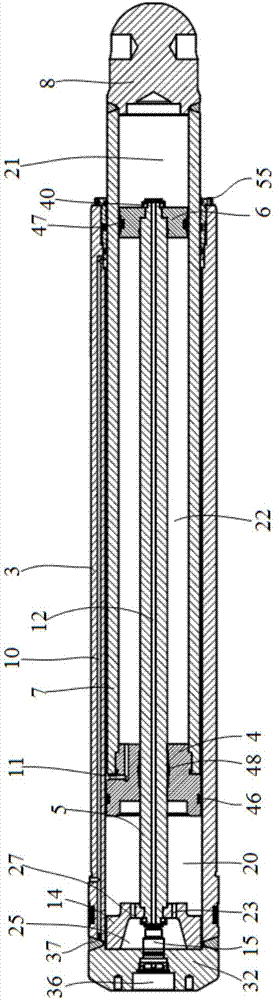

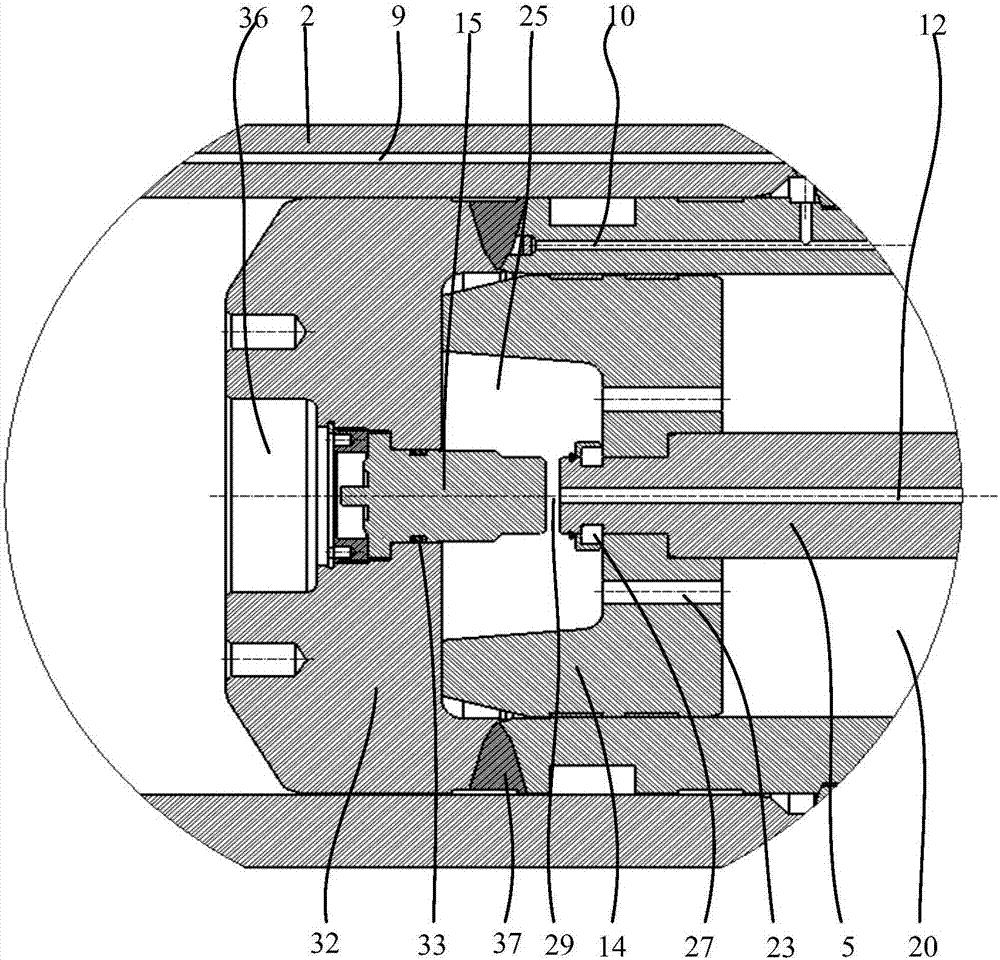

[0049] See attached figure 1 The double-acting hydraulic mechanism provided by Embodiment 1 of the present invention includes a first cylinder body 3, a second cylinder body 7, a first guide sleeve 4, a second guide sleeve 14, a piston rod 5, a piston 6, a first valve seat 32, first valve 15 . The first valve seat 32 is fixedly connected to the proximal end of the first cylinder body 3 (in this embodiment, the first valve seat 32 is welded to the proximal end of the first cylinder body 3 by welding spot 37), and the first valve 15 is set by The first valve hole 36 on the first valve seat 32 is set on the first valve seat 32; the second cylinder 7 is sleeved in the first cylinder 3, and the first guide sleeve 4 is fixedly connected to the second cylinder 7 The proximal end and the inner wall of the first cylinder 3 form a sliding pair, the second guide sleeve 14 is fixedly connected to the inner wall of the first cylinder 3, and the inner cavity of the first cylinder 3 is divi...

Embodiment 2

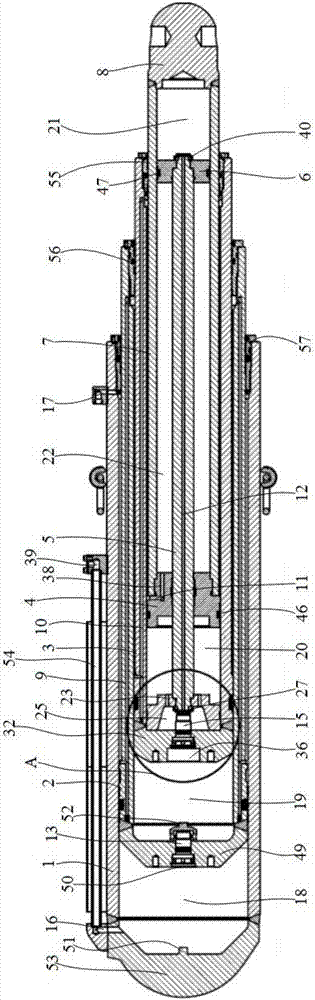

[0055] See attached figure 2 The multi-stage telescopic hydraulic mechanism provided by Embodiment 2 of the present invention includes the outermost cylinder 1 , several intermediate cylinders 2 , the double-acting hydraulic mechanism provided by the present invention, the second valve seat 49 , and the second valve 13 . A number of intermediate cylinders 2 are nested in layers one by one, and form a sliding pair between each other; the double-acting hydraulic mechanism is nested in the innermost intermediate cylinder 2, and the first cylinder 3 and the innermost intermediate cylinder 2 A sliding pair is formed between the inner walls of the middle cylinder body 2; a fifth cavity 19 is provided inside the middle cylinder body 2, and when the first valve 15 is in an open state, the fifth cavity 19 communicates with the second cavity 25 through the first valve hole 36; The second valve seat 49 is fixedly connected to the proximal end of the middle cylinder body 2, and the secon...

Embodiment 3

[0063] The hydraulic support provided by Embodiment 3 of the present invention includes the multi-stage telescopic hydraulic mechanism provided by the present invention, the column head (8), and the column head (8) is fixedly connected to the distal end of the second cylinder (7).

[0064] The hydraulic support provided in the third embodiment of the present invention applies the multi-stage telescopic hydraulic mechanism provided in the second embodiment of the present invention. Therefore, the hydraulic support can also increase the expansion and contraction ratio under the condition of low hydraulic oil pressure, and reduce the sealing cost. and cylinder material performance requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com