Middle reheating type turbine cooler system applied to airplane pod

A turbine cooler and turbine technology, applied in the direction of machines/engines, mechanical equipment, aircraft parts, etc., can solve the problems of low utilization rate of cooling gas, increase of aircraft flight resistance, waste of compressed air, etc., to save power consumption and increase heat , the effect of relieving power tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solution and advantages of the present invention clearer, refer to the attached image 3 Examples are also given to further describe the present invention in detail.

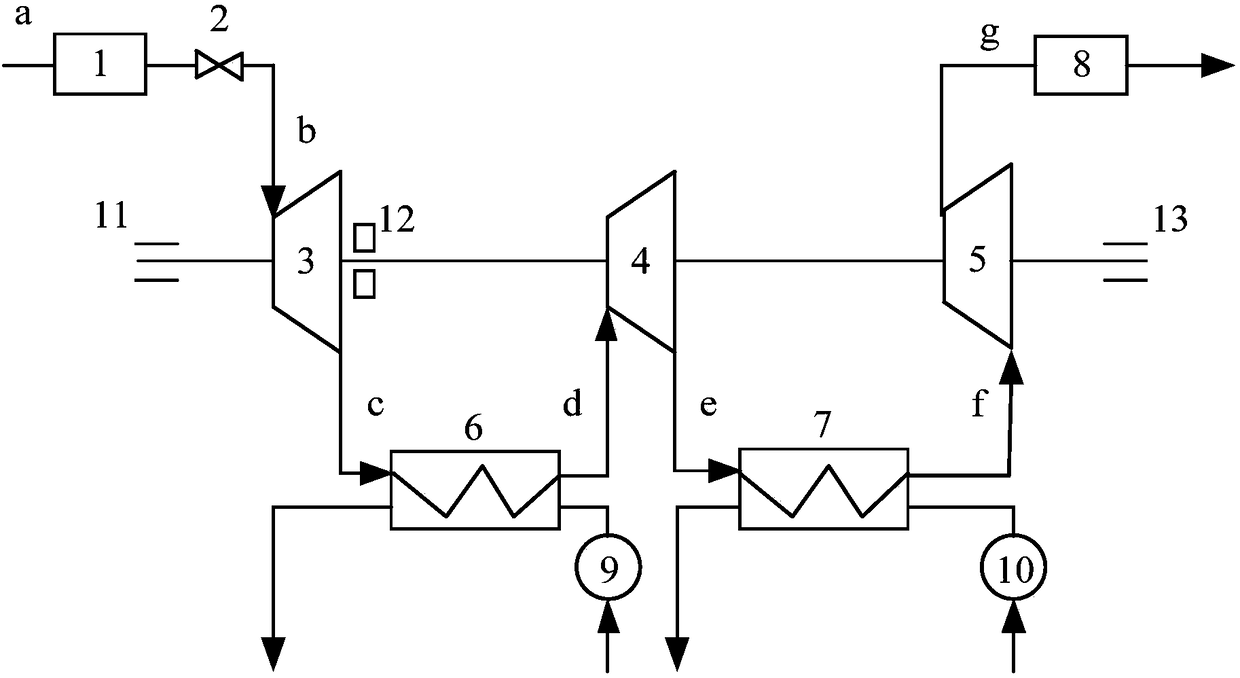

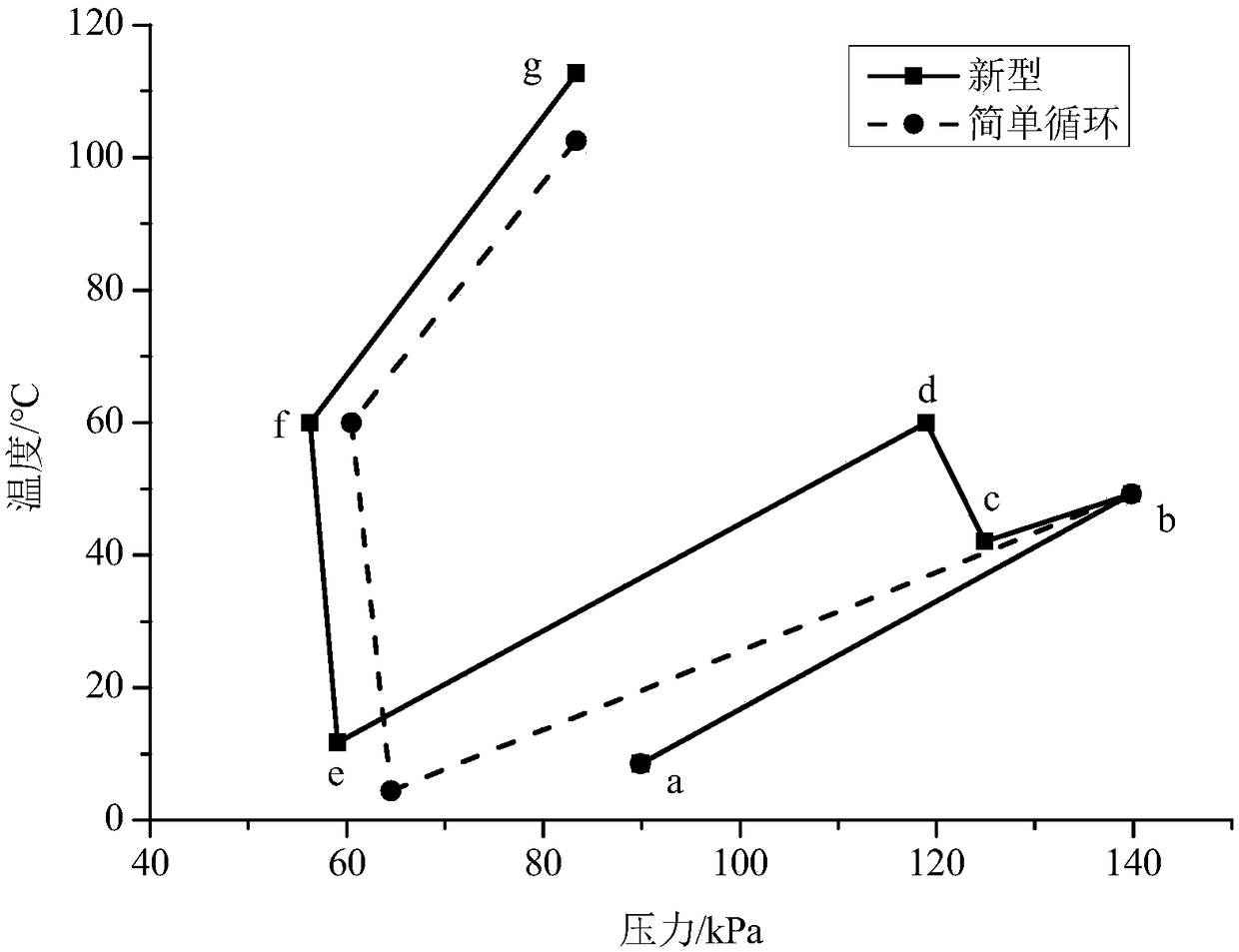

[0032] like figure 1 As shown, the present invention is applied to the intermediate reheating type turbo cooler system of the airborne pod, and the main working parts include the air intake system 1, the primary turbine 3, the secondary turbine 4, the primary heat exchanger 6, the secondary heat exchanger Heater 7, compressor 5, exhaust system 8. The first-stage turbine 3, the second-stage turbine 4, and the compressor 5 are coaxially arranged. The front end of the first-stage turbine 3 is provided with a radial bearing 11, the rear end is provided with a thrust bearing 12, and the rear end of the compressor 5 is provided with a radial bearing 13.

[0033] During the flight of the aircraft, the pod flies with the carrier aircraft at high speed. The ram air pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com