Silencing device of compressor

A technology of a muffler and a compressor, applied in the field of compressors, can solve the problems of small internal space of the muffler, poor noise reduction effect, poor noise reduction effect, etc., and achieve the effects of increasing the expansion ratio, improving the noise reduction effect, and increasing the noise reduction volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

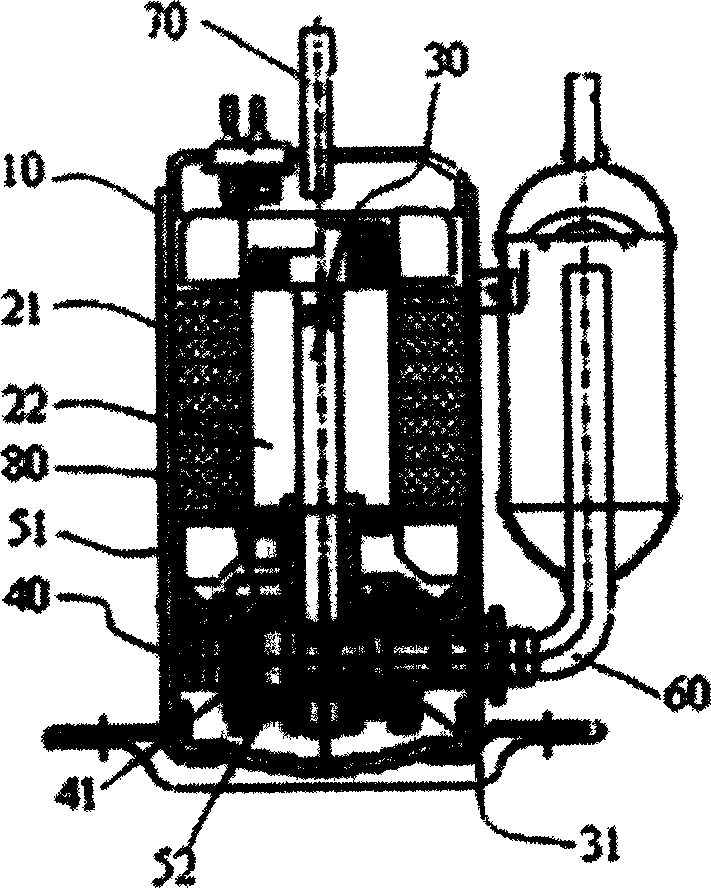

[0020] The muffler of the compressor of the present invention will be described with reference to the drawings and embodiments.

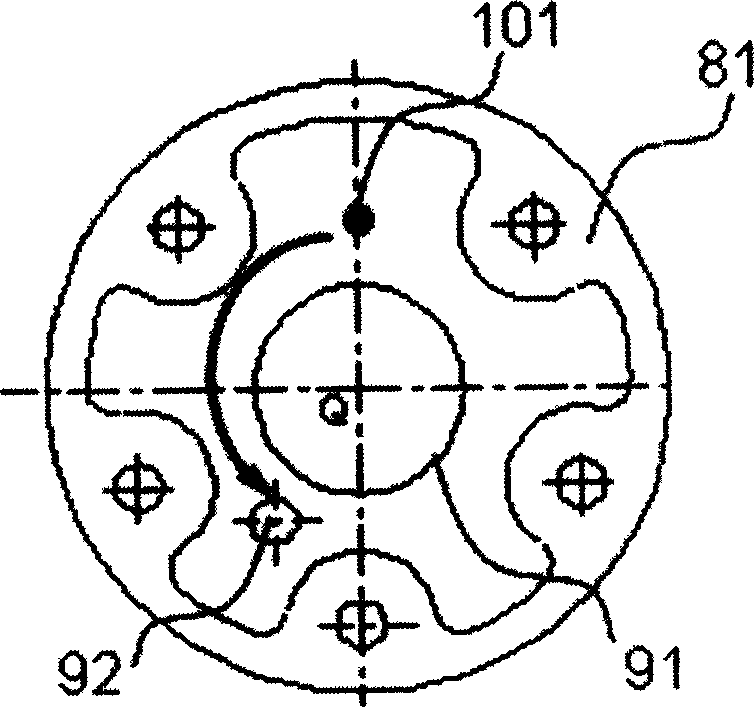

[0021] Such as Figure 4 , 5 As shown, the structure of the muffler of the compressor of the present invention includes a double-layer structure of an inner muffler with a vent hole and an outer muffler installed above the upper bearing with a vent hole, wherein: the inner layer The position of the exhaust hole 97 of the muffler 83 is set so that the exhaust hole 101 of the upper bearing is used as the base point to rotate counterclockwise to the third phase limit, so as to extend the path of the refrigerant flowing through the inner muffler 83 .

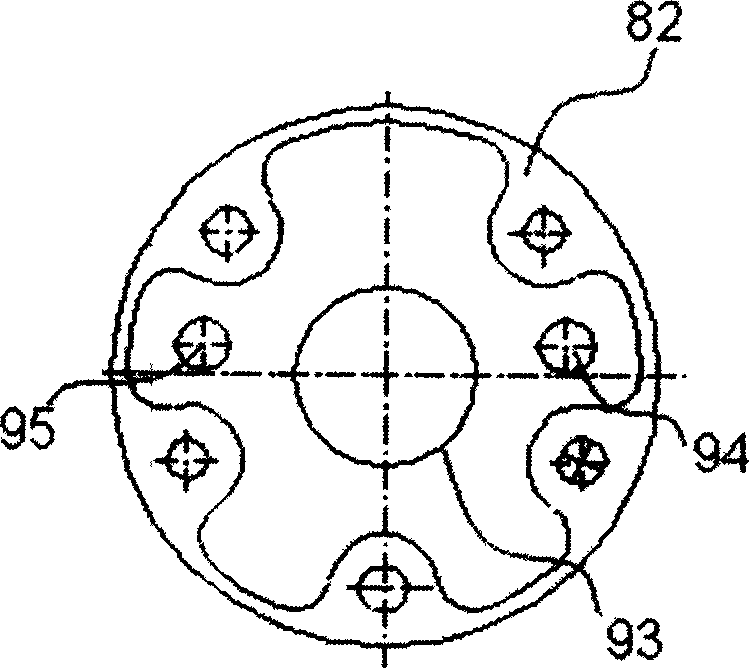

[0022] The shape of the outer layer muffler 84 is a three-lobe type; the distance between the exhaust holes 99 and 100 of the outer layer muffler 84 is set to be equal to an odd multiple of the half-wavelength of the noise frequency to be reduced, and passes through the exhaust hole 99 The phase of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com