Patents

Literature

55results about How to "Large noise reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

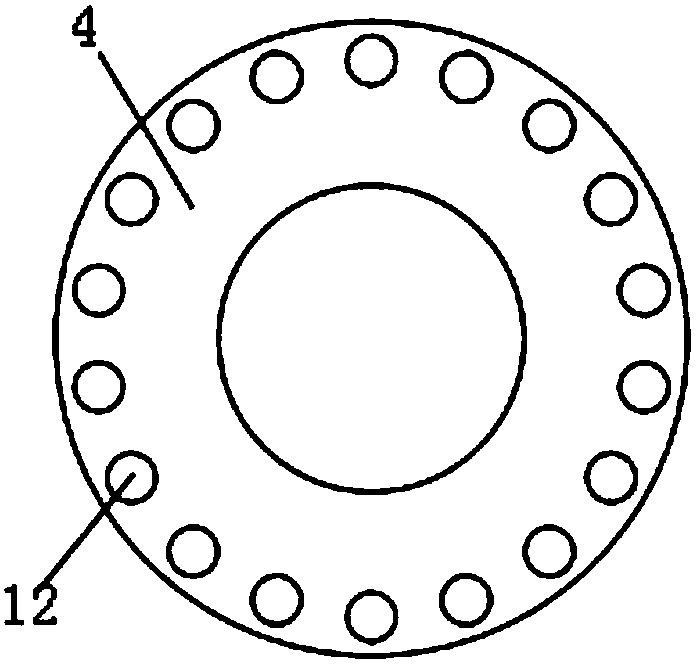

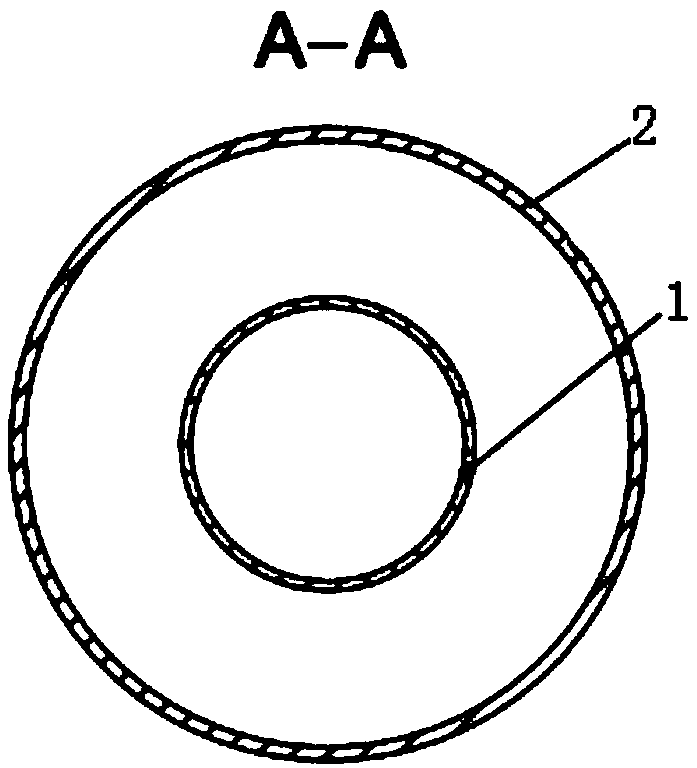

Broadband multi-cavity resonance-type air intake muffler and working method thereof

InactiveCN106050491AReduce power lossSmall intake back pressureMachines/enginesIntake silencers for fuelResonant cavityCavity resonance

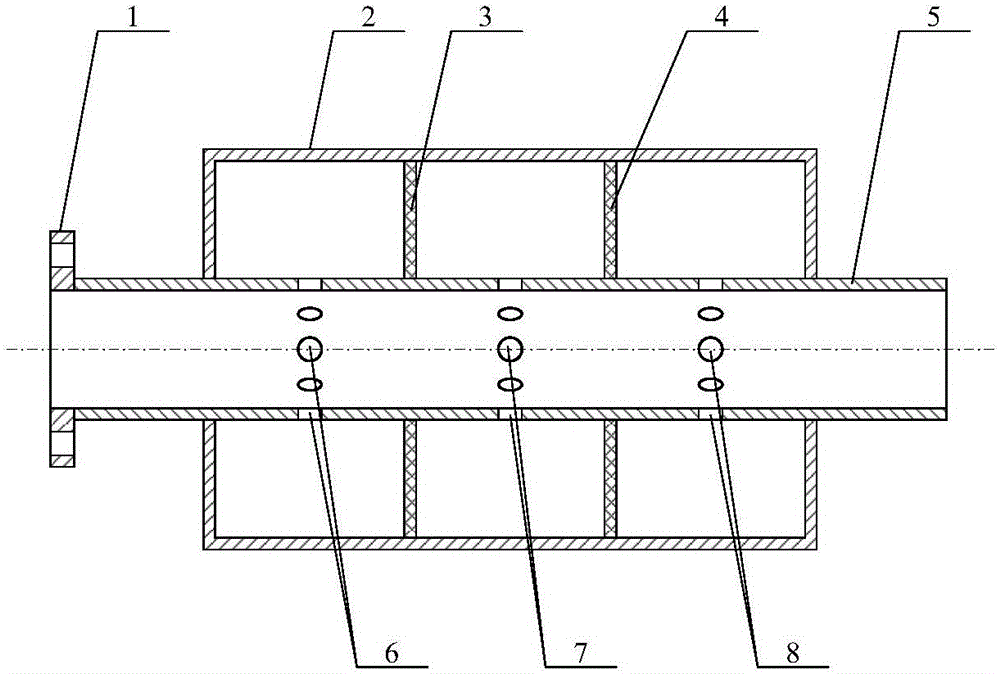

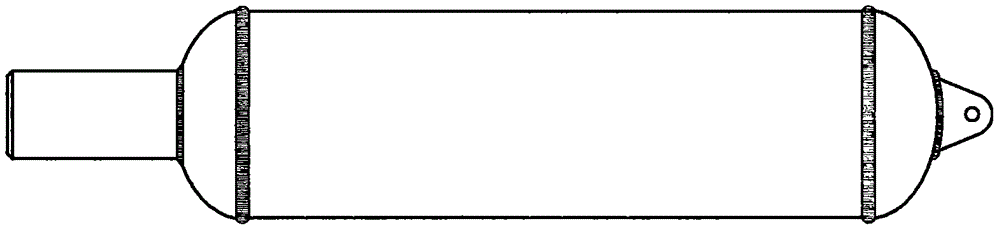

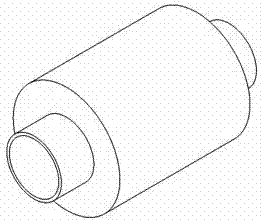

The invention discloses a broadband multi-cavity resonance-type air intake muffler. The broadband multi-cavity resonance-type air intake muffler comprises a penetrating cylindrical muffler shell, wherein a perforated tube is connected with the interior of the muffler shell in a penetrating manner; an inner cavity is formed between the muffler shell and the perforated tube; a plurality of partition plates are arranged in the inner cavity in the direction perpendicular to the axis; the inner cavity is divided by the partition plates into a plurality of resonant cavities; and a plurality of lines of noise-eliminating through holes which are distributed circumferentially are formed in the perforated tube, and correspondingly positioned at the middles of the resonant cavities. The broadband multi-cavity resonance-type air intake muffler disclosed by the invention is wide in noise-eliminating frequency band, large in noise-eliminating amount, small air intake backpressure, low in engine power loss, small in size, light in weight, simple in structure, convenient to mount, and easy to machine, and has the advantages that engineering is easy to achieve and the application prospect is wide.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

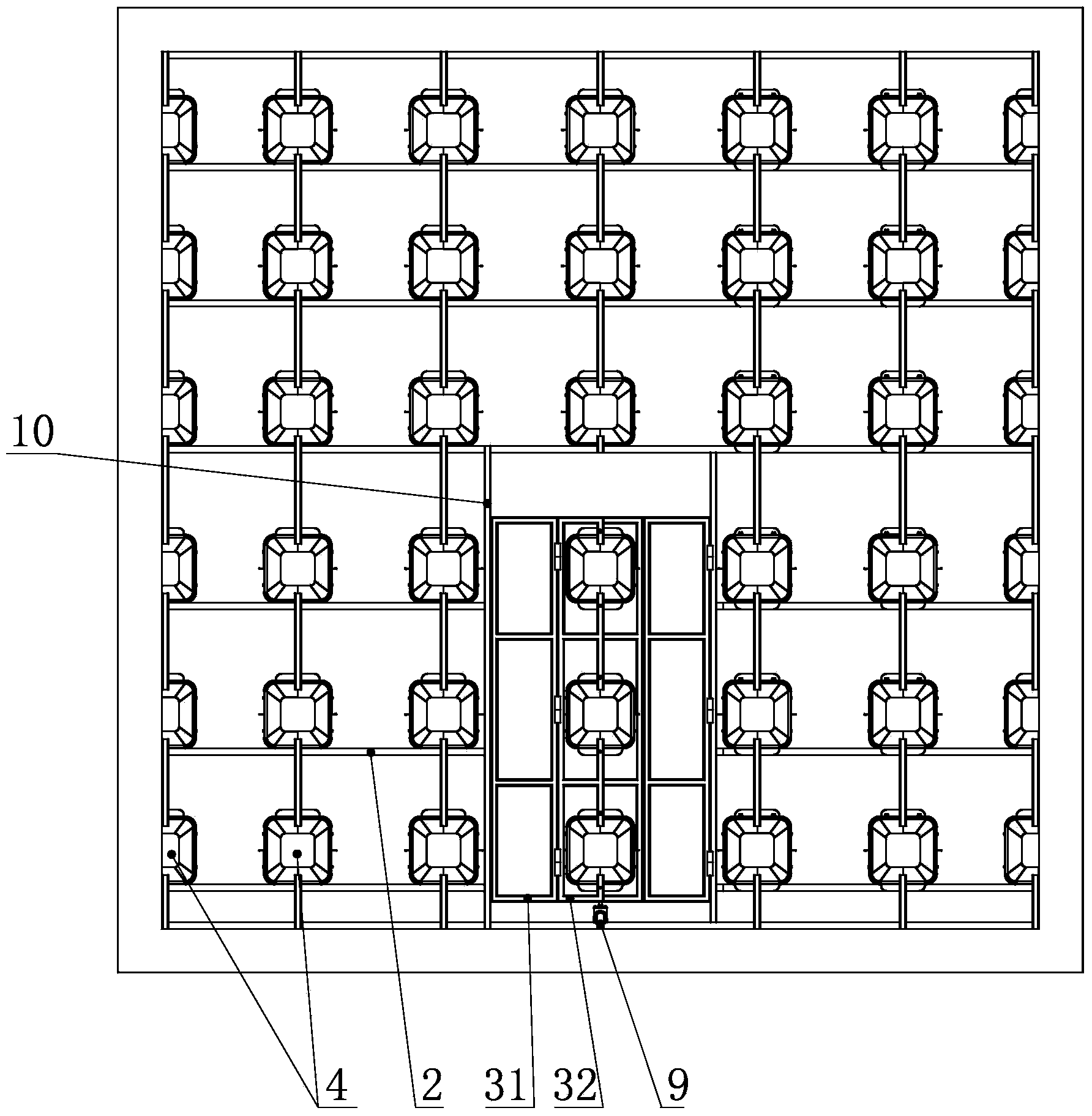

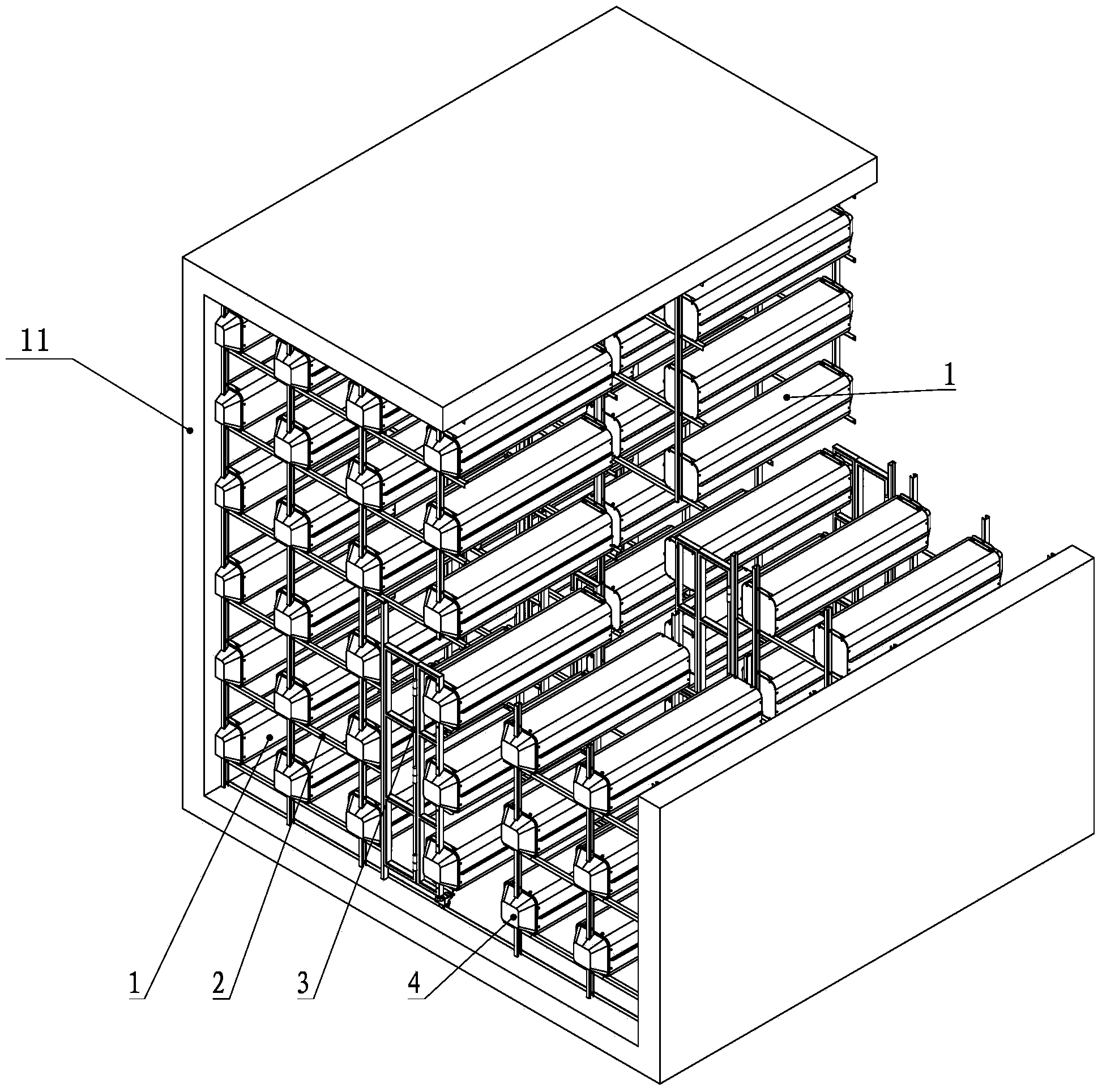

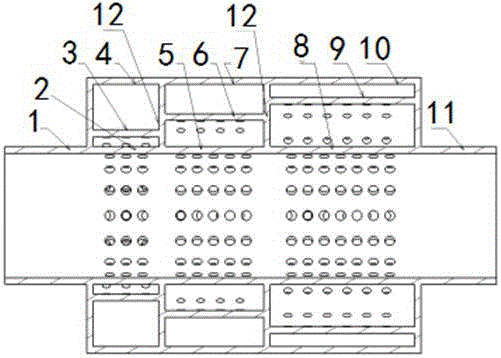

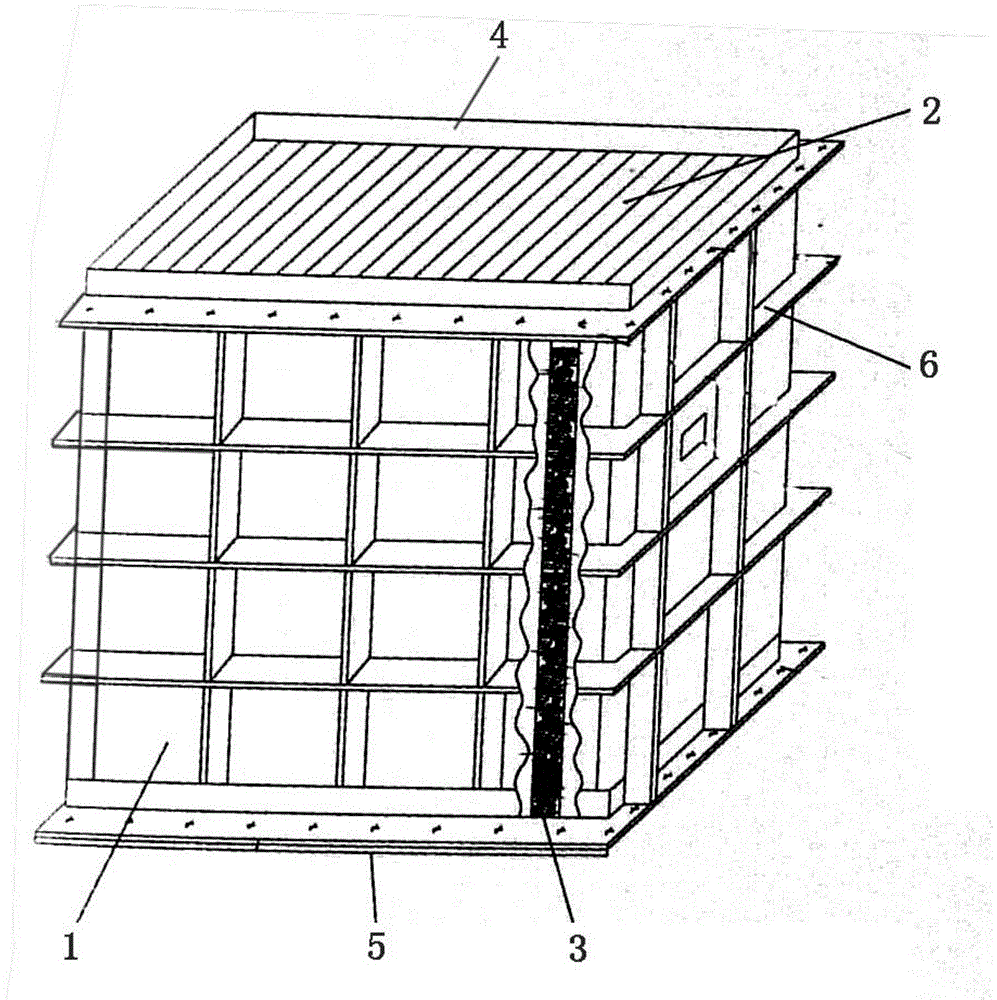

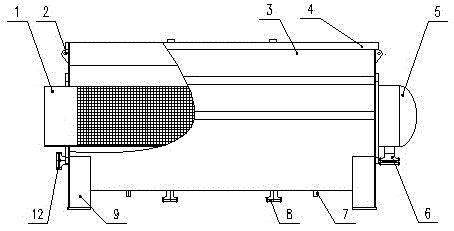

Combined type array impedance recombination silencer

ActiveCN103807995ASimple maintenanceEasy to installNoise suppressionSound producing devicesLow frequency bandEngineering

The invention relates to a noise reduction silencing device, in particular to a combined type array impedance recombination silencer. The combined type array impedance recombination silencer comprises silencing tube bodies, a support, an access door and a flow guide cover. The support is arranged in a latticed shape and provided with an access door frame, the two ends of each silencing tube body are fixedly installed on the corresponding latticed intersection points of the support, the axes of the silencing tube bodies are arranged in parallel in the air flow direction, and the silencing tube bodies are arranged through the support and fixed to a ventilation pipeline. The access door is installed on the access door frame on the support in a matched mode, the access door is of a connecting rod structure and is hinged to the access door frame, and sliding wheels are arranged at the bottom of the access door. The flow guide cover comprises a large-area lower bottom face and a small-area upper bottom face and the large-area lower bottom face is matched with the end faces of the silencing tube bodies. According to the combined type array impedance recombination silencer, the combination type can be reasonably adjusted according to the flow field characteristic, the resistance structure is utilized, the silencing effect of a certain frequency band, especially the middle-low frequency band, is effectively improved, the production efficiency can further be improved, and transportation, storage and maintenance are convenient.

Owner:ZHEJIANG JINDUN FANS HLDG

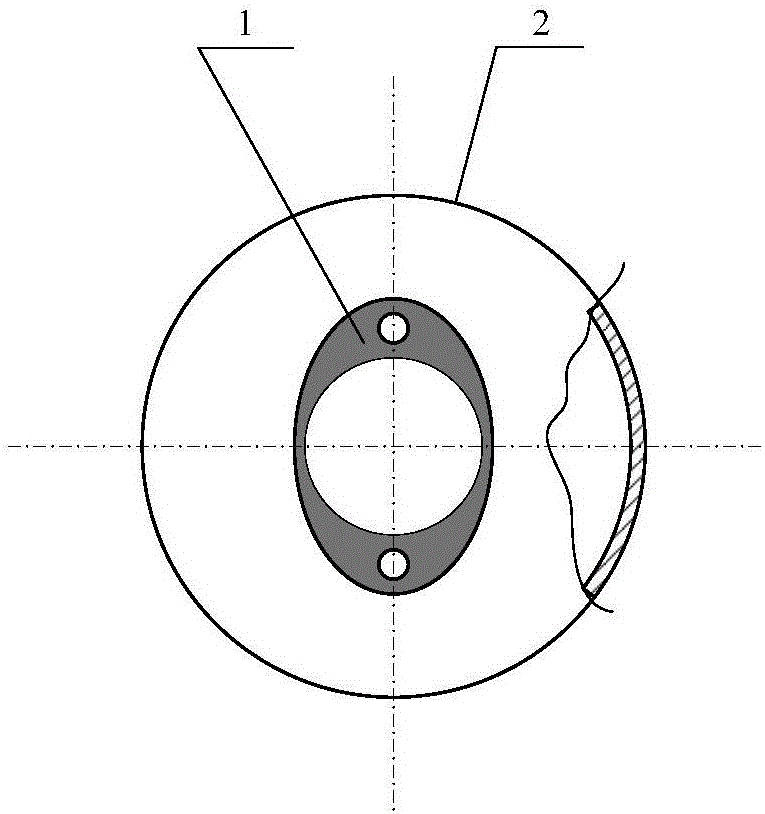

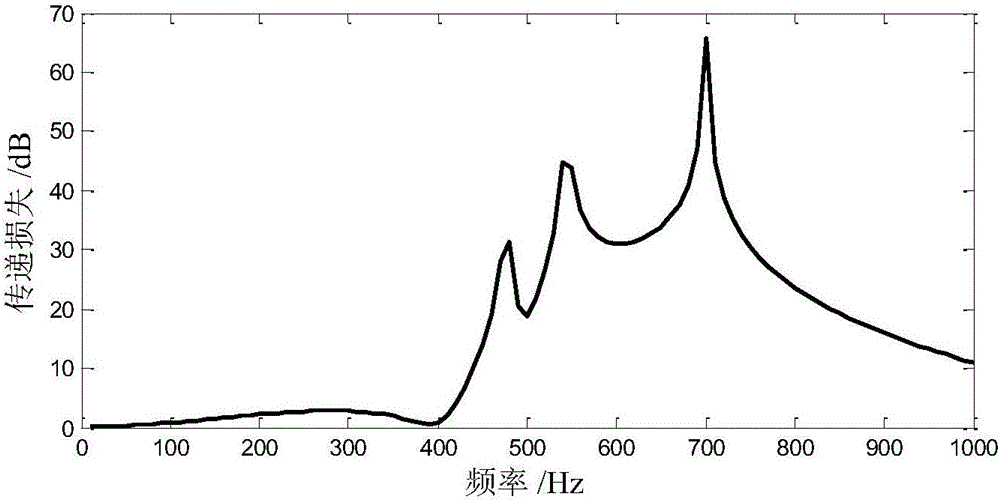

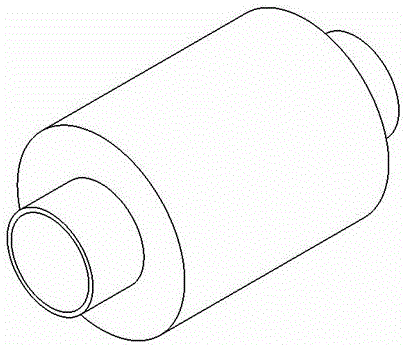

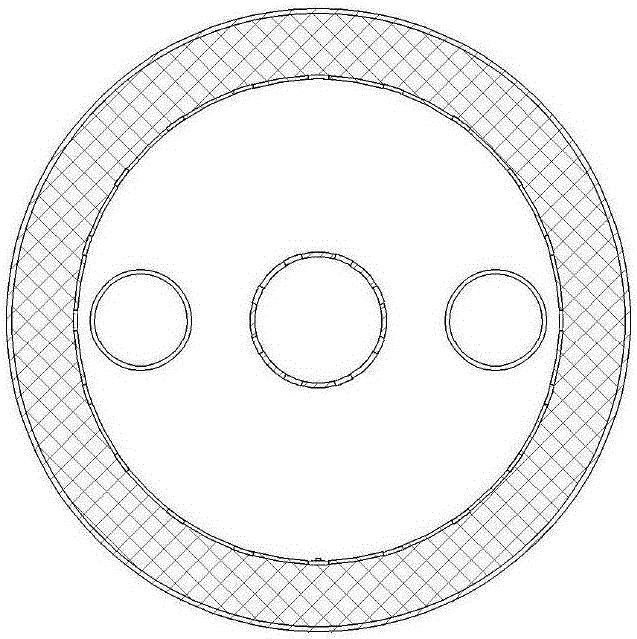

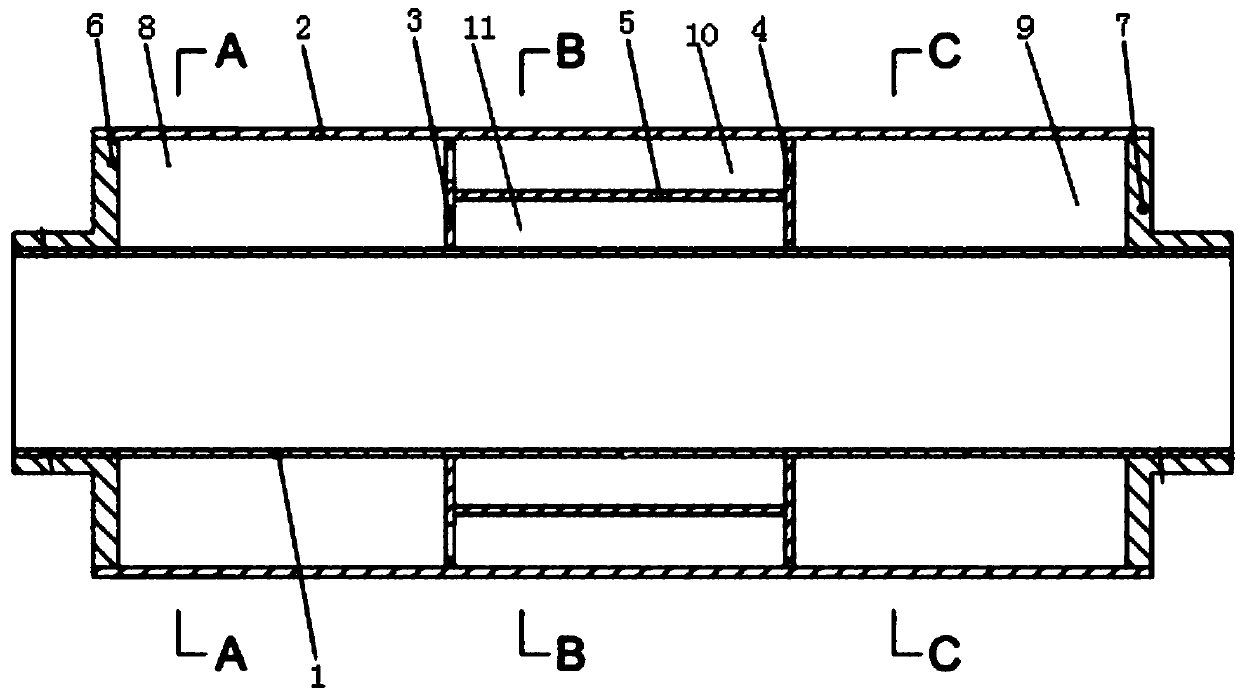

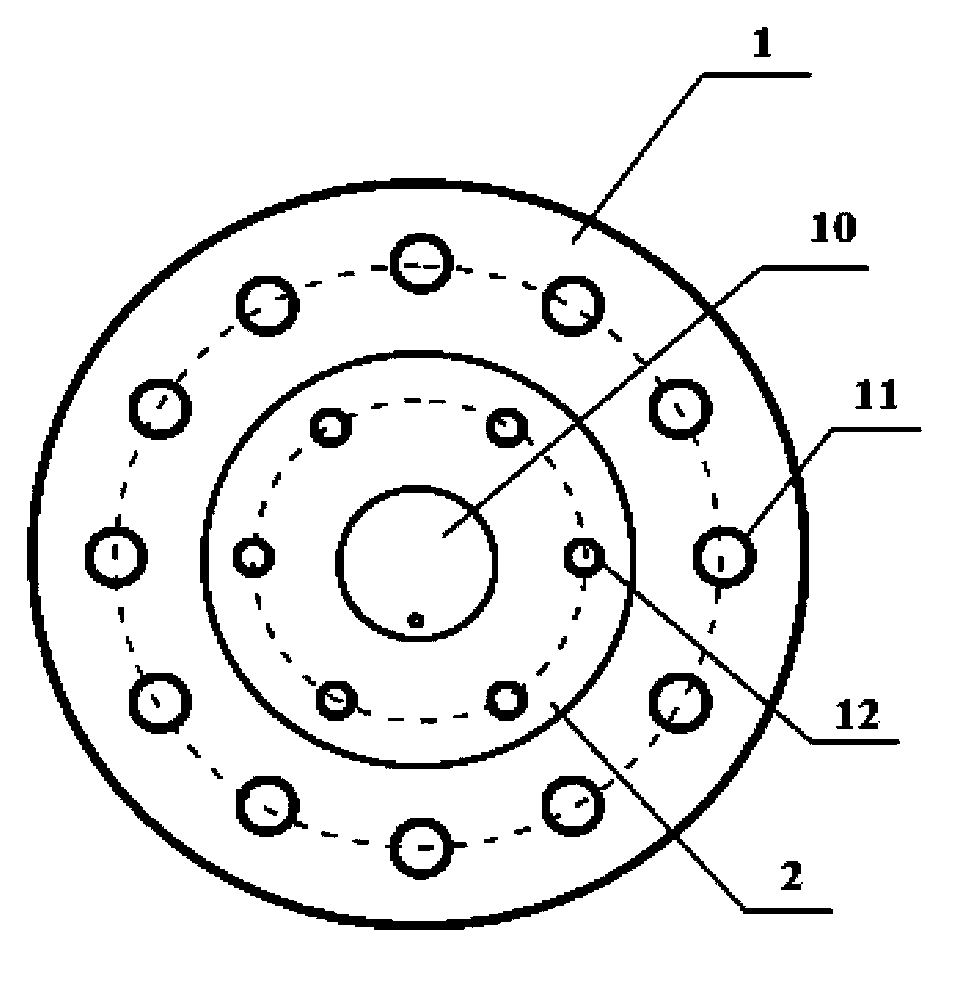

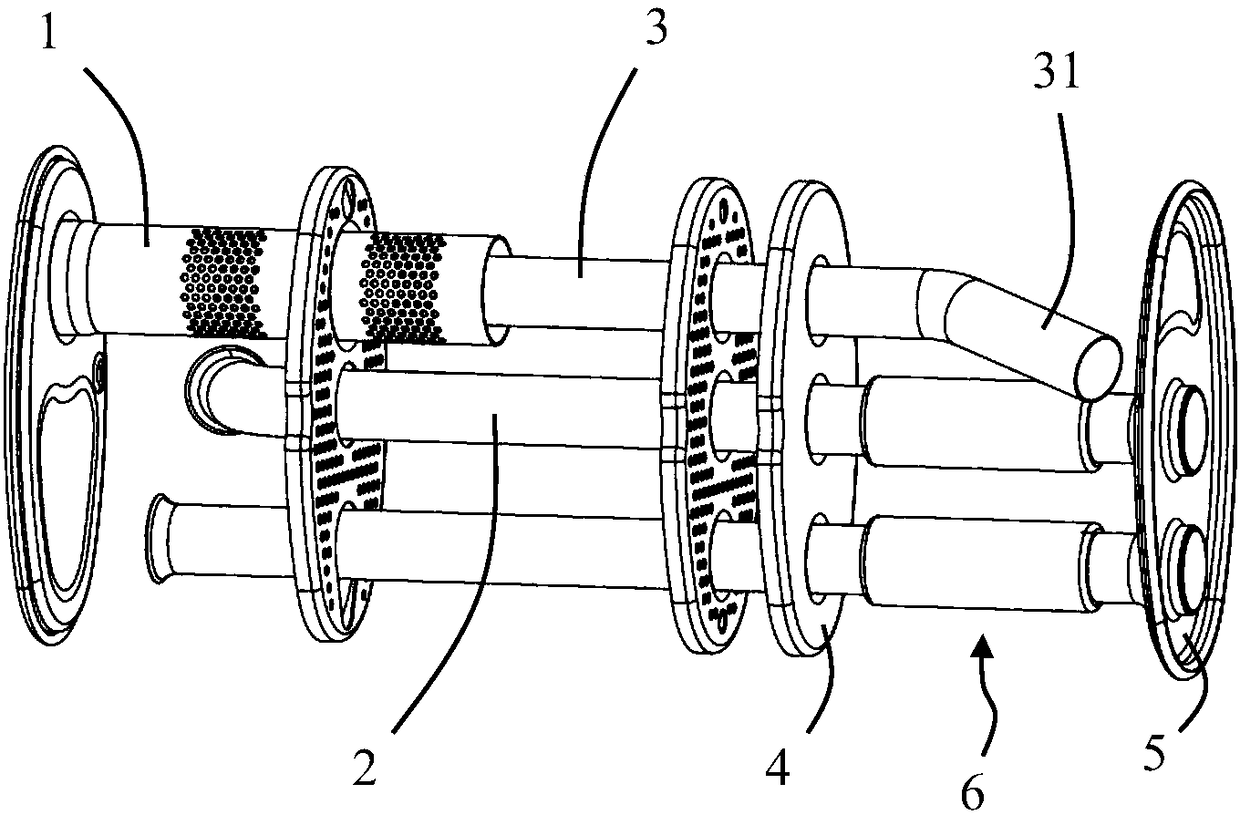

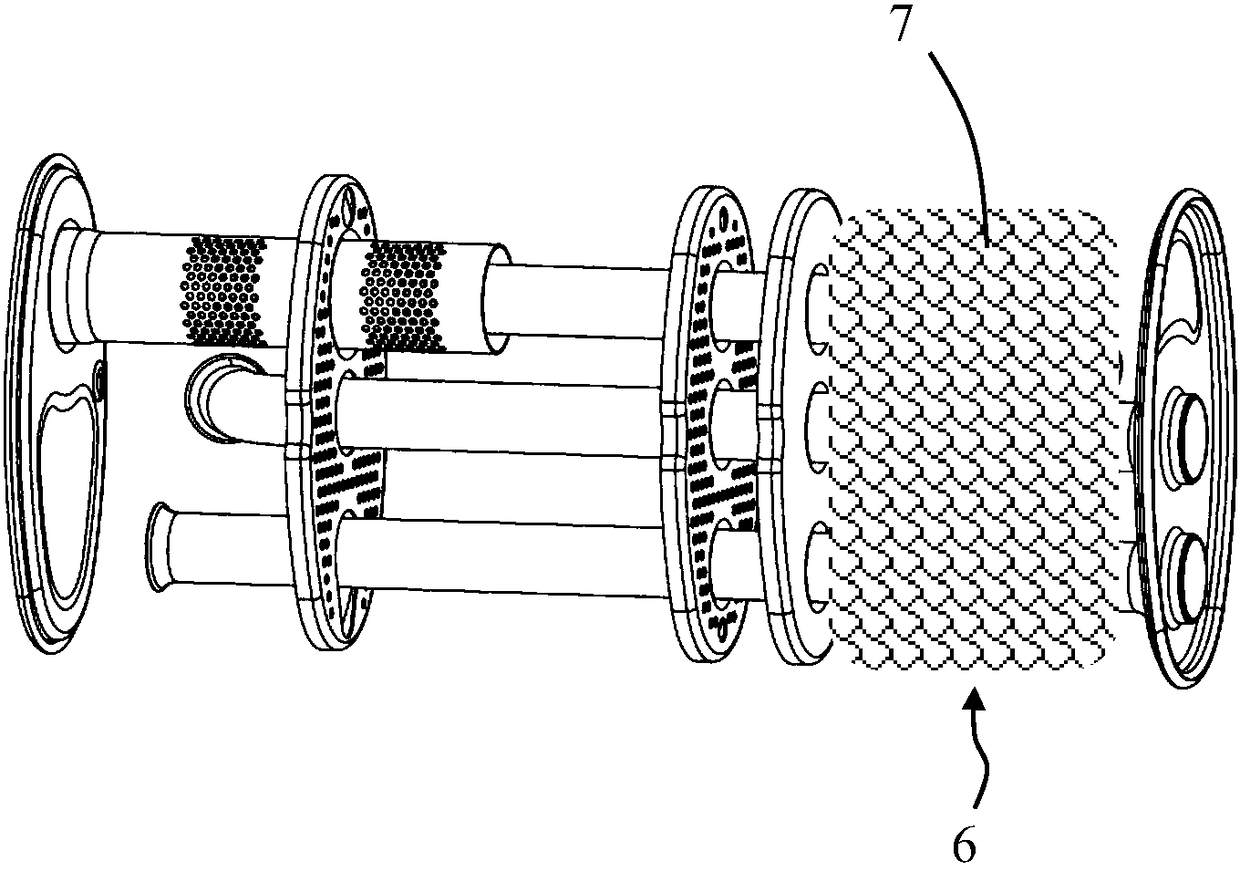

Multi-cavity direct-through dual-layer perforating silencer capable of eliminating wide-band noise

InactiveCN106837625ACompact structureLarge noise reductionPipe elementsMachines/enginesTransfer matrixEngineering

The invention provides a multi-cavity direct-through dual-layer perforating silencer capable of eliminating wide-band noise. The multi-cavity direct-through dual-layer perforating silencer capable of eliminating the wide-band noise comprises an inlet end, a silencer body and an outlet end. At least two dual-layer perforating pipes are arranged in the silencer body. The dual-layer perforating pipes are connected in series and separated through partition plates. Each dual-layer perforating pipe comprises an outer pipe body and an inner pipe body, wherein through holes are distributed in the outer pipe body and the inner pipe body, a closed cavity is defined by the outer pipe body, the silencer body and the corresponding partition plate, and another closed cavity is defined by the inner pipe body, the outer pipe body and the corresponding partition plate. The silencer has the advantages that airflow circulates directly from the inlet end to the outlet end, the pressure loss is low, the size is small, the structure is simple, cost is low, and by designing the structure parameters through a multi-cavity one-dimension transfer matrix method, the high-amplitude and wide-band silencing effect can be achieved.

Owner:TONGJI UNIV

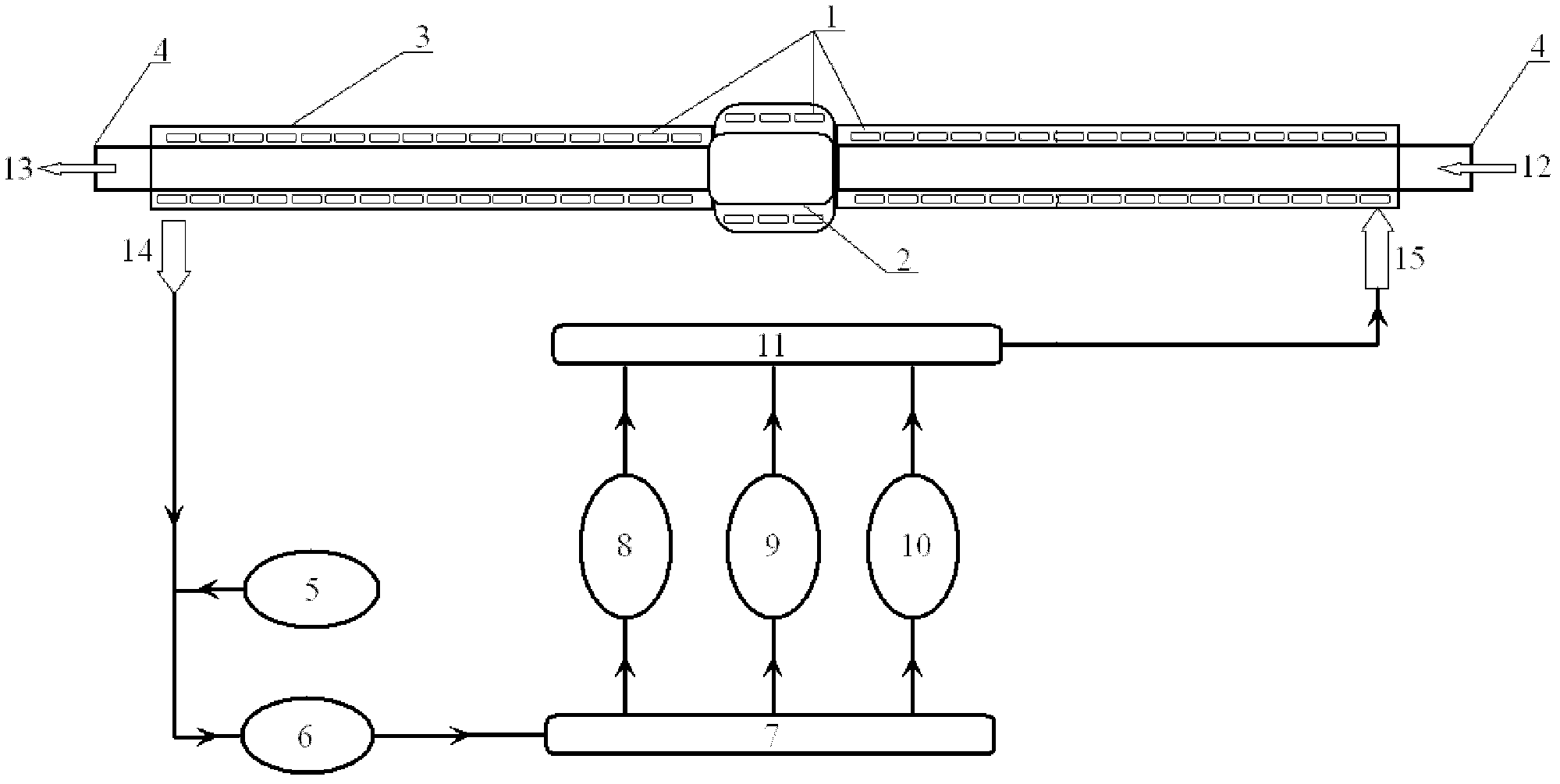

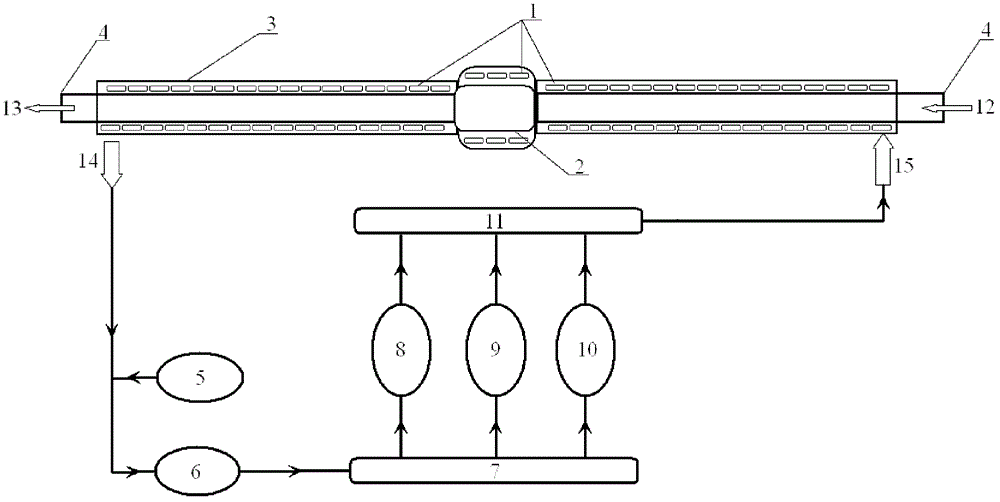

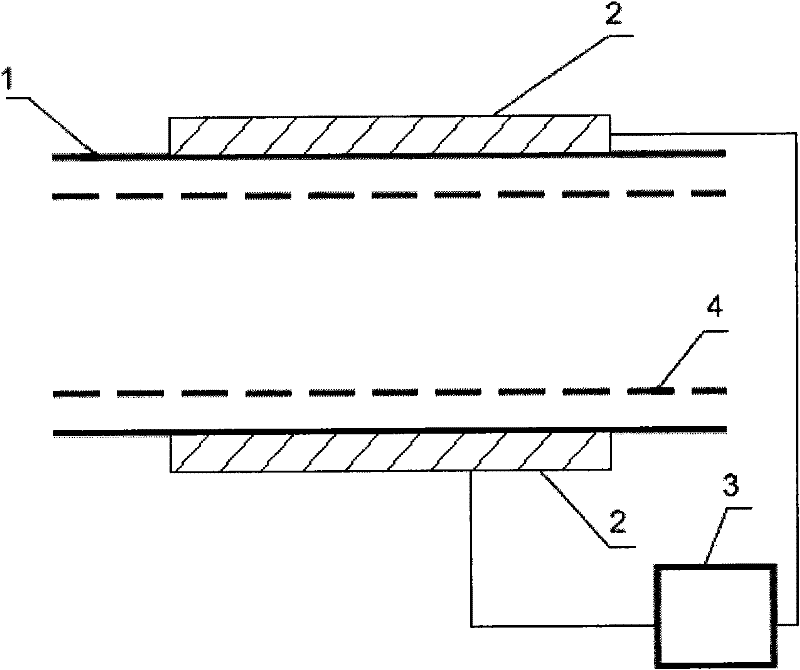

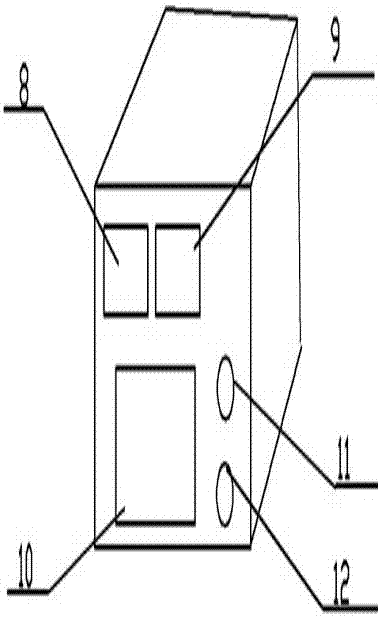

Device for denoising, ice blockage prevention and cold energy utilization of natural gas pipeline

ActiveCN103216700AReduce noiseLarge noise reductionThermal insulationValve members for heating/coolingEngineeringStreamflow

The invention relates to a device for denoising, ice blockage prevention and cold energy utilization of a natural gas pipeline. The device relates to the technical field of pipeline systems, and is characterized in that two sections of natural gas pipelines (4) are connected into a whole through a pressure regulating valve (2); a heat exchange flat pipe (1) with an outer coating (3) is wrapped on the whole natural gas pipeline (4) and the pressure regulating valve (2); a solar heater (8), a summer indoor cold supply system for working and living areas (9) and a natural gas heating furnace (10) are connected in parallel between a water segregator (7) and a water collector (11); the water collector (11) is provided with a pipeline connected to one end of the heat exchange flat pipe (1); the other end of the heat exchange flat pipe (1) is connected with a circulating pump (6) through the pipeline and then connected to the water segregator (7); and a constant pressure tank (5) is connected to an inlet of the circulating pump (6). The device can control aerodynamic noise of the pressure regulating valve of the natural gas pipeline to be within a state-specified standard, is large in noise reduction, alleviates the problem of ice blockage, is obvious in cold energy utilization effect, does not affect flow rate, is simple and convenient to install, and is low in cost.

Owner:PIPECHINA SOUTH CHINA CO

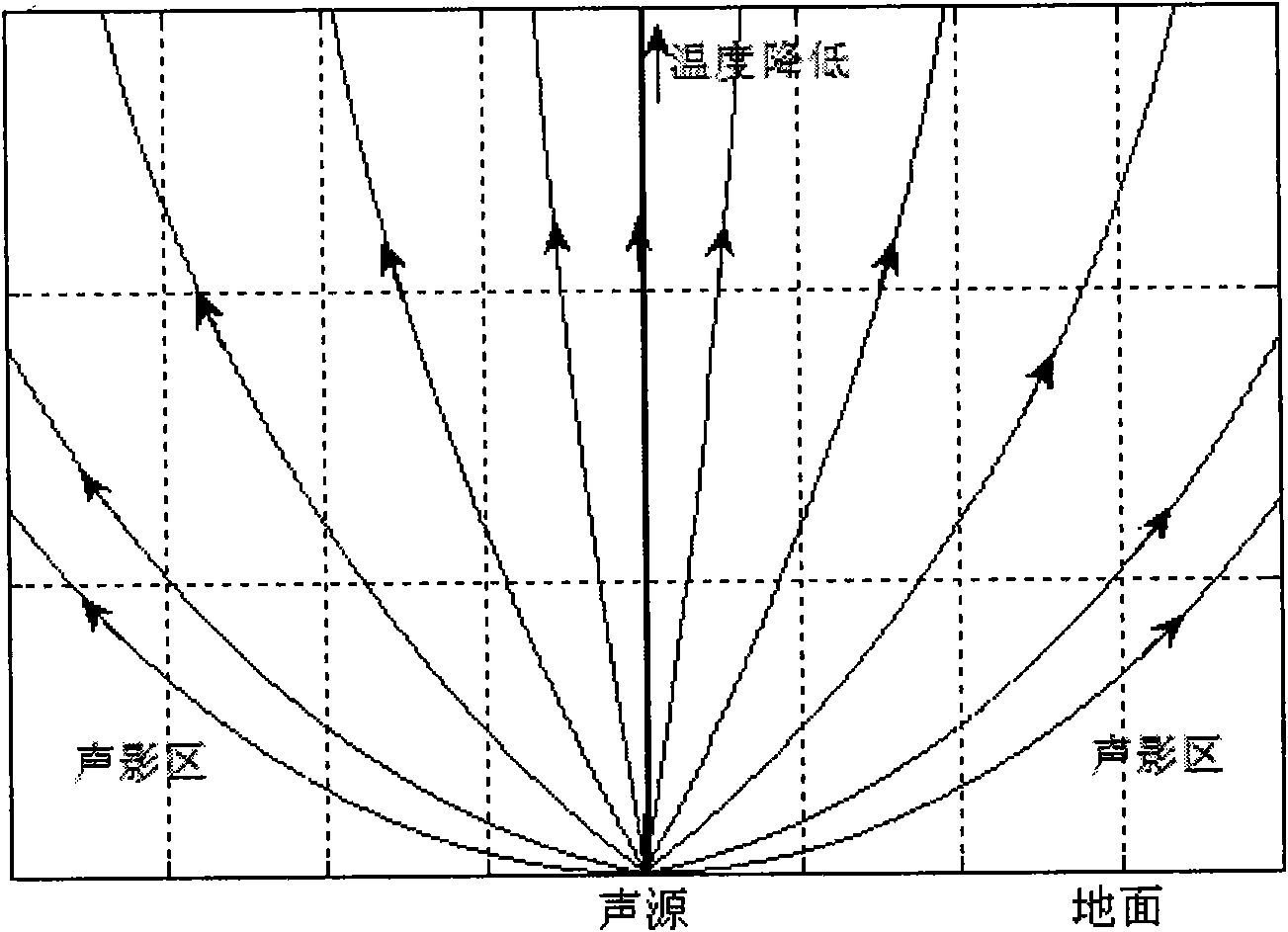

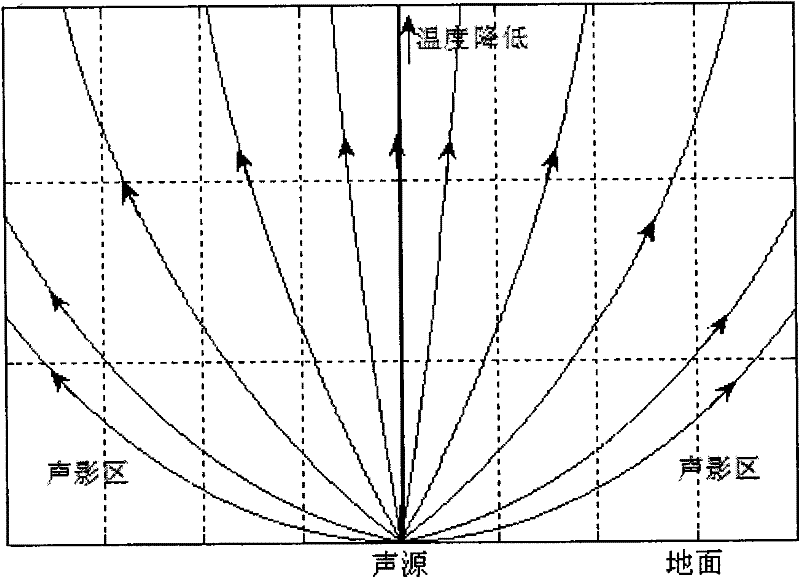

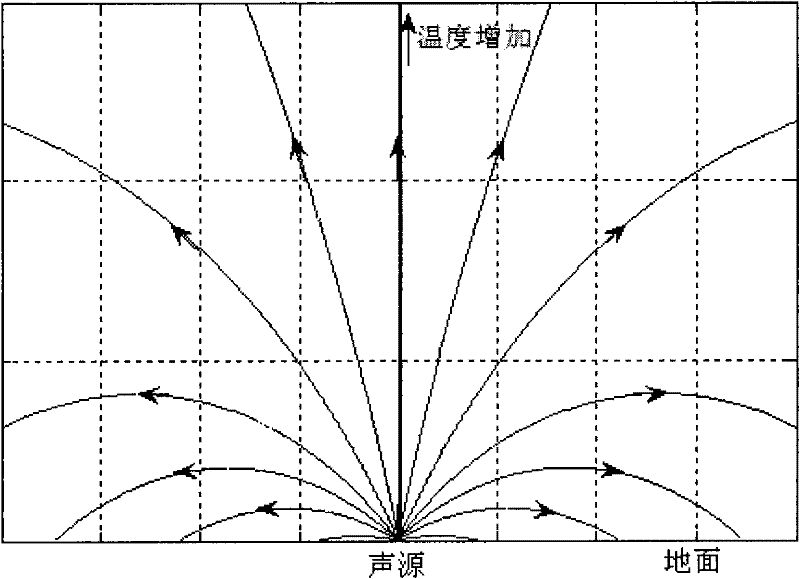

Muffler based on sound ray deflection theory

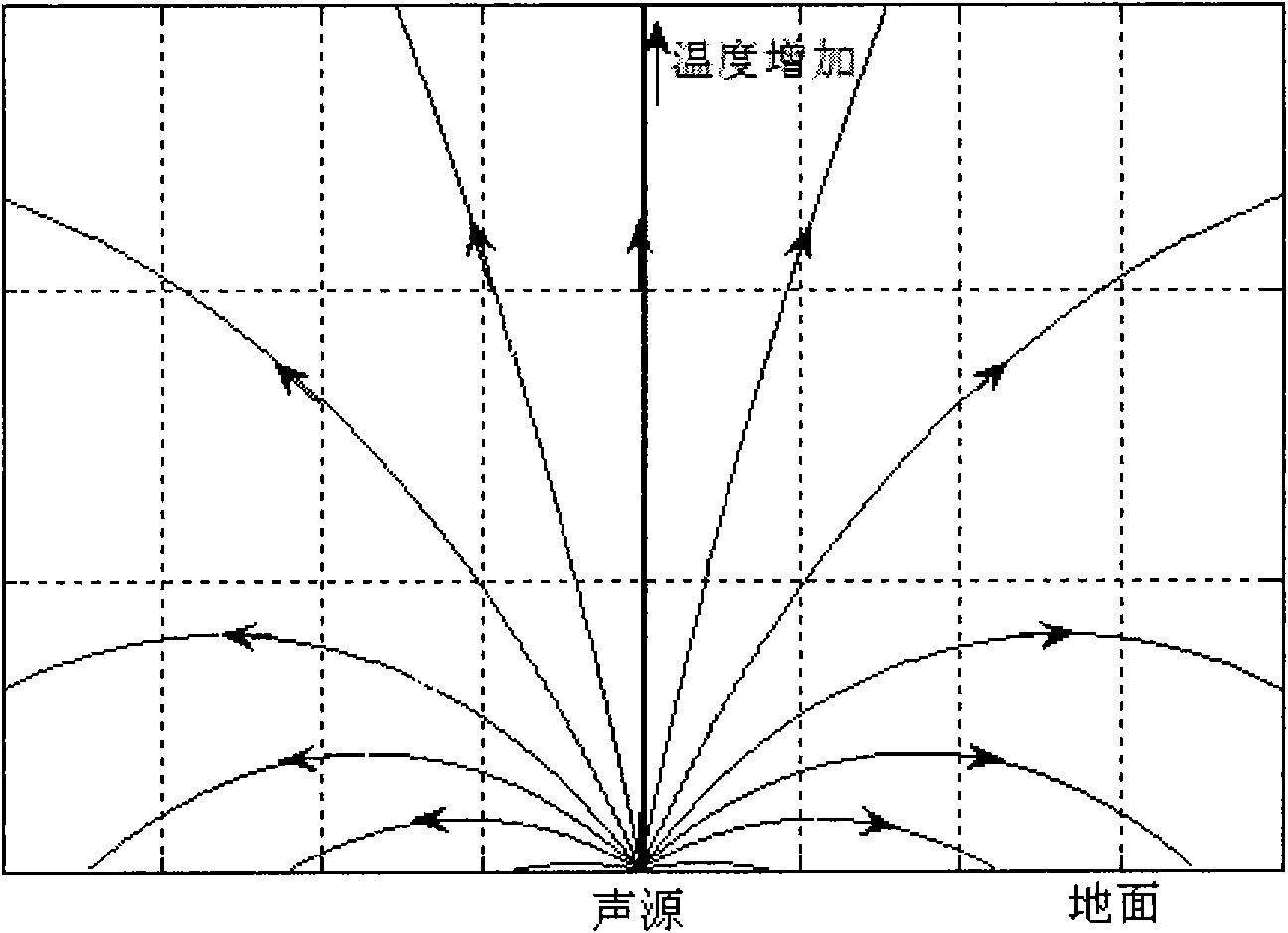

ActiveCN101782008AImprove noise reductionRaise the temperature gradientSilencing apparatusMachines/enginesTemperature controlAviation

The invention relates to a muffler based on a sound ray deflection theory, which comprises a muffler shell, a low-temperature refrigerating system and a temperature controller. The inner wall of the muffler shell is coated with a sound-absorbing material or structure, and the low-temperature refrigerating system is installed on the outer wall of the muffler shell. A low-temperature refrigerating system pipeline covers at least 5% of the area of an airflow pipeline outer wall. In the invention, the low-temperature refrigerating system is installed on the muffler, a greater (1-2,000 DEG C) temperature gradient is generated corresponding to the high temperature in the airflow pipeline, the sound rays are bent and deflected towards a cool end which refers to the sound-absorbing material and structure at the inner wall of the airflow pipeline so as to reduce the passed sound wave components not contacted with the sound-absorbing material or structure of the muffler in a muffler pipeline, increase the efficient absorption of noises in the pipeline and reduce the radiated noise. The invention can be applied to the muffler design of an aviation turbofan engine nacelle and an air charging / discharging pipeline system, such as a helicopter shaft turbine noise-elimination duct, a gas turbine and the like, and other environmental conditions where are convenient to and allow to provide the low-temperature refrigerating system at the cool end.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

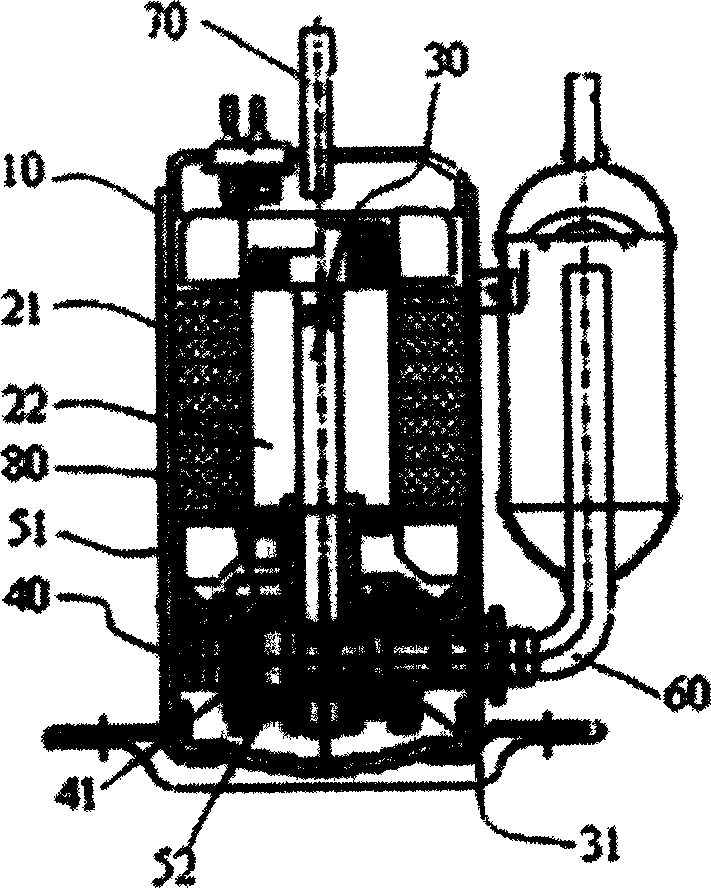

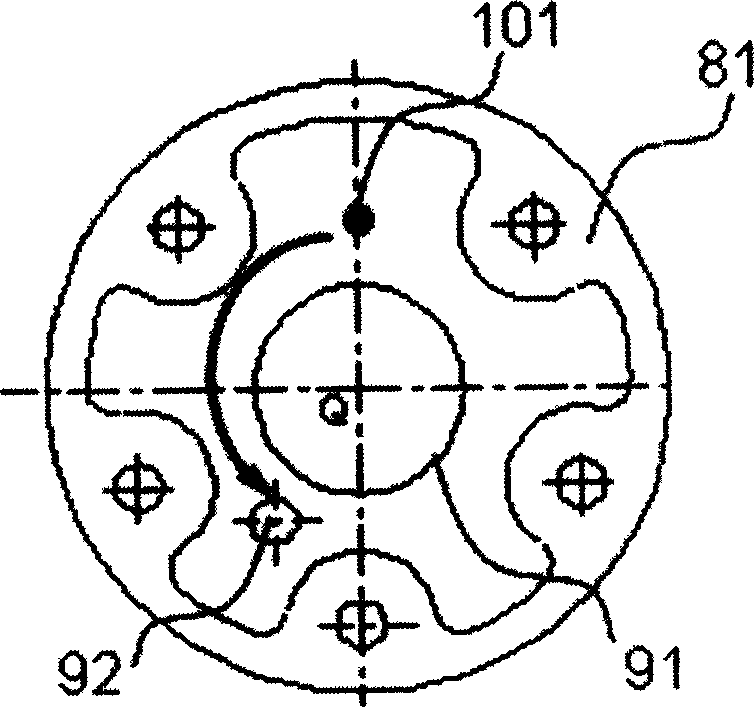

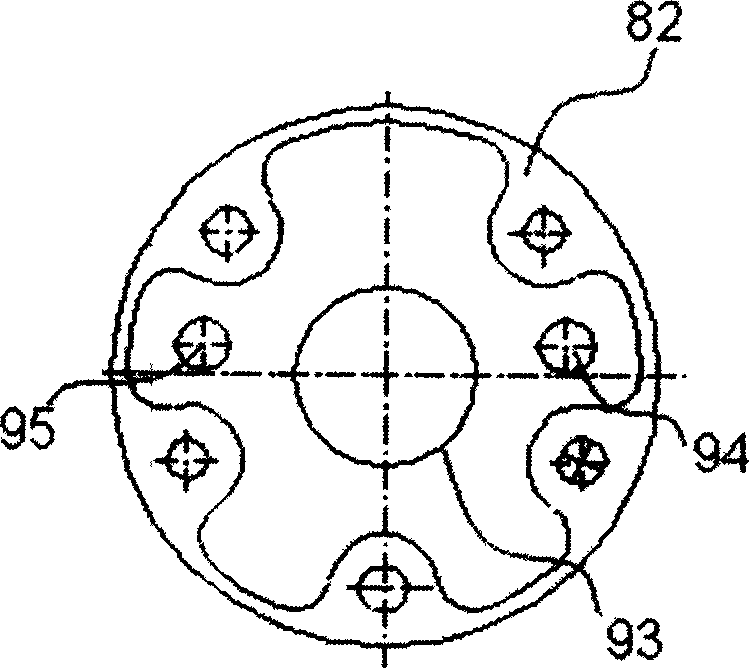

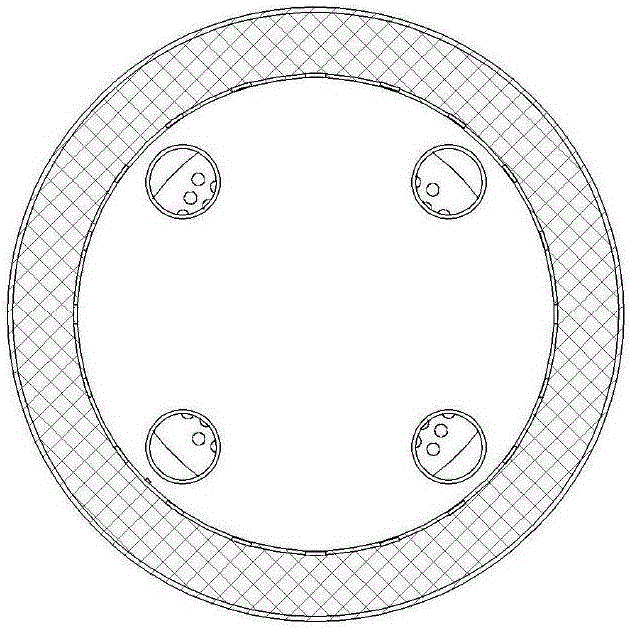

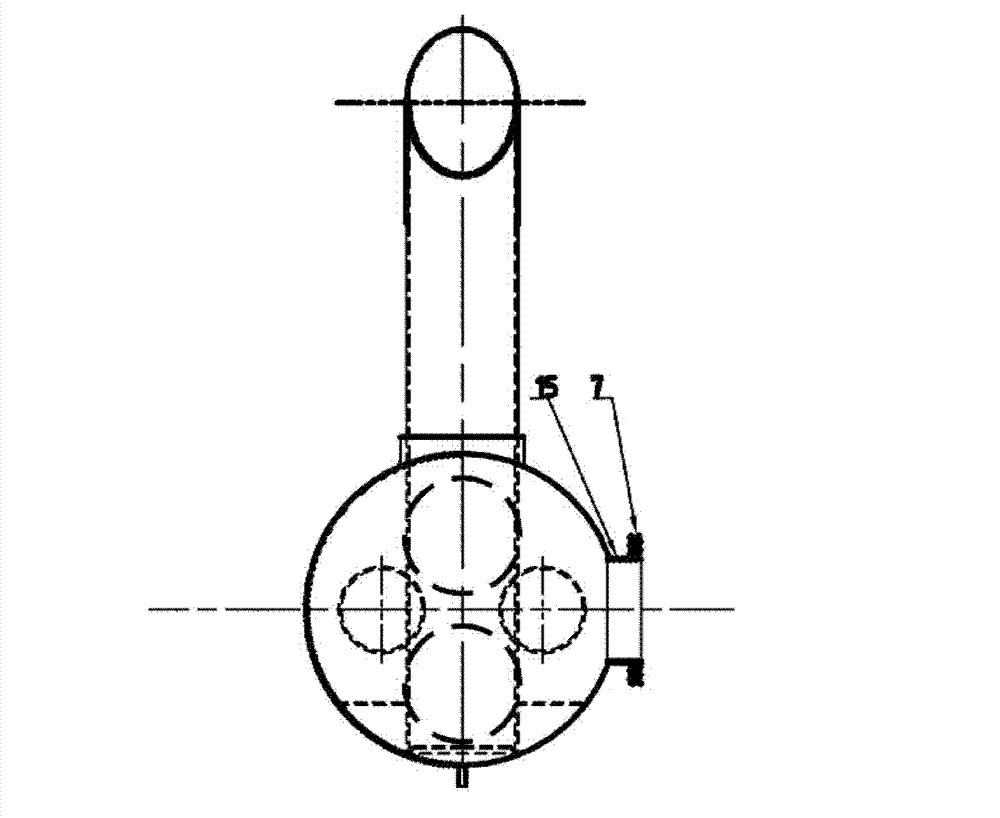

Silencing device of compressor

InactiveCN1580574AExtend the flow pathChange shapeRotary/oscillating piston pump componentsLiquid fuel engine componentsSuppressorEngineering

This invention provides a sound suppressor of a compressor including a double layer of an internal sound suppressor and an external sound suppressor with exhaust outlets above the upper bearing with exhaust outlet, among which, the exhaust outlet position of the intenal sound suppressor is set at the place taking the outlet of the upper bearing as the base point rotating counter-clock-wise to the third phase to prolong the flowing path of gas in the inteal layer sound suppressor. The outer sound suppressor is a three flap for increaisng its cavity volume. The distance between two rows of gas holes of the outer suppressor is designed equalizing to the odd times of half-wavelength of the bearing eliminated noise frequency and in opposite phase to the flown sound wav from the hole.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

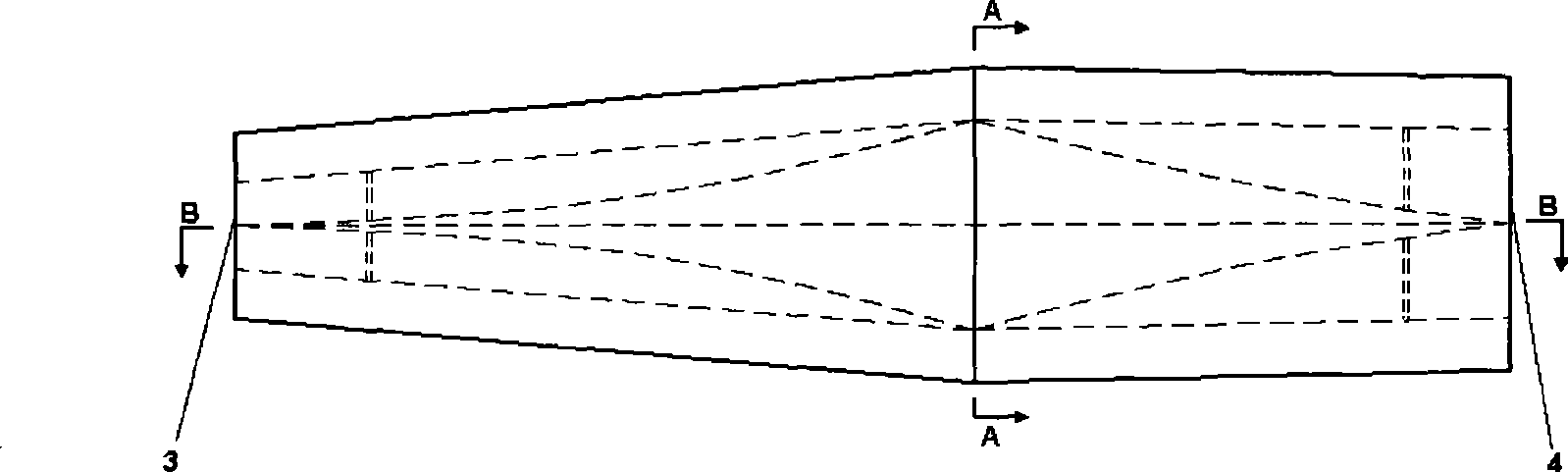

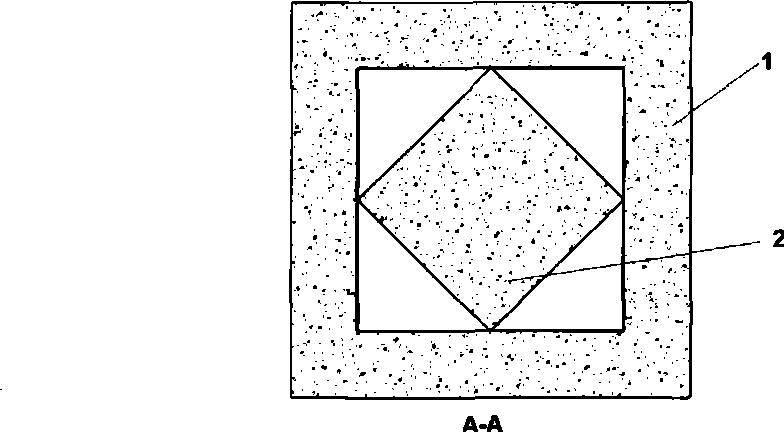

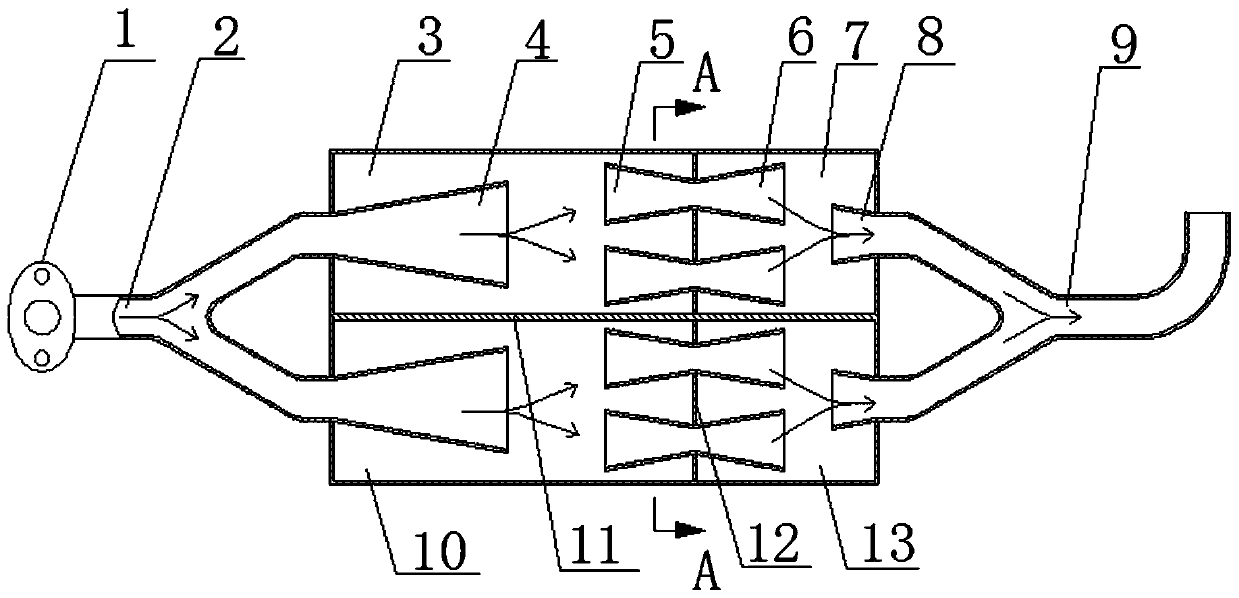

Dispersion type noise deadener

InactiveCN101418820AImprove the chance of sound absorptionIncrease the number of reflectionsPump componentsSilencing apparatusNoise controlFriction loss

The invention relates to a diffusion type silencer of noise control technical field, which comprises a sound absorption air duct and a sound absorption cone, wherein, the sound absorption air duct is hollow, and is two opposing tetrahedral frustums which are connected in series via end cove flange; the inside of the sound absorption air duct is provided with the sound absorption cone fixed by a support frame, the sound absorption cone is two opposing pyramids, the big end of the sound absorption cone is in the sound absorption air duct and at the maximum section place of the air duct, and the small end is at the air inlet or outlet plane of the sound absorption air duct. The silencer of the invention has simple structure, low cost, large silencing quantity, and less resistance loss.

Owner:SHANGHAI JIAO TONG UNIV

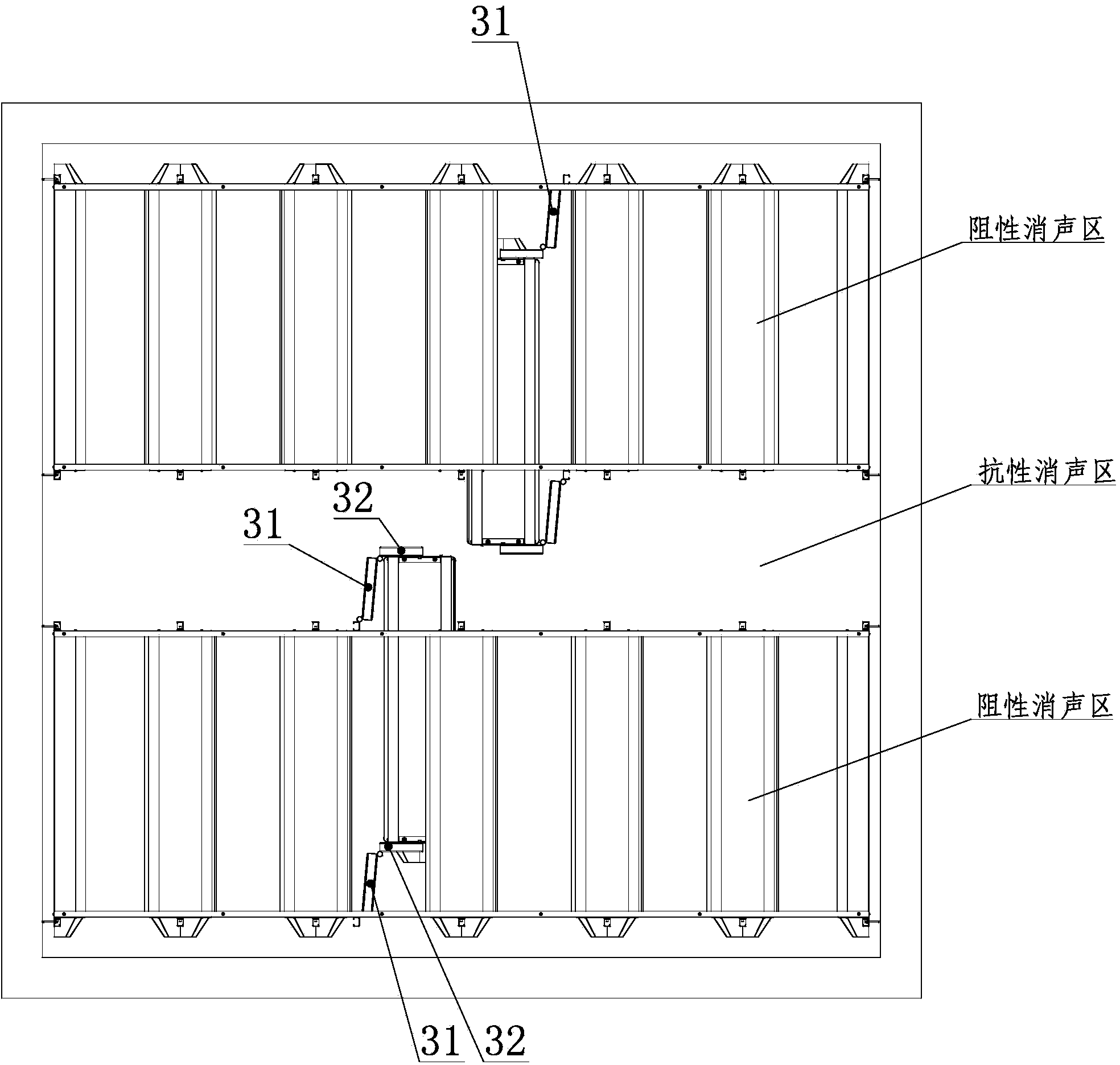

Complex silencer for diesel generator unit

ActiveCN106401697AWide Anechoic Frequency Band RangeIncrease pass frequencySilencing apparatusMachines/enginesCombustionResonance

The invention relates to a silencer applied to the field of silencing and noise reduction for internal combustion engines, in particular to a complex silencer for a diesel generator unit. The complex silencer for a diesel generator unit comprises an intake tube, a dissipative silencing structure connected with the intake tube in series, a resistant silencing structure arranged inside the dissipative silencing structure, and a gas outlet tube connected with the dissipative silencing structure in series, wherein three expansion chambers are formed by a resonance perforated plate, a first-level resistant baffle and a second-level resistant baffle together, and are arranged in the direction from the intake tube to the gas outlet tube in the order of the first expansion chamber, the second expansion chamber and the third expansion chamber. Because the dissipative silencing structure and the resistant silencing structure are connected in series for use, the range of the silencing frequency band is broader; and making use of different expansion ratios, the passing frequency of exhaust flow is increased, the peak value of silencing of the silencer can be large, and the silencing capacity can be increased. The complex silencer for a diesel generator unit has the advantages of being broad in silencing frequency band, small in volume, simple in structure, low in transmission loss and light in integral weight. Meanwhile, the effect of improving the anticorrosion function is achieved by using metal tubes and metal plates.

Owner:SHENYANG AEROSPACE XINGUANG GRP

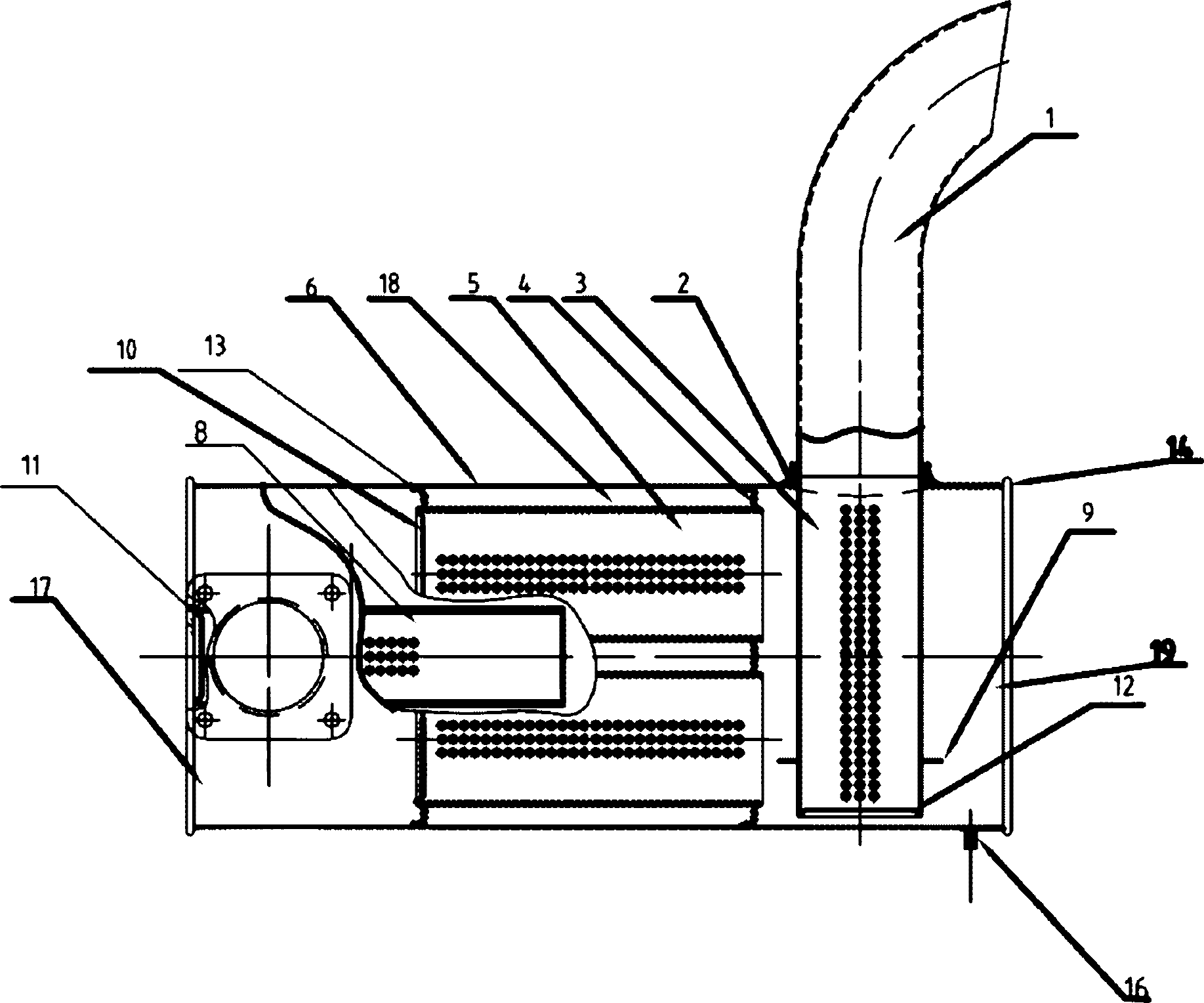

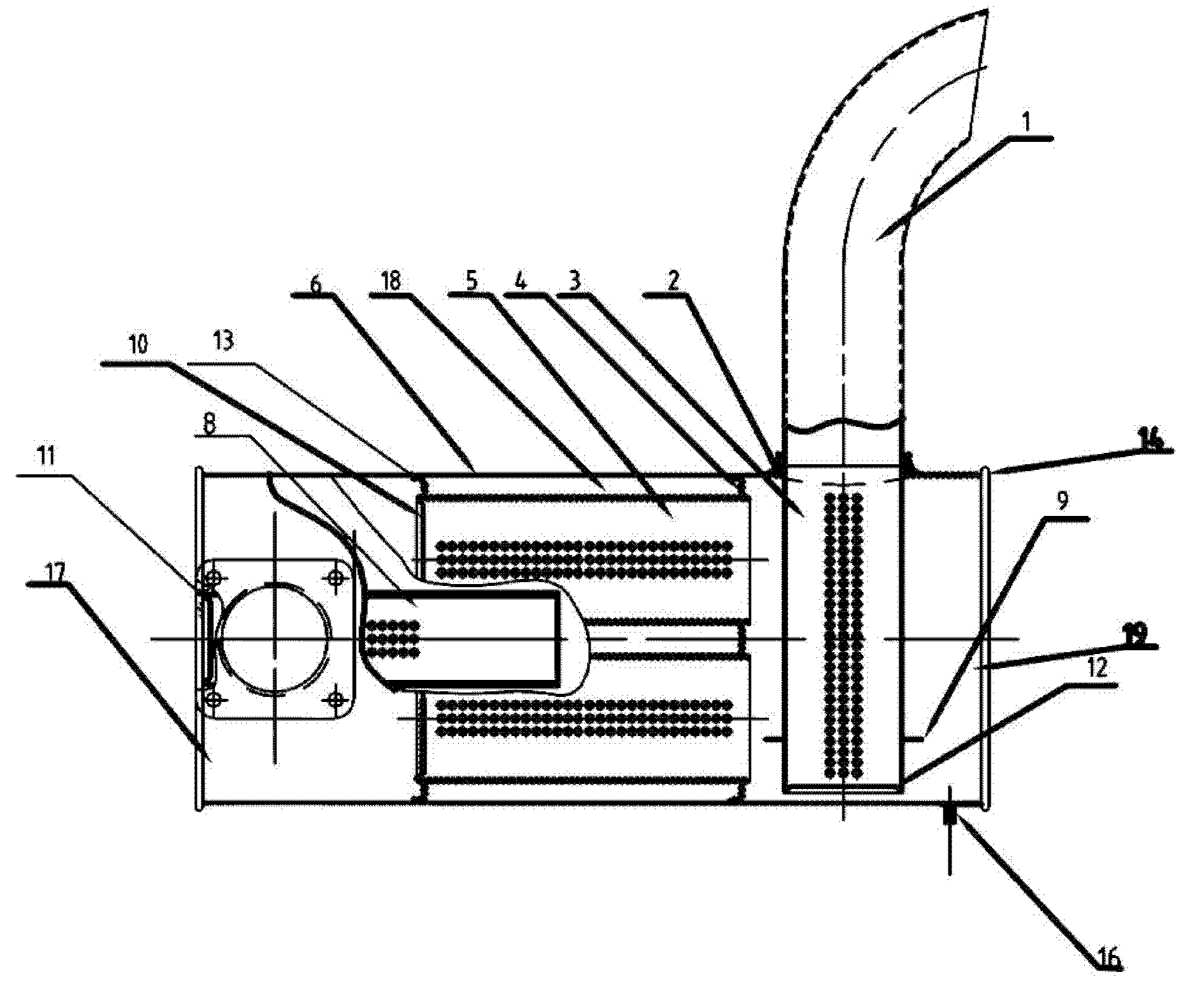

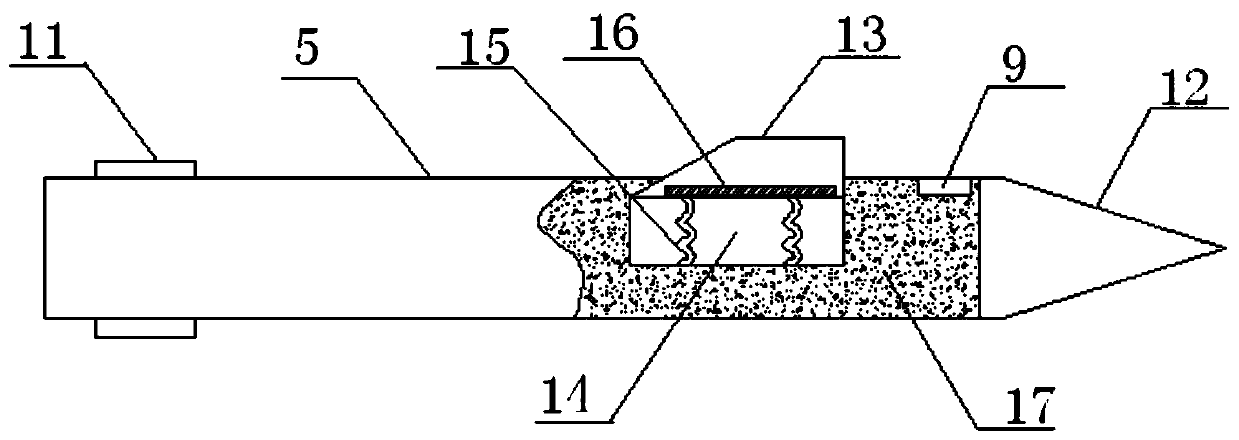

Reactive muffler for engineering machine

InactiveCN102606268AReasonable flowReduce regenerative noiseExhaust apparatusSilencing apparatusUltrasound attenuationEngineering

The invention discloses a reactive muffler for an engineering machine, which comprises a flange plate, a connecting pipe, a barrel and a smoke exhaust pipe. The inside of the barrel is sequentially divided into a cavity I, a cavity II and a cavity III by a front partition board and a rear partition board from front to back, two first sound attenuation barrels which are positioned in the cavity I and the cavity II are disposed on the front partition board, two second sound attenuation barrels are arranged in the cavity II, a third sound attenuation barrel is disposed in the cavity III, the first sound attenuation barrels and the second sound attenuation barrels are arranged along the axial direction of the barrel, the third sound attenuation barrel is perpendicular to the first sound attenuation barrels and the second sound attenuation barrels, the connecting pipe and the smoke exhaust pipe are perpendicularly connected onto the barrel and are spatially perpendicularly arranged in a crossed manner, the connecting pipe is communicated with the cavity I, the smoke exhaust pipe is communicated with the cavity III, and the flange plate is connected with the cavity I via the connecting pipe. The reactive muffler is reasonable in structure, fine in acoustic performance and long in service life, regenerated noise of airflow is low, and a muffler effect for low, medium and high-frequency noise of exhaust of an engine is remarkable.

Owner:SHANDONG UNIV

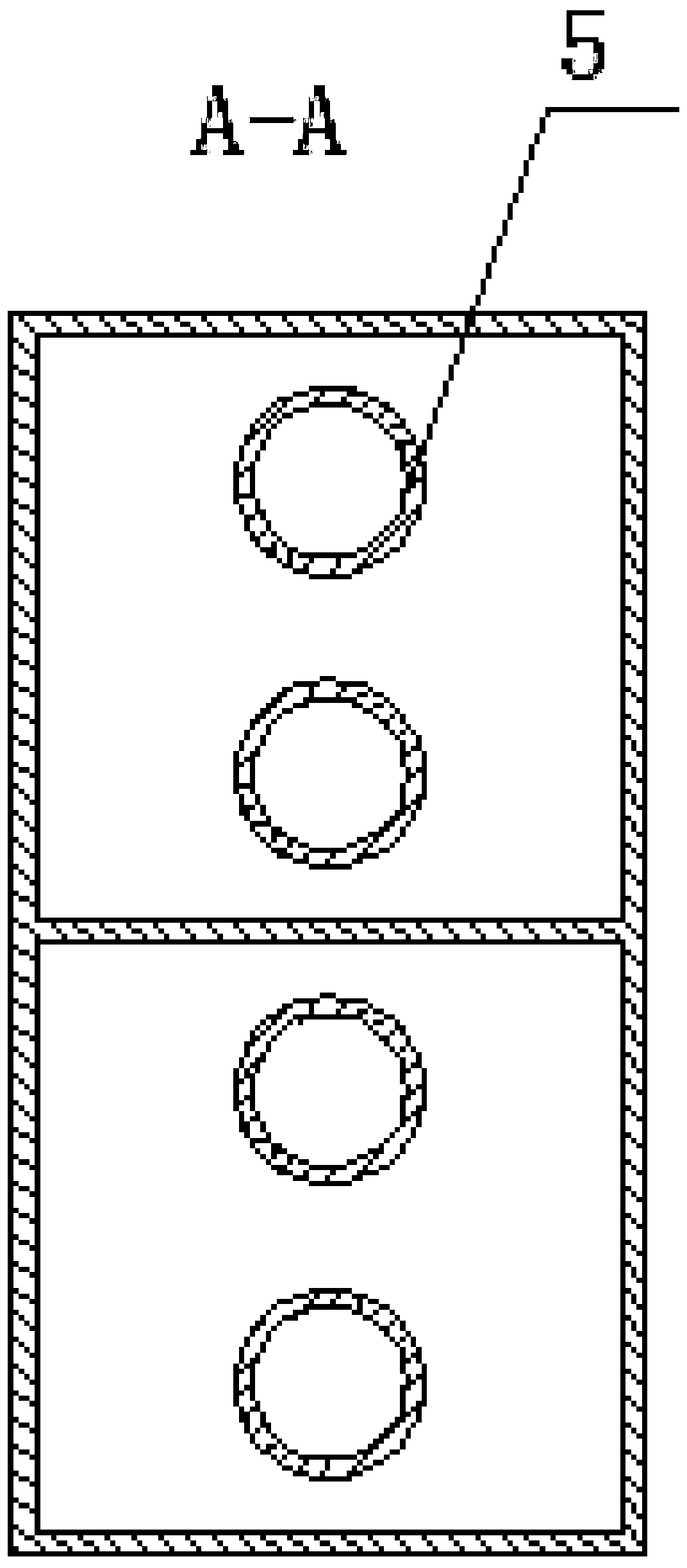

Paralleling varied deep secondary back cavity micro-perforated pipe silencer

The invention provides a paralleling varied deep secondary back cavity micro-perforated pipe silencer. The paralleling varied deep secondary back cavity micro-perforated pipe silencer comprises a micro-perforated pipe, an outer barrel, a front partition plate, a rear partition plate and a sleeve. The micro-perforated pipe and the outer barrel are coaxially arranged in a sleeved mode. Through micropores are formed in the pipe wall of the micro-perforated pipe evenly. The center lines of the through micropores are perpendicular to the center axis of the micro-perforated pipe. The air inlet end and the exhaust end of the micro-perforated pipe are connected with the two ends of the outer barrel in a sealed mode through a front end cover and area end cover. The front partition plate and the rear partition plate are arranged on the micro-perforated pipe in a sleeving mode. The outer edge of the front partition plate and the outer edge of the rear partition plate are connected with the innerwall of the outer barrel so that a front cavity, a middle cavity and a rear cavity can be formed. The sleeve is arranged on the micro-perforated pipe in a sleeving mode. The front end and the rear endof the sleeve are connected with the end face of the front partition plate and the end face of the rear partition plate correspondingly, and the middle cavity is divided into an upper cavity and a lower cavity. The silencer can achieve the good silencing effect in the whole frequency spectrum range, especially in the middle-high frequency range.

Owner:WUHAN UNIV OF TECH

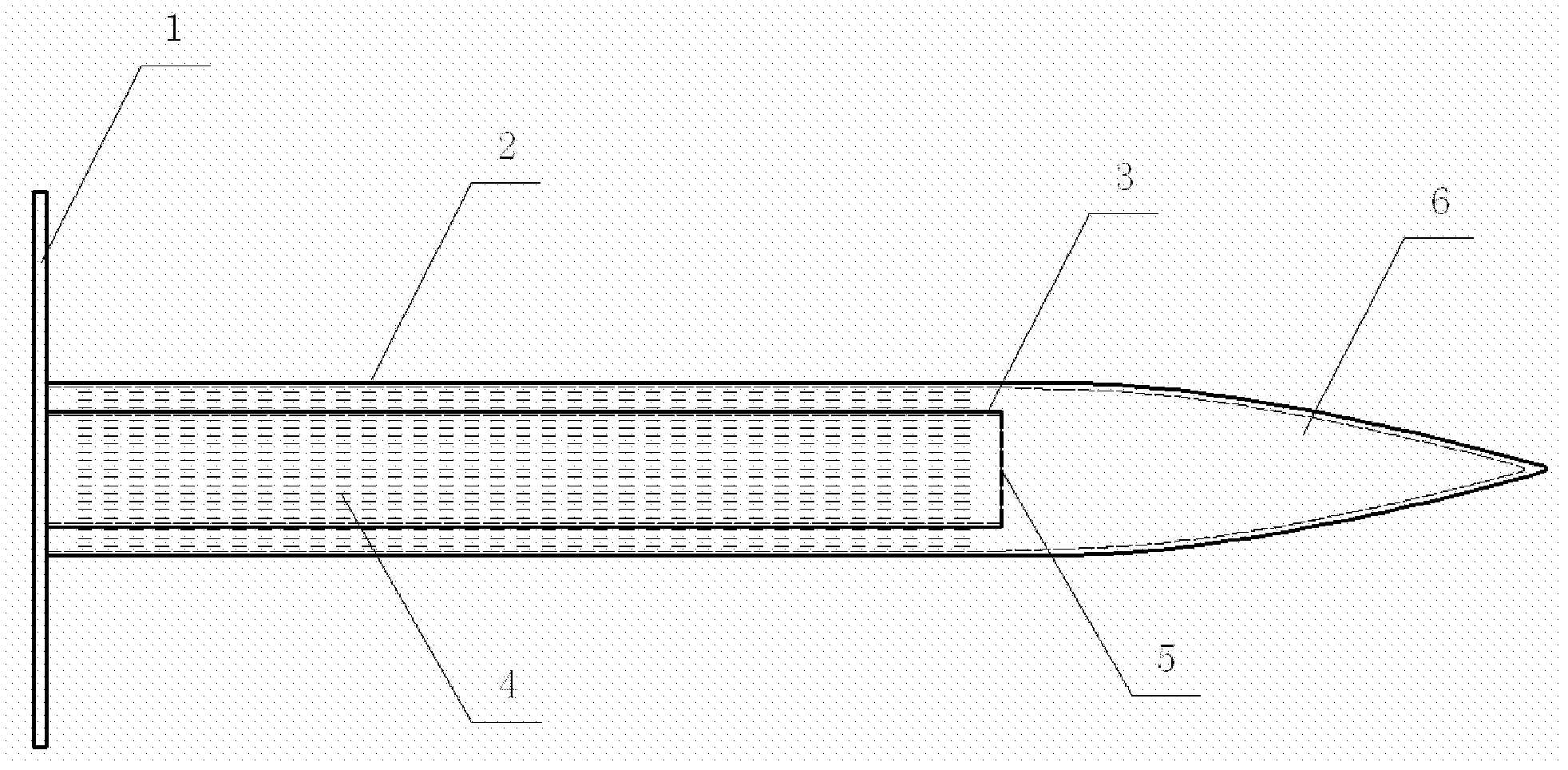

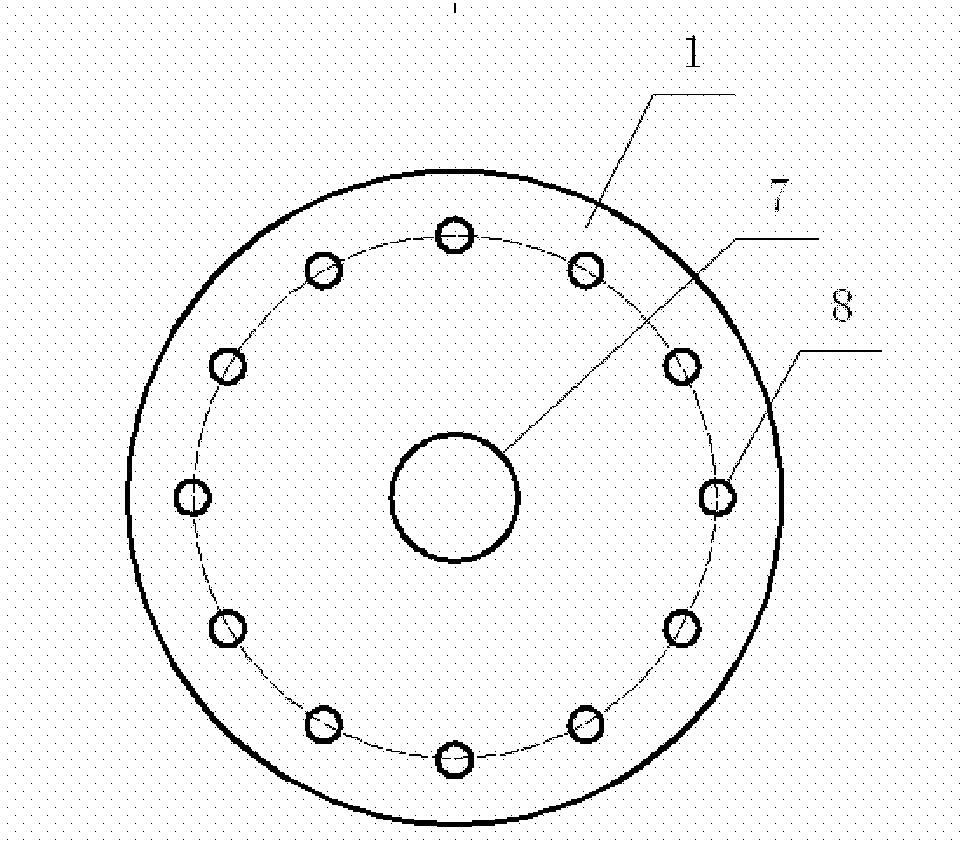

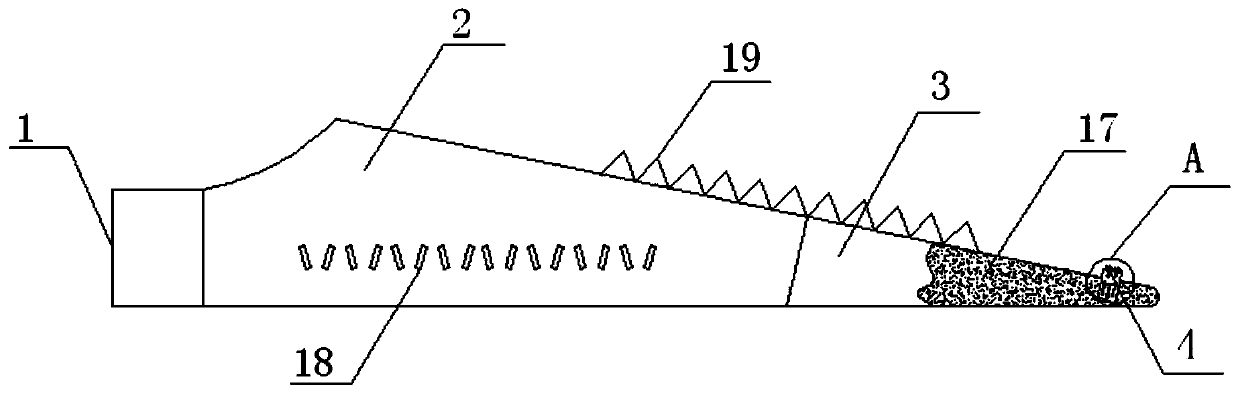

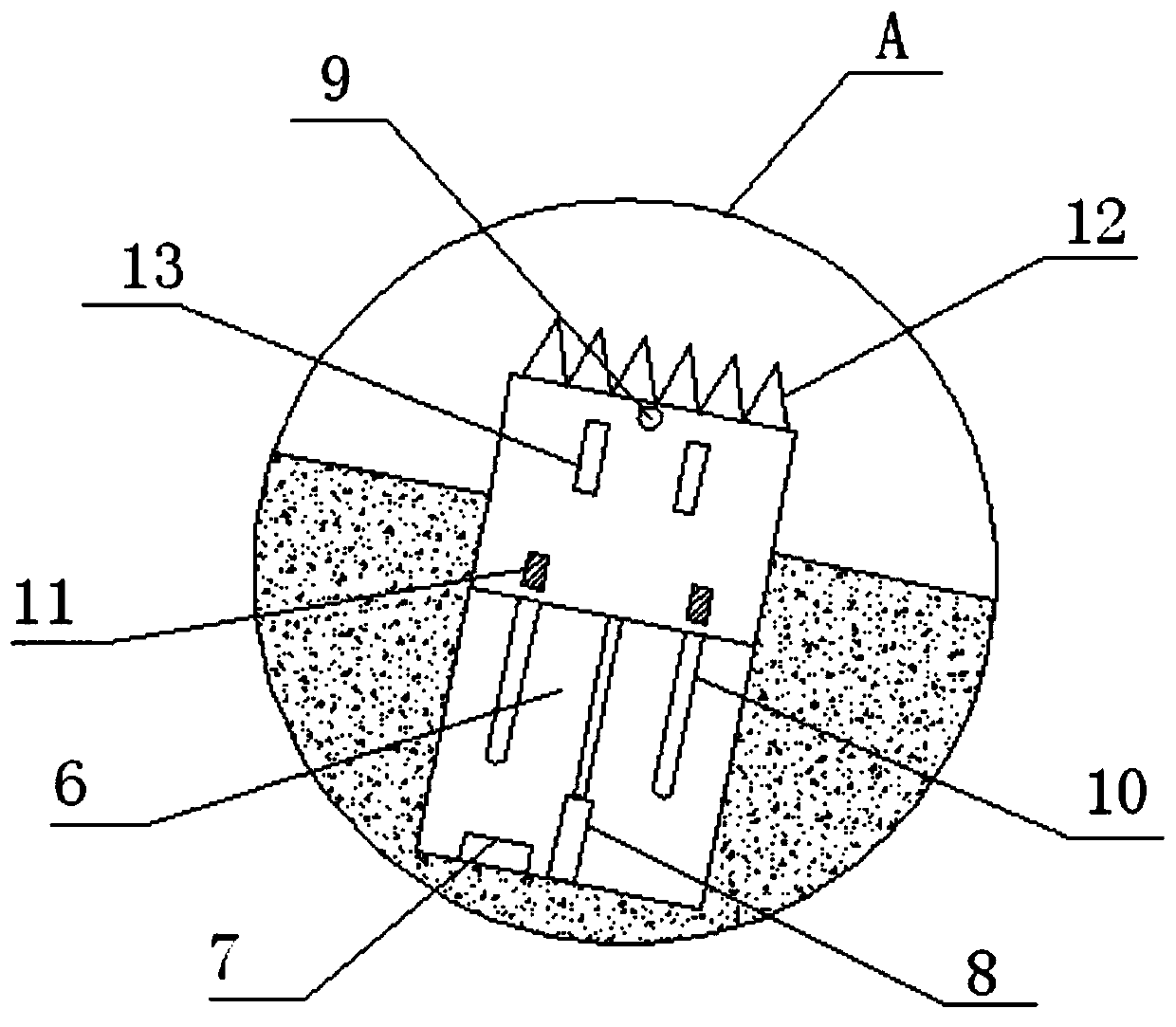

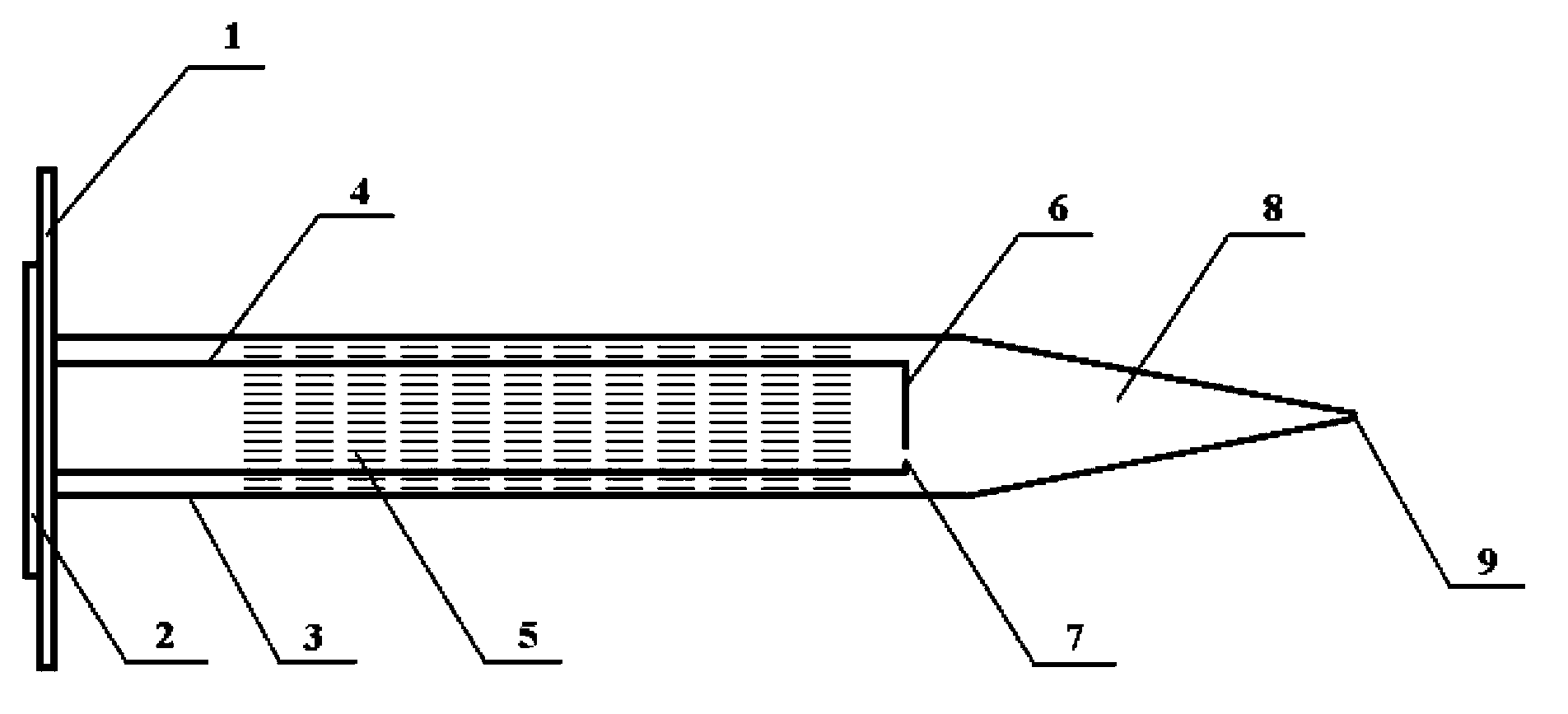

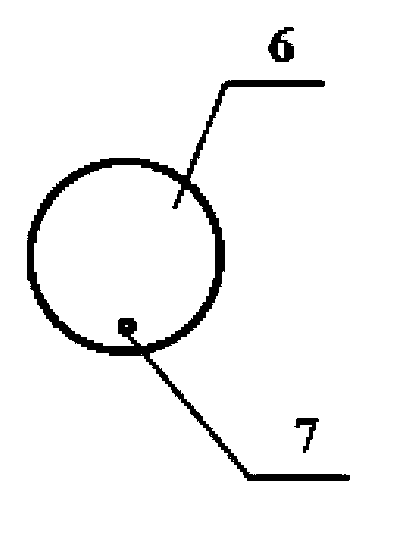

Embedded general silencing device for natural gas pipeline

The invention discloses an embedded general silencing device for a natural gas pipeline, which relates to the technical field of pipeline systems. The embedded general silencing device is formed by welding a flange sheet (1), a silencing outer tube (2), a silencing inner tube (3), a sealing end (5) and a streamlined fairing (6), wherein after one end of the silencing inner tube (3) of the sealing end (5) is sleeved in the silencing outer tube (2) provided with the streamlined fairing (6), the silencing outer tube (2) and the silencing inner tube (3) are fixedly connected with the flange sheet (1). According to the embedded general silencing device, the pneumatic noise of the natural gas pipeline can be controlled within the national standard, and the conveying of the pipeline is not influenced.

Owner:PETROCHINA CO LTD

High-temperature high-pressure steam/gas discharge composite silencer

InactiveCN106251851AUnrestricted horizontal displacementUnrestricted Vertical MovementSound producing devicesProduct gasEngineering

A compound muffler for high temperature and high pressure steam / gas discharge. It is a new type of noise reduction device for various types of high-temperature and high-pressure air exhaust / exhaust steam, including: the two ends of the injection outer cylinder armor are welded with oval head armor; One end of the head armor piece is welded with the interface throttle pipe piece A with the pipe end plate A piece, and the other end of the oval head piece A piece is welded with the lifting ear piece A; On the joint throttling tube A, there is welded the plugging ring plate A with the throttling and decompression tube A and the tube end plate B respectively; the above-mentioned related components are welded firmly and manufactured with them. Consists of a complete set of products.

Owner:潘泉方

Draught fan silencer

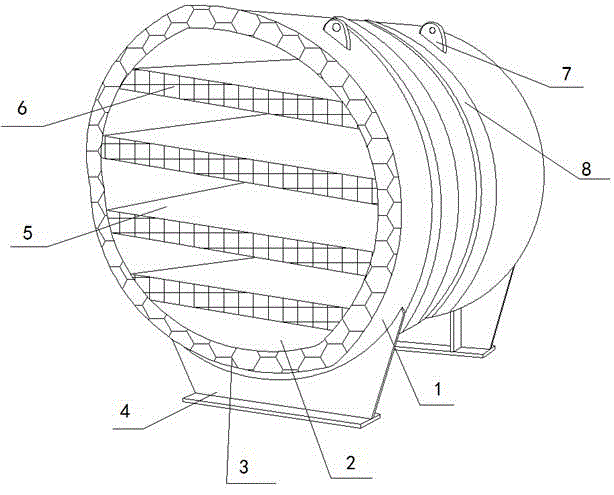

PendingCN105041727AReduce aerodynamic noiseHigh strengthPump componentsPumpsFriction lossPower noise

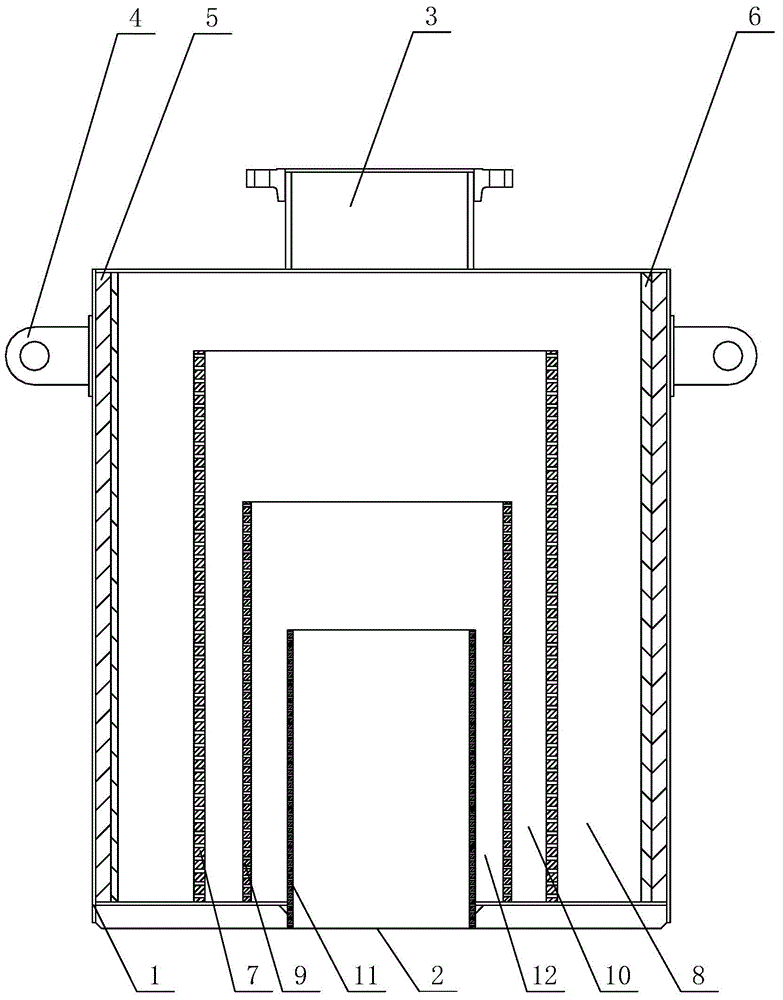

A draught fan silencer comprises an outer wall, an inner wall, a sound insulation packing material, a supporting base, silencing interlayers, resistance type silencing sheets, lifting rings and reinforcing ribs. The supporting base is arranged at the lower end of the outer wall. The silencing interlayers are connected with the inner wall and internally provided with the resistance type silencing sheets. The lifting rings are arranged at the upper end of the outer wall. The outer wall is made of stainless steel. The sound insulation packing material is arranged between the outer wall and the inner wall. The multiple silencing interlayers are arranged in parallel at equal intervals. The reinforcing ribs are arranged on the outer wall. The draught fan silencer has the beneficial effects that air power noise generated by draught fans of various types is lowered, the silencing amount is large, the silencing band width is high, resistance loss is small, and the structure is simple, installation is convenient; the strength of a shell is enhanced through the reinforcing ribs, the overall strength of the product is enhanced, and the silencer is prevented from being scattered in the transportation or installation process.

Owner:WUXI HUALIN REFRIGERATION MACHINERY CO LTD

Wind turbine blade noise reduction device and noise reduction method thereof

InactiveCN109931212AIncrease distanceReduce aerodynamic noiseWind motor controlMachines/enginesElectricityTurbine blade

The invention provides a wind turbine blade noise reduction device and a noise reduction method thereof. The wind turbine blade noise reduction device comprises a wind turbine blade body which is divided into a blade front portion and a blade rear portion, the blade front portion is two thirds of the length of the wind turbine blade body, and the blade rear portion is one third of the length of the wind turbine blade body; one end of the blade rear portion of the wind turbine blade body is provided with a noise reduction device, and the inner wall of the side wall of the blade rear portion isprovided with an installation groove matched with a blade tip small wing; a storage battery is arranged in the installation groove; and an electric telescopic rod is connected between the bottom wallof the interior of the installation groove and the blade tip small wing. According to the wind turbine blade noise reduction device and the noise reduction method thereof, the noise reduction device is arranged, turbulent flow and vortices are inhibited by the blade tip small wing advantageously, vortex air flow is caught and guided through a small wing flap, aerodynamic noise, caused by non-steady pressure pulsation and wake vortices, of the surface of the blade is reduced through small wing sawteeth, and accordingly, the wind turbine blade body can be subjected to efficient noise reduction through combination of the three modes.

Owner:安徽驭风风电设备有限公司

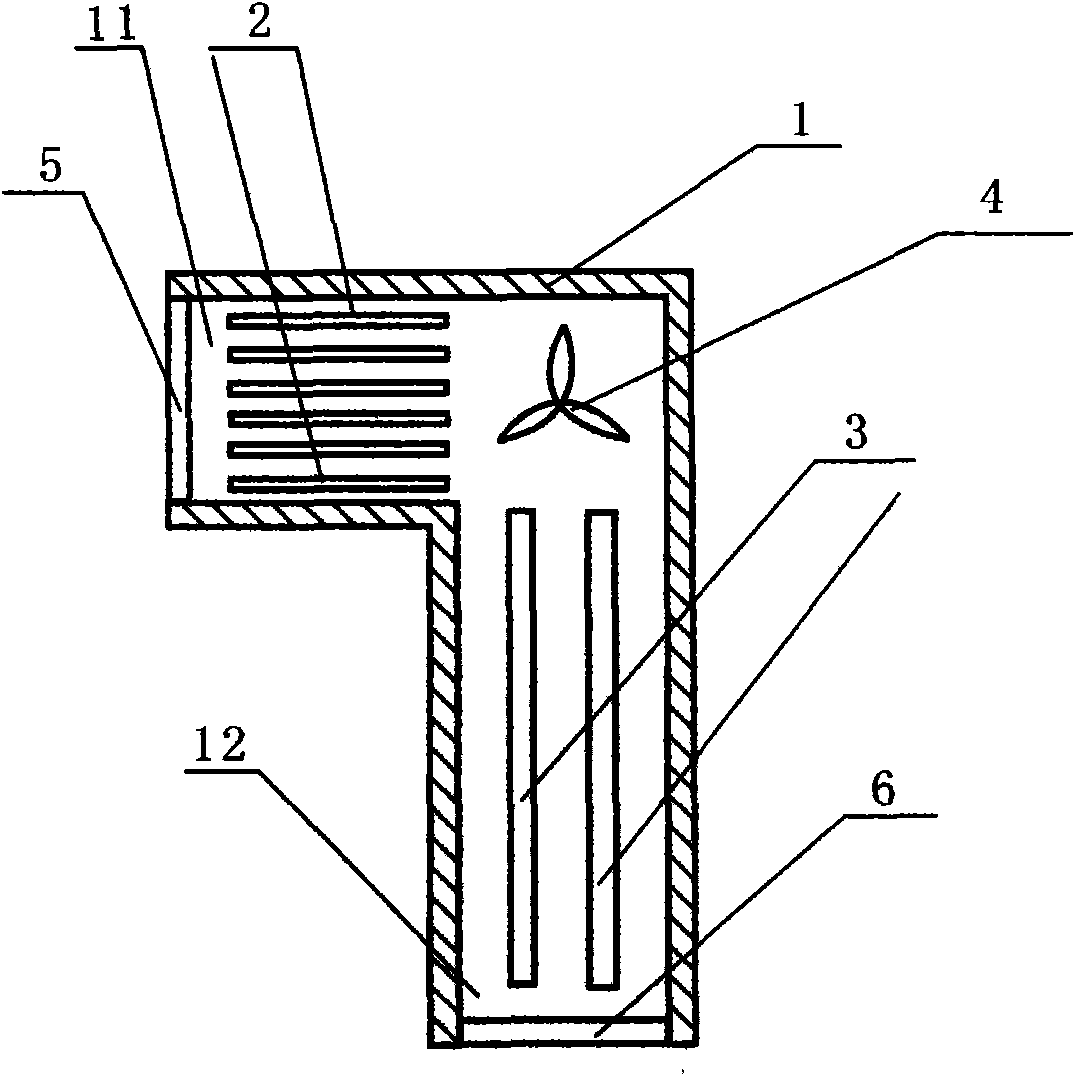

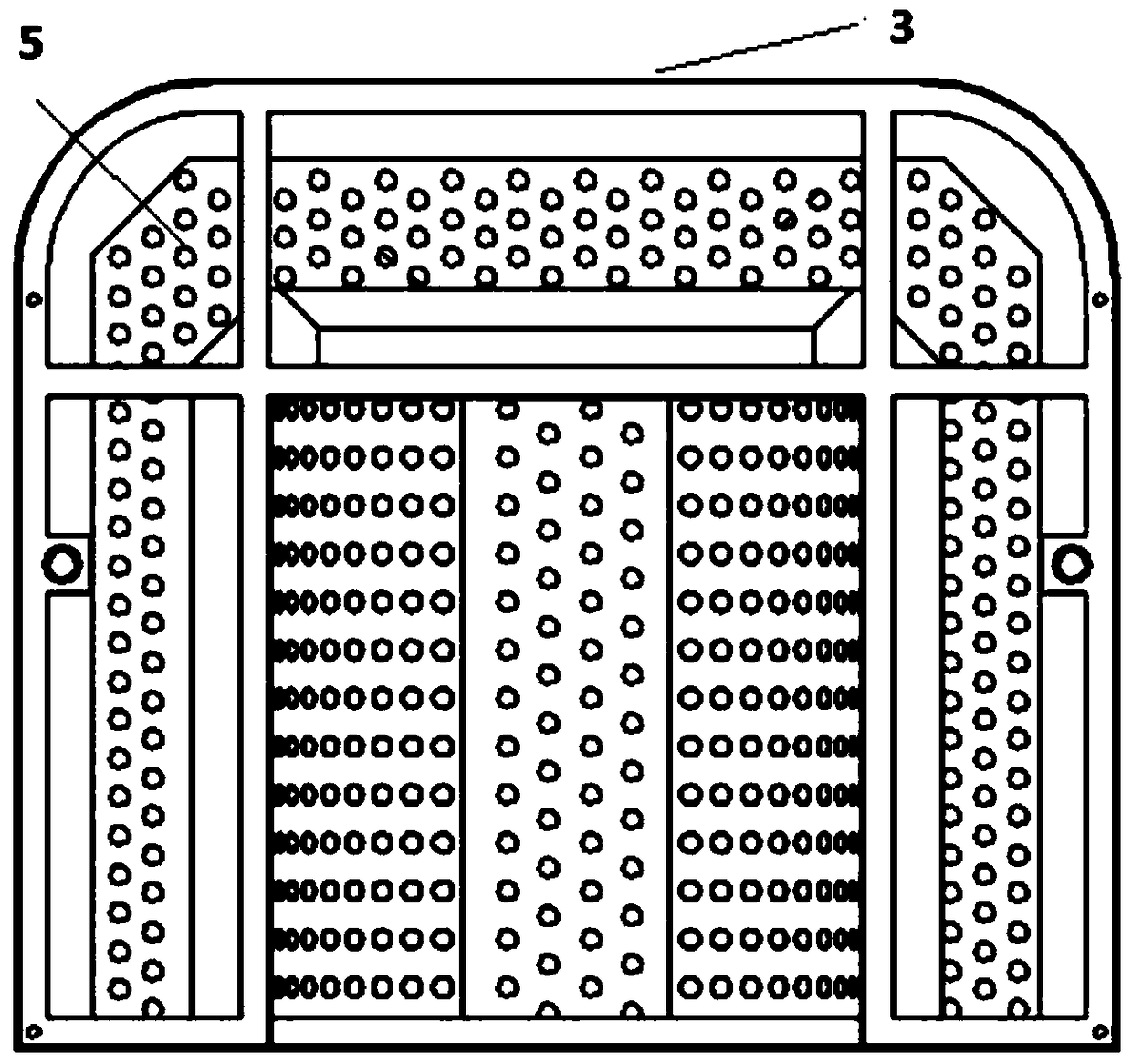

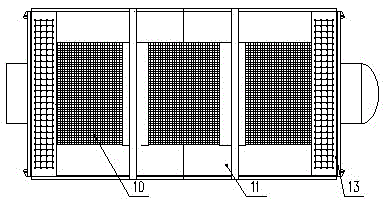

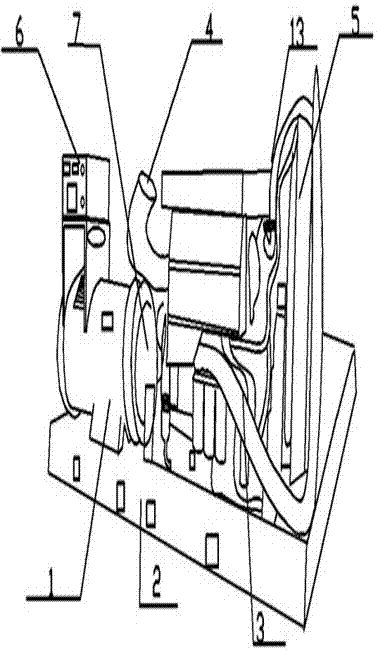

Ventilation silencer

InactiveCN101625146ALarge noise reductionAnechoic frequency is wideLighting and heating apparatusHeating and ventilation casings/coversExhaust gasAgricultural engineering

The invention relates to a ventilation silencer, which is mainly composed of a frame body (1), a high-frequency silencing sheet (2), a low-frequency silencing sheet (3), an exhaust fan (4), a ventilation shutter (5) and an air filtering net (6); the ventilation silencer is characterized in that: the high-frequency silencing sheet (2), the low-frequency silencing sheet (3) and the exhaust fan (4) are arranged in an inner cavity formed by the frame body (1), the ventilation shutter (5) is arranged at a horizontal opening end (11) of the frame body (1), and the air filtering net (6) is arranged at a vertical opening end (12) of the frame body (1); wherein the frame body (1) mainly comprises a case body and a cover board, the cover board is arranged on the surface of the case body to protect the case body, and the frame body (1) is in a 7 shape, and the inner part of the frame body forms a cavity; one side of the frame body (1) forms an exhaust fan mounting door (13), the exhaust fan (4) is arranged at the position of the exhaust fan mounting door (13), the high-frequency silencing sheet (2) is arranged in the horizontal inner cavity of the cavity, and the low-frequency silencing sheet (3) is arranged in the vertical inner cavity of the cavity, thereby achieving the design purposes.

Owner:四川三元环境治理股份有限公司

Novel silencing device

InactiveCN107725147ALarge noise reductionReduce exhaust resistanceSilencing apparatusMachines/enginesEngineeringNoise reduction

The invention is a novel muffler device. Two identical mufflers are connected in parallel, and the inner cavity is separated by a micro-perforated plate and asbestos between the two mufflers. The inner cavity of the muffler is divided into two Two exhaust chambers make the exhaust noise collide back and forth in the exhaust channel. The asbestos layer can absorb part of the noise. The insertion pipe of the muffler adopts a tapered pipe to reduce the exhaust resistance of the muffler. The airflow of the two mufflers passes through After the second chamber, it joins in the exhaust pipe and exits the muffler. Through simulation and testing, the noise reduction effect of the muffler of the invention is better than that of the traditional muffler, and the exhaust resistance of the muffler is lower than that of the traditional muffler.

Owner:GUILIN UNIV OF ELECTRONIC TECH

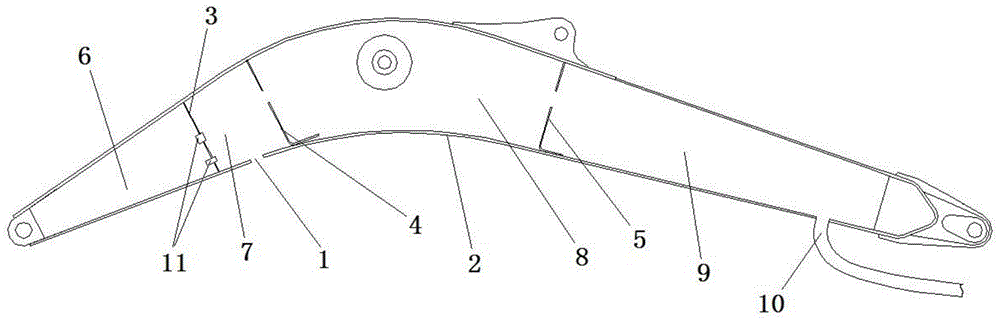

Excavator noise reduction boom and excavator

ActiveCN104652506BLarge noise reductionWide range of anechoic frequenciesMechanical machines/dredgersResonanceExcavator

The invention relates to excavators and booms thereof and discloses a silenced boom of an excavator. The silenced boom of the excavator is used for overcoming disadvantages of the existing excavators that special silencers are used. The silenced boom of the excavator comprises a box body structure with an internal cavity, wherein both the front end and the rear end of the box body structure are hinged ends; partition plates which are used for partitioning the internal cavity into a plurality of chambers, which at least comprise an air intake chamber, a resonant chamber and an exhaust chamber, are arranged in the box body structure; an air intake port communicating with the air intake chamber and an exhaust port communicating with the exhaust chamber are formed in the box body structure; resonance throat tubes are arranged on the partition plate between the air intake chamber and the resonant chamber, and an exhaust passage exists from the air intake chamber to the exhaust chamber. Meanwhile, the invention further discloses the excavator with the boom. The silenced boom has the advantages of low exhaust resistance, good silencing effect, whole-machine cost reduction and mounting space saving and meanwhile has the advantage that the structural strength of the boom is improved.

Owner:LIUZHOU LIUGONG EXCAVATORS +2

Fan sound eliminator

The invention relates to a fan sound eliminator which comprises a housing, sound elimination pieces, a sound absorbing material, installing flanges and an interface flange. Two ends of the housing are respectively and fixedly connected with the interface flanges, the sound elimination pieces and the sound absorbing material are located in the housing, the sound elimination pieces are arranged at intervals, two ends of each sound elimination piece are respectively and fixedly connected with the installing flanges, the sound absorbing material is filled in each sound elimination piece, and the installing flanges are fixed to the interface flanges. The fan sound eliminator has the advantages of being simple in structure and convenient to install.

Owner:常州市江南环保设备有限公司

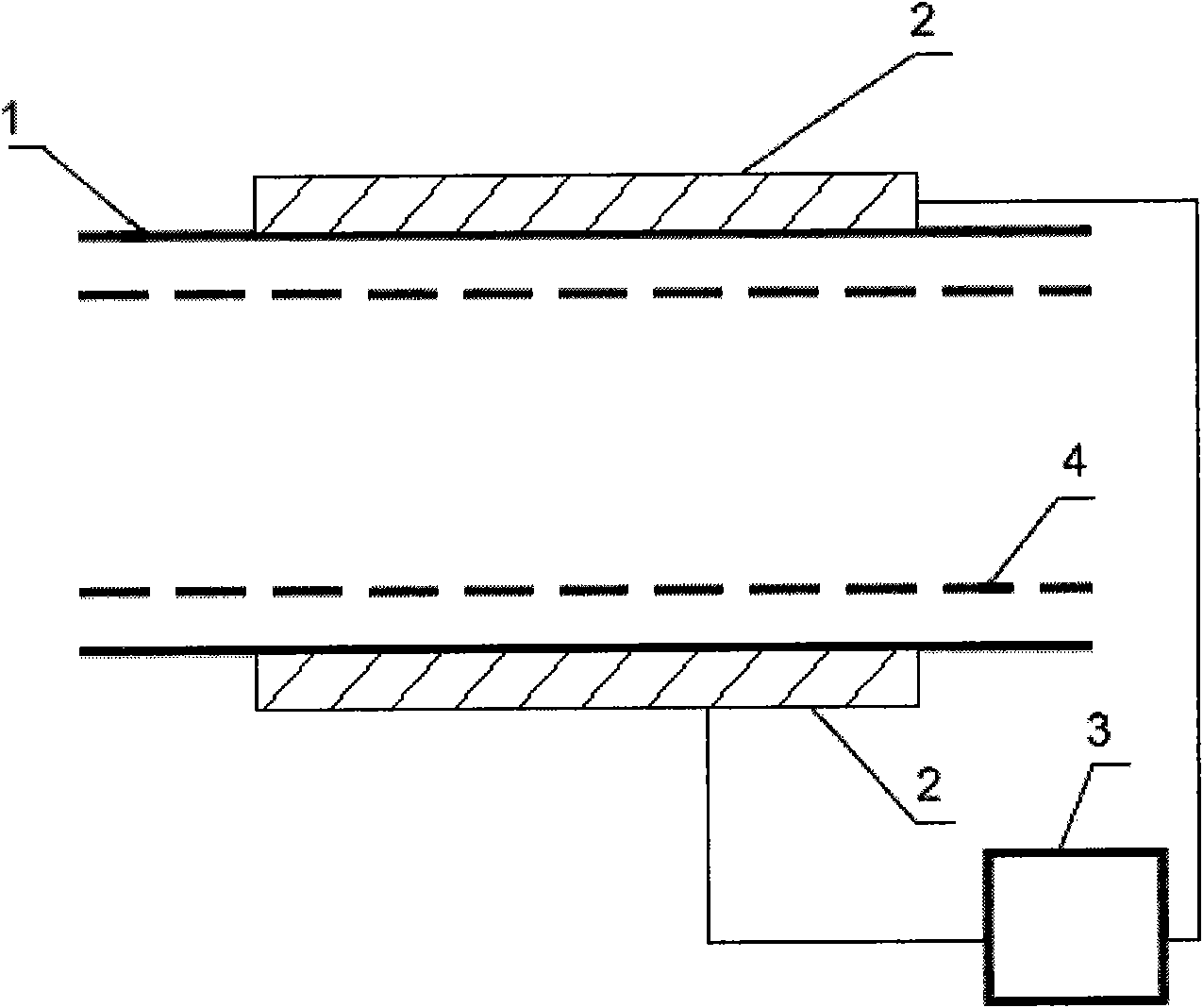

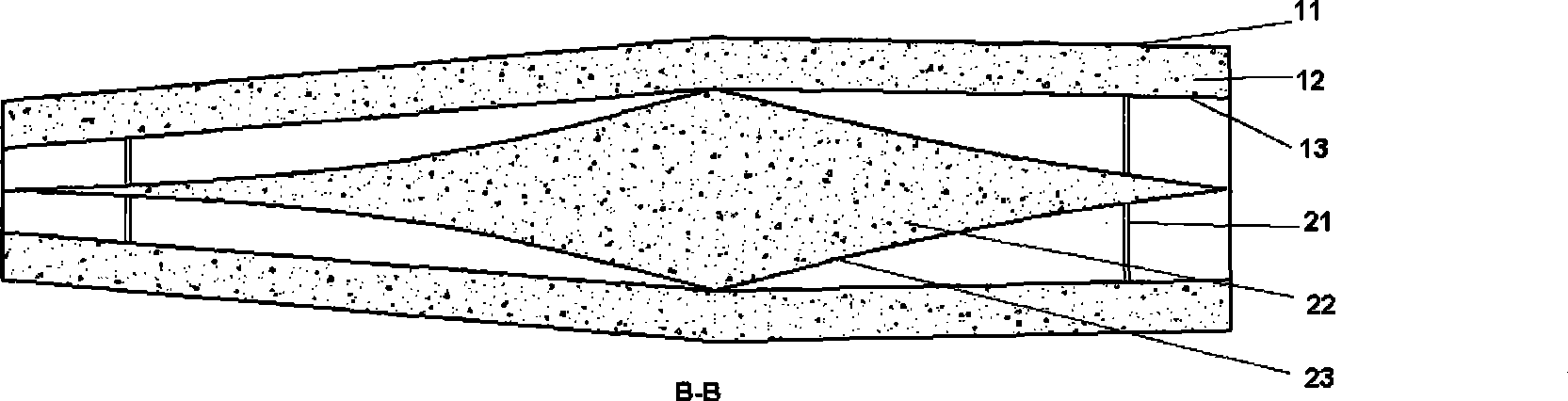

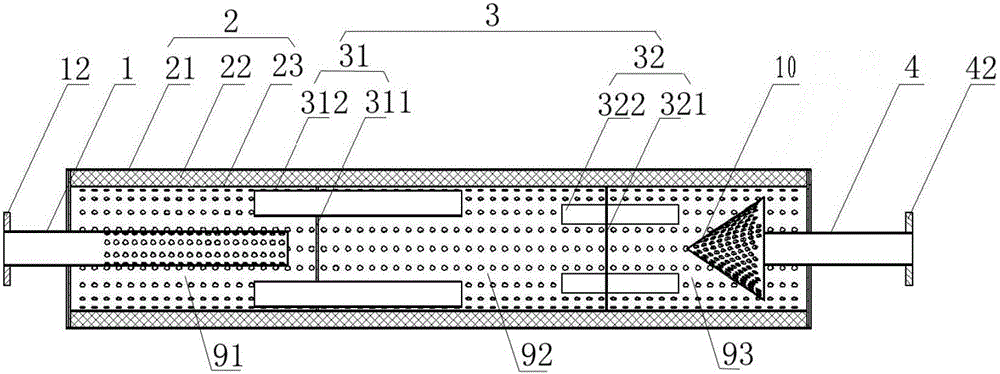

Customized built-in anti-blockage denoising device for natural gas pipeline

The invention belongs to a customized built-in anti-blockage denoising device for a natural gas pipeline and relates to the technical field of pipeline systems. The customized built-in anti-blockage denoising device for the natural gas pipeline is formed by welding a first flange (1), a second flange (2), a silencing outer pipe (3), a silencing inner pipe (4), a seal end (6) and a streamline rectifying shield (8) through flange connecting. The silencing outer pipe (3) with the streamline rectifying shield (8) is fixedly connected with the first flange (1); the silencing inner pipe (4) with the seal end (6) is fixedly connected with the second flange (2) and the silencing outer pipe (3) and the silencing inner pipe (4) are connected by a flange; by taking the first flange (1) and the second flange (2) as the rear parts, multiple seams (5) are circumferentially uniformly distributed in the middle of the silencing outer pipe (3) and the middle front part of the silencing inner pipe (4). The pneumatic noise of the natural gas pipe is controlled in the national standard provisions without generating blockage and influencing the pipeline conveying.

Owner:PIPECHINA SOUTH CHINA CO

A device for noise reduction, ice blockage prevention and cold energy utilization of natural gas pipelines

ActiveCN103216700BLarge noise reductionAlleviate ice blockageValve members for heating/coolingThermal insulationEngineeringHeating furnace

The invention relates to a device for denoising, ice blockage prevention and cold energy utilization of a natural gas pipeline. The device relates to the technical field of pipeline systems, and is characterized in that two sections of natural gas pipelines (4) are connected into a whole through a pressure regulating valve (2); a heat exchange flat pipe (1) with an outer coating (3) is wrapped on the whole natural gas pipeline (4) and the pressure regulating valve (2); a solar heater (8), a summer indoor cold supply system for working and living areas (9) and a natural gas heating furnace (10) are connected in parallel between a water segregator (7) and a water collector (11); the water collector (11) is provided with a pipeline connected to one end of the heat exchange flat pipe (1); the other end of the heat exchange flat pipe (1) is connected with a circulating pump (6) through the pipeline and then connected to the water segregator (7); and a constant pressure tank (5) is connected to an inlet of the circulating pump (6). The device can control aerodynamic noise of the pressure regulating valve of the natural gas pipeline to be within a state-specified standard, is large in noise reduction, alleviates the problem of ice blockage, is obvious in cold energy utilization effect, does not affect flow rate, is simple and convenient to install, and is low in cost.

Owner:PIPECHINA SOUTH CHINA CO

Reactive muffler for engineering machine

InactiveCN102606268BReasonable flowReduce regenerative noiseExhaust apparatusSilencing apparatusUltrasound attenuationEngineering

The invention discloses a reactive muffler for an engineering machine, which comprises a flange plate, a connecting pipe, a barrel and a smoke exhaust pipe. The inside of the barrel is sequentially divided into a cavity I, a cavity II and a cavity III by a front partition board and a rear partition board from front to back, two first sound attenuation barrels which are positioned in the cavity I and the cavity II are disposed on the front partition board, two second sound attenuation barrels are arranged in the cavity II, a third sound attenuation barrel is disposed in the cavity III, the first sound attenuation barrels and the second sound attenuation barrels are arranged along the axial direction of the barrel, the third sound attenuation barrel is perpendicular to the first sound attenuation barrels and the second sound attenuation barrels, the connecting pipe and the smoke exhaust pipe are perpendicularly connected onto the barrel and are spatially perpendicularly arranged in a crossed manner, the connecting pipe is communicated with the cavity I, the smoke exhaust pipe is communicated with the cavity III, and the flange plate is connected with the cavity I via the connecting pipe. The reactive muffler is reasonable in structure, fine in acoustic performance and long in service life, regenerated noise of airflow is low, and a muffler effect for low, medium and high-frequency noise of exhaust of an engine is remarkable.

Owner:SHANDONG UNIV

Muffler based on sound ray deflection theory

ActiveCN101782008BImprove noise reductionRaise the temperature gradientSilencing apparatusMachines/enginesAviationNacelle

The invention relates to a muffler based on a sound ray deflection theory, which comprises a muffler shell, a low-temperature refrigerating system and a temperature controller. The inner wall of the muffler shell is coated with a sound-absorbing material or structure, and the low-temperature refrigerating system is installed on the outer wall of the muffler shell. A low-temperature refrigerating system pipeline covers at least 5% of the area of an airflow pipeline outer wall. In the invention, the low-temperature refrigerating system is installed on the muffler, a greater (1-2,000 DEG C) temperature gradient is generated corresponding to the high temperature in the airflow pipeline, the sound rays are bent and deflected towards a cool end which refers to the sound-absorbing material and structure at the inner wall of the airflow pipeline so as to reduce the passed sound wave components not contacted with the sound-absorbing material or structure of the muffler in a muffler pipeline, increase the efficient absorption of noises in the pipeline and reduce the radiated noise. The invention can be applied to the muffler design of an aviation turbofan engine nacelle and an air charging / discharging pipeline system, such as a helicopter shaft turbine noise-elimination duct, a gas turbine and the like, and other environmental conditions where are convenient to and allow to provide the low-temperature refrigerating system at the cool end.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

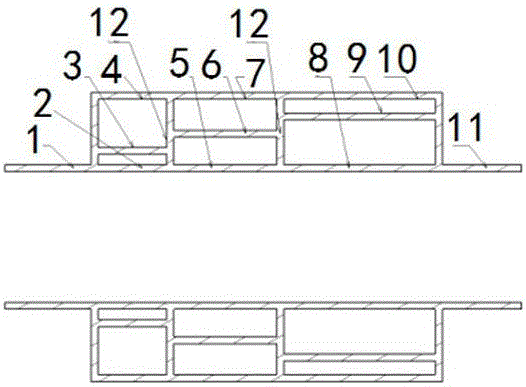

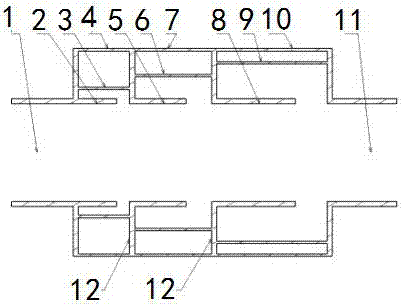

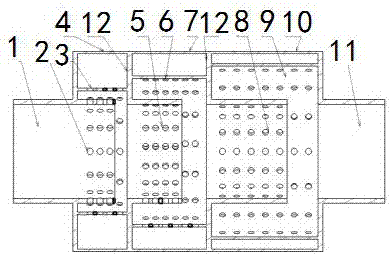

Multi-cavity insert tube type double-layer perforated silencer capable of eliminating broadband noise of supercharging air intake system

InactiveCN106894924ACompact structureGood noise reduction effectMachines/enginesIntake silencers for fuelBroadband noiseEngineering

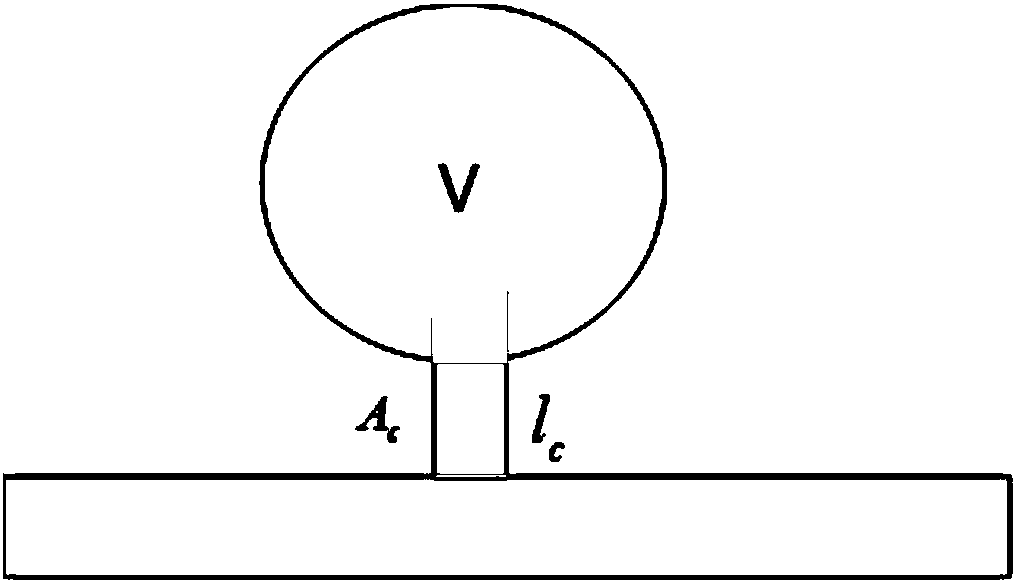

The invention relates to a multi-cavity insert tube type double-layer perforated silencer capable of eliminating broadband noise of a supercharging air intake system. The silencer comprises an inlet end, silencer main bodies and an outlet end. The silencer main bodies are internally provided with at least two double-layer perforated tubes. All the double-layer perforated tubes are connected in series and partitioned through partition plates. Each double-layer perforated tube comprises an outer tube body and an inner tube body which are provided with perforated holes, the outer tube bodies, the corresponding silencer main body and the corresponding partition plate form a closed cavity, the inner tube body extends from the inlet side to the outlet side, and the inner tube body, the corresponding outer tube body and the corresponding partition plate form an unclosed cavity. The silencer is low in pressure loss, compact in structure and low in manufacturing cost, and structural parameters are designed through a multi-cavity one-dimensional transfer matrix method to achieve the high-amplitude broadband silencing effect.

Owner:TONGJI UNIV

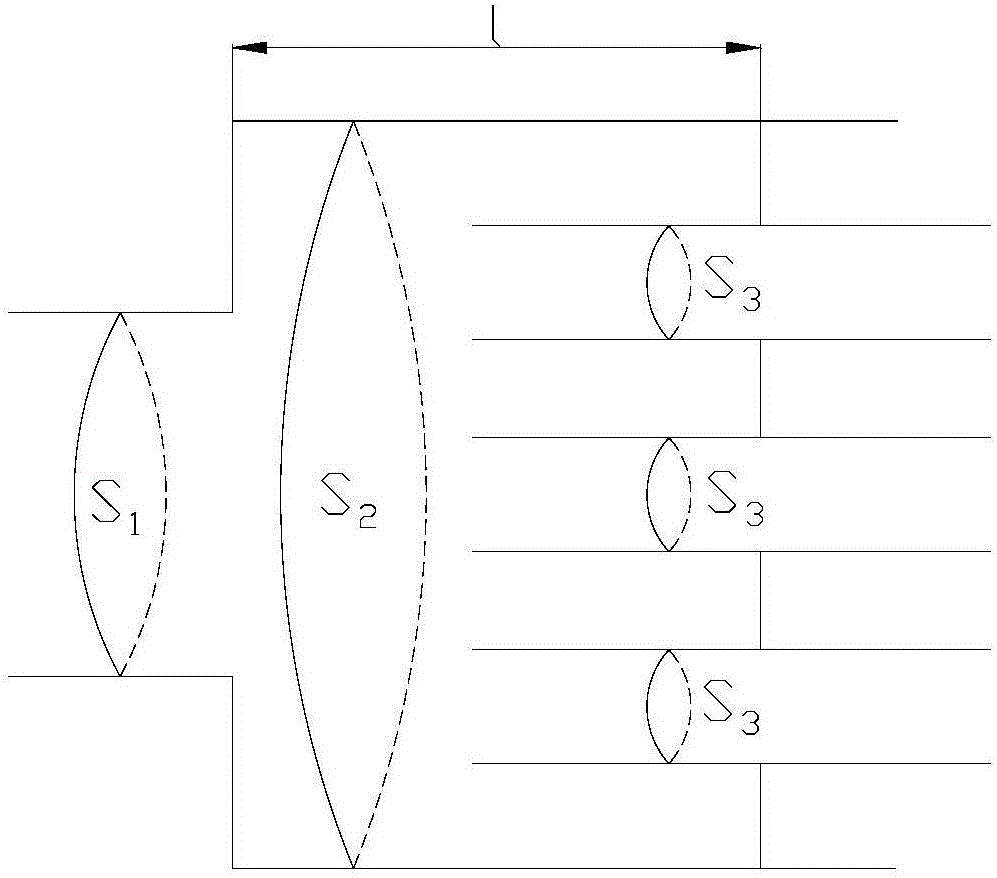

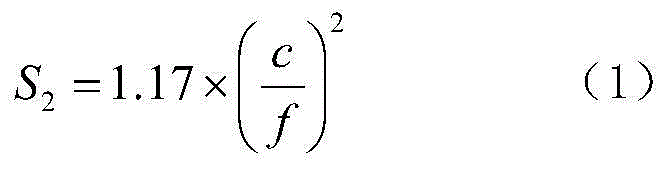

Single-node sudden-changed section tubular muffler for high-power diesel engine

InactiveCN105019983AAvoid blindnessLarge noise reductionSilencing apparatusMachines/enginesEngineeringNoise reduction

The invention discloses a single-node sudden-changed section tubular muffler for a high-power diesel engine. The single-node sudden-changed section tubular muffler consists of an induction passage, an expansion room and exhaust passages. The traverse section area S1 of the induction passage, the traverse section area S2 of the expansion room, the traverse section area S3 of each exhaust passage and the length l of the expansion room satisfy the equations (1)-(4) in the specification, wherein c relates to exhaust sound velocity m / s; f relates to a frequency which has a larger influence on noise among exhaust frequencies; n relates to the number of the exhaust passages; m is an odd number; and w is zero or a positive integer. Maximum noise reduction can be realized; an optimum noise reduction effect is achieved; blindness in a design process of the muffler is avoided; and a large amount of complicated and tedious trial workload is omitted.

Owner:CRRC DALIAN CO LTD

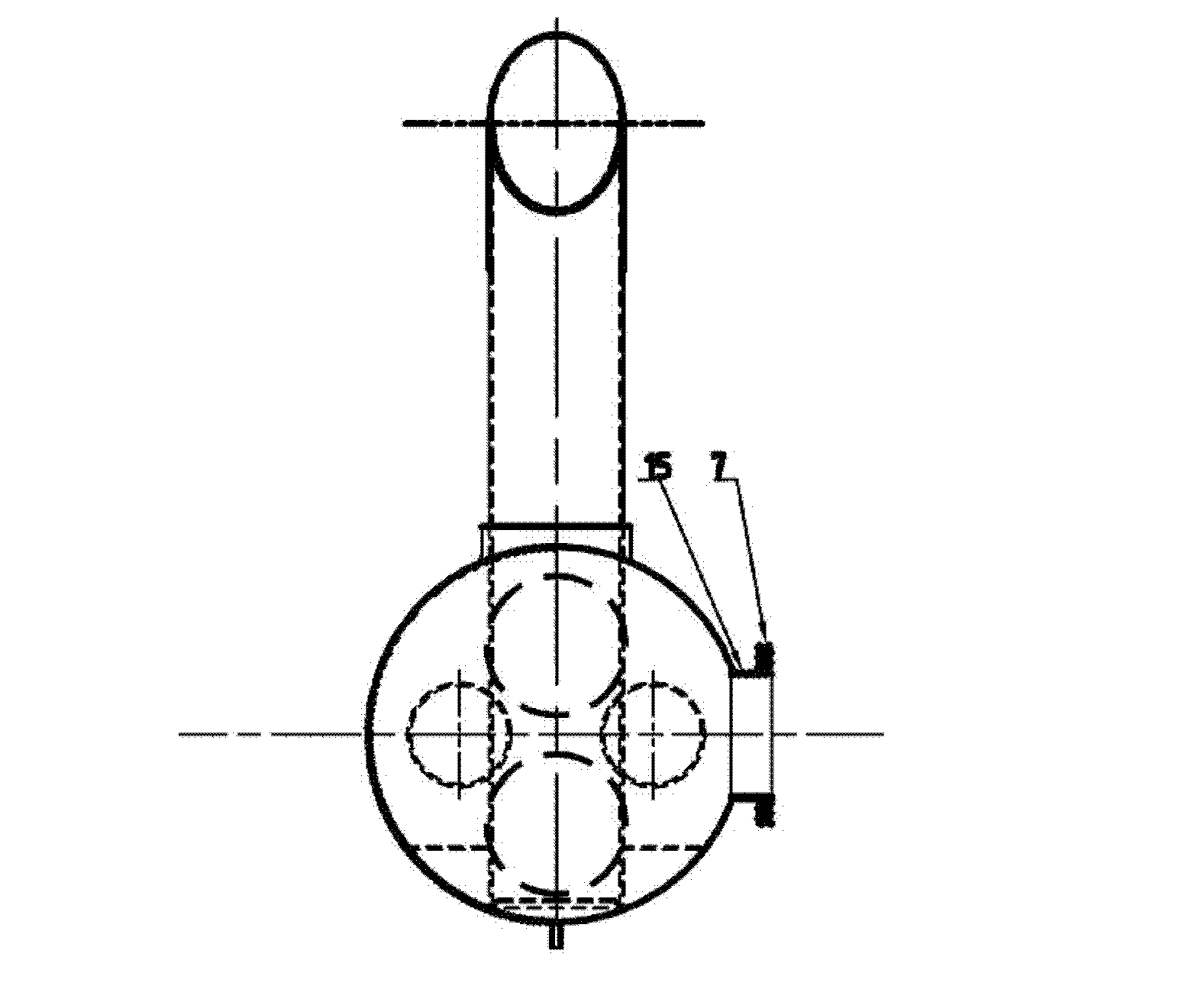

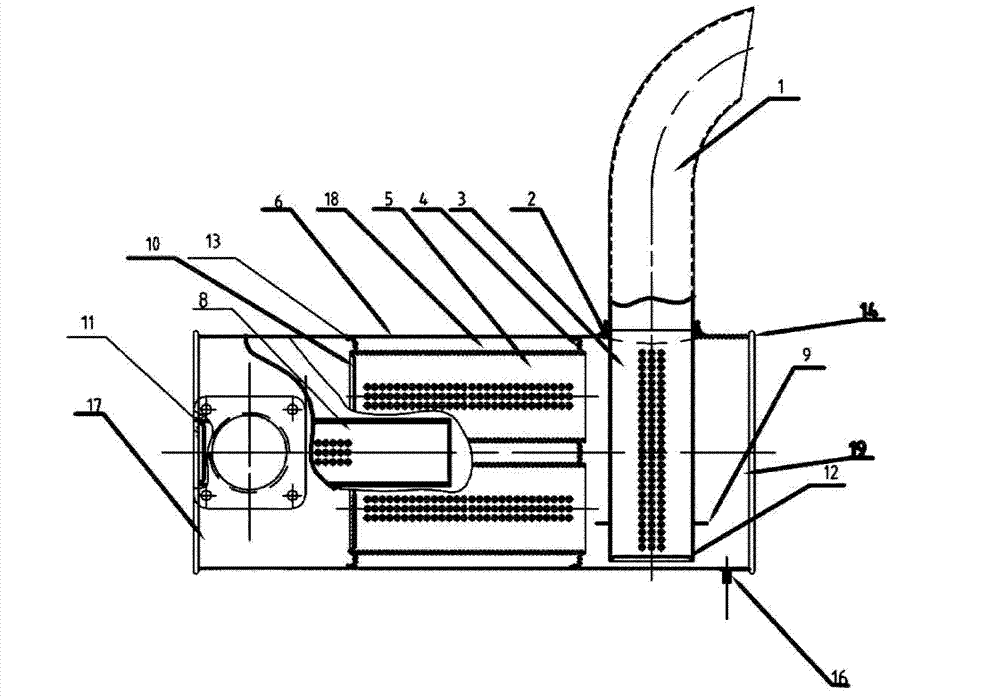

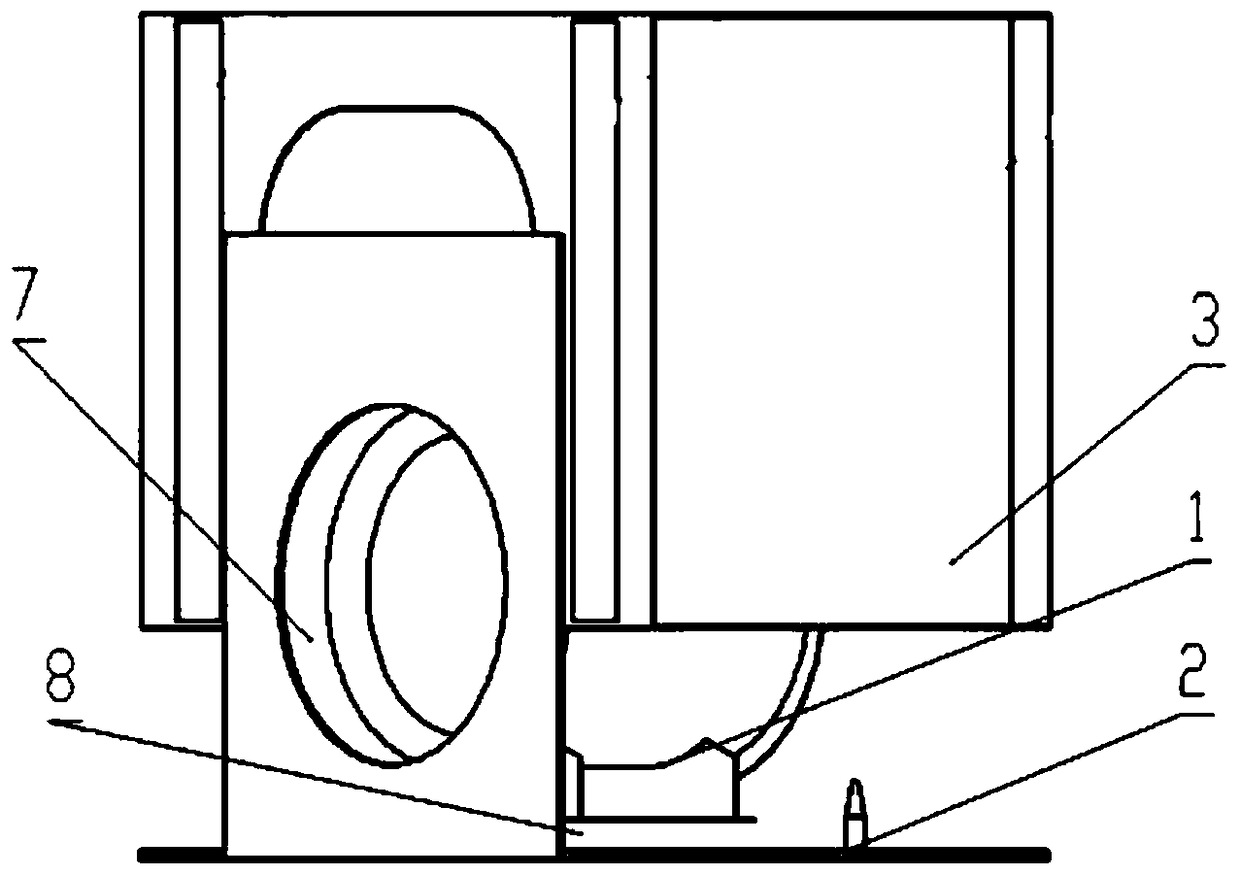

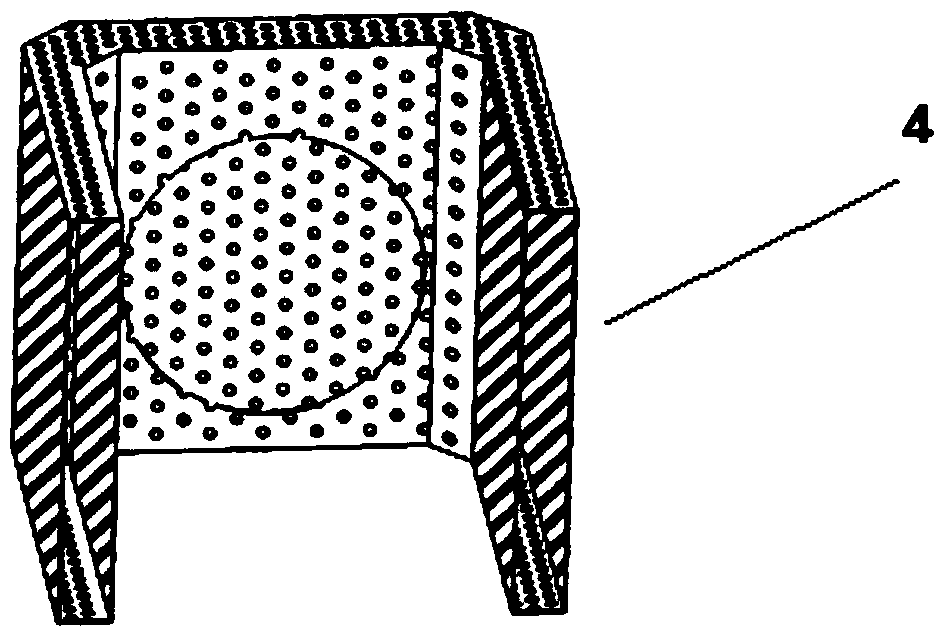

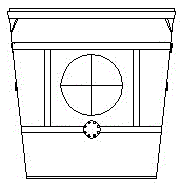

A fan air inlet muffler

ActiveCN105864108BReduce noiseLarge noise reductionPump componentsPumpsAgricultural engineeringMuffler

The invention provides a fan air inlet muffler, which is installed at the fan air inlet pipe (1), comprising: a fixed plate (2) and a sound insulation cover (3); the sound insulation cover (3) is a cover for the fan inlet The square cover on the air duct (1), the shell of the sound insulation cover (3) is a solid plate; there is a round hole in the middle of the front plate of the shell, through which the air inlet pipe (1) of the fan passes; On both sides, two rectangular openings of the same size are symmetrically opened as air inlets; inside the sound insulation cover (3), a U-shaped perforated plate (4) is provided on both sides of the fan inlet pipe (1). ), form a U-shaped air inlet channel (5) with the shell of the sound insulation cover (3); a round hole is arranged on the rear plate of the U-shaped perforated plate (4), which communicates with the fan air inlet pipe (1) ; A conical deflector (6) is provided on the inner wall of the rear panel of the shell of the sound insulation cover (3) facing the air inlet of the fan, for guiding the wind into the air inlet of the fan.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

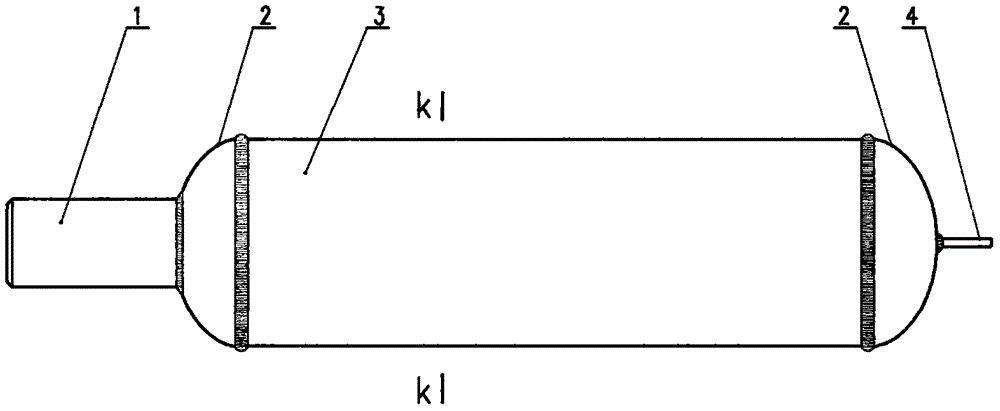

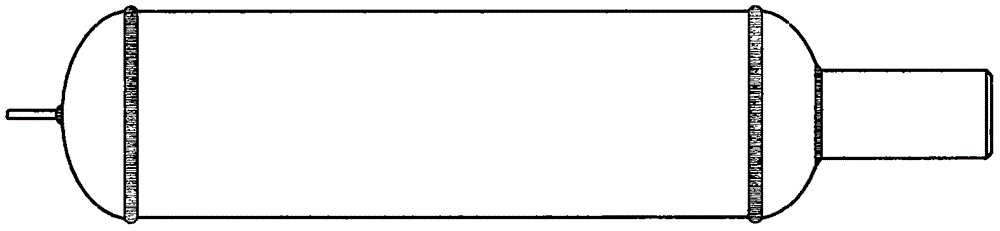

Pipe blowing silencer

InactiveCN105465538AGood noise reductionLarge noise reductionPipe elementsSteam boilersEngineeringNoise reduction

The invention discloses a pipe blowing silencer. The pipe blowing silencer comprises a silencer shell, wherein an inlet connection tube is arranged at the left end of the silencer shell; a debris discharge observation hole is formed below the inlet connection tube; the right end of the silencer shell is provided with a shell cover; a main pipe debris discharge opening is arranged below the shell cover; two ends of the bottom of the silencer shell are provided with pedestals; silencer debris discharge openings and water drainage ports are arranged at the middle part of the bottom of the silencer shell; silencing chambers are arranged in the silencer shell; and an upper cover plate is arranged on the upper part of the silencer shell. According to the pipe blowing silencer, debris in the silencing chambers can be cleaned through the debris discharge observation hole; the debris can be effectively removed; and reusing of the next time is facilitated, so that noise reduction can be realized better.

Owner:LIANYUNGANG BODA MECHANICAL EQUIP MFG CO LTD

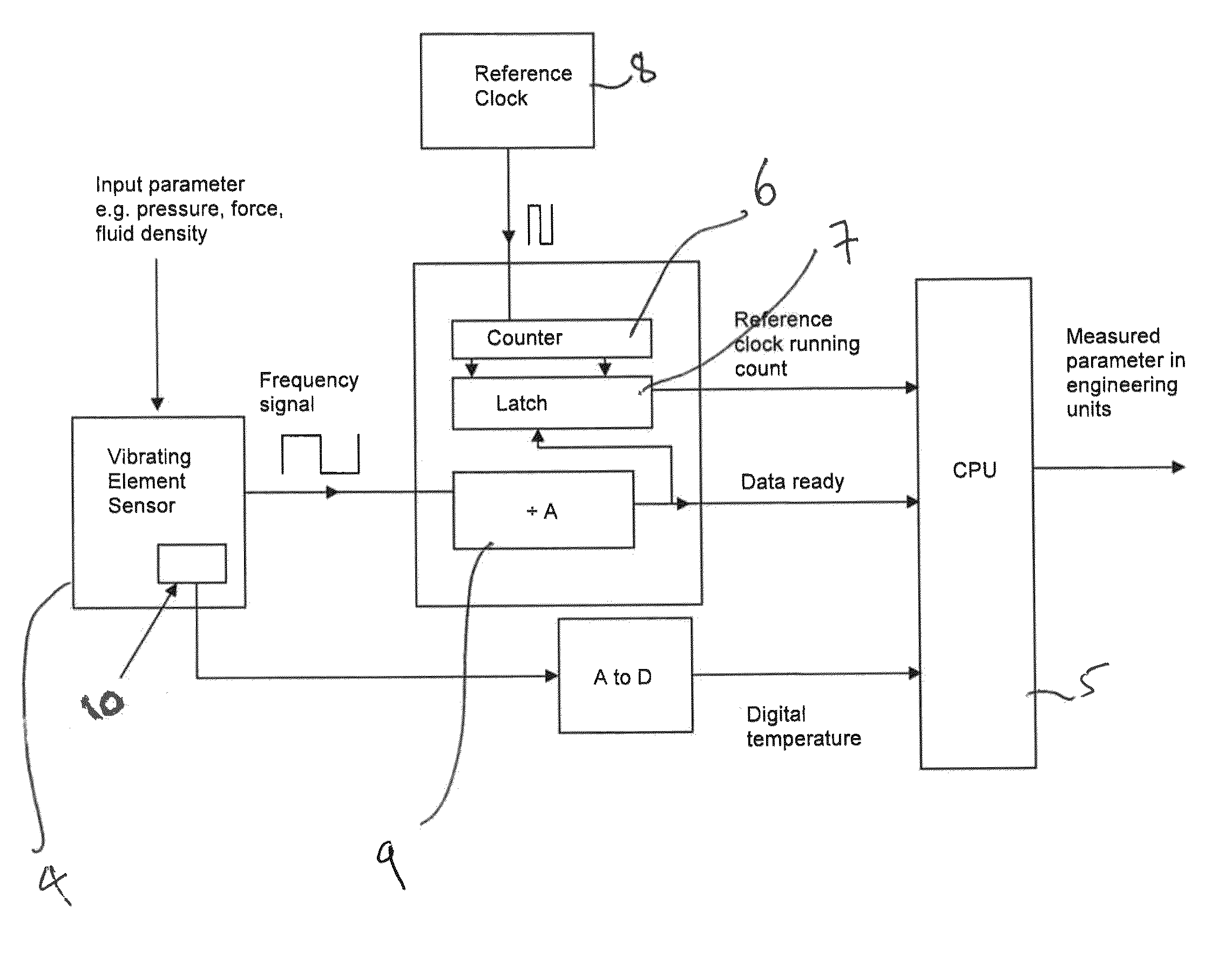

Noise reduction system and method

ActiveUS8947071B2Reduce impactLow update rateFrequency to pulse train conversionFluid pressure measurement using capacitance variationEngineeringElectrical and Electronics engineering

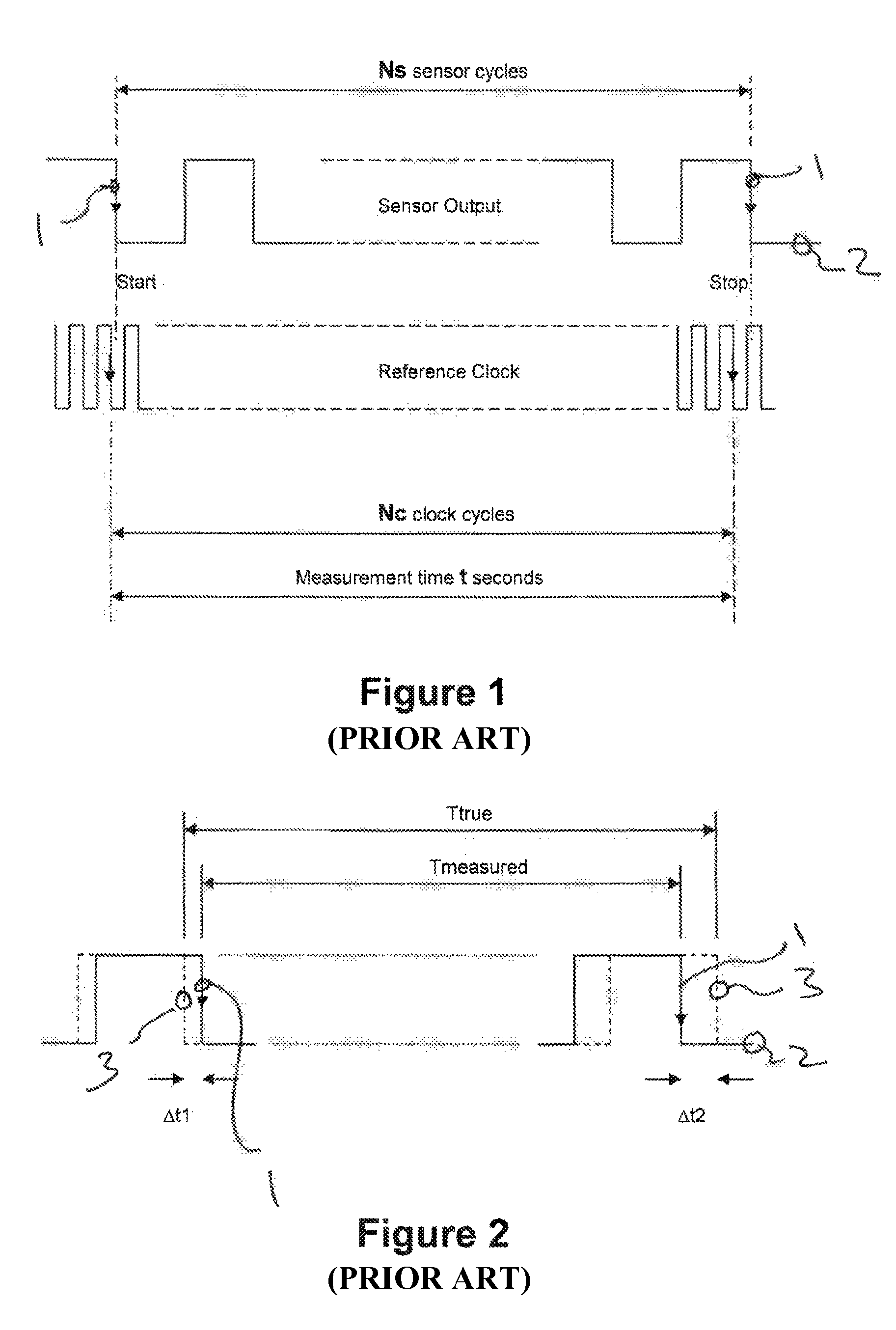

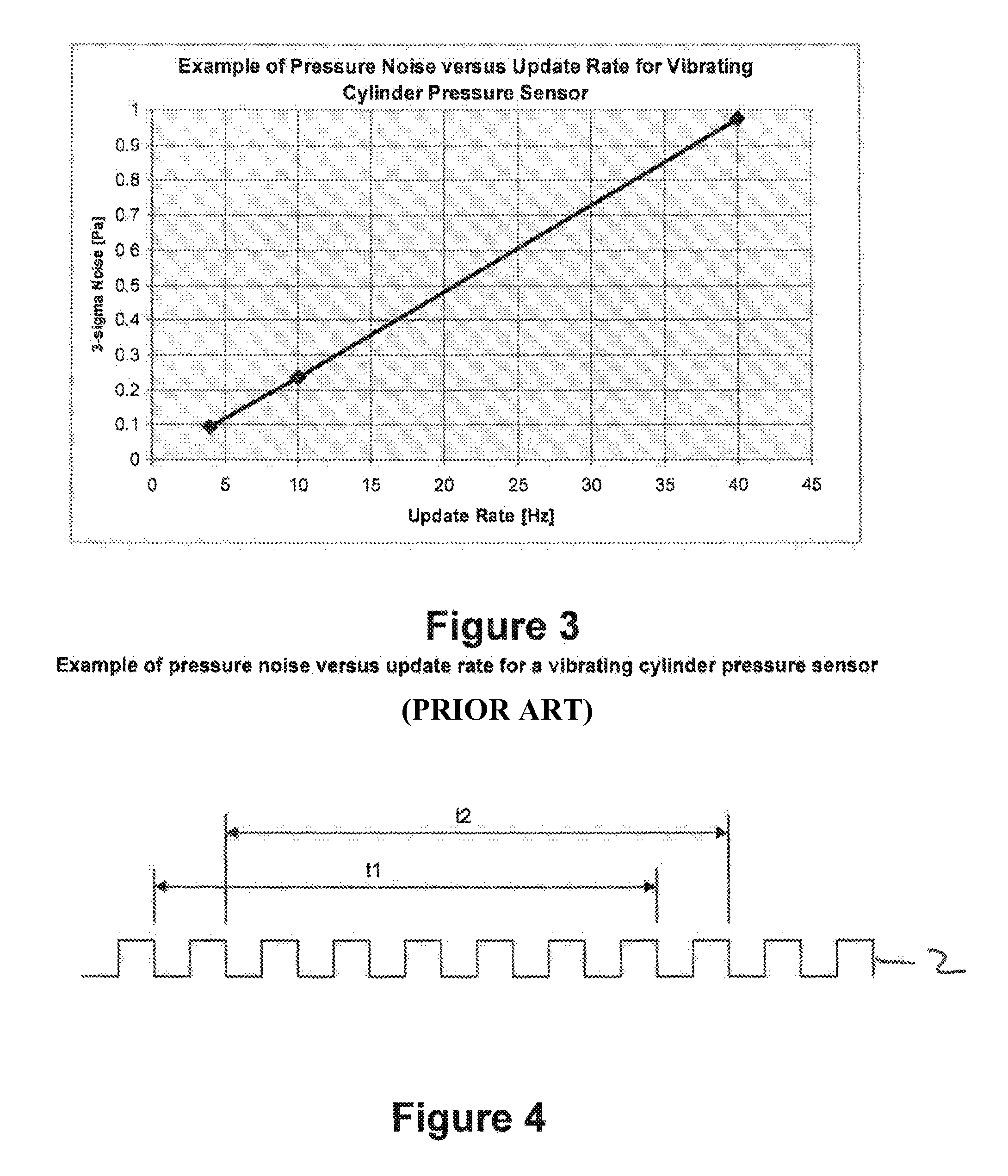

A system and method for measuring frequency which reduces the impact of noise. The system and method includes the steps of sampling a signal train over a first signal portion of the signal train, determining a first average period for the first signal portion (t1) of the signal train, sampling the signal train over a second signal portion (t2) of the signal train, wherein, the second portion of the signal train overlaps with the first signal portion, determining a second average period for the second signal portion (t2) of the output signal train, and then determining the average of the determined average periods.

Owner:WESTON AEROSPACE

Silencer for diesel generating set

InactiveCN105626196AReduce low, mediumReduce high frequency noiseLiquid coolingSilencing apparatusIntermediate frequencyEngineering

The invention discloses a silencer for a diesel generating set. The silencer comprises a shell. A gas inlet and a gas outlet are formed in the shell, and the shell is provided with an interlayer. A cooling water channel is arranged in the interlayer, and a sound absorption material is arranged on the inner wall of the shell. A first barrel is arranged in the shell, and a first cavity is formed between the first barrel and the shell. A second barrel is arranged in the first barrel, and a second cavity is formed between the second barrel and the first barrel. A third barrel is arranged in the second barrel, and a third cavity is formed between the third barrel and the second barrel. The third barrel is connected with the gas inlet, and a plurality of holes are evenly distributed in the barrel wall of each of the first barrel, the second barrel and the third barrel. The first barrel, the second barrel and the third barrel are arranged, so that the gas flow divergence ratio of gas is increased, and then the sound deadening capacity is improved; and the sound absorption material is used in cooperation, and therefore the low-frequency noise, intermediate-frequency noise and high-frequency noise of engine exhaust gas can be lowered.

Owner:江苏瑞昌哥尔德发电设备股份有限公司

Silencer

InactiveCN109139190AIncreased transmission lossIncrease surface areaSilencing apparatusMachines/enginesGlass fiberAcoustic wave

The invention discloses a silencer. The silencer comprises a shell, an air inlet pipe, an air outlet pipe and a connecting pipe connecting with the air inlet pipe, the interior of the shell at least comprises a first baffle, a second baffle and a Helmholtz cavity formed between the first baffle and the second baffle, the connecting pipe is provided with an extension part extending into the Helmholtz cavity, and the silencer further comprises glass fibers arranged in the Helmholtz cavity in a filling manner. According to the arrangement, the surface area of a resistive silencing element is increased, the sound wave absorbing efficiency is improved, the transmission loss of the Helmholtz cavity is increased, and the silencing amount is increased.

Owner:SHANGHAI TENNECO EXHAUST SYST

Diesel generator device with low noise

InactiveCN107989693ALarge noise reductionReduce resistanceMachines/enginesEngine componentsWater tanksDiesel engine

The invention discloses a diesel generator device with low noise. The diesel generator device with low noise comprises a generator (1), a diesel engine (3), a heat-dissipating water tank (5) and a control box (6). The diesel generator device is characterized in that the generator (1) is fixedly connected to the diesel engine (3) through a docking port (7), and the diesel engine (3) is connected tothe heat-dissipating water tank (5) and the an air filter (4) through a pipeline (13); and the control box (6) is fixedly mounted on the generator (1).

Owner:陈跃华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com