Silencer

A technology of muffler and Helmz cavity, applied in the direction of sound absorption, muffler device, machine/engine, etc., can solve the problems of affecting acoustic performance, single problem frequency, no supply, etc., to improve absorption efficiency, enhance transmission loss, The effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

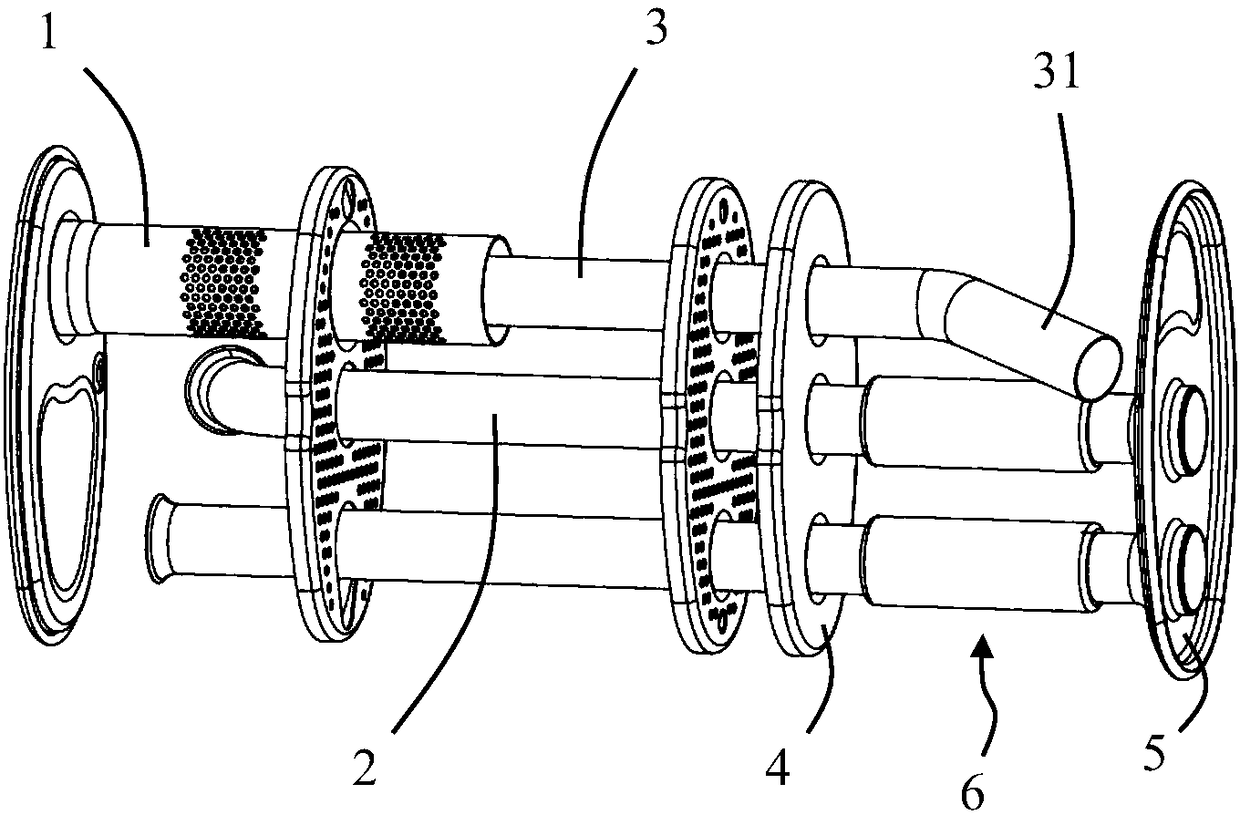

[0019] Please refer Figure 1 to Figure 3 As shown, the present invention discloses a muffler, which includes a housing (not shown), an air inlet pipe 1, an air outlet pipe 2 and a connecting pipe 3 connected to the air inlet pipe 1. The housing includes at least a first baffle 4, a second baffle 5, and a Helmz cavity 6 between the first baffle 4 and the second baffle 5. The connecting pipe 3 is provided with an extension portion 31 extending into the Helmtz cavity 6. In the illustrated embodiment of the present invention, the extension portion 31 extends obliquely into the Helmtz cavity 6.

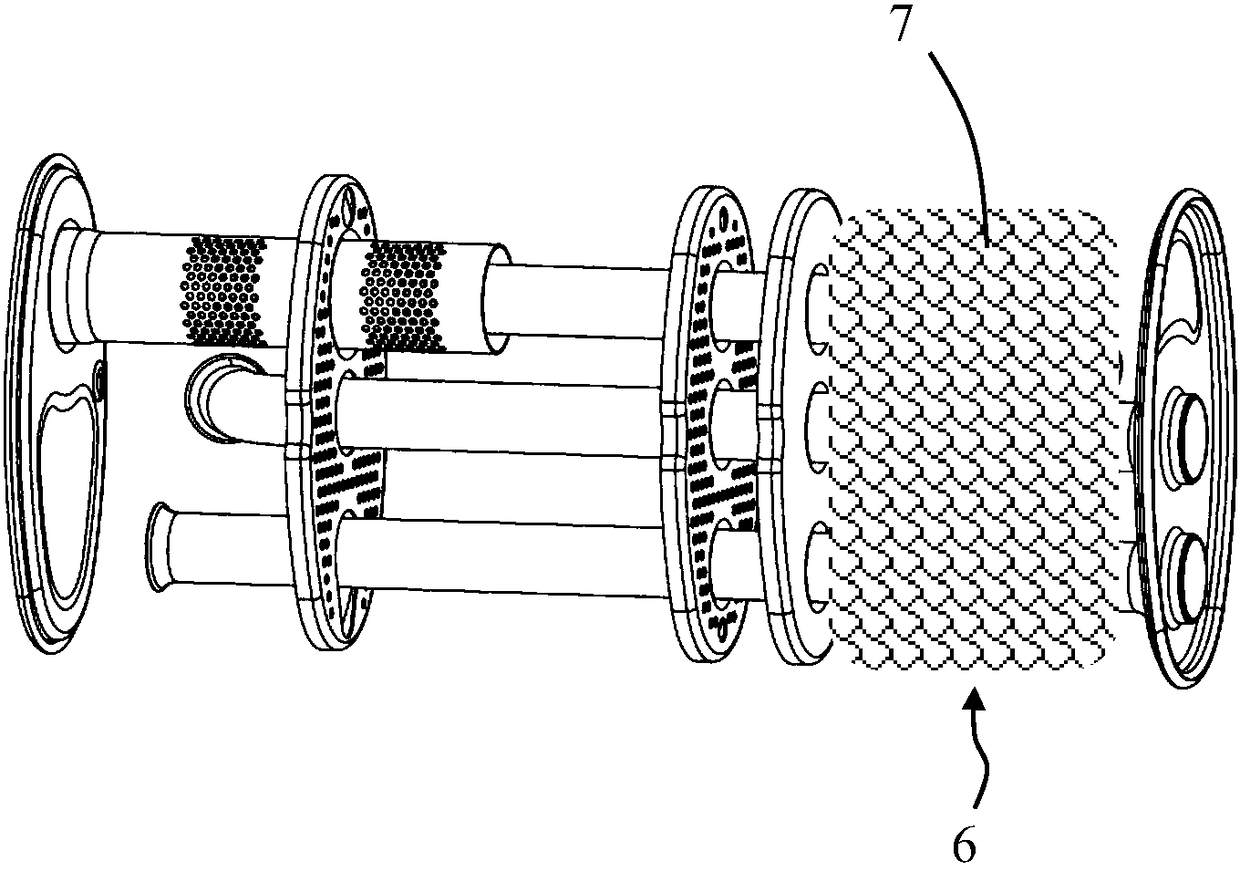

[0020] It is well known that sound waves can be absorbed by viscous and thermally conductive solids. Please refer image 3 As shown, the muffler also includes glass fibers 7 filled in the Helmtz cavity 6, that is, a porous material with a larger surface area is provided in the cavity to absorb more sound energy.

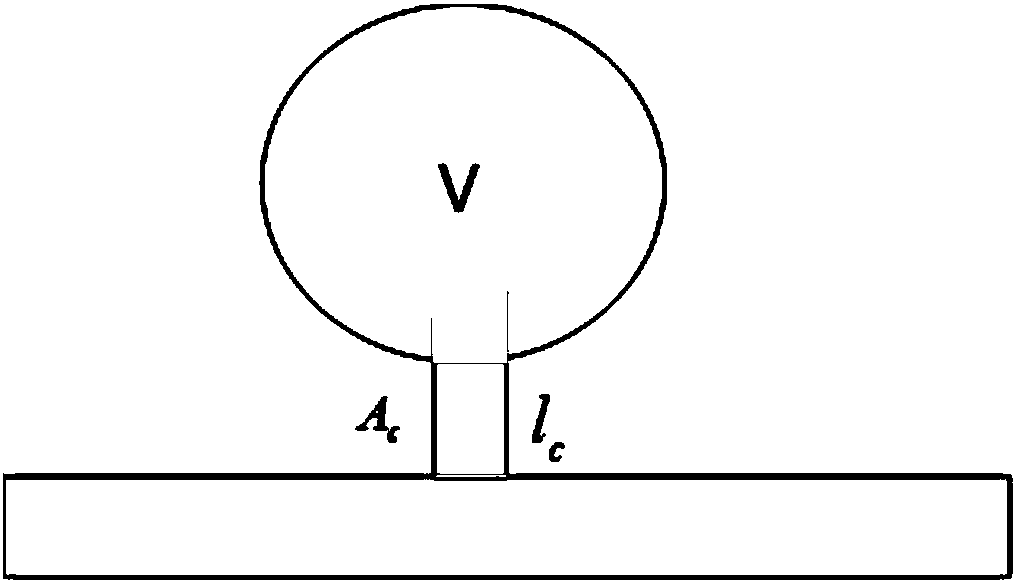

[0021] The Helmtz cavity 6 is a closed cavity with only an air inlet and no a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com