Single-node sudden-changed section tubular muffler for high-power diesel engine

A high-power diesel engine and muffler technology, applied in the direction of intake muffler, machine/engine, muffler device, etc., can solve the problems of reduced noise reduction, zero muffler muffler, high frequency failure, etc., to avoid blindness, the most The best noise reduction effect and the effect of saving the workload of trial calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

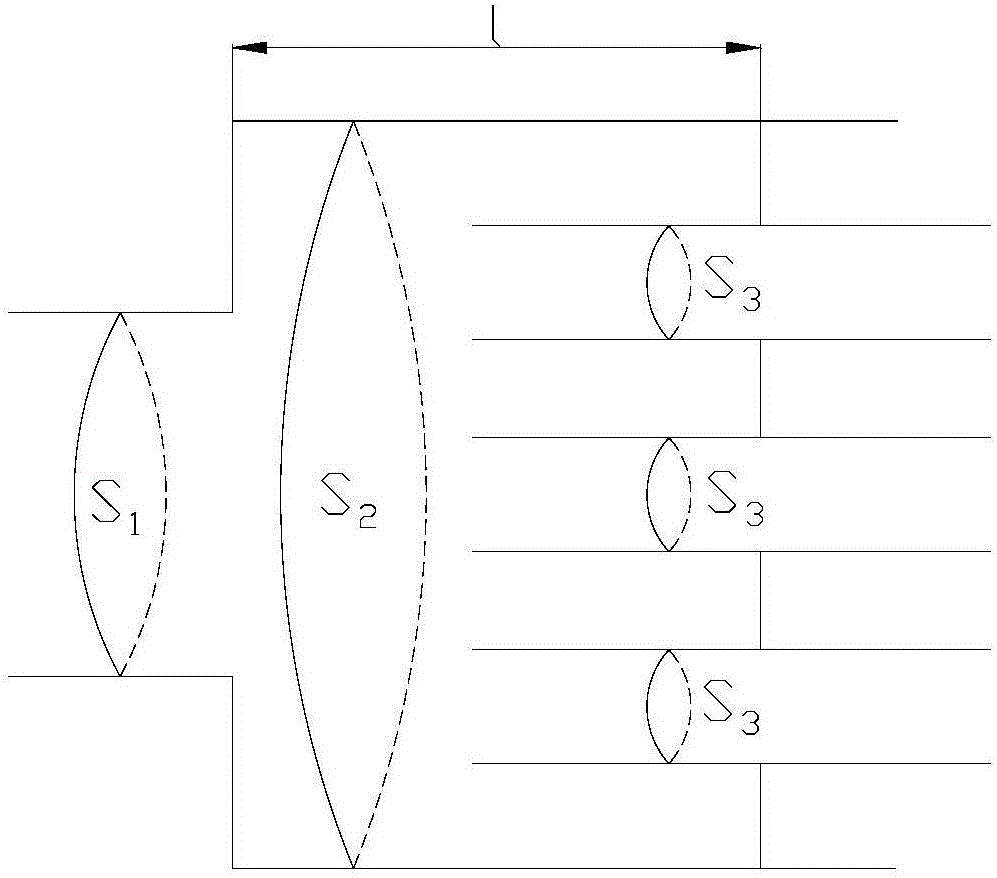

[0015] The given exhaust conditions of the diesel engine are: the cross-sectional area of the exhaust port is 0.28 square meters, the frequency f=800Hz which has a greater impact on the noise in the exhaust frequency, the exhaust sound velocity c=528 m / s, and the exhaust air velocity is 10 m / s, the exhaust flow rate is 13880 cubic meters / hour. Determine the cross-sectional area S of the intake channel of the muffler according to the given conditions 1 , the cross-sectional area of the expansion chamber S 2 , Exhaust channel cross-sectional area S 3 And the expansion chamber length l.

[0016] Step 1: Determine the cross-sectional area S of the intake channel of the muffler 1 . Take the cross-sectional area of the exhaust port of the diesel engine as the cross-sectional area of the intake channel of the muffler, that is

[0017] S 1 =0.28m 2

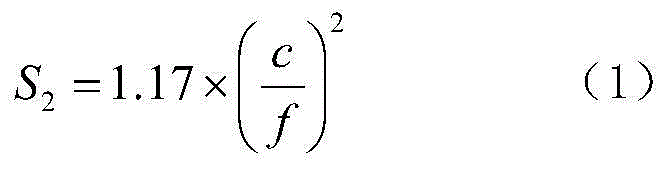

[0018] Step 2: Determine the cross-sectional area S of the expansion chamber of the muffler 2 . Substitute the relevan...

Embodiment 2

[0029] The given exhaust conditions of the diesel engine are: the cross-sectional area of the exhaust port is 0.05 square meters, the frequency f = 800Hz where the exhaust frequency has a greater influence on the noise, the exhaust sound velocity c = 229 m / s, and the exhaust air velocity is 10 m / sec, the exhaust flow is 7770 cubic meters per hour. Determine the cross-sectional area S of the intake channel of the muffler according to the given conditions 1 , the cross-sectional area of the expansion chamber S 2 , Exhaust channel cross-sectional area S 3 And the expansion chamber length l.

[0030] Step 1: Determine the cross-sectional area S of the intake channel of the muffler 1 . Take the cross-sectional area of the exhaust port of the diesel engine as the cross-sectional area of the intake channel of the muffler, that is

[0031] S 1 =0.05m 2

[0032] Step 2: Determine the cross-sectional area S of the expansion chamber of the muffler 2 . Substitute the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com