Reactive muffler for engineering machine

A technology for resistant noise reduction and construction machinery, which is applied in the direction of mechanical equipment, machines/engines, noise reduction devices, etc., can solve problems such as insignificant sound absorption effects, achieve reasonable flow direction, increase noise reduction, and increase passage area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

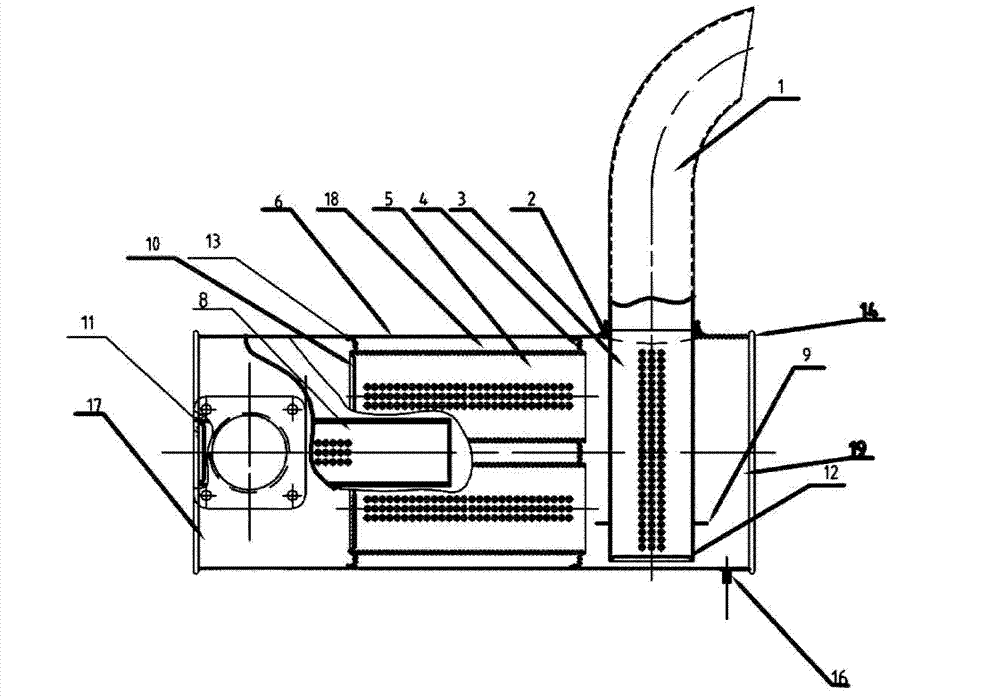

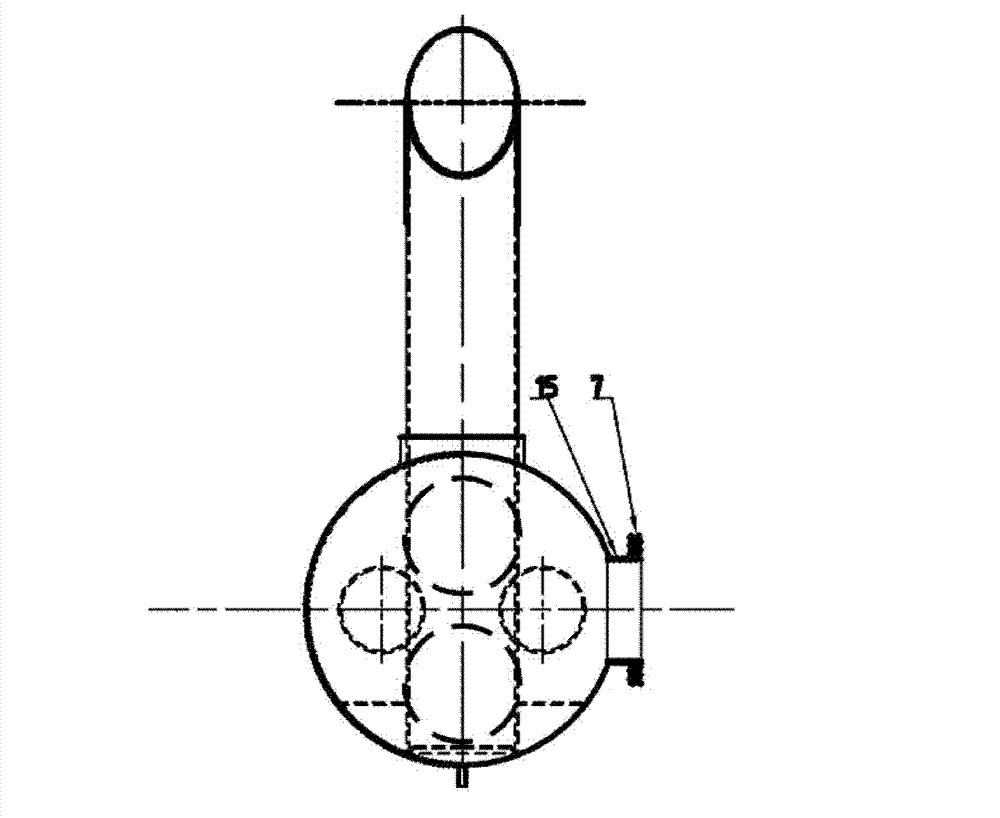

[0017] Such as figure 1 , figure 2 As shown in , the resistant muffler for construction machinery includes a flange 7, a connecting pipe 15, a cylinder body 6, and a smoke exhaust pipe 1, and the cylinder body 6 is provided with a front partition 4 and a rear partition 13, The cylinder body 6 is divided into chamber I17, chamber II18, and chamber III19 in sequence; the connecting pipe 15 and the exhaust pipe 1 are vertically connected with the cylinder body 6, and the exhaust pipe 1 is arranged on the cylinder body through the exhaust pipe seat 2 6; the connecting pipe 15 and the smoke exhaust pipe 1 are vertically intersected in space, and the connecting pipe 15 and the smoke exhaust pipe 1 communicate with the chamber I17 and the chamber III19 respectively; the flange 7 is connected with the chamber I17 through the connecting pipe 15 There are two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com