Hydrogen making apparatus using high concentrated organic wastewater and its hydrogen making method

A technology for organic wastewater and hydrogen production equipment, applied in fermentation, anaerobic digestion treatment and other directions, can solve the problems of unsuitability for large-scale industrial production, low shock load resistance, low biological holding capacity, etc., and achieve significant economic benefits and Social benefits, strong shock load resistance, and high biological holdings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

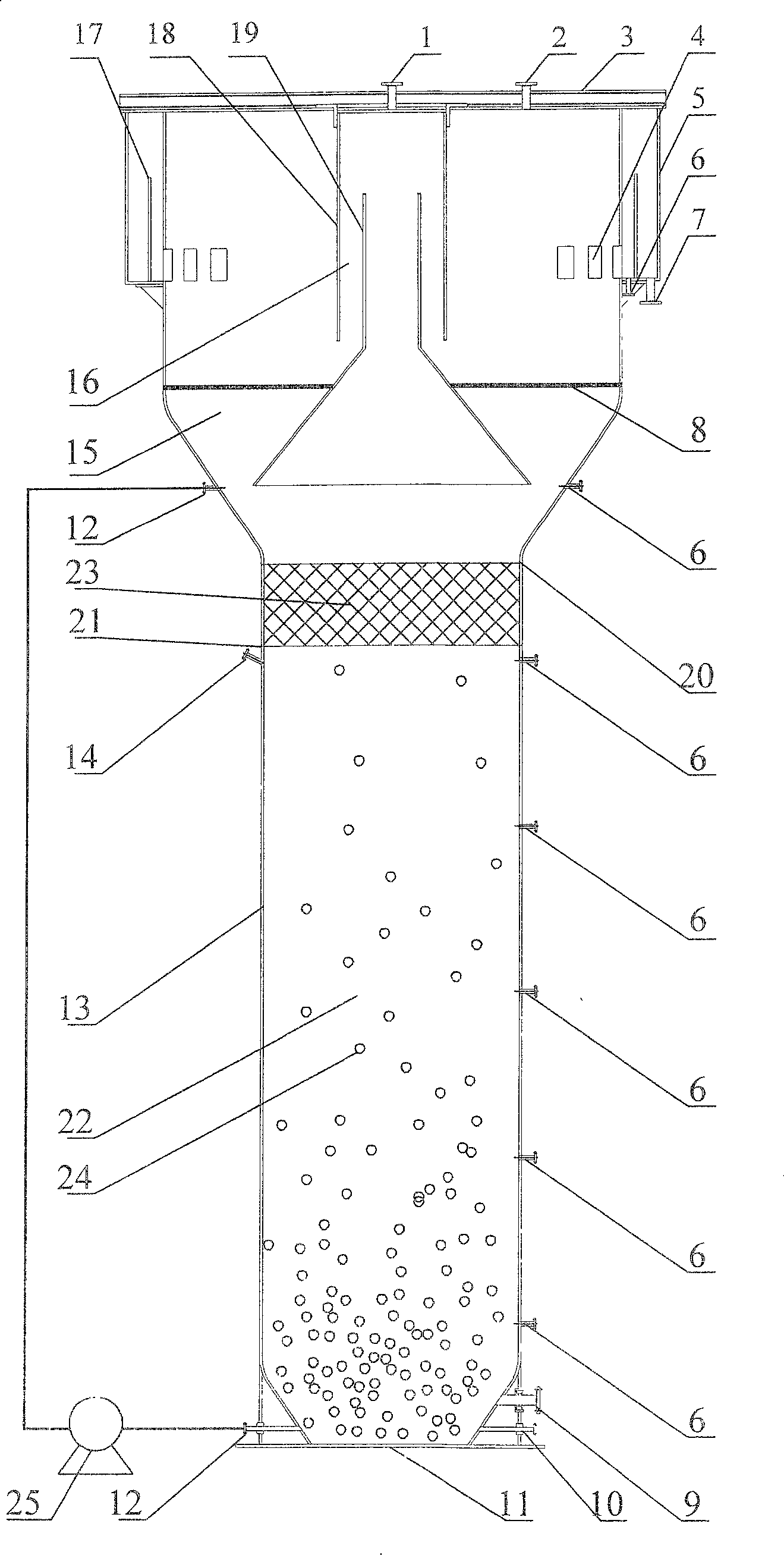

[0013] Embodiment 1: Combining figure 1 This embodiment is described. This embodiment consists of a first exhaust pipe 1, a second exhaust pipe 2, an upper cover plate 3, an outer cylinder wall 5, a sampling pipe 6, a water outlet pipe 7, a rectifying cylinder 18, and a three-phase separator 19. , bracket 8, cylinder wall 13, water inlet pipe 9, external circulation pipeline 12, vent pipe 10, bottom plate 11, temperature sensor 14, water outlet guide plate 17, upper bracket 20, lower bracket 21, filter material layer 23 and reaction The outer cylinder wall 5 is arranged on the outer wall of the upper part of the cylinder wall 13, the bottom end of the outer cylinder wall 5 is connected with the outer wall of the cylinder wall 13, and the outer cylinder wall 5 is connected with the outer wall of the cylinder wall 13. A guide hole 4 is opened, and a water outlet guide plate 17 is arranged in the cavity between the outer cylinder wall 5 and the cylinder wall 13. The upper ends of...

specific Embodiment approach 2

[0016] Embodiment 2: The filter material layer 23 in this embodiment is longitudinally fixed in the upper bracket 20 and the lower bracket 21 by corrugated plates. Water flows from the gaps between the corrugated plates.

specific Embodiment approach 3

[0017] Embodiment 3: In this embodiment, the distances between the sampling tubes 6 on the outer wall of the right cylindrical wall 13 are set at the same height.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com