Novel aluminum alloy mixing pin

A stirring needle, aluminum alloy technology, applied in metal processing equipment, non-electric welding equipment, welding equipment and other directions, can solve problems such as the inability to achieve aluminum alloy plate welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

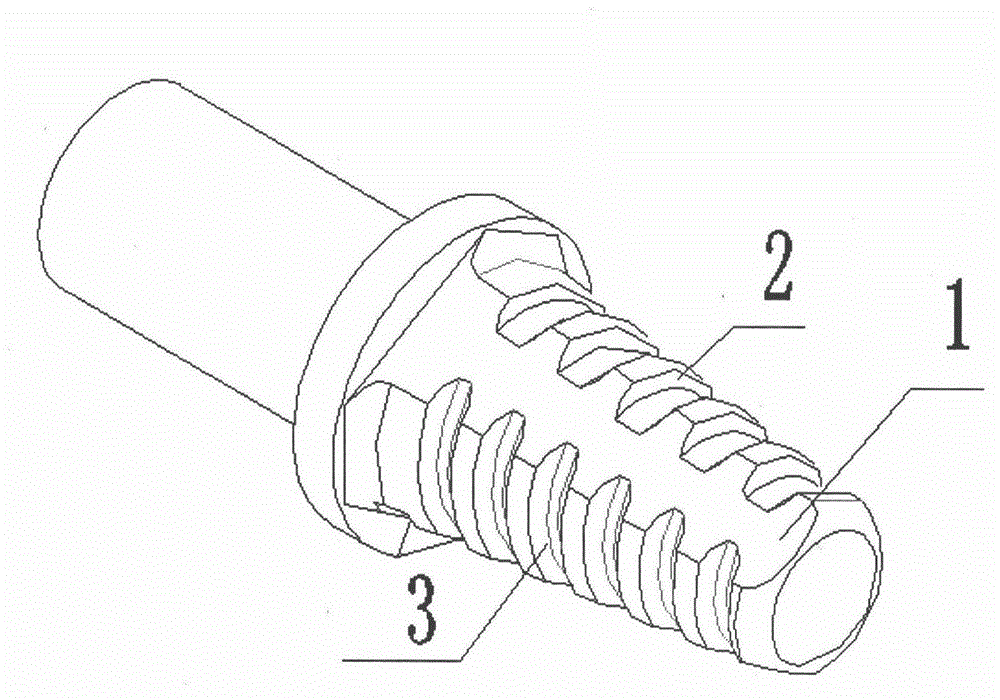

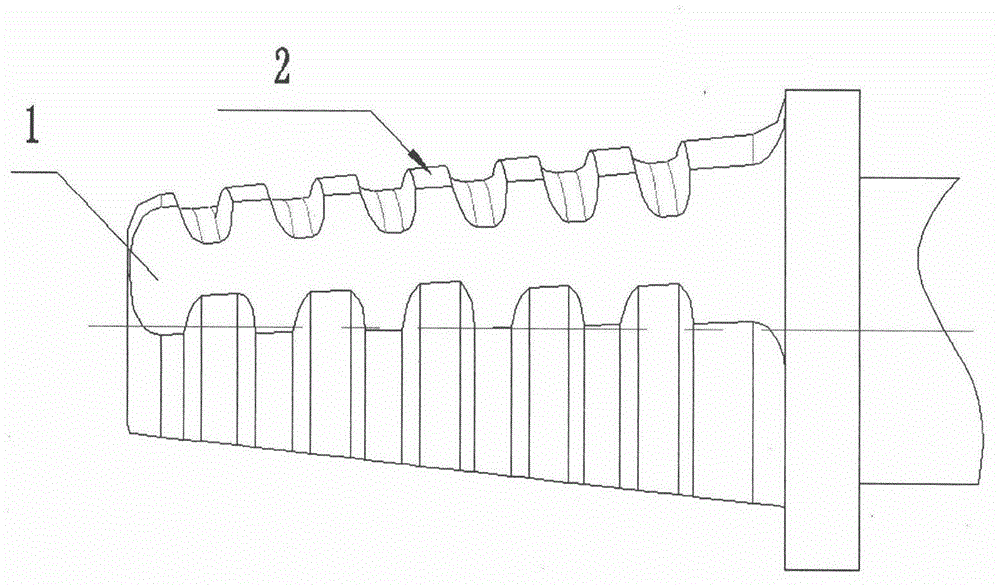

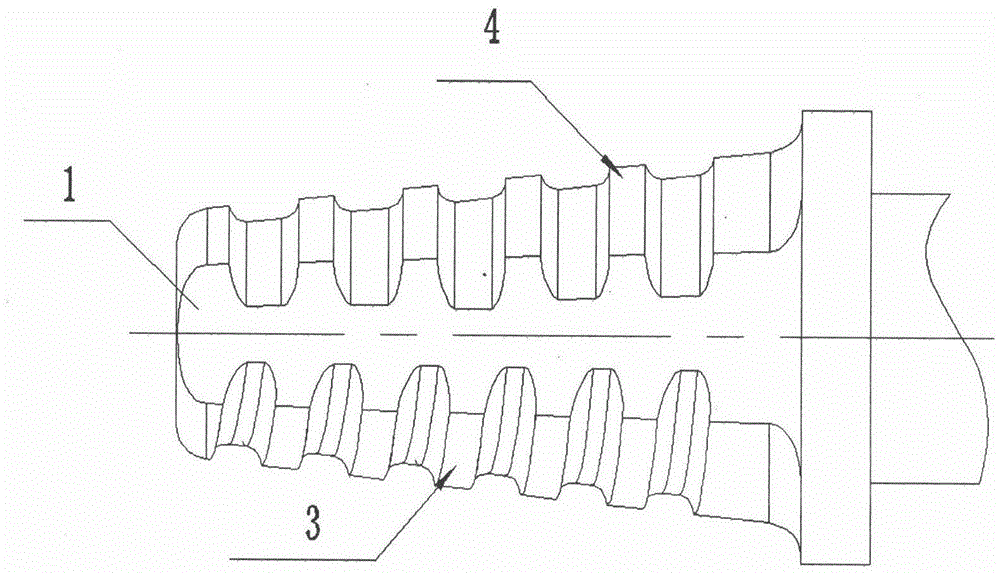

[0016] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention provides a novel aluminum alloy stirring needle, including a conical stirring needle 1, and the conical surface of the conical stirring needle is provided with a multi-handed helix.

[0017] There are 3 straight edges 111, 112, 113 evenly distributed on the conical surface of the conical stirring needle, and 3 conical surfaces, 121, 122, 123, and the helical lines of different rotation directions are respectively arranged on the 3 conical surface edges , which are right-handed helix 2, left-handed helix 3 and circular helix 4, respectively.

[0018] The role of the stirring needle is to generate heat through rotating friction to provide the heat required for welding, and to drive the flow of materials around the stirring needle to form a weld; the shape of the stirring needle is crucial to the stir welding technology, which determines the heating and plasticity of the material flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com