High-temperature high-pressure steam/gas discharge composite silencer

A gas emission, high temperature and high pressure technology, applied in the direction of sounding equipment, instruments, etc., can solve the problems of low noise reduction, large installation space, poor safety, etc., and achieve the effects of large noise reduction, convenient maintenance and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

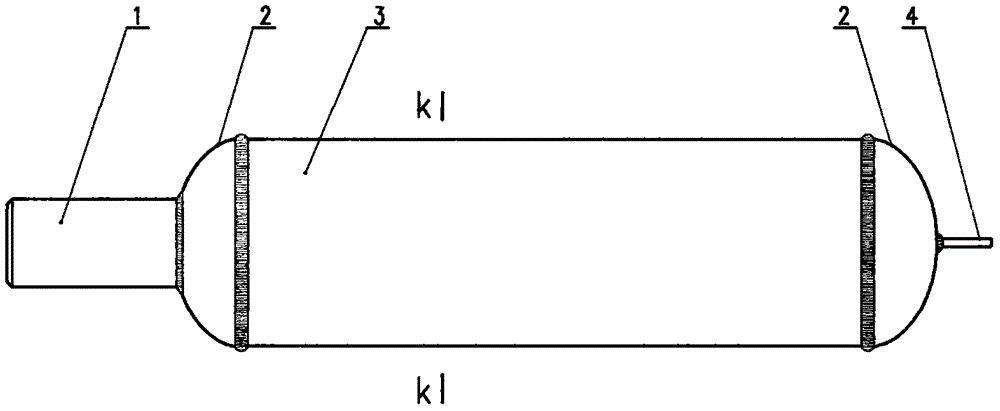

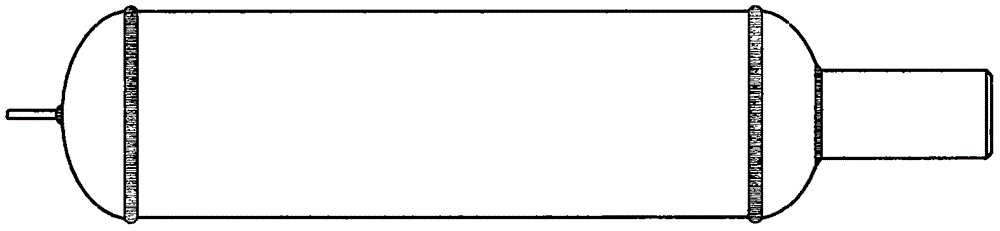

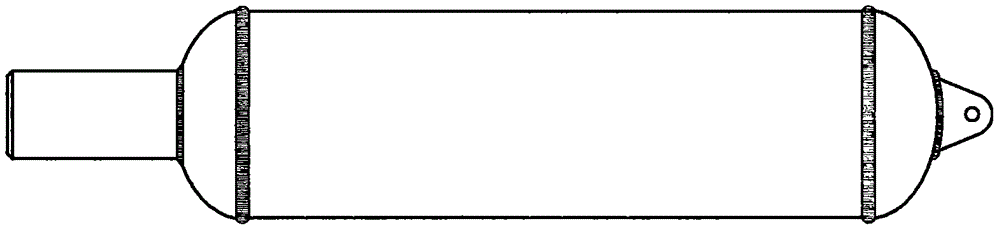

[0066] exist figure 1 , Figure 8 In the shown embodiment, include and be provided with: the two ends of spraying outer cylindrical body armor (3) respectively are welded with oval head armor (2); One end of oval head armor (2) is welded with The joint throttle tube A (1) of the pipe end plate A (7) and the other end of the elliptical head A (2) are welded with lifting lug A (4); On the interface throttle tube A (1) of the inner cavity of the piece (3), there is welded a plugging ring plate A with a throttle and decompression tube A (6) and a tube end plate B (8) respectively. (5); The above-mentioned associated components are respectively the first complete set of products that are firmly welded and integrated with their manufacture.

[0067] exist Figure 9 , Figure 14 , Figure 16 In the shown embodiment, include and be provided with: the two ends of injection outer cylinder body B (11) are respectively welded with elliptical head B (10); One end of elliptical head B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com