Paralleling varied deep secondary back cavity micro-perforated pipe silencer

A technology of micro-perforation and equal depth, which is applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., which can solve the problems of poor noise reduction effect and achieve the effect of large noise reduction, wide application field and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

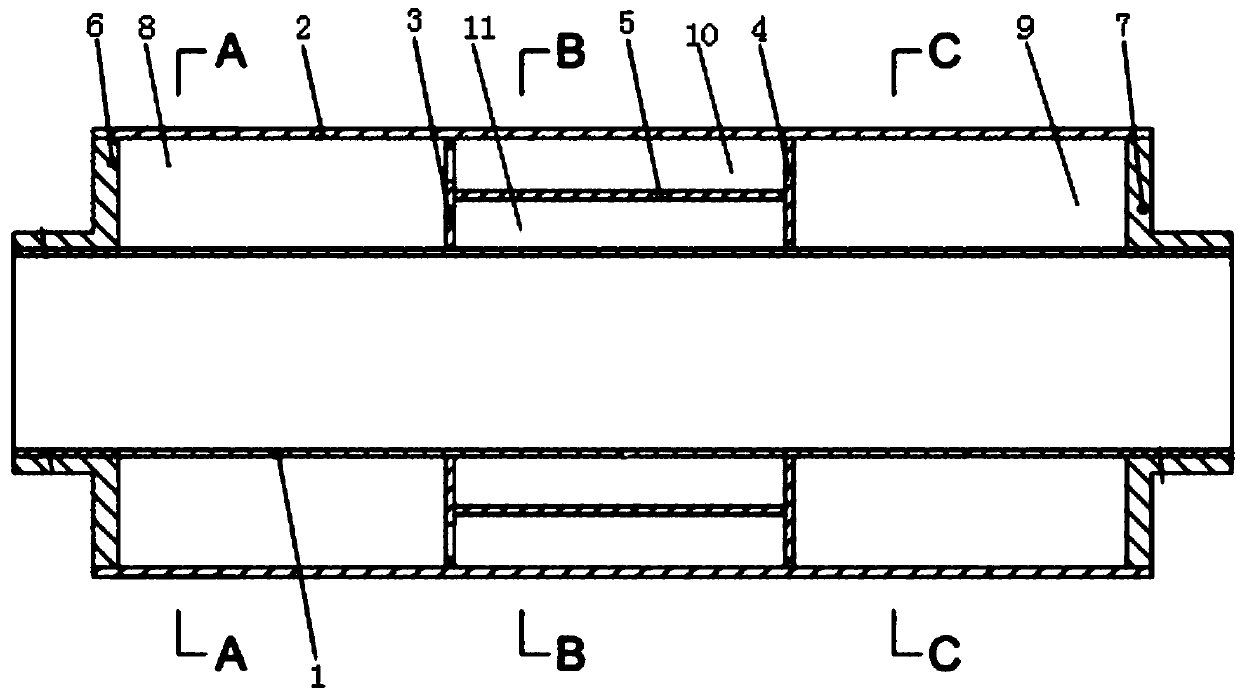

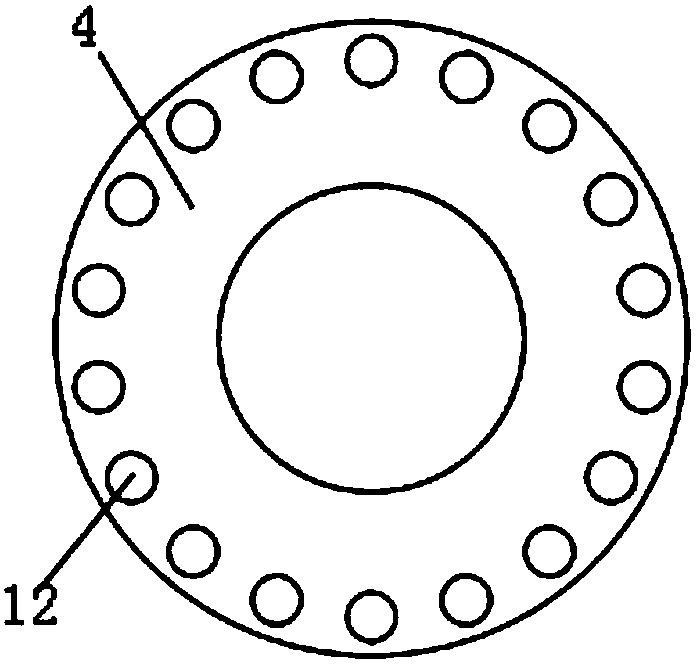

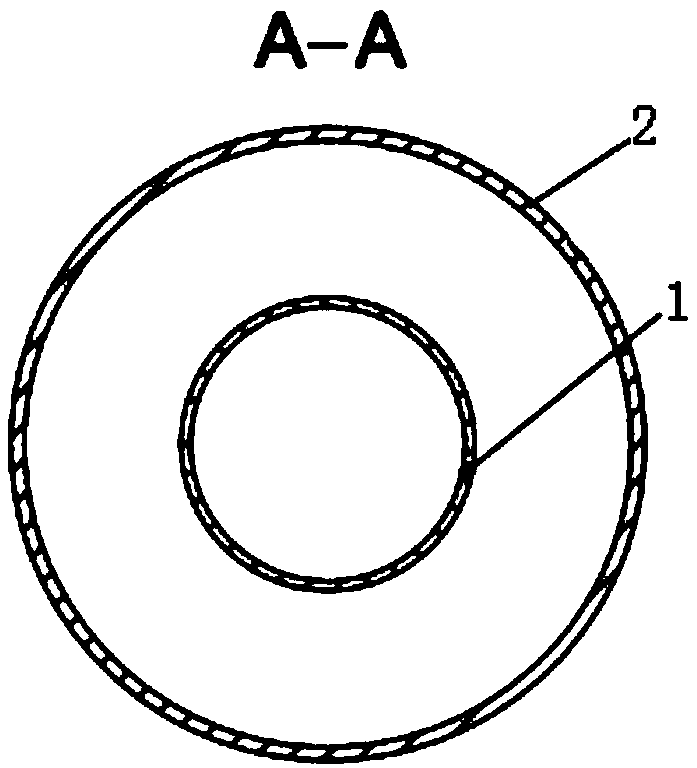

[0026] The wall thickness of the micro-perforated tube is 0.7 mm, and the axial lengths of the front tube body, the middle tube body and the rear tube body are all 70 mm. The diameter of the straight-through microholes on the front tube body is 0.7mm, the perforation rate is 1.6%, the holes are arranged in a square shape, the distance between the holes is 4.9mm, the depth of the front cavity is 18mm, and the depth of the upper cavity is 8mm. The diameter of the communicating hole is 5mm. The diameter of the straight-through microholes on the middle tube body is 0.5mm, the perforation rate is 0.97%, the holes are arranged in a square shape, the distance between the holes is 4.5mm, and the depth of the lower cavity is 9mm. The diameter of the through microholes on the back pipe body is 0.7mm, the perforation rate is 2%, the holes are arranged in a square, the distance between the holes is 4.4mm, and the depth of the back cavity is 18mm. This embodiment has a good noise reductio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com