Broadband multi-cavity resonance-type air intake muffler and working method thereof

A technology of intake muffler and working method, which is applied in the field of vehicle parts, can solve the problems of large volume, narrow muffler frequency band, and difficult installation, and achieve the effect of small volume, small intake back pressure, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

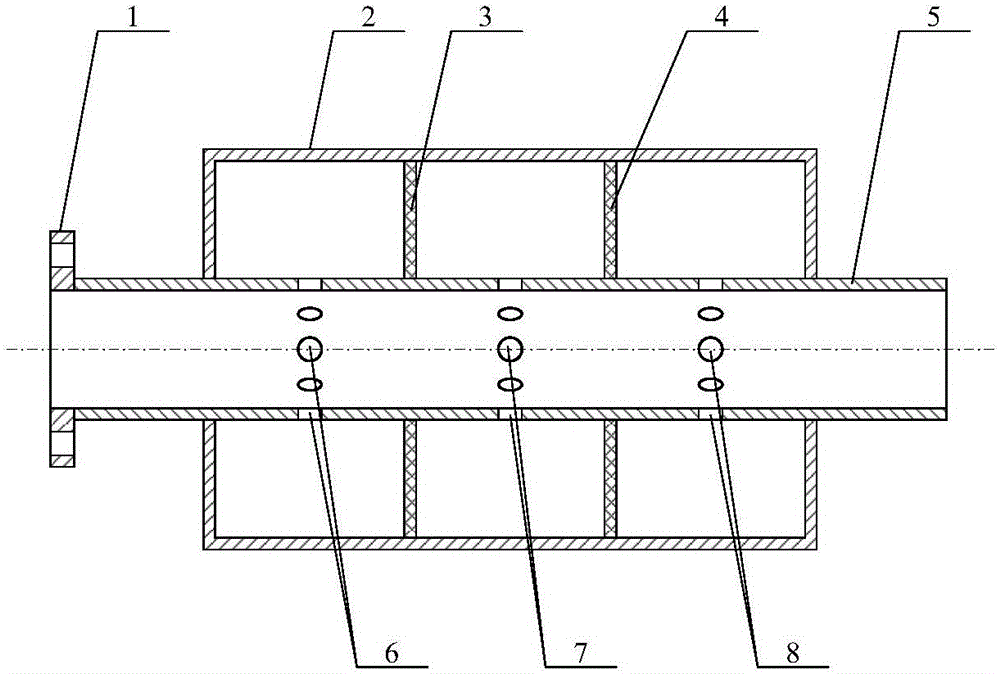

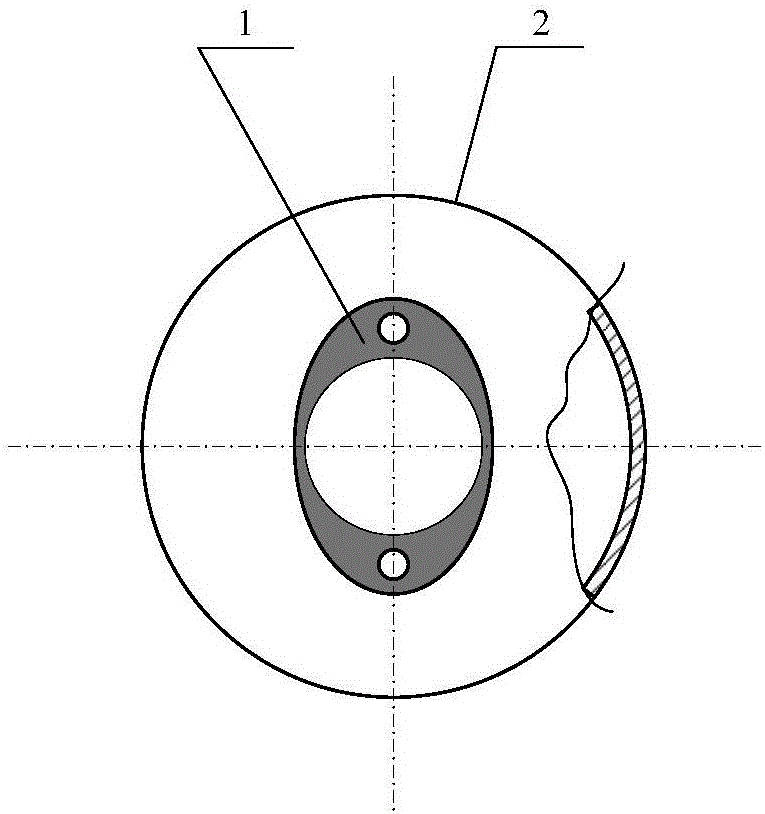

[0036] Such as figure 1 and figure 2 As shown, an embodiment of the present invention includes connecting flange 1, flange 1 is welded with perforated pipe 5, perforated pipe 5 is welded with cylindrical muffler shell 2, and the first weld between the left side of muffler shell 2 and perforated pipe 5 Cavity partition 3; the second chamber partition 4 is welded between the right side of the muffler shell 2 and the perforated pipe 5; the left part of the perforated pipe 5 is circumferentially arranged with the first chamber muffler through-hole 6; the middle part of the perforated pipe 5 The second chamber muffler through-holes 7 are arranged circumferentially; the third chamber muffler through-holes 8 are arranged circumferentially on the right side of the perforated pipe 5 .

[0037] In this embodiment, the intake muffler housing 2, the first chamber partition 3 and the perforated pipe 5 constitute the first resonance chamber of the intake muffler; the muffler housing 2, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com