Pipe blowing silencer

A muffler and muffler technology, applied in the direction of pipe components, pipes/pipe joints/pipe fittings, components of steam boilers, etc., can solve the problems of rust inclusions, short service life, deformation of mufflers, etc., and achieve good noise reduction and use Long life and large noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

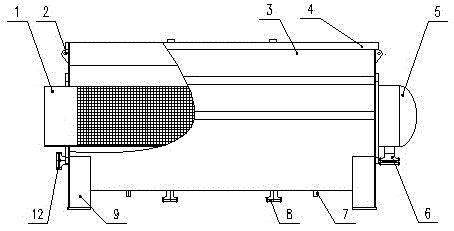

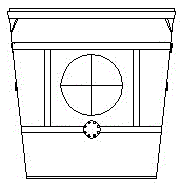

[0024] The blowpipe muffler is generally installed in an outdoor open area. The inlet connecting pipe 1 is connected to the incoming steam pipe. The muffler support 9 is placed flat on the prefabricated cement on the flat ground. The support 9 and the platform generally do not need to be fixed forcibly, allowing the muffler to expand freely. The four corners of the upper part of the muffler are fixed on the surrounding ground anchors or counterweights with pulleys.

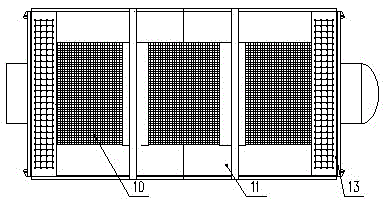

[0025] After each use of the muffler, the internal sundries must be cleaned up, especially the sundries in the round hole of the main pipe. The sundries in the outer muffler chamber can be cleaned through the sundry observation hole 12 with a small tool to eliminate the noise. The debris on the chamber 10 holes must also be cleaned up for safe use next time.

[0026] After the muffler is used every time, the 5 end of the muffler with head can be raised, so that the water collected inside the muffler will be discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com