Ball mill acoustic hood noise control method

A technology for noise control and sound insulation cover, which is applied to sound equipment, special data processing applications, instruments, etc., can solve the problems of single material and difficult noise control effect of ball mill, and achieves technical requirements, remarkable sound insulation effect and economic benefits. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with examples.

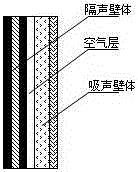

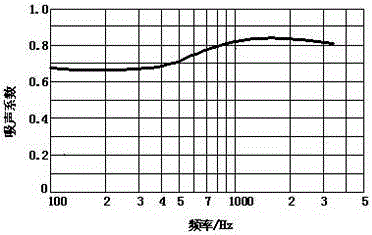

[0020] The present invention takes the motor and reducer of the ball mill as the research object. After analyzing the noise characteristics of the ball mill, it proposes a noise reduction scheme in which a sound insulation cover is installed outside the motor as the main noise reduction means. Based on the meta-model, the noise-reducing effect of the sound-insulating enclosure adopting the broadband compound sound-absorbing structure is analyzed, and the deficiency of the noise-reducing effect in some areas of the sound-insulating enclosure of this structure is pointed out. According to the measured noise signal, its frequency spectrum is analyzed to determine the main frequency of the noise.

[0021] 1 Design of sound insulation cover: After the actual test and analysis on the ball mill site, it can be known that the main factor causing environmental noise pollution around the ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com