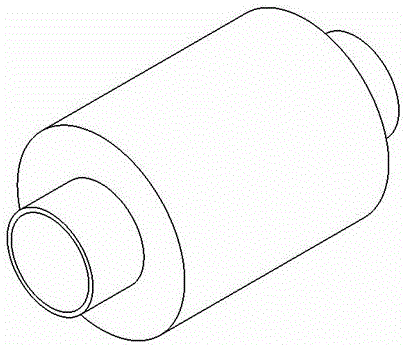

Multi-cavity direct-through dual-layer perforating silencer capable of eliminating wide-band noise

A muffler, double-layer technology, applied in the direction of intake muffler, machine/engine, pipe/pipe joint/pipe fitting, etc. The effect of compact structure and large noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

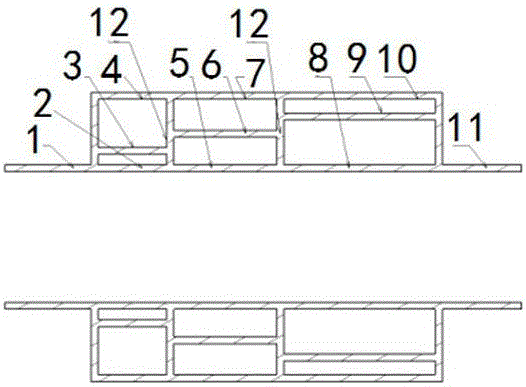

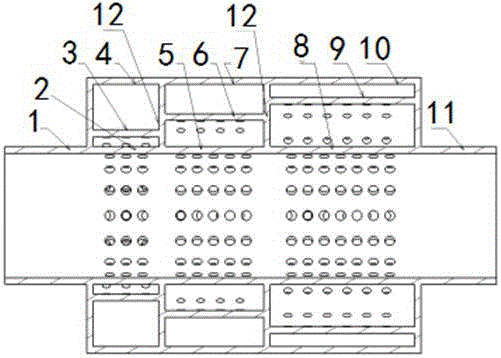

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: The parameters of the multi-cavity inserted tube-type double-layer perforated muffler for eliminating supercharged intake broadband noise are shown in Table 1:

[0038]

[0039] The transmission loss of this muffler is as Figure 4 As shown, the noise reduction frequency range of the example muffler is approximately 1500-3500Hz, and the noise reduction amplitude is relatively high. The total length is only 100mm, the outer diameter is 80mm, and the structure is compact, which is very suitable for broadband noise control of the supercharged intake system.

Embodiment 2

[0040] Embodiment 2: The parameters of the multi-cavity inserted tube-type double-layer perforated muffler used to eliminate the broadband noise of pressurized air intake, other parameters remain unchanged, only the length ratio of each double-layer perforated tube is changed, as shown in Table 2 :

[0041]

[0042] Such as Figure 5 Shown is the effect of each cavity length ratio on the acoustic performance of the muffler. The length of the cavity is kept at 100mm, and the porosity of the middle cavity is kept at 10%. It can be seen that the length of the cavity has a great influence on the transmission loss amplitude and peak frequency of the muffler. In actual engineering design, a reasonable matching design is required to obtain Ideal muffler acoustics.

Embodiment 3

[0043]Embodiment 3: The parameters of the multi-cavity inserted tube-type double-layer perforated muffler used to eliminate the broadband noise of pressurized air intake are unchanged, and only the porosity ratio of each double-layer perforated tube is changed, as shown in Table 3. Show:

[0044]

[0045] Such as Figure 6 Shown is the effect of the porosity ratio of each cavity on the acoustic performance of the muffler. The length of the cavity is kept at 100mm, and the length of each double-layer perforated tube is 40mm; The ideal acoustic characteristics of the muffler can only be obtained through reasonable matching design.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com