Novel silencing device

A muffler device and a new type of technology, applied in muffler devices, engine components, machines/engines, etc., can solve the problems of large pressure loss and small transmission loss of mufflers, and achieve small pressure loss, small exhaust resistance, and reduced exhaust gas. The effect of air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

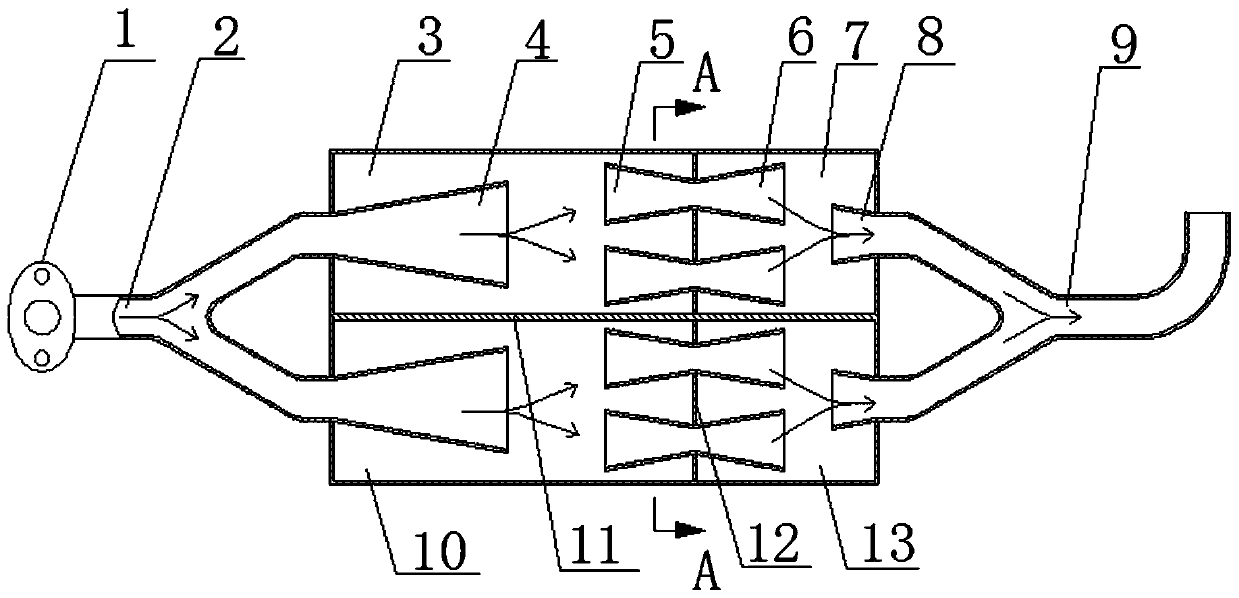

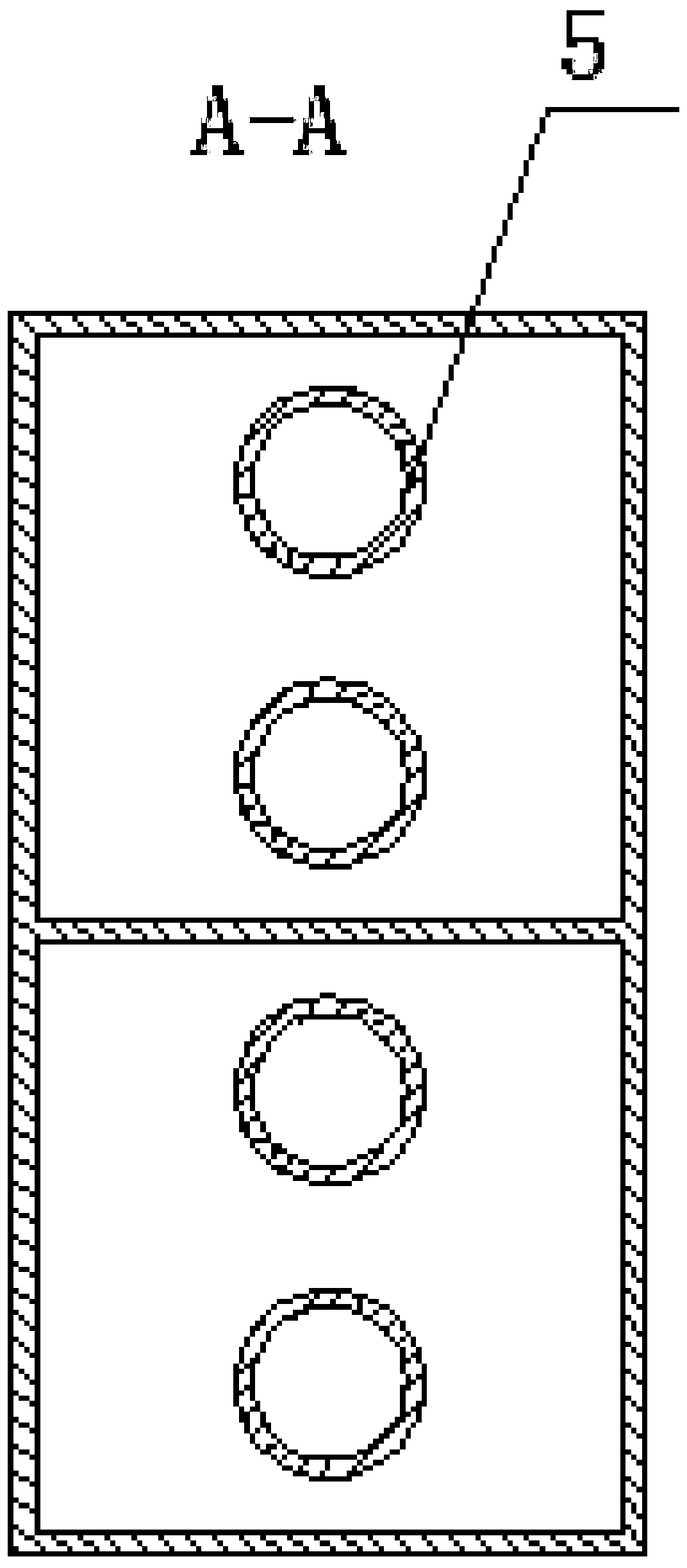

[0024] refer to Figure 1-2 , a new type of muffler device, which is composed of two square mufflers with the same shape and size connected in parallel. A perforated plate 12 with micro holes is used inside the two mufflers to separate the muffler into a first chamber and a second chamber. The perforated plate 12 There is an asbestos layer on the surface, and through holes are evenly distributed on the perforated plate. and the noise reduction after the second chamber muffler, thereby increasing the noise reduction effect of the muffler. The sectional view of the muffler is composed of two square mufflers (such as figure 2 shown).

[0025] The inner cavity of the first chamber is provided with a mesh plate 11, and the first chamber is divided into the first upper chamber 3 and the first lower chamber 10 by the mesh plate 11, and the flange 1 is respectively connected to the first lower chamber 3 through the air inlet pipe 2. The first upper chamber 3 and the first lower ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com