Muffler based on sound ray deflection theory

A muffler and sound ray technology, which is applied in the direction of mufflers, machines/engines, engine components, etc., can solve the problems of noise and noise, and the effect cannot be exerted, so as to increase the temperature gradient, improve the sound absorption coefficient, and increase the sound absorption volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

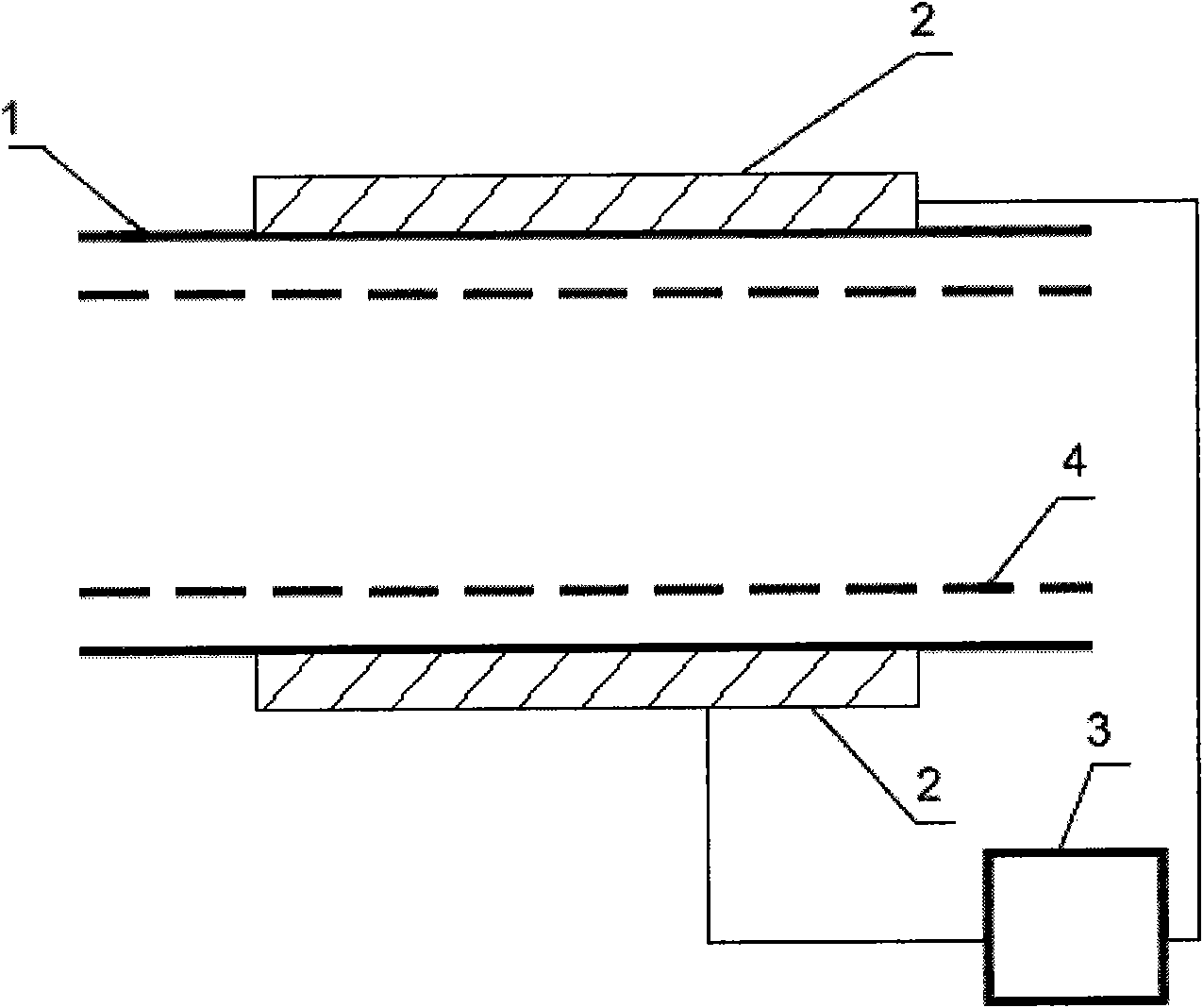

[0066] refer to Figure 4 , the muffler with low-temperature refrigeration system based on the sound ray deflection theory made in this embodiment, utilizes an existing muffler, and fixes a layer of sound-absorbing material and structure 4 on the inner wall of the shell 1 of the muffler, and in the muffler A low-temperature refrigeration system 2 is arranged on the outer wall of the shell 1. A layer of 100mm thick ice layer 2' is coated on the outer wall of the shell 1 of the muffler as a low-temperature refrigeration system 2, and then a layer of composite sound-absorbing structure is laid on the inner wall of the shell 1 of the muffler, for example, a composite layer is used on the surface The sound-absorbing cotton tube bundle micro-slit perforated plate resonant sound-absorbing device, the thickness of the sound-absorbing material or the sound-absorbing structure 4 is 1000 mm, which can be implemented by those skilled in the art. On the basis of covering the casing 1 of t...

Embodiment 2

[0080] refer to Figure 7 The muffler with a low-temperature refrigeration system based on the deflection theory of sound rays produced in this embodiment is composed of a muffler shell 1, a low-temperature refrigeration system 2, a temperature control device 3, and a sound-absorbing material or sound-absorbing structure 4. In the muffler A low-temperature refrigeration system 2 is installed on the outer wall of the housing 1, and the refrigeration system adopts a compressor for refrigeration, wherein the refrigeration system is composed of a compressor 10, a condenser 11, an evaporator 12, and a liquid storage dryer 5. The temperature control device 3 is a temperature control device commonly used in this profession, that is, the temperature control device 3 is composed of an expansion valve 6, a capillary temperature bulb 7, and a refrigeration piping system. The evaporator is wound on the outer wall of the muffler pipe to absorb heat, and the quantitative control of the temp...

Embodiment 3

[0083] refer to Figure 8 The muffler with a low-temperature refrigeration system based on the deflection theory of sound rays produced in this embodiment is composed of a muffler shell 1, a low-temperature refrigeration system 2, a temperature control device 3, and a sound-absorbing material or sound-absorbing structure 4. In the muffler A low-temperature refrigeration system 2 is installed on the outer wall of the housing 1. The low-temperature refrigeration system in this embodiment adopts semiconductor refrigeration, wherein the semiconductor refrigeration system is composed of insulating ceramic sheets 13, metal conductors 14, N-type and P-type semiconductors 15, and a DC power supply 16. The temperature The control device 3 can adopt conventional cooling fins, fans, or air cooling, water cooling and other methods to control heat dissipation. The semiconductor refrigeration patch is pasted on the outer wall of the muffler pipe, and the quantitative control of the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com