Customized built-in anti-blockage denoising device for natural gas pipeline

A natural gas pipeline, anti-blocking technology, applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of difficult to guarantee noise reduction effect, ice blockage and blockage, and affect flow, so as to reduce the outward transmission The effect of reducing noise and avoiding eddy current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

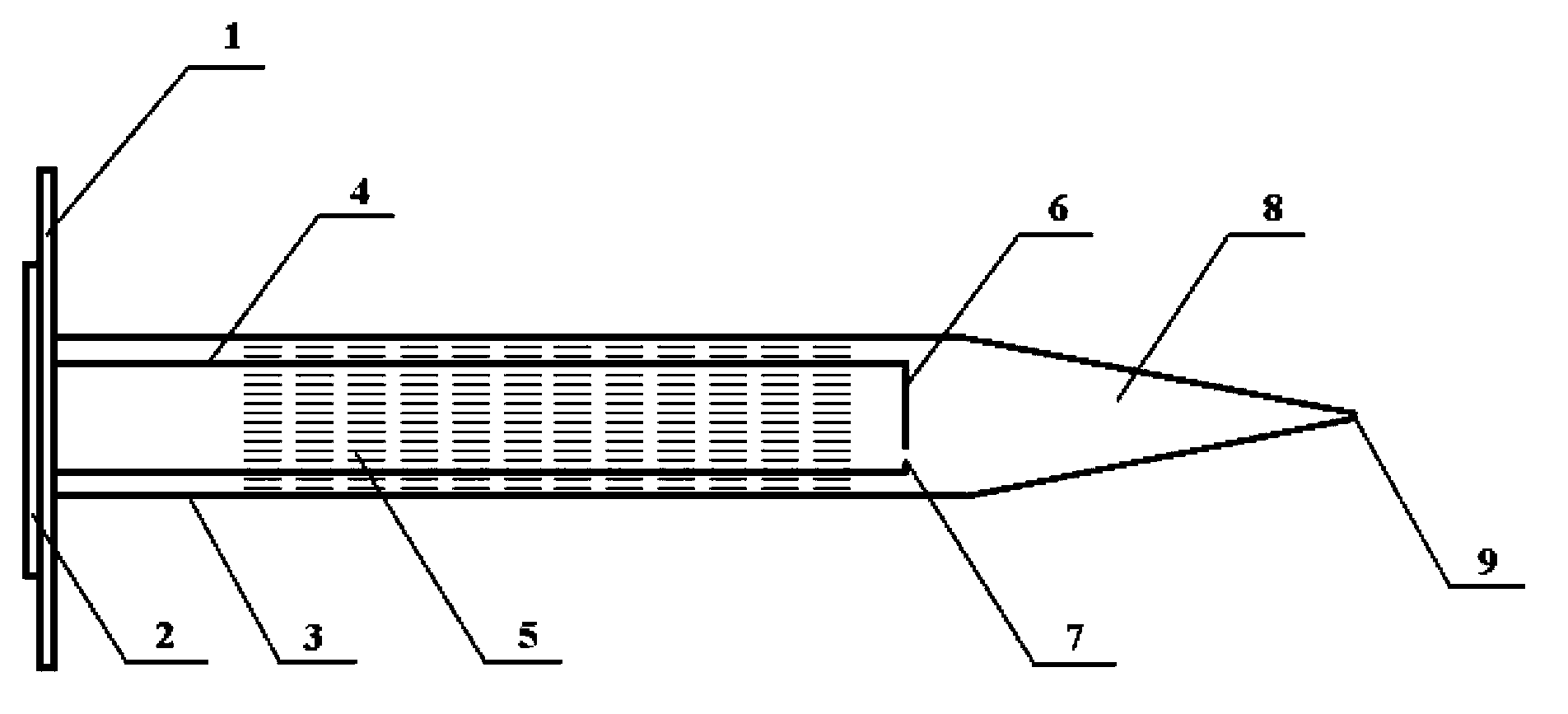

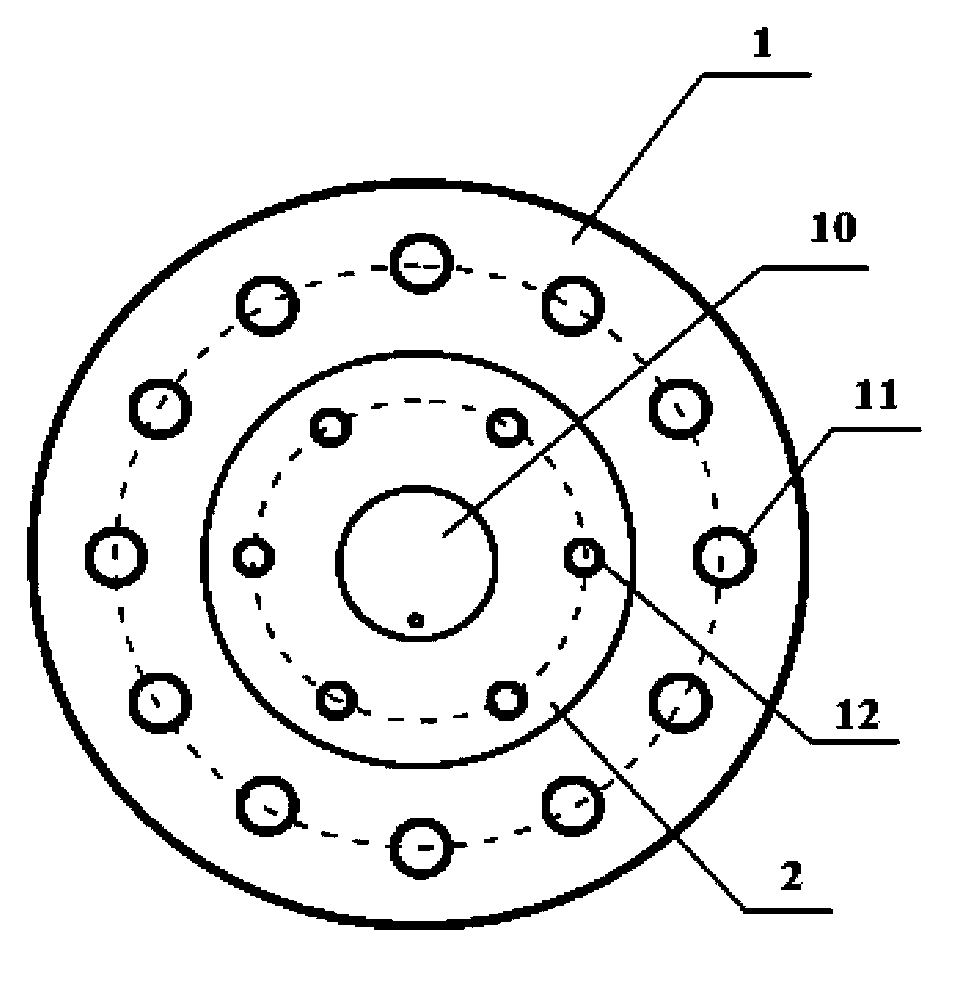

[0029] Embodiment. The specific embodiment of the present invention is described with this example and the present invention is described further. This example is an experimental prototype, its composition is as follows Figure 1-Figure 4 shown.

[0030] The structure of this example is as follows Figure 1-Figure 4 As shown, the noise reduction device is composed of the first flange piece 1, the second flange piece 2, the noise reduction outer pipe 3, the noise reduction inner pipe 4, the head 6 and the streamlined fairing 8 through welding and flange connection. to make. The silencing outer pipe 3 with the streamlined fairing 8 is fixedly connected with the first flange 1, the silencing inner pipe 3 with the head 6 is fixedly connected with the second flange 2, and the two are connected through the flange. The air flow first enters the muffler inner pipe 4 through the air delivery hole 10 on the second flange piece 2, enters the muffler outer pipe 3 through the slit 5 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com