Excavator noise reduction boom and excavator

A technology for excavators and booms is applied in the field of excavators to achieve the effect of reducing the cost of the whole machine, large noise reduction and good noise reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation will be described below in conjunction with the accompanying drawings.

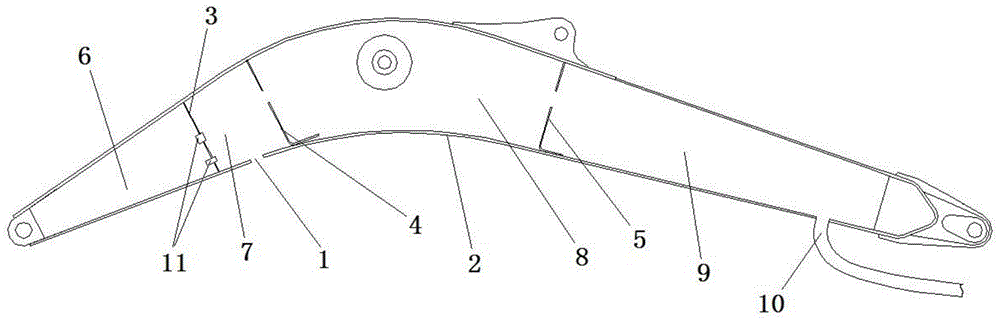

[0022] Such as figure 1 As shown, the sound-absorbing boom of the excavator is similar in external shape to the boom of the transmission excavator. Both the front end and the rear end of the box structure are hinged ends, and the first partition 3, the second partition 4, and the third partition 5 are sequentially arranged in the box structure to connect the inner cavity of the box structure 2 from the rear end to the front end. Separated into a resonant chamber 6, an air inlet chamber 7, an intermediate chamber 8 and an exhaust chamber 9 arranged in sequence. The box structure is provided with an air inlet 1 and an exhaust port 10, the air inlet 1 is used to introduce engine exhaust gas into the air intake cavity, and the exhaust port 10 communicates the exhaust cavity with the outer space of the box structure. On the first partition 3 between the air inlet chamber 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com