Bidirectional vacuum prepressing blowing filling soft soil foundation treatment method

A soft soil foundation and treatment method technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of long drainage path and poor drainage effect, and achieve the goal of increasing reinforcement depth, increasing transmission depth, and saving materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

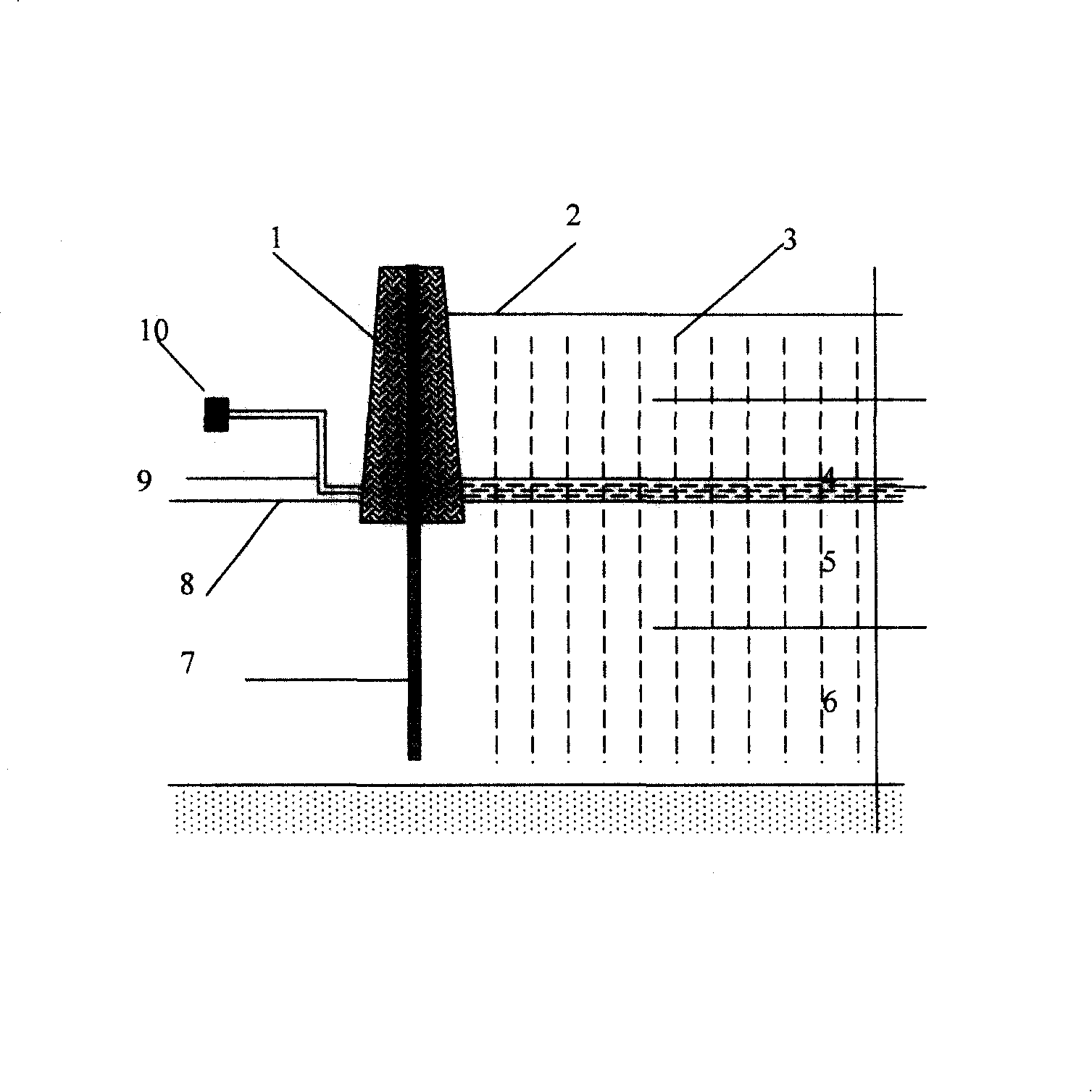

[0017] In conjunction with the accompanying drawings, the two-way vacuum preloading blow-fill soft soil foundation treatment method of the present invention, the steps are as follows:

[0018] Before the filling starts, in conjunction with the construction of the cofferdam 1, a sealing wall 7 is built near the cofferdam 1 such as the lower soil layer, and a vacuum pipe 9 is pre-buried at the bottom of the cofferdam 1 .

[0019] After the construction of the cofferdam 1 is completed, the accumulated water in the cofferdam 1 is drained, and a layer of sand cushion 5 is laid. The vacuum pipe 9 at the bottom is connected, and finally a layer of geotextile is laid on the sand cushion 5 .

[0020] On the sand cushion 5 and the geotextile, the plastic drainage board (3) is set up in the lower soft soil 6 according to the horizontal spacing, and a section of the drainage board 3 exposed on the ground surface is vertically tied upwards on the moso bamboo frame, and the exposed height i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com