Comprehensive utilization method of powder by-products generated in spray forming process and product application

A spray forming and by-product technology, which is applied in the field of material preparation, can solve storage problems, reduce spray forming efficiency and material utilization, and pollute the environment, and achieve the effects of fewer processes, high raw material utilization, and low preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

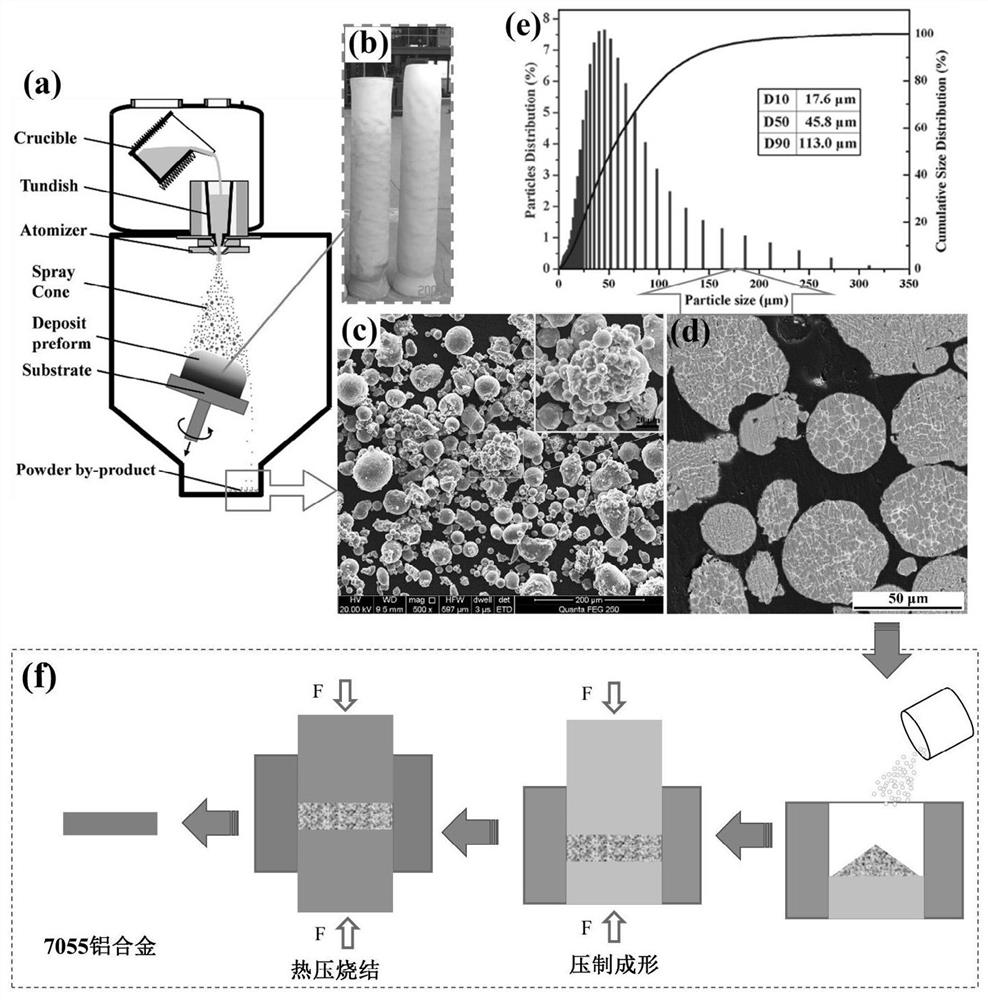

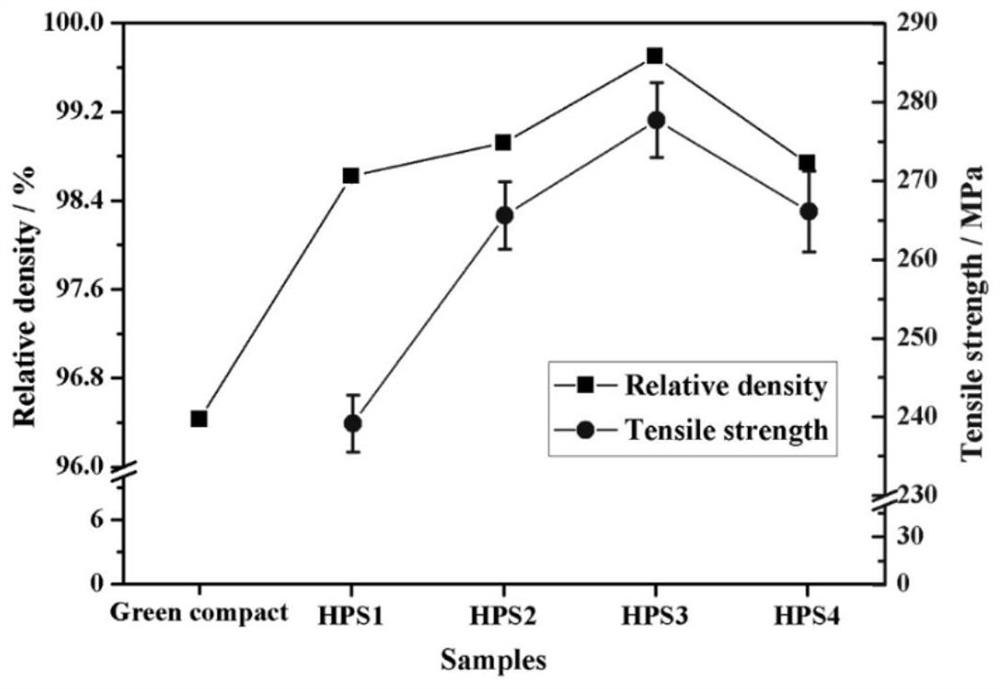

[0033] According to the preparation method of the present invention, the powder by-product produced in the process of spray forming 7055 aluminum alloy is used as raw material (powder morphology and particle size such as figure 1 c-e), its chemical composition meets the composition standard of 7055 aluminum alloy. From figure 1 The morphology of the powder by-products of c can be seen that the powder by-products produced during the spray-forming 7055 aluminum alloy process are significantly different from the commercially available standard 7055 aluminum alloy powders, that is, the fine particles are solidified together or solidified in the Powder cells are formed on the surface of large particles. Subsequently, put the weighed 7055 aluminum alloy powder into the steel mold cavity, and vibrate the mold sleeve to spread the powder in the mold cavity. Then, carry out press forming under the pressure of 400MPa by hydraulic press, make 7055 aluminum alloy green body. Finally,...

Embodiment 2

[0042] For example: using the powder by-products produced in the process of spray forming Al25Si4CuMg alloy as raw material to prepare high-performance Al25Si4CuMg alloy by hot pressing and sintering;

[0043] According to the preparation method of the present invention, the powder by-product produced in the spray forming Al25Si4CuMg alloy process is a raw material (powder appearance such as Figure 4 ), its chemical composition conforms to the composition standard of Al25Si4CuMg alloy. Put the weighed Al25Si4CuMg alloy powder into the steel mold cavity, and vibrate the mold cover to spread the powder in the mold cavity. Then, it is press-formed by a hydraulic press under a pressure of 400MPa to obtain an Al25Si4CuMg alloy green body. Finally, the green body is packed in a graphite mold and sintered and densified in a vacuum hot-press furnace. When the vacuum is pumped to 1×10 -2 When the temperature is 5°C / min, start heating at 5°C / min. When the sintering temperature is 68...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com