Novel self-tapping drill assembling bolt

A combination bolt, a new type of technology, applied in the directions of screws, repair drills, drilling tool accessories, etc., can solve problems such as poor adaptability, achieve high firmness and stability, improve adaptability, and reduce waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

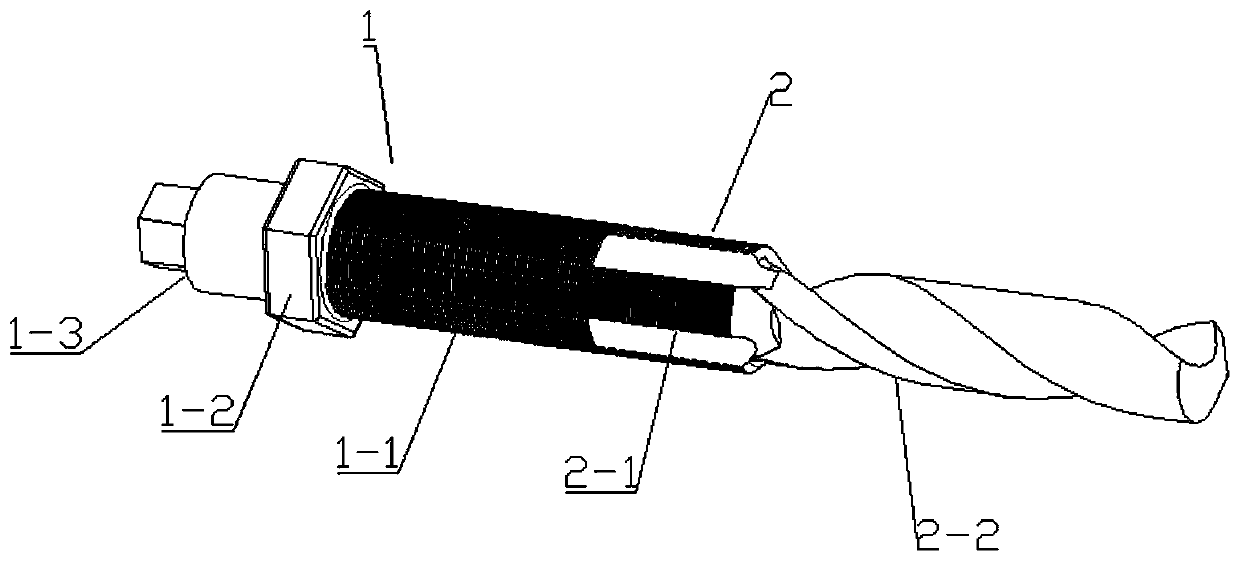

[0033] Such as Figure 1~2 As shown, the present invention is a novel self-tapping drill combination bolt, comprising a fixed bolt 1 and a tapping rod body 2, and the tapping rod body 2 includes an integrally formed tap screw tapping section 2-1 and a drill pipe drilling section 2 -2, the fixing bolt 1 includes a screw 1-1, one end of the screw 1-1 is assembled and connected with the free end of the tap screw tapping section 2-1 on the tapping rod body 2, and the other end of the screw 1-1 is fixed A hex nut 1-2 and a first connector 1-3 extending along the length direction of the screw rod 1-1 are provided; the end of the first connector 1-3 is set as a polygonal prism structure suitable for drilling equipment, Alternatively, the free end surface of the first connector 1-3 is provided with a third installation slot 1-3-1 suitable for drilling equipment; The thread segment 2-1 taps the external thread that matches the threaded slot.

[0034] As a preference, a first installa...

Embodiment 2

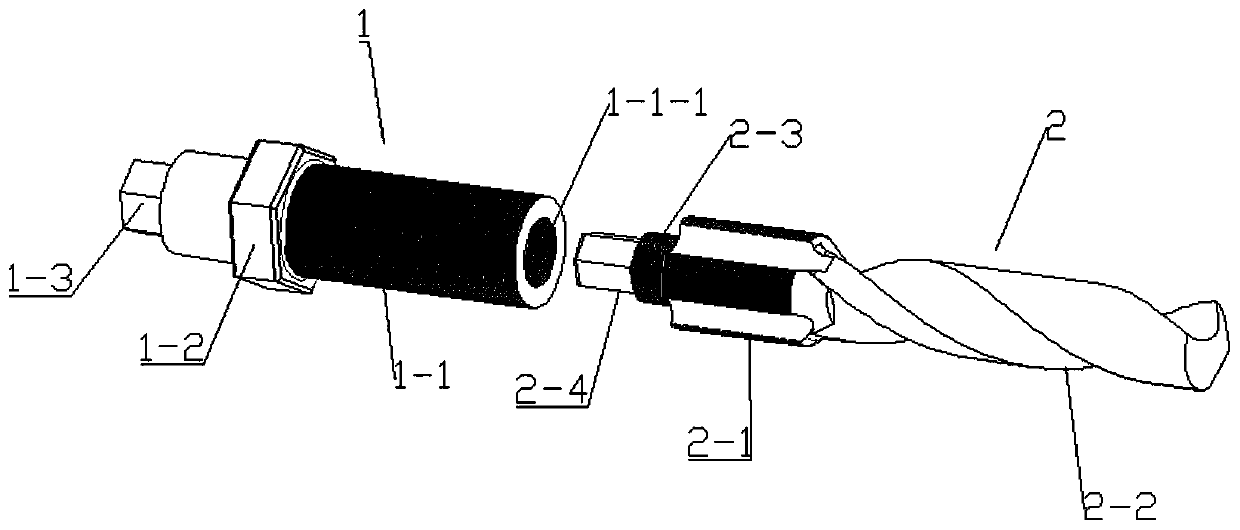

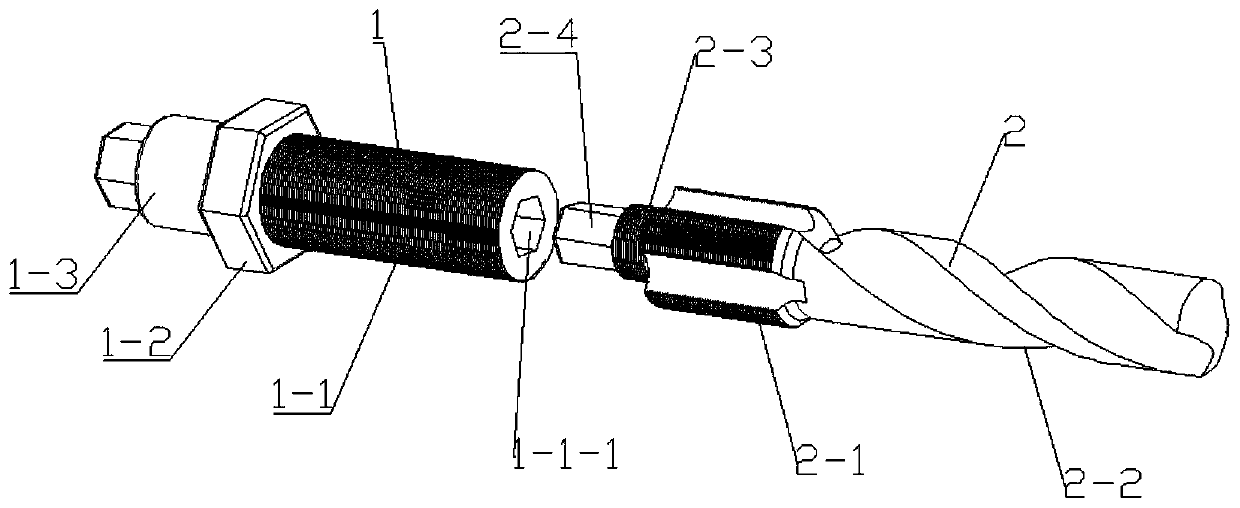

[0039] Such as image 3 As shown, the present invention is a novel self-tapping drilling combination bolt. The difference from Embodiment 1 is that the end face of one end of the assembled connection of the screw rod 1-1 and the tap screw tapping section 2-1 is provided with a first The installation slot 1-1-1, the free end of the tap screw tapping section 2-1 is provided with a third connector 2-4 that is compatible with the first installation slot 1-1-1, so The cross-sections of the first installation slot 1-1-1 and the third connector 2-4 are polygonal structures, and the fixing bolt 1 is tapped with the tap screw through the first installation slot 1-1-1 The third connection head 2-4 on the section 2-1 is fitly connected.

[0040] As a further preference, the cross-sections of the first installation slot 1-1-1 and the third connector 2-4 are both hexagonal.

Embodiment 3

[0042] Such as Figure 4 As shown, the present invention is a novel self-tapping drilling combination bolt, and the difference from Embodiment 1 is that the end where the screw 1-1 is assembled and connected with the tap screw tapping section 2-1 is provided with a second joint 1-4, the free end surface of the tap screw tapping section 2-1 is provided with a second installation slot 2-5 that is compatible with the second connector 1-4, and the second connector 1 -4 and the cross-section of the second installation slot 2-5 are polygonal structures, and the fixing bolt 1 passes through the second connection head 1-4 and the second installation slot on the tapping section 2-1 of the tap screw 2-5 chimeric connections.

[0043] As a preference, the free end of the tap screw tapping section 2-1 is also provided with an internal thread installation slot 2-6 coaxially penetrating through the upper port and the bottom of the second installation slot 2-5, and the second installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com