Electric spark induction controllable erosion and mechanical finishing compound cutting dual-servo feeding processing system

A technology of mechanical trimming and compound cutting, which is applied in the field of EDM-induced controllable ablation and mechanical trimming compound cutting dual-servo feed processing system to achieve the effects of expanding the application range, solving low machining efficiency and reducing tool loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

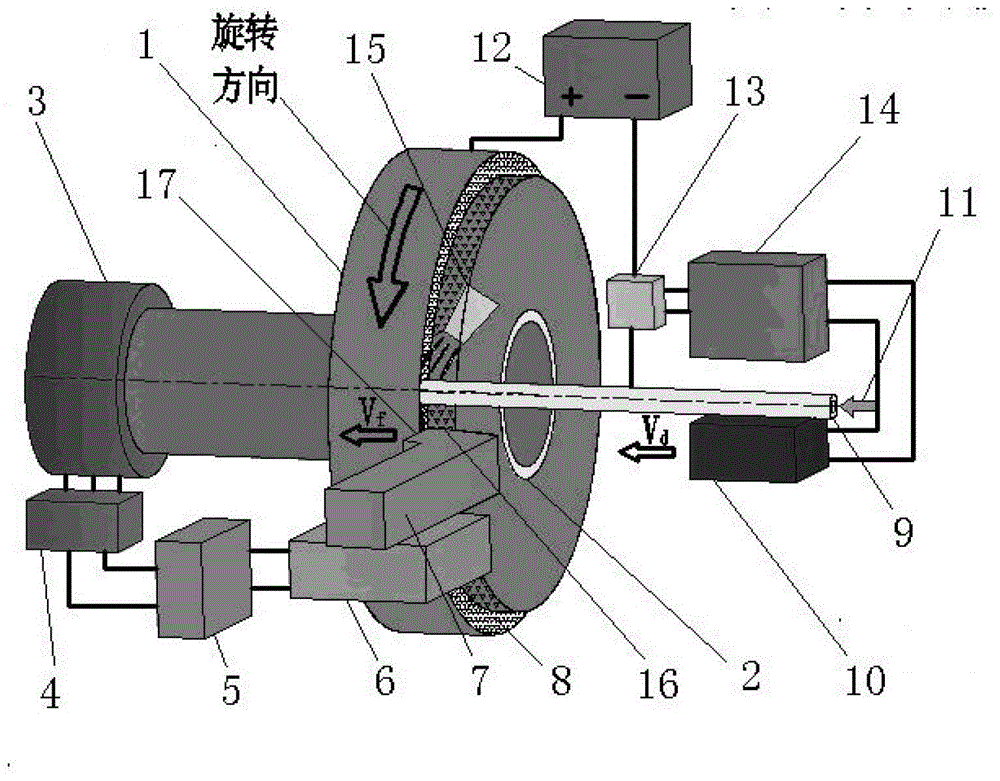

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] Such as figure 1 - 4 shown.

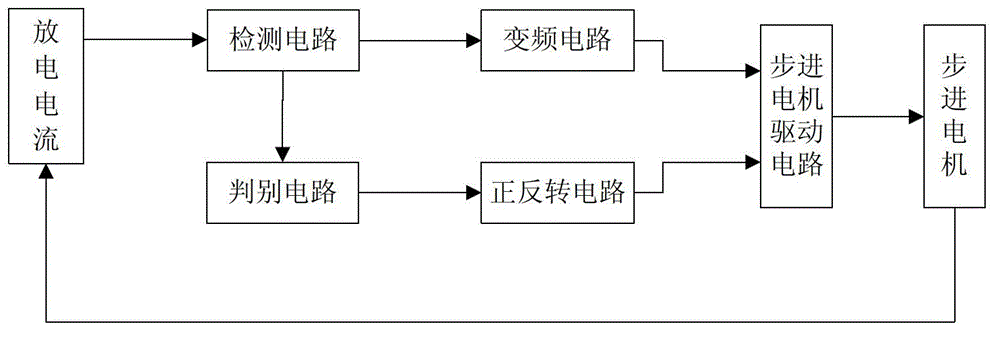

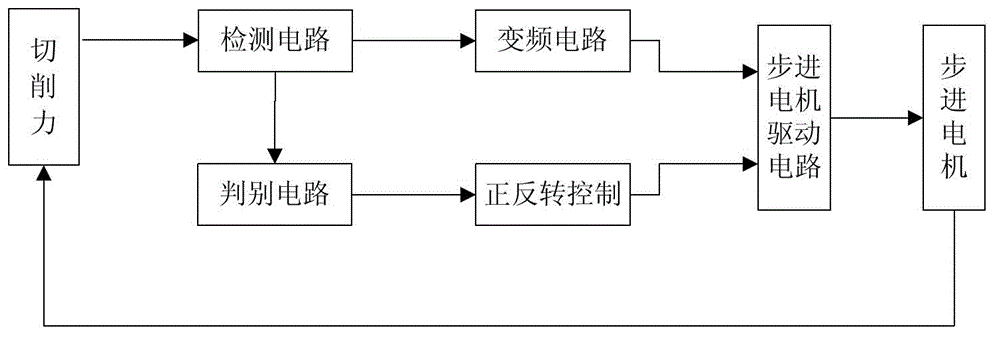

[0033] An EDM-induced controllable ablation and mechanical trimming combined cutting dual-servo feed processing system, with image 3 The cylindrical turning processing system shown is taken as an example. It consists of the following two sets of complementary electric spark induction ablation electrode servo feed control system and mechanical dressing tool servo feed control system. In the above-mentioned dual servo feed control Under the control of the system, the induction ablation electrode servo feed control system completes the electric spark induced controllable ablation, the mechanical dressing tool servo feed control system completes the mechanical trimming, and alternately repeats the electric spark induced controllable ablation and mechanical trimming process. Complete the processing of difficult-to-mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com