Preparation method of aluminum-plastic composite film

A technology of aluminum-plastic composite film and aluminum foil, which is applied in the field of composite film, can solve the problems of harsh process conditions, high performance requirements of inner layer materials, and difficult use, and achieve low process requirements, low material performance requirements, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

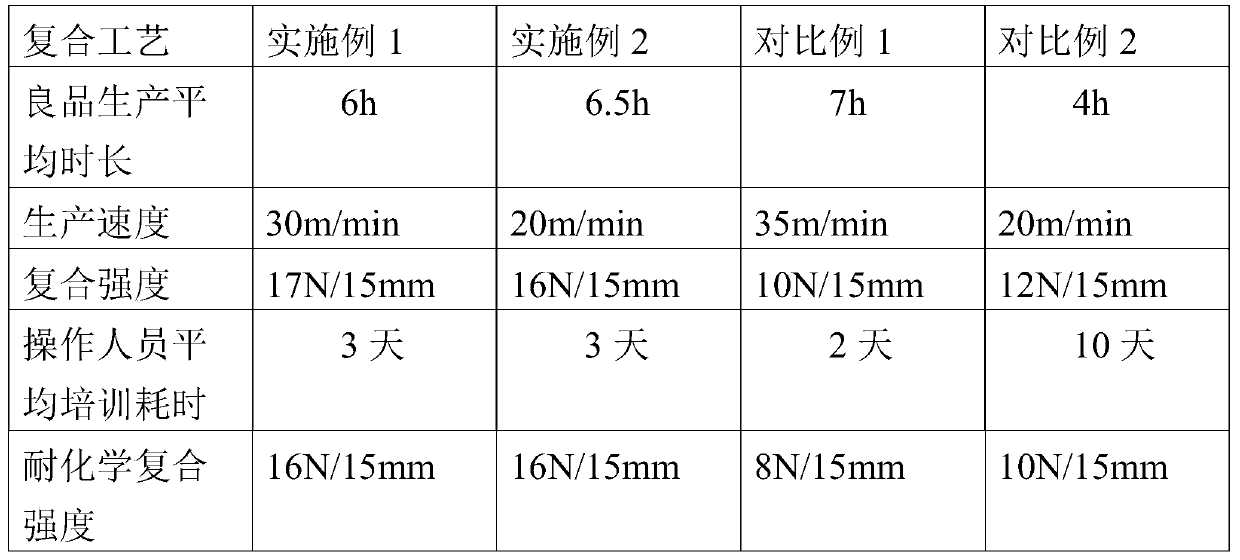

Embodiment 1

[0052] Use maleic anhydride grafted polypropylene emulsion, and add 0.5% trimethylbenzoyl diphenyl phosphine oxide (TPO) of total mass fraction therein, 0.05% benzoin, 0.05% propylbenzene peroxide (DCP) and 5% polyurethane diol prepolymer is moderated and uniform, and added to the first coating mechanism 3 .

[0053] Use an alkaline degreasing agent to degrease and clean the 40 μm single-gloss aluminum foil, and dry it for later use.

[0054] Use the coating production line to prepare a 250nm high-density self-healing film on the surface of the aluminum foil after degreasing and drying, apply a protective film layer treatment agent on the bright surface of the aluminum foil, and heat it in an oven to react and dry it, and then wind it up spare. The production running speed of the coating production line is 20m / min, and the reaction drying temperature is 210°C.

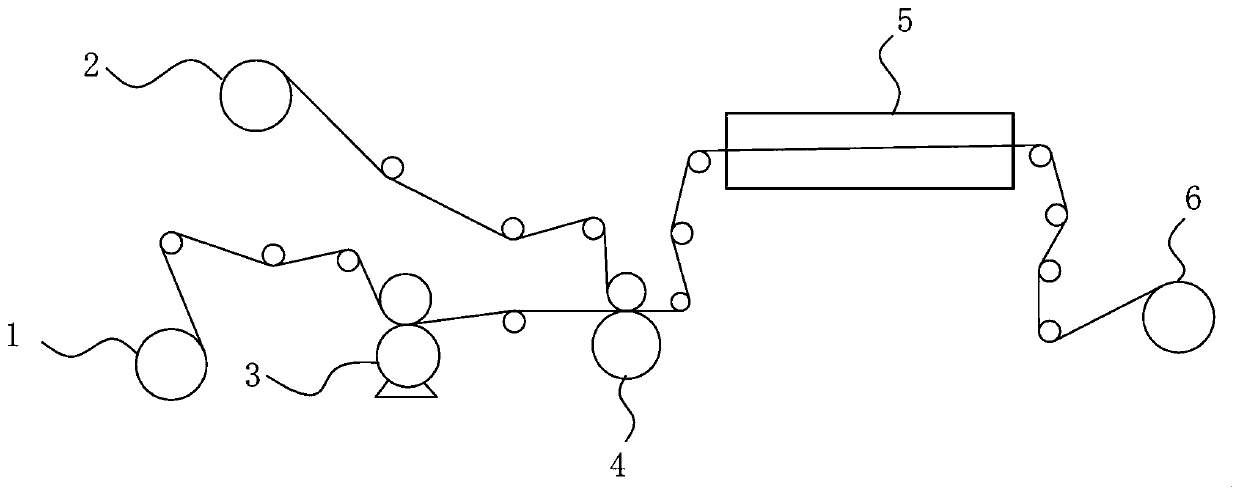

[0055] Put the aluminum foil prepared with high-density self-healing film on the first unwinding mechanism 1 on th...

Embodiment 2

[0059] Use maleic anhydride grafted polypropylene emulsion, and add 0.5% trimethylbenzoyl diphenyl phosphine oxide (TPO) of total mass fraction therein, 0.05% benzoin, 0.05% propylbenzene peroxide (DCP) and 5% polyurethane diol prepolymer is moderated and uniform, and added to the first coating mechanism 3 .

[0060] Use an alkaline degreasing agent to degrease and clean the 45 μm single-gloss aluminum foil, and dry it for later use.

[0061] Use the coating production line to prepare a high-density self-healing film with a surface of 1 μm on the aluminum foil after degreasing and drying, apply a protective film layer treatment agent on the bright surface of the aluminum foil, heat and dry in an oven, and then wind up spare. The production running speed of the coating production line is 20m / min, and the reaction drying temperature is 180°C.

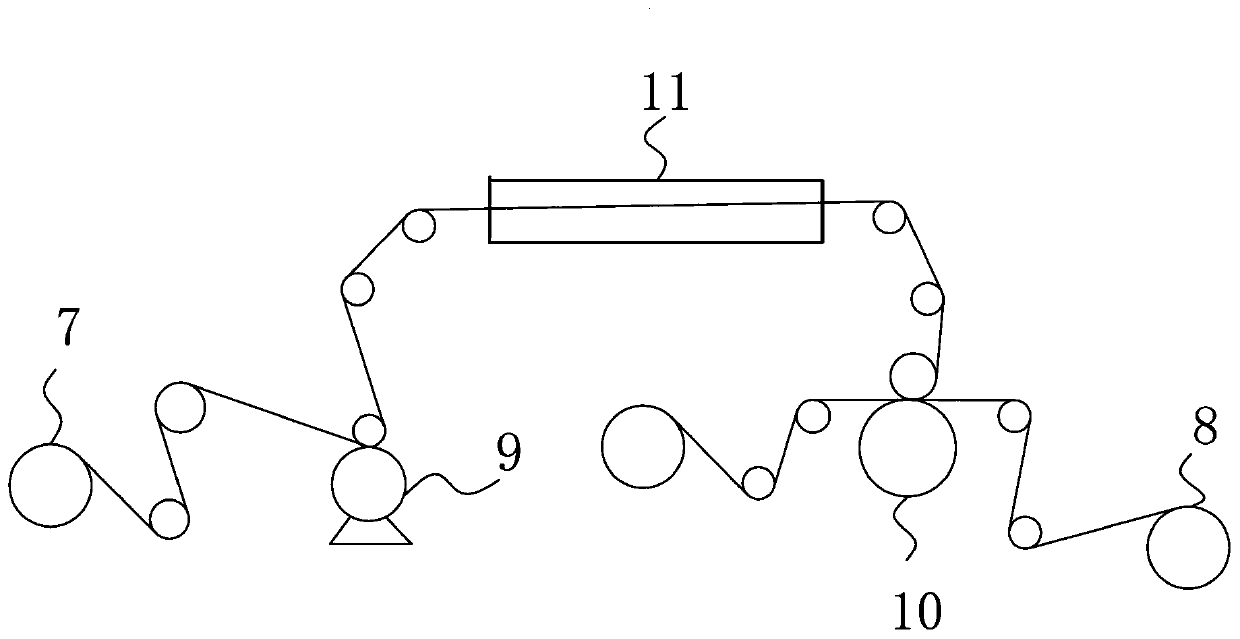

[0062] Put the aluminum foil prepared with high-density self-healing film on the first unwinding mechanism 1 on the irradiation compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com