Liquid stream battery stack

A liquid flow battery stack, the same technology, applied in the fields of energy storage and electrochemistry, can solve the problems of battery energy efficiency reduction, achieve the effects of reducing self-discharge, simplifying the installation process, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

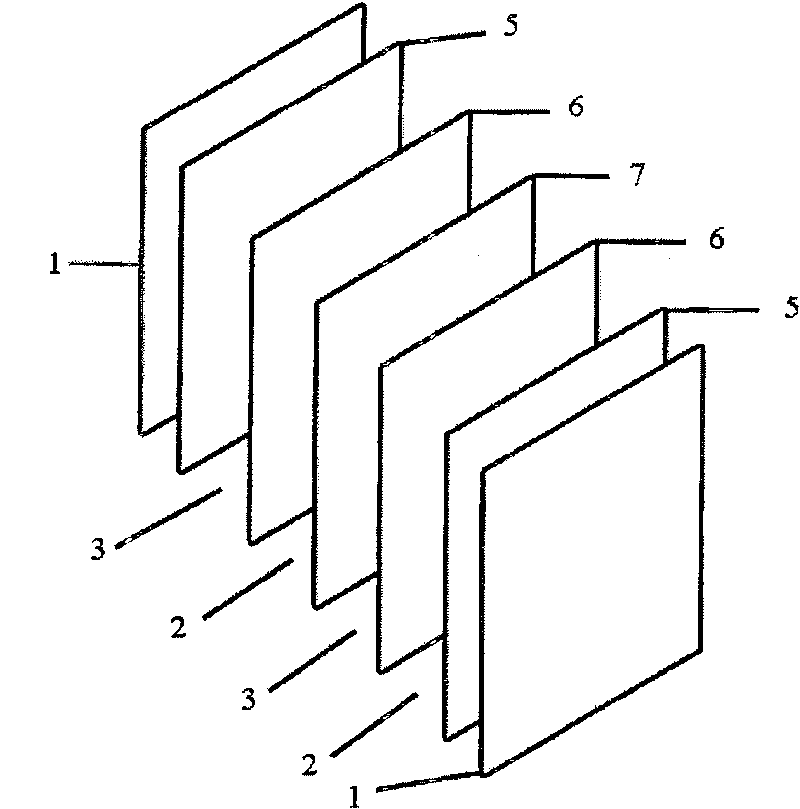

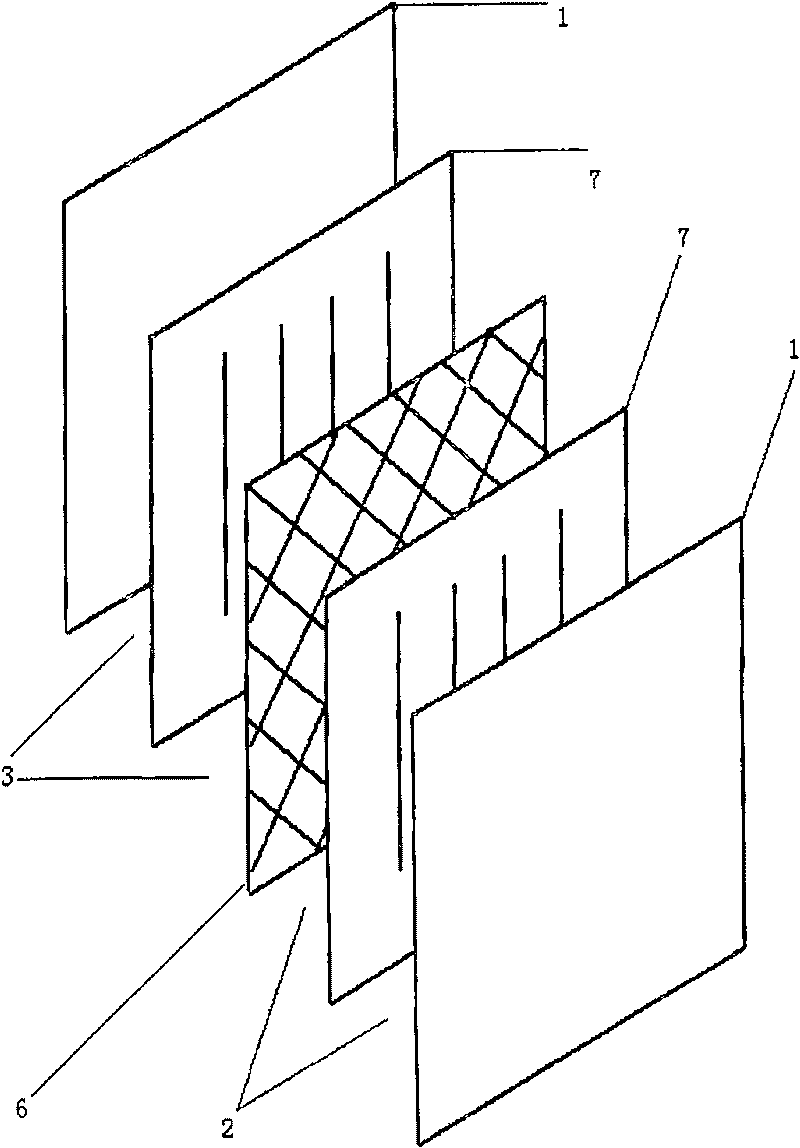

[0016] See attached figure 2 , the present invention---a liquid flow battery stack, including two end plates 1, a diaphragm 6, and two bipolar plates 7, the liquid flow battery stack is separated into positive electrodes by a diaphragm 6 between the two end plates 1 Two regions of electrolyte solution 2 and negative electrode electrolyte solution 3, a bipolar plate 7 with the same polarity as the electrolyte solution in the corresponding region and the same polarity on the front and back sides is arranged in each region, and the two poles of the same bipolar plate 7 in parallel.

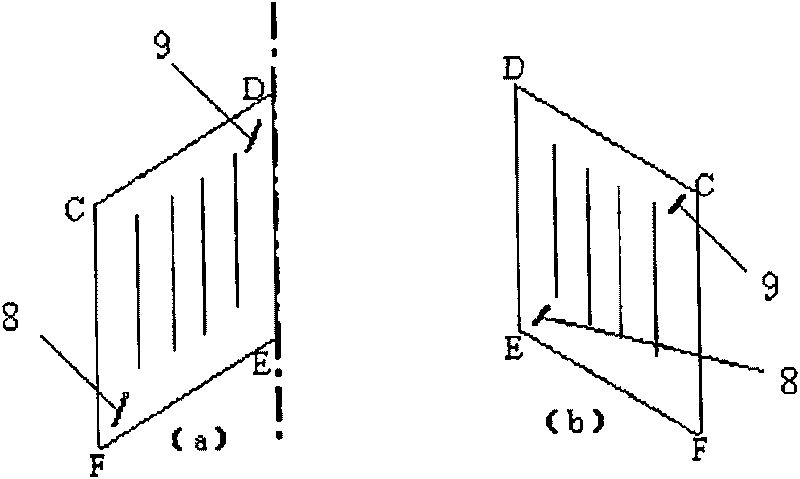

[0017] See attached Figure 4 (a), (b), in the present invention, the liquid inlet 8 of each bipolar plate 7 is all arranged at the same position below the bipolar plate 7, and the liquid outlet 9 is all arranged at the same position above the bipolar plate 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com